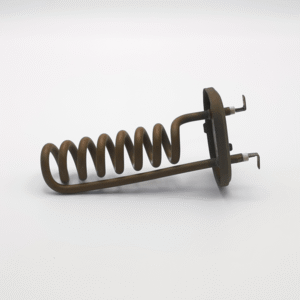

The die-casting heating element adopts ceramic substrate and thick film resistor slurry printing process, integrated PID temperature control module, achieves 3-5 seconds fast heating, energy efficiency ≥96%, working temperature range 80℃-500℃, supports power (1000W-6000W) and shape customization, has IPX6 waterproof, anti-aluminum/magnesium alloy molten corrosion and dry burning resistance, adapts to high-frequency continuous die-casting scenes, and has a lifespan of more than 50,000 hours, meeting the requirements of high stability and low energy consumption die-casting process.

Mindestbestellmenge: 1000

Lieferfrist: 15-25 Tage

Standort der Fabrik: Zhongshan, Guangdong, China

Industrial die-casting machine (aluminum/magnesium alloy), automotive parts die-casting molds, home appliance accessories die-casting equipment, medical equipment die-casting molding machine, new energy battery shell die-casting line, aerospace parts die-casting system, LED lamp holder die-casting equipment, mold constant temperature heating system.

| Parameter | Spezifikationsbereich |

|---|---|

| Leistungsbereich | 500W-2000kW |

| Betriebsspannung | 220V (single-phase, household/commercial); 380V (three-phase, industrial); 480V (optional, export equipment) |

| Widerstandswert | 2Ω-50Ω (single unit or multi-unit combination) |

| Betriebstemperatur | Surface: 80℃-600℃ (normal); Steam generation scenario: 120℃-180℃ (atmospheric steam) |

| Material | Heating element: Nickel-chromium alloy (Cr20Ni80, Φ0.5mm-Φ2.5mm); Housing: Aluminum alloy (6063/6061) or 304/316 stainless steel |

| Maße | Length: 50mm-5000mm; Diameter/thickness: 10mm-300mm (adaptable to heating chambers of die casting machines, steam irons, coffee machines, etc.) |

| Lebensdauer | 5000h-15000h (normal maintenance, no overload/corrosion) |

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.