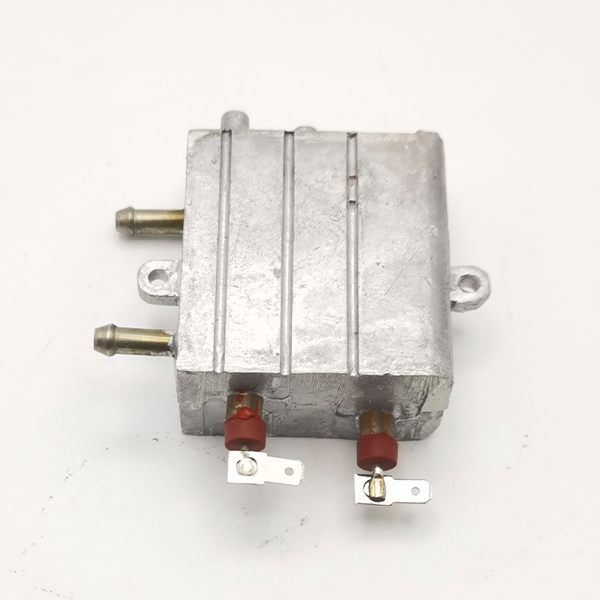

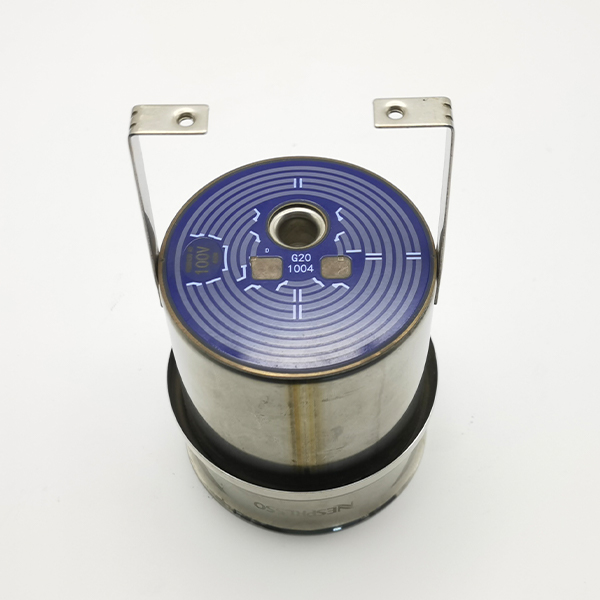

Coffee machine heating element

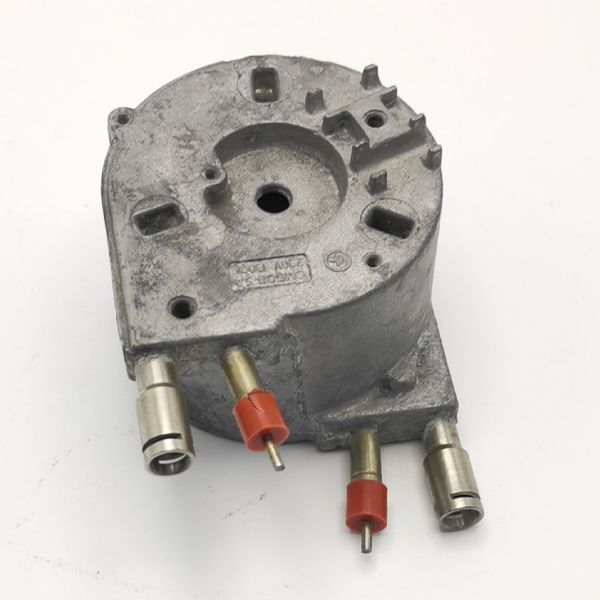

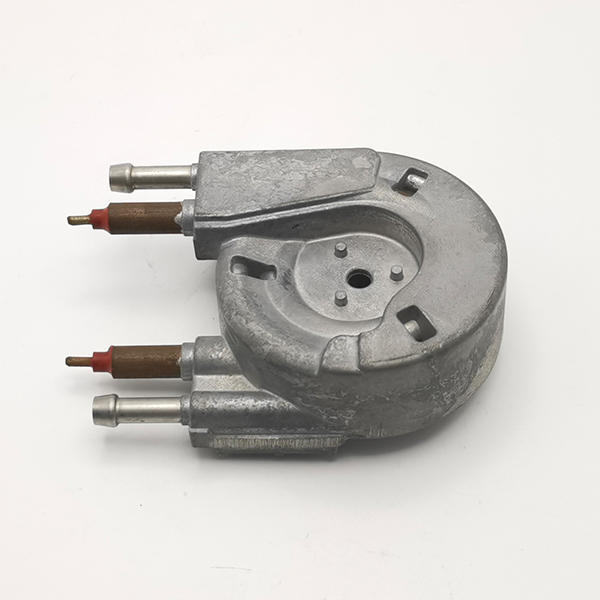

Coffee machine die-cast boiler

The die-cast boiler of a coffee machine is a core heating element formed by die-casting. It is usually made of aluminum alloy or stainless steel and has both high strength and lightweight characteristics. Its closed cavity design is directly related to the water system of the coffee machine. It is responsible for storing cold water and heating it to a suitable extraction temperature (usually 88-96°C). It is the “thermal energy center” for stable water supply of the coffee machine. The die-casting process ensures that the boiler has no welding gaps, high pressure resistance (commonly 1-1.5bar) and corrosion resistance, and is suitable for the high-frequency use needs of home or commercial coffee machines.

Performance advantages and applications: As the “temperature engine” of the coffee machine, the die-cast boiler conducts heat quickly and evenly through the built-in heating tube (mostly nickel-chromium alloy), shortening the preheating time (more than 30% higher than the traditional welded boiler); at the same time, the one-piece molding structure avoids the risk of water leakage and ensures the long-term stability of the water system. Its surface is specially treated (such as anodizing or coating) to further reduce scale adhesion and extend the cleaning cycle. Whether it is the precise temperature control of a home espresso machine or the high-frequency cup-dispensing requirements of a commercial machine, the die-cast boiler can provide a stable temperature base for coffee extraction with reliable heating performance and durability, which directly affects the aroma and taste of the coffee.

Italian semi-automatic coffee machine, fully automatic drip coffee machine, capsule coffee machine (such as Nespresso compatible models)

Italian semi-automatic coffee machine, fully automatic commercial coffee machine (such as La Marzocco/Lavazza),

Delonghi Inissia/Magnifica/Eletta series semi-automatic coffee machines, Barista/Tribes series fully automatic coffee machines,

Italian semi-automatic coffee machines, fully automatic commercial coffee machines (such as La Marzocco/Lavazza)

capsule coffee machines (Nespresso/Dolce Gusto), Delonghi/Philips/Nestle models, hotel commercial electric coffee equipment

Nespresso/Dolce Gusto capsule coffee machine, Lavazza Blue series, Eureka Mignon system

Lavazza Blue series, Eureka Mignon system, Philos series fully automatic coffee machine

Delonghi/Philips/Nestle models, hotel commercial electric coffee equipment, catering chain fully automatic coffee machine boiler components

Delonghi/Philips/Nestle fully automatic coffee machines, Lavazza Blue series, Eureka Mignon system

Saeco EVO series, Lirio series, Ticinese series fully automatic coffee machines, Saeco Xelsis/Incanto commercial models

Nespresso Inissia/Vertuo/Creatista series capsule coffee machines, S.A.M. fully automatic capsule system, Lavazza Blue series compatible models,

Philips Epoca/Sahara/Elevate series fully automatic coffee machines, Philips Saeco Xelsis/Incanto commercial models

The heater for electric coffee pots adopts food-grade 304 stainless steel substrate and thick film resistor technology

Our stainless steel heating accessories serve as integral heating components in mixer-related household appliances,

Our stainless steel electric heating components are designed for coffee cups and serve as integrated heating elements in electric pot heaters for milk frothers and coffee machines

Our factory specializes in the production of special accessories for electric coffee makers, including heating chassis, temperature control modules and anti-dry burning components

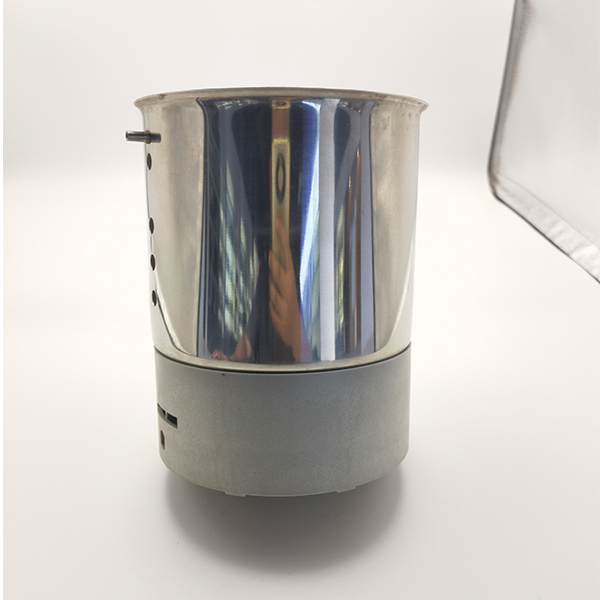

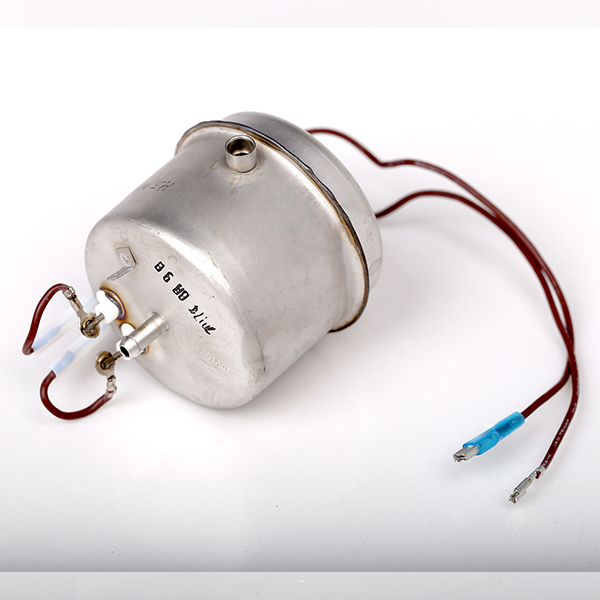

Coffee machine stainless steel heating pot

The stainless steel heating pot of the coffee machine is the core component directly responsible for heating. It is made of food-grade 304/316 stainless steel in one piece or by welding. The inner wall is smooth without dead corners. It is suitable for the water system of the coffee machine. The built-in heating tube (nickel-chromium alloy/thick film) converts electrical energy into thermal energy to heat the cold water or coffee liquid in the water storage chamber, which is the “stable source” of coffee extraction temperature.

Performance advantages: Stainless steel is naturally corrosion-resistant and scale-resistant (lower scaling rate than aluminum alloy), with uniform heat conduction (temperature difference ≤3℃), avoiding local overheating and damaging flavor; the smooth inner wall is easy to clean (can be directly wiped/rinsed), durable (lifespan of more than 5 years), stable temperature control (±1℃) in both home and commercial scenarios, ensuring the restoration of coffee aroma and taste.

Coffee quick heating tube

The coffee machine quick heating pipe is the core component for fast heating in the coffee machine. It usually adopts nickel-chromium alloy heating wire, thick film coating or optimized flow channel design, integrated into the water system (such as brewing head, preheating module), directly heats the water flow or coffee liquid for a short time to meet the needs of fast cup production.

Performance advantages: High power density (commonly above 6000W) and short heating path design, which can heat room temperature water to coffee extraction temperature (88-96℃) within 10-30 seconds; corrosion-resistant material (such as stainless steel substrate + ceramic coating), reduces scale adhesion and prolongs life; suitable for home/commercial scenarios, improves coffee making efficiency, and ensures the immediacy and stability of hot water supply.

Designed for coffee equipment, this high-performance electric heating element finds application in drip coffee makers, espresso machines, French press, and other coffee devices

The immersion heating element is designed for drip coffee, French press, moka pot and other coffee equipment. It adopts food-grade 316L stainless steel + ceramic coating insulation structure

The heating element is designed for drip coffee, espresso coffee, French press and other coffee equipment. It adopts food-grade 316L stainless steel + ceramic coating insulation structure

The immersion heating element designed for commercial semi-automatic/fully automatic espresso machines adopts food-grade 316L stainless steel + ceramic coating insulation structure

Home appliances: semi-automatic coffee machine, capsule coffee machine, espresso machine, moka pot heating base.Industrial equipment: commercial fully automatic coffee machine

The heating system designed specifically for espresso machines integrates boilers, heat exchangers, temperature control modules and heat recovery technology, adapts to the power range of 300W-20kW

Embedded heating element designed for espresso machines, drip coffee machines and hand brewing utensils, adopts 316L stainless steel + ceramic coating heat conduction structure

The core of the heating system of Delonghi coffee machines (such as EC680/EC860/EC9155 models) is a stainless steel boiler or a copper heat exchanger, which is suitable for a power range of 300W-1500W

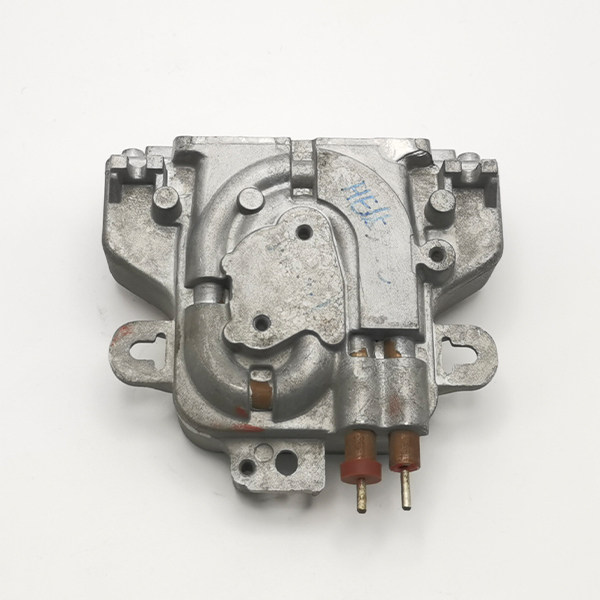

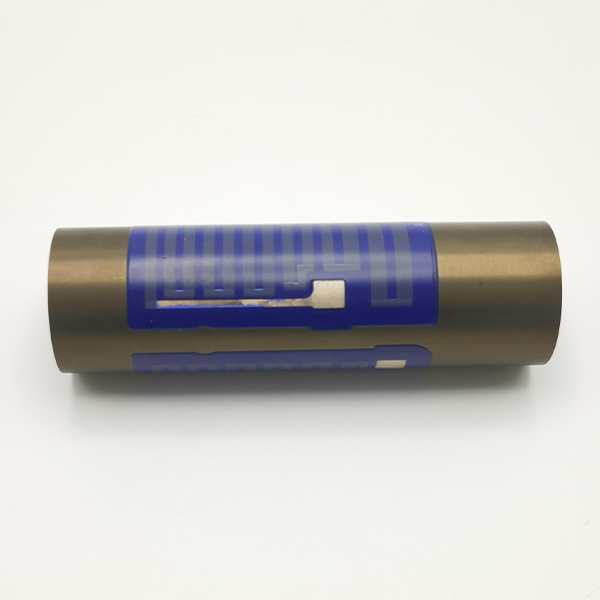

Coffee machine aluminum heating tube

The aluminum heating tube of the coffee machine is the core component used to quickly heat the water flow in the coffee machine. It is usually made of aluminum alloy (such as 6061 or 6063 aluminum) as the shell, with a built-in nickel-chromium alloy heating wire and an outer layer wrapped with insulating magnesium oxide powder, forming a compact structure of “heating wire-insulating layer-aluminum tube”. Its design fits the water system of the coffee machine (such as the brewing head, preheating module), and heats the aluminum tube shell through electric current, indirectly transferring heat to the water flowing through it to complete rapid heating.

Performance characteristics and applications: The thermal conductivity of aluminum is high (about 237W/(m·K)), so that the heating tube can heat up quickly (it can increase by 20-30℃ within 30 seconds), which is suitable for the high-frequency short-time heating needs of household or small commercial coffee machines; aluminum alloy is light in weight and low in cost, reducing the weight and manufacturing cost of the whole machine. However, it should be noted that aluminum is easy to oxidize and scale in a hard water environment (long-term use may affect the thermal conductivity efficiency), and usually requires surface anodizing to enhance corrosion resistance; it is recommended to use a soft water system or clean it regularly to extend the service life (generally 2-3 years).

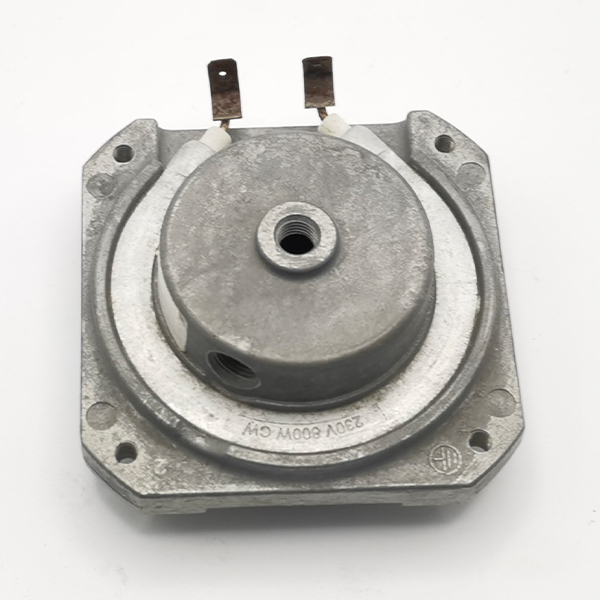

Coffee machine heating plate

The coffee machine heating plate is the core component for directly heating water or coffee liquid. It is usually made of stainless steel, aluminum alloy or ceramic composite material. The surface is integrated with nickel-chromium alloy heating tube or thick film heating circuit. It adopts flat design to increase the contact area with the liquid. It is installed on the brewing head, water tank or preheating module, responsible for quickly raising the liquid temperature to the required temperature for coffee extraction (88-96℃).

Performance advantages and applications: Metal materials (such as stainless steel) have fast thermal conductivity (temperature difference ≤5℃), and the flat structure ensures uniform heating (avoids local overheating and damage to flavor); ceramic coating models resist scale adhesion (scaling rate reduced by 40%) and are more durable (lifespan 3-5 years). It is suitable for the precise temperature control (±2℃) of home espresso machines or the high-frequency cup delivery requirements of commercial machines, directly ensuring the release of coffee aroma and the mellow taste, and is the “core cornerstone” of stable heating for coffee machines.

Embedded/portable heating element designed for coffee lovers, suitable for 300W-800W power range, temperature resistance up to 260℃ (short time), heat distribution uniformity ΔT≤2℃

The high-performance heating element designed for espresso machines, drip coffee machines and capsule coffee machines adopts food-grade 316L stainless steel substrate,

Ultra-thin embedded heating element designed for coffee cups/mugs, suitable for 300W-800W power range, temperature resistance up to 260℃ (short time), heat distribution uniformity ΔT≤2℃

The coffee pot heating plate adopts a composite process of stainless steel substrate and nickel-chromium alloy heating tube, integrated with PID temperature control module

Thick film heating tube adopts ceramic substrate and thick film resistor slurry printing process. The tubular structure design supports directional centralized heating, integrated PID temperature control module

Nespresso Inissia/Vertuo/Creatista series capsule coffee machines, Barista Pro steam wand, Eureka Mignon capsule system, commercial-grade S.A.M. fully automatic coffee machine,

Commercial baking equipment, industrial tunnel ovens, medical sterilizers, laboratory tube furnaces, chemical reactors, ceramic sintering equipment, food processing hot air systems, constant temperature control devices.

Nespresso Inissia/Vertuo/Creatista series capsule coffee machines, Barista Pro steam wands, Eureka Mignon capsule systems, commercial-grade S.A.M. fully automatic coffee machines,

Coffee cup heating film

The coffee cup heating film is a flexible heating element that fits the inner or outer wall of the coffee cup. It is usually composed of a heating layer (graphene, carbon fiber or metal foil), an insulating substrate (PET/PI high temperature resistant plastic) and an electrode circuit. It is only 0.1-0.5mm thick, thin and soft. It can be directly encapsulated in the cup wall or pasted on the cup body. The heating layer is stimulated by current to generate heat to keep the coffee warm or heat it.

Performance advantages and applications: Light and thin design does not take up space (suitable for all types of cups); uniform heating (temperature difference ≤5℃) to avoid local overheating that damages the coffee flavor; instant heating when powered on (3-5 seconds to heat up), low power consumption (5-15W) can maintain a constant temperature of 60-80℃ for 2-3 hours; safe without open flames, supports automatic power-off protection (anti-dry burning/overheating). Suitable for home thermos cups, portable coffee cups or commercial scenarios, directly solves the problem of fast coffee cooling and improves the drinking experience

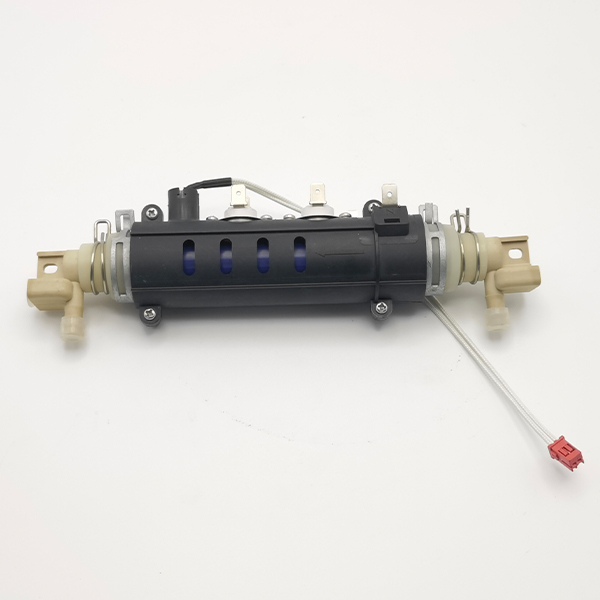

Coffee machine steam boiler

The coffee machine steam boiler is a core component designed for making milk foam and heating milk in Italian coffee. It is usually composed of a stainless steel or copper cavity, a built-in electric heating tube (or steam coil) and a temperature control system. Its working principle is: the water is heated to boiling (about 100°C) through the electric heating tube, and high-pressure steam (common pressure 0.5-1.2bar) is generated and stored in the cavity. When milk foam is needed, the steam is released and mixed with milk. It is a “key tool” for the fusion of coffee latte art and flavor.

Performance advantages and applications: The stainless steel cavity has strong corrosion resistance (adapted to hard water environment), and the copper cavity has faster heat conduction (heating efficiency increased by 20%); precise temperature control (pressure fluctuation ≤0.1bar) ensures stable steam and produces delicate and dense milk foam. Commercial models have a larger steam volume (15-30g/min), and household models pay more attention to energy saving (low standby power consumption). Regular descaling is required (it is recommended once a month in hard water areas) to extend the life (generally 3-5 years). It is the “milk foam core” of coffee shops and home Italian machines.

Commercial electric boilers, instant electric water heaters, steam generators (hotels/hospitals), coffee machine boilers (capsule/fully automatic models)

Our Coffee Boiler heating elements are designed for electric boiler heaters, serving as critical components in household appliances (e.g., steam irons, espresso machines, electric steamers, humidifiers)

Meant for home appliances such as steam ovens, humidifiers, and steam irons, this electric boiler steamer is a compact, high-efficiency steam generator

Our steam generator heating elements are core components for electric boiler heaters, serving as the primary heat source in both household and commercial steam systems.

Embedded heating element designed for espresso machines, drip coffee machines and hand brewing utensils, adopts 316L stainless steel + ceramic coating heat conduction structure

Italian semi-automatic coffee machines, fully automatic commercial coffee machines (such as Lavazza/De’Longhi/Philips), capsule coffee machines (Nespresso/Dolce Gusto)

The high-efficiency heating tube designed for espresso machines, drip coffee machines and capsule coffee machines adopts 316L stainless steel + nano-ceramic coating

Our Stainless Steel Water Cup Body serves as a primary liquid-container component in electric kettles, coffee machines, electric pots, bottle warmers, soy milk makers, and blenders.

Coffee machine accessories

Coffee machine accessories are key auxiliary components to ensure the stable operation of the coffee machine and improve the quality of coffee extraction. They cover the entire process of heating, extraction, steam, cleaning and daily use. Common types include heating elements (boilers, heating tubes), extraction components (powder bowls, powder tampers), steam systems (steam pipes, steam heads), cleaning tools (descalers, brushes) and basic containers (water tanks, coffee grounds boxes), etc., which are suitable for different home and commercial scenarios.

Function and value: Heating accessories (such as boilers and heating tubes) are responsible for providing stable hot water/steam, which directly affects the coffee extraction temperature (88-96℃) and milk foam quality; extraction accessories (powder bowls, powder tampers) determine the extraction uniformity and flavor level by accurately controlling the amount and compactness of coffee powder; steam accessories (steam pipes, steam heads) are used for milk whipping, and their materials (stainless steel/copper) and structures (porous/spiral) affect the fineness of milk foam; cleaning accessories (descalers, brushes) extend the life of the machine and avoid clogging by scale/residues; basic containers (water tanks, grounds boxes) ensure the convenience and hygiene of water use. The various accessories work together to build a complete chain of the coffee machine from heating to cupping.

Lấy một trích dẫn tùy chỉnh

Nếu bạn có thể cung cấp thông tin chính xác về thông số nhu cầu, chúng tôi có thể gửi báo giá cho bạn sớm nhất trong vòng 24 giờ.

Đây là danh sách những câu hỏi thường gặp của khách hàng. Chúng tôi sẽ trả lời ngắn gọn từng câu hỏi, bao gồm các khía cạnh như sản phẩm, chất lượng và dịch vụ. Nếu quý khách có thắc mắc khác, vui lòng để lại tin nhắn để được tư vấn. Xin chân thành cảm ơn.

We are a source factory with independent production capacity, with 40 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

Chúng tôi hỗ trợ thử nghiệm mẫu miễn phí, và cước phí phải được thanh toán trước (thu khi giao hàng). Các mẫu thông thường được giao trong vòng 7-10 ngày làm việc, kèm theo báo cáo thử nghiệm SGS và bảng thông số hiệu suất.

Phản hồi trực tuyến từ 8:30 đến 17:30 các ngày làm việc. Trong trường hợp khẩn cấp, bạn có thể gửi yêu cầu công việc qua trang web chính thức. Chúng tôi cam kết phản hồi kỹ thuật trong vòng 2 giờ và cung cấp giải pháp trong vòng 48 giờ.

Chúng tôi có hai cơ sở sản xuất tại Trung Sơn và Vũ Hồ, với sản lượng hàng tháng hơn 3 triệu sản phẩm, được trang bị dây chuyền dập hoàn toàn tự động và xưởng lắp ráp tự động. Thời gian giao hàng tiêu chuẩn là 15 ngày, đơn hàng tùy chỉnh được giao trong vòng 30 ngày. Chúng tôi hỗ trợ cung cấp theo lô.

Có chứng nhận ISO9001/14001, CE (EU), ETL (Bắc Mỹ), RoHS (bảo vệ môi trường), sản phẩm chống cháy nổ được chứng nhận kép ATEX/IECEx và đáp ứng các quy định REACH.

Cung cấp các sản phẩm cho các thương hiệu hàng đầu thế giới như Philips, Midea, Supor, Delonghi, BSH và SEB Group, được sử dụng trong các dự án cao cấp như máy pha cà phê, bàn là điện, máy lọc nước và hệ thống sưởi năng lượng mặt trời, và có thể cung cấp danh sách tham khảo về các khách hàng tương tự.