If your Maytag DE412 dryer has no heat, a failed Heizelement is the likely culprit. You can solve most no heating problems with a manageable DIY heating element replacement. This repair requires only a few basic tools: a 5/16″ nut driver, a putty knife, and a Phillips screwdriver. The most common of the parts for maytag de412 is the element assembly, part number 307178. You can find quality Heizelemente für Haushaltsgeräte from various Hersteller von Heizelementen, wie Jinzhong Elektroheizung.

Profi-Tipp: Diese DIY replacement can save you a significant amount of money compared to a professional service call.

| Reparatur Typ | Cost Range (Source 1) | Cost Range (Source 2) |

|---|---|---|

| DIY-Ersatz | $20 bis $100 | $35 to $150 |

| Professional Repair | $70 to $250 | $150 bis $350 |

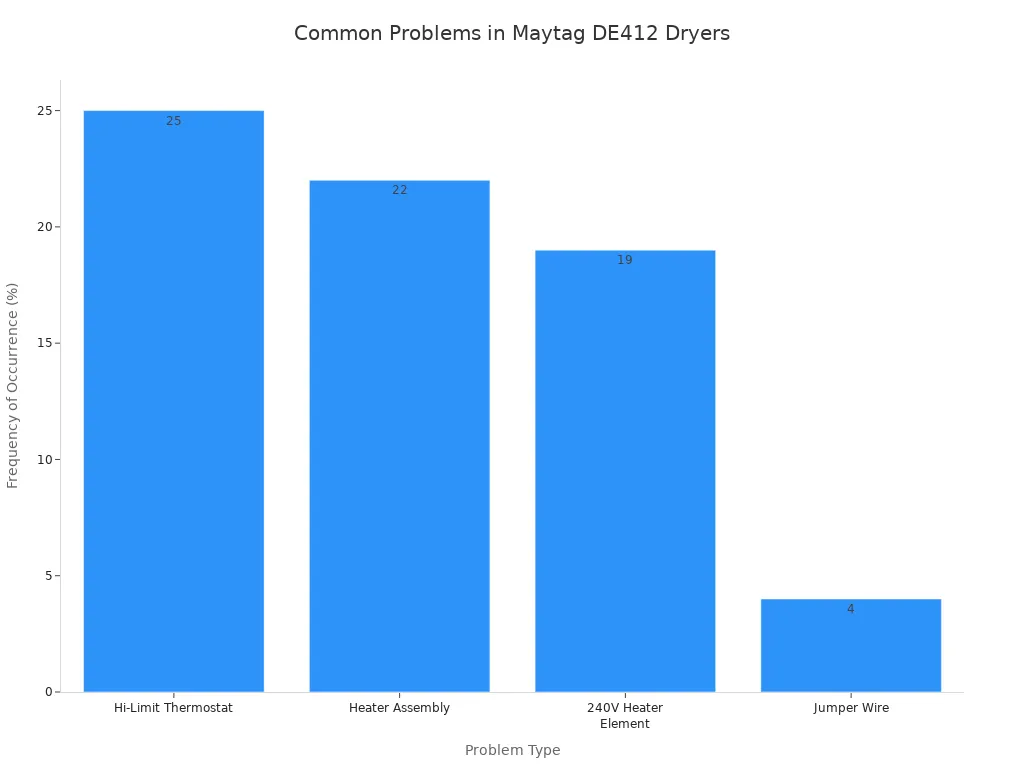

A faulty heating element or heater assembly is one of the most frequent issues for this Maytag model.

First Steps: Safety and Diagnosing the “No Heat” Problem

An excellent repair job starts with careful preparation. Before you begin disassembling your dryer, you must confirm the problem, gather your tools, and ensure the appliance is safe to work on. This initial phase is crucial for a smooth and successful repair.

Confirming a Failed Heating Element

When your dryer not heating is the issue, the heating element is the most common cause. A visual inspection can often confirm your suspicions. Look inside the dryer drum for any signs that point to a failed element.

Visual Clues of a Faulty Element

- Discoloration on the wall next to the heating unit.

- Scorch marks on the adjacent wall.

- Melting on the wall near the heating unit.

If you observe any of these signs, the element has likely burned out. Another clear indicator of a problem is if the dryer runs but produces no heat or not enough heat. If your dryer doesn’t heat at all, you can be confident that replacing the heating element will solve the problem. This guide provides step-by-step repair instructions to get your appliance back to providing proper heating.

Essential Tools and Your Replacement Part

You will need a few basic tools to complete this job. Having them ready will make the process much faster.

| Werkzeug | Size/Type | Zweck |

|---|---|---|

| Nut Driver | 5/16″ | Removing hex-head screws |

| Putty Knife | Stiff blade | Releasing top panel clips |

| Schraubendreher | Phillips | Removing various screws |

The primary part you need is the heating element assembly, part number 307178. You can purchase a genuine Maytag part or a compatible alternative from suppliers like McCombs Supply Co. They offer a dryer heater element specifically for Maytag models that is also compatible with Whirlpool part numbers, ensuring you get the right component for the job. Having the correct parts on hand is essential for a successful repair.

Safety First: Disconnecting Power and Gas

⚠️ Your safety is the top priority. Before you touch a single screw, you must completely disconnect the dryer from its power source. An electric shock can cause serious injury.

- For Electric Dryers: Unplug the power cord from the wall outlet. Do not just turn off the cycle. You must physically disconnect it.

- For Gas Dryers: In addition to unplugging the power cord, you must also shut off the gas supply. Find the gas shutoff valve behind the dryer and turn it to the “Off” position.

Taking these simple safety steps ensures you can work on the appliance without risk. Once power and gas are disconnected, you are ready to begin the disassembly and get to the core of the no heat issue.

Gaining Access to Your Maytag Dryer’s Internals

With the appliance safely disconnected, you can now begin the disassembly. Gaining access to the internal components of your maytag dryer is a straightforward process. You will start by opening the main cabinet, which involves removing the top and front panels.

Releasing and Lifting the Top Panel

Your first step is to release the top panel. This panel is held in place by two internal spring clips located at the front corners of the machine.

You will use your stiff putty knife for this task. Slide the putty knife into the seam between the top and front panels, about two to three inches in from each corner. Press inward to release each clip. You should feel a slight give or hear a pop as each clip disengages. Once both clips are free, you can lift the top panel. It is hinged at the back, so you can open the dryer like a car hood.

Profi-Tipp: Lean the opened top panel against the wall behind the appliance. This keeps it securely out of your way while you work on the interior components.

Removing the Front Panel

With the top panel lifted, you can now see the screws that secure the front panel to the cabinet. Before you can remove the front panel, you must first locate and remove two hex-head screws at the bottom.

- Locate the two screws on the front panel.

- These screws are situated near the base of the panel.

- They are approximately 4 inches above the floor.

Use your 5/16″ nut driver to remove these two screws. Next, remove the two screws located inside the top of the cabinet that hold the front panel in place. With all four screws removed, you can carefully tilt the front panel forward and lift it off the two clips holding it at the bottom.

⚠️ Wichtig: Do not pull the front panel completely away yet. It is still connected by the door switch wire harness. You must disconnect this small plastic harness before you can set the panel aside. Squeeze the sides of the connector and pull it apart. You can now safely move the front panel out of your work area, giving you clear access to the inside of your maytag.

The Core Task: The Heating Element Replacement

You have now accessed the dryer’s interior. This next phase covers the central task of the repair. Following these step-by-step repair instructions carefully will ensure a successful heating element replacement.

Locating the Old Heating Element Assembly

Look inside the dryer cabinet on the right-hand side. You will see a large, cone-shaped metal housing. This is the heating element assembly. The assembly contains the coiled wire that generates the heat for your dryer. You can often see the thin heating element coil wrapped around ceramic insulators inside this housing. A faulty heating element coil is the direct cause of your heating problem.

Component Identification The assembly is a single unit that includes the outer metal cone, the internal insulators, and the heating element coil itself. It is held to the back wall of the dryer.

Photograph and Disconnect the Wires

Before you disconnect anything, you must take a clear photograph of the wiring. This picture will be your guide for reconnecting the new element correctly.

- Machen Sie ein Foto: Use your phone to capture a well-lit image showing exactly where each wire connects to the assembly.

- Drähte abklemmen: You will typically find three connection points.

- Two wires connect directly to the terminals of the heating element.

- One wire connects to the high-limit thermostat, which is the small, circular component mounted on the element housing.

- Remove Wires: Gently pull the wire connectors straight off their terminals. If they are tight, you can wiggle them slightly side-to-side to loosen them. Do not pull on the wires themselves.

This simple step prevents incorrect wiring, which could damage the new element or create a safety hazard.

Entfernen des alten Heizelements

With the wires disconnected, you can now remove the entire assembly. The process is straightforward and requires your 5/16″ nut driver.

| Aktion | Tool/Method | Beschreibung |

|---|---|---|

| Remove Mounting Screw | 5/16″ Nut Driver | Locate the single hex-head screw that secures the top of the assembly to the rear wall of the dryer cabinet. Remove this screw. |

| Lift Out the Assembly | By Hand | The bottom of the assembly rests in a slot. Tilt the top of the element housing toward you and lift it up and out of the dryer. |

You have now successfully removed the old component. You are ready to proceed with the installation of the new replacement part, which will restore proper heating to your appliance.

Einbau des neuen Maytag-Heizelements

You are now ready to install the new heating element. This process reverses the disassembly steps. Careful installation ensures your dryer provides reliable heating for years to come.

Positioning the New Element Assembly

You will first position the new assembly inside the dryer cabinet. Take the new heating element assembly and orient it just like the old one. The bottom of the housing has a small tab. You must align this tab with the corresponding slot on the rear wall of the dryer cabinet. Slide the tab into the slot. This action properly seats the bottom of the element. The top of the housing should now rest flat against the back wall, with the screw hole perfectly aligned. This step is crucial when you install the new heating element coil.

Securing the New Element in Place

With the assembly correctly positioned, you can now secure it. You will use the same 5/16″ hex-head screw that you removed earlier. This single screw holds the entire assembly firmly in place.

| Schritt | Aktion | Werkzeug |

|---|---|---|

| 1 | Align the Screw Hole | Position the top of the element housing so the hole lines up with the hole in the dryer’s back panel. |

| 2 | Insert and Tighten | Use your 5/16″ nut driver to drive the screw in. Tighten it until it is snug. |

Tipp: Do not overtighten the screw. A snug fit is all you need to properly install the new heating element coil and prevent any rattling.

Reconnecting the Wires Correctly

This is the most critical step for a successful repair. Incorrect wiring can damage the new element or create a safety hazard. Refer to the photograph you took before disconnecting the old component.

Reconnect each wire to its corresponding terminal on the new heating element coil. The connectors should slide on firmly. For a durable, safe connection that maximizes the life of your new heating element coil, you should inspect the wire ends.

- Clean the new terminals on the element with a small wire brush or light sandpaper for a perfect connection.

- Replace the old wire terminals if they show any signs of corrosion or damage.

- Cut back the wire and attach a new terminal if the wire itself appears burnt or discolored near the end.

Once you have reattached all the wires, give each one a gentle tug. This confirms they are secure and will not vibrate loose. Your new maytag heating element is now fully installed, and the main part of the repair is complete.

Putting Your Dryer Back Together

With the new heating element installed, you are on the home stretch. Reassembling your dryer is a matter of reversing the steps you took to open it. Careful attention during this phase ensures all parts fit together correctly and function safely. You will have your appliance ready for a test run in just a few minutes.

Reinstalling the Front Panel

You will begin by reattaching the front panel. First, carefully lift the panel and hang it on the two clips located at the base of the dryer cabinet. The panel should rest securely on these clips, allowing you to work with both hands.

Next, you will secure the panel with the four screws you removed earlier. It is best to start the screws by hand to avoid cross-threading before tightening them with your nut driver.

| Screw Location | Quantity | Tool Required |

|---|---|---|

| Inside Top of Cabinet | 2 | 5/16″ Nut Driver |

| Bottom of Front Panel | 2 | 5/16″ Nut Driver |

Tilt the top of the panel into place. Insert and tighten the two screws inside the top of the cabinet. Finally, install the two remaining screws near the bottom of the panel. Your front panel is now securely reattached.

Reconnecting the Door Switch Harness

Before you can close the top panel, you must reconnect the door switch. This is a critical safety feature that prevents the dryer from running when the door is open. Forgetting this step will result in a machine that will not start.

- Locate the two ends of the plastic wire harness connector. One end is attached to the front panel, and the other comes from the main body of the machine.

- Align the connectors properly. They are designed to fit together in only one way.

- Push the two halves together firmly until you hear and feel a distinct click.

Profi-Tipp: Give the connection a gentle tug after you plug it in. This confirms the harness is locked in place and will not disconnect from vibrations during operation.

Closing and Securing the Top Panel

The final step in the reassembly process is to close the top panel. This action will fully enclose the cabinet and prepare the appliance for its final test.

- Carefully lower the hinged top panel down into its closed position.

- Align the front edge of the top panel with the front panel of the machine.

- Apply firm downward pressure on the front corners of the top panel. You should hear a solid “snap” on each side as the spring clips re-engage.

- Run your hand along the seam between the top and front panels. It should be smooth and even, with no gaps.

Your Maytag dryer is now fully reassembled. You have successfully completed the physical portion of the repair and are ready to move on to the final testing phase.

Final Step: Testing Your Heating Element Replacement

You have successfully installed the new component and reassembled your dryer. The final phase is to test your work. This step confirms the repair was successful and your appliance is ready for regular use.

Restoring Power to the Dryer

You are now ready to restore power to the appliance. Your safety remains the priority during this step.

- Electric Dryer: Carefully plug the power cord back into the wall outlet.

- Gas Dryer: Reconnect the power cord first. Then, turn the gas supply valve back to the “On” position.

Ensure the area is clear and the dryer is stable. You have now prepared the machine for its first test cycle.

Running a Test Cycle to Confirm Heat

This is the moment of truth. You will now run a short cycle to verify that the new heating element is working correctly and resolving your no heat issue.

- Close the dryer door securely.

- Select a timed dry cycle with a high heat setting.

- Start the dryer.

- Allow the machine to run for three to five minutes.

- Carefully open the door and feel the air inside the drum.

You should feel a noticeable flow of warm air. The inside of the drum may also feel warm or hot to the touch. This confirms your new element is providing proper heating. If you feel warmth, your repair is a success!

What to Do If It Still Has No Heat

If you still have a no heat or not enough heat problem, do not be discouraged. The heating element is the most common failure, but another component in the heating circuit may be at fault. A dryer that doesn’t heat after an element replacement usually points to a secondary issue.

The most likely culprit is a blown thermal fuse. You can test this component with a multimeter.

- Locate the thermal fuse, typically found on the blower housing.

- Use a multimeter set to continuity to test the fuse.

- A good fuse will show continuity (a continuous electrical path).

- If the multimeter shows no continuity, the fuse has blown and you must replace it.

If the thermal fuse is blown, you should also inspect your dryer’s exhaust vent for clogs. A restriction is the primary cause of overheating that blows the fuse. If the fuse is good, other parts could be causing the no heat or not enough heat problem. A defective timer motor, for instance, can prevent the heating circuit from activating.

| Potential Issue | Component to Check | Aktion |

|---|---|---|

| No Heat | Thermosicherung | Test for continuity. |

| Not Enough Heat | Hi-Limit Thermostat | Test for continuity. |

| No Heat | Timer | Check for motor function. |

Checking these secondary components will almost certainly solve any lingering no heat or not enough heat issues.

Congratulations on completing the heating element replacement for your Maytag. Your dryer now has reliable heating. This successful repair saved you both time and money over a professional service call. You have restored your appliance to full working order.

To extend the life of your new heating element, you must keep your Maytag dryer’s airflow clear. Regularly clean the lint screen after every load. This simple replacement maintenance ensures your element provides powerful heating for years.

FAQ

### Why is my dryer running but has no heat?

A dryer with no heat usually points to a failed heating element coil. This component generates the warmth for the drying cycle. When it burns out, the dryer will tumble without producing any heat, leaving your clothes wet. This is the most common cause of a no heat problem.

### How long does this dryer repair take? ⏱️

You can typically complete this repair in about 30 to 60 minutes. The process is straightforward for most DIYers. Having your tools and replacement parts ready beforehand will help you finish the job quickly and efficiently.

### Can I test the heating element coil before buying new parts?

Yes, you can test the old heating element coil for continuity using a multimeter. A reading of infinity indicates a break in the coil, confirming it needs replacement. This test ensures you are purchasing the correct parts for the repair.

### What if the dryer has not enough heat after replacement?

If your dryer still has not enough heat, check your vent ducting for lint buildup. A clogged vent restricts airflow, which can cause not enough heat and lead to other issues. A clear vent is essential for your maytag dryer to function correctly.

### Are there other parts I should inspect during this repair?

While you have the dryer open, you should inspect the high-limit thermostat and thermal fuse. These safety parts can also cause a no heat condition. Checking them now can save you from needing another repair later.

### Where can I find the correct parts for my Maytag?

You can find genuine maytag parts at appliance parts suppliers online or locally. Ensure you purchase the correct heating element assembly (part number 307178) or a compatible alternative to guarantee a successful repair and proper function.