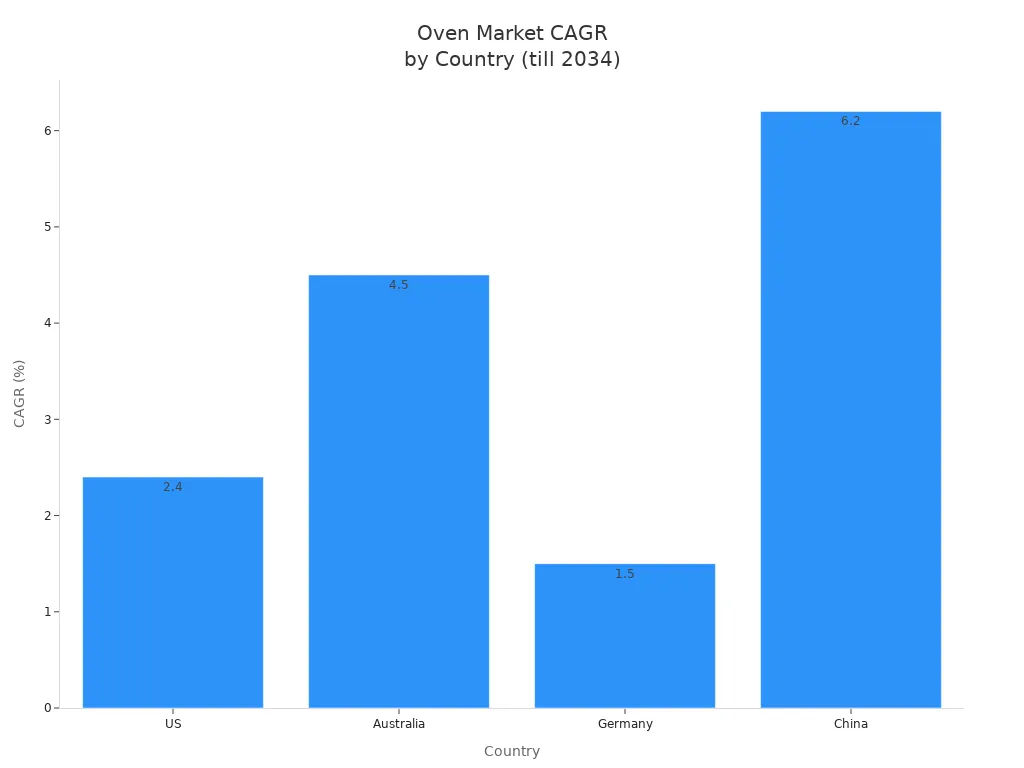

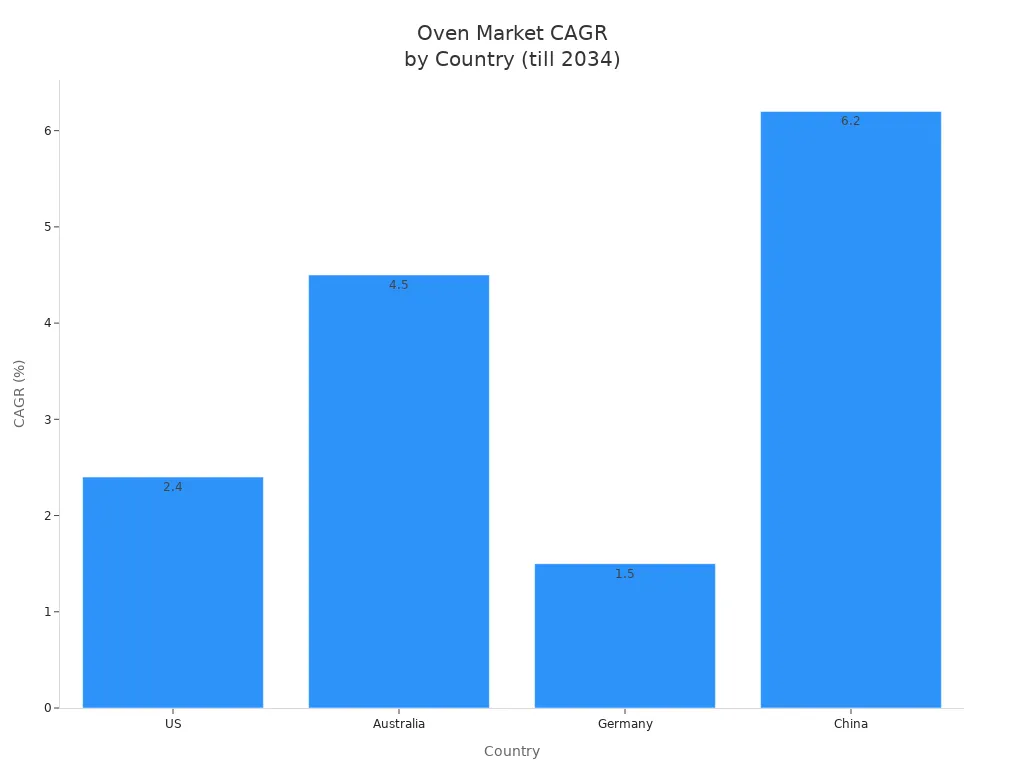

Modern kitchens now feature advanced oven heating elements that deliver faster, more precise heat. As the global oven market approaches USD 5 billion by 2034, manufacturers like Электрическое отопление Цзиньчжун и другие ведущие производители нагревательных элементов continue to innovate. The popularity of multi-technology heating elements, inverter systems, and smart connectivity transforms household appliances and enhances cooking performance.

In 2024, over 53% of new appliances adopt multi-mode нагревательный элемент technology, which ensures even heat and improved energy efficiency for нагревательные элементы бытовых приборов.

| Technology / Feature | Adoption / Popularity Metrics | Key Benefits / Notes | Leading Manufacturers / Examples |

|---|---|---|---|

| Multi-technology heating modes | Over 53% of recent models integrate convection, microwave, and impingement | Faster and more precise cooking | Whirlpool, Miele, TurboChef |

| Inverter-based heating systems | 31% of new ovens incorporate inverter systems | Energy efficiency, reduces electricity consumption by up to 23% | Whirlpool (Smart Inverter High-Speed Oven) |

| AI-enabled sensors and smart inverter | 19% increase in auto-cook and moisture detection | Improves cooking accuracy and reduces human intervention | Whirlpool, Bosch (TouchConnect HomeLine) |

Overview of Modern Oven Heating Elements

Types of Oven Heating Elements

Electric Heating Elements

Electric heating elements remain the most common choice in modern ovens. These elements use advanced alloys such as nickel-chromium or iron-chromium-aluminum to convert electrical energy into heat. Manufacturers design these heating elements for rapid thermal response and improved durability. Stainless steel and encapsulated tubular designs now replace older cast iron models, providing better heat transfer and corrosion resistance. Many household appliances rely on electric heating elements for consistent performance.

Induction Heating Elements

Induction heating elements use electromagnetic fields to generate heat directly within cookware. This technology allows for precise temperature control and rapid heating. Induction elements do not heat the oven cavity itself, which increases safety and energy efficiency. Many appliances with induction heating elements offer digital interfaces for easy adjustments.

Convection Heating Elements

Convection heating elements work with integrated fans to circulate hot air throughout the oven. This design ensures even heat distribution and reduces cooking times. Modern convection ovens often include multiple heating elements to optimize temperature for different dishes. Many household appliances now feature convection systems for improved results.

Infrared Heating Elements

Infrared heating elements use ceramic or carbon fiber materials to emit radiant heat. These elements provide fast, direct heating and enhance browning and crisping. Infrared technology improves energy efficiency and allows for more accurate heat control. Many appliances with infrared heating elements support advanced cooking modes.

Hybrid and Combination Heating Elements

Hybrid and combination heating elements blend multiple technologies, such as convection, microwave, and steam. These systems offer flexibility and allow users to select the best heating method for each recipe. Many modern ovens feature hybrid heating elements to meet diverse cooking needs.

Key Features and Innovations in Heating Elements

Rapid Heating Technology

Recent advances in heating element design enable rapid preheating and faster cooking. Multi-spiral and enclosed heating structures increase the surface area for heat transfer. Low voltage operation supports quick thermal response and power-off protection.

Energy Efficiency Improvements

Modern heating elements use energy-efficient designs to reduce electricity consumption. Convection fans and encapsulated elements minimize heat loss. Many appliances now meet international standards for energy savings.

Smart Controls and Connectivity

Цифровые интерфейсы управления have become standard in modern ovens. These interfaces blend physical buttons with touch displays that activate when users approach. Smart technology integration allows remote monitoring and control of heating elements through smartphones.

Enhanced Durability and Materials

Manufacturers use advanced heat-resistant materials inside the oven cavity to improve durability. Heating elements now feature corrosion-resistant alloys and fire-retardant coatings. These improvements ensure long-lasting performance, even under frequent use.

Even Heat Distribution

Convection heating elements and zoned heating systems deliver even heat throughout the oven. Multiple heating elements work together to eliminate hot spots and ensure consistent results. Automatic heating programs optimize heat for different dishes, enhancing user experience.

Modern oven heating elements distinguish themselves from traditional models by using advanced materials, digital controls, and energy-efficient designs. Features such as integrated steam generation, self-cleaning functions, and concealed hardware reflect a shift toward streamlined, future-proof appliances.

| Особенность | Traditional Oven Heating Elements | Modern Oven Heating Elements |

|---|---|---|

| Materials | Cast iron, heavy metals | Stainless steel, advanced alloys |

| Контроль температуры | Basic, limited precision | Digital controls with precise adjustments |

| Эффективность | Lower efficiency, higher energy consumption | Energy-efficient designs, often with convection fans |

| Дополнительные возможности | Simple top and bottom elements | Steam generation, multiple heating elements for even heat |

Benefits of Trending Oven Heating Elements

Improved Cooking Performance with Heating Elements

Faster Preheating Times

Modern heating elements deliver remarkable improvements in preheating speed. Ovens equipped with graphite heating elements reach cooking temperatures almost instantly, often in under 0.2 seconds. This rapid response outpaces quartz and traditional metal coil systems, which can require several minutes to reach 350°F. The following points highlight the scientific advancements:

- Dr. Robert Chen from MIT notes that graphite heats up nearly instantaneously, while quartz and conventional ovens take much longer.

- Graphite heating elements transfer heat five times faster than metal coils, eliminating the need for lengthy preheating.

- Comparative studies show quartz elements need 60 seconds to 3 minutes, convection ovens 5 to 10 minutes, and traditional ovens up to 15 minutes to reach 350°F, whereas graphite ovens achieve this in less than a second.

- The Culinary Institute of America recognizes graphite heating as a major leap in kitchen appliance efficiency.

- Expert testing confirms graphite heating reduces cooking times by about 30% and uses 40% less energy.

These advancements allow users to begin cooking almost immediately, streamlining meal preparation and enhancing overall kitchen productivity.

Precise Temperature Control

Trending heating elements provide precise temperature regulation, which is essential for consistent results. Stainless steel heating elements distribute heat evenly, minimizing energy waste and ensuring uniform cooking. High power density elements, ranging from 60 to 100W/cm², enable rapid temperature increases. For example, they can heat 250ml of water in just 20 seconds, compared to 60 seconds with older technologies.

- Advanced control systems, such as PID controllers with solid state relays, reduce excessive cycling and thermal stress.

- Separate process and high-limit sensors maintain tight temperature control.

- Intelligent temperature control technology, combined with sensors, prevents overheating and fluctuations.

- Optimized heat conduction paths improve thermal efficiency and reduce heat loss.

- High-durability materials extend service life and lower maintenance costs.

These features collectively enable ovens to maintain stable temperatures, reduce energy consumption, and extend the lifespan of the heating element.

Consistent Cooking Results

User testing demonstrates that modern heating elements, when paired with advanced thermostat controls, maintain stable average temperatures and manage hot or cold spots effectively. The placement of thermostats and the design of the oven cavity influence how heat is sensed and distributed. For instance, placing a cookie sheet on the bottom shelf can raise the average oven temperature by 12°F but may also increase fluctuations. Despite these variables, trending heating elements cycle on and off to maintain target temperatures, ensuring consistent cooking outcomes. This stability supports reliable baking, roasting, and broiling, even when oven loads or configurations change.

Enhanced Energy Efficiency of Heating Elements

Низкое потребление энергии

Trending heating elements significantly improve energy efficiency in modern ovens. Studies reveal that radiative heat transfer accounts for over half of the heat flux at typical oven temperatures. By optimizing radiative efficiency, manufacturers reduce overall energy consumption. Experimental data from prototype low-emissivity electrically heated ovens show energy savings between 36% and 57% compared to standard commercial electric ovens. These prototypes use exposed sheathed electrical heating elements within reflective compartments, increasing the proportion of thermal radiation reaching the food and reducing cooking time.

Analysis of typical electric ovens indicates that nearly half of the energy input is absorbed by the oven structure, with additional losses through walls and vents. Advanced heating element designs address these inefficiencies, helping appliances meet Minimum Energy Performance Standards and reducing both energy use and emissions.

Eco-Friendly Options

Manufacturers now offer a range of eco-friendly heating element options for both residential and commercial ovens. For example, the Easy-Bake Oven replaced its original incandescent bulb with a larger, more energy-efficient heating element, reducing energy use while expanding baking possibilities. The table below summarizes additional sustainable options:

| Eco-friendly Oven Heating Element Options | Описание |

|---|---|

| Boilerless Combi Ovens with Water-Injected Heating Elements | Generate steam by injecting water directly onto heating elements, conserving water and energy. Favored by over 65% of commercial operators. |

| Low-Energy Consumption Heating Elements | Designed to reduce energy use, supporting sustainability in commercial appliances. |

| AI-Driven Cooking Automation | Optimizes heating and steam calibration for improved energy efficiency and sustainability. |

| Hydrogen-Powered Heating Elements | Emerging technology for commercial ovens, reducing carbon footprint by using hydrogen. |

| Eco-Friendly Cleaning Solutions and Recyclable Accessories | Integrated with heating technologies to minimize environmental impact. |

Infrared, ceramic, and induction heating elements also contribute to lower energy consumption by directly heating food, retaining heat efficiently, and offering precise control.

Safety and Reliability of Oven Heating Elements

Overheat Protection Features

Safety remains a top priority in the design of trending heating elements. Modern toaster ovens and full-size ovens comply with standards such as IEC 60335-2-9 and UL certification, which require rigorous safety measures. These appliances incorporate thermal cutoff protection devices that disconnect power if the heating element exceeds safe operating temperatures. Many heating elements use PTC (Positive Temperature Coefficient) technology, which self-regulates temperature by increasing electrical resistance as heat rises. This automatic adjustment prevents overheating, enhances safety, and extends the lifespan of the heating element.

Child Safety Locks

Manufacturers integrate child safety locks into oven controls to prevent accidental activation or changes to settings. These locks add an extra layer of protection, especially in households with young children. The presence of such features ensures that ovens remain safe to use in family environments, reducing the risk of burns or unintended operation.

Long-Lasting Performance

Reliability data from major brands such as GE, Whirlpool, Frigidaire, and Thermador show that heating elements typically last between 5 and 10 years. Service rates, material quality, and rigorous laboratory testing all contribute to long-lasting performance. For example, nickel-chromium alloys with corrosion-resistant coatings undergo ASTM B117 and ISO 9227 testing to ensure durability. Manufacturers use aging test ovens to simulate years of wear and tear, exposing heating elements to extreme conditions. This process helps predict long-term stability and supports the development of products that maintain consistent performance throughout their expected lifespan.

Certified ovens undergo extensive testing to ensure structural integrity and safe operation at high temperatures, meeting standards such as UL 1098, CE, CSA, ETL, and NSF Std./ANSI 4. These certifications guarantee that heating elements meet strict safety and sanitation requirements, providing peace of mind for consumers and commercial operators alike.

How to Choose the Right Heating Element for Your Kitchen

Factors to Consider When Selecting Heating Elements

Compatibility with Existing Oven

Selecting the correct heating element for a kitchen begins with compatibility. The heating elements must match the oven’s wattage rating to ensure safe and effective operation. Physical fit is essential; the element should align with the oven’s coil size and pattern. Electrical connections must correspond to the oven’s connector type, whether push-on, screw-in, or plug-in. Manufacturer part numbers and model information help identify suitable replacements. Some brands share manufacturers, allowing cross-brand compatibility, but caution is necessary. Industry standards, such as UL or ETL listings, guarantee safety and performance.

Tip: Always disconnect power before replacing a heating element to prevent electrical hazards.

Compatibility Checklist:

- Confirm wattage rating matches the oven’s specifications.

- Check physical dimensions and coil pattern.

- Verify connector type and part number.

- Ensure the element fits securely in the oven cavity.

- Use the correct bake element for long-term reliability.

Cost and Budget Considerations

Cost plays a significant role in choosing heating elements. In 2024, the average replacement cost for a stovetop heating element ranges from $150 to $220, including parts and labor. Electric oven repairs typically cost between $100 and $250, while gas oven repairs may reach $600 due to additional safety requirements. Labor rates for specialists vary based on expertise. Homeowners should weigh the benefits of OEM parts, which offer better reliability and fit, against generic options that may be less expensive but could compromise durability.

Maintenance Requirements

Maintenance needs differ among heating element types. Electric heating elements require regular cleaning to remove grease and food debris. Inspection for damage and checking electrical connections help maintain performance. Fuel-fired burner ovens need annual testing of safety interlocks and shut-off valves. Steam, hot water, or heat transfer oil heated ovens require periodic inspection and cleaning of heating coils. All types benefit from regular calibration of safety devices and sensors, such as thermocouples and airflow switches.

| Тип нагревательного элемента | Maintenance Focus | Frequency/Notes |

|---|---|---|

| Electric Elements | Clean regularly, inspect for damage, check connections | Frequent, ongoing maintenance |

| Fuel-fired Burner Ovens | Test safety interlocks, inspect ignition and flame sensors | Annual and periodic checks |

| Steam/Hot Water/Oil Ovens | Inspect and clean coils, test pressure relief valves | Periodic and annual maintenance |

| All Types | Test and calibrate safety devices and sensors | Ongoing for safety and temperature control |

Cooking Needs and Preferences

Cooking habits influence the choice of heating elements. Bake elements provide even, consistent heat for baking and roasting. Broil elements deliver intense, direct heat for broiling. Location of the element affects heat distribution and cleaning ease. Material quality, such as nickel-chromium alloy, ensures durability and energy efficiency. Connector type must match the oven model for proper fit and safety. OEM parts offer reliability, while generic parts may suit budget-conscious buyers.

| Фактор | Описание | Considerations |

|---|---|---|

| Тип элемента | Bake element (bottom) provides even, consistent heat; Broil element (top) provides intense, direct heat | Choose based on cooking needs (baking vs broiling) |

| Расположение | Bottom element for baking/roasting; Top element for broiling; Some ovens have hidden elements or fans for heat circulation | Location affects heat distribution and cleaning ease |

| Качество материала | Typically nickel-chromium alloy or other heat-resistant materials | High-quality materials ensure durability and energy efficiency |

| Connector Type | Push-on, screw-in, or plug-in connectors | Must match oven model for proper fit and safety |

| Replacement Type | OEM parts vs Generic parts | OEM offers better reliability and fit but higher cost; Generic parts are cheaper but may have fit or durability issues |

Top Brands and Models of Oven Heating Elements in 2024

Leading Brands Overview

Asia-Pacific manufacturers dominate the oven heating element market in 2024, holding over 45% market share. Chinese companies lead with a broad product range, from budget-friendly to high-end industrial heating elements. Vietnamese suppliers are emerging for flexible prototyping and industrial finned elements. Brands focus on advanced materials, such as silicon carbide and molybdenum disilicide, for high-temperature and energy-efficient applications. Automation in food processing and commercial bakery sectors drives market growth.

| Brand / Supplier | Product Type | Review Score | Основные характеристики |

|---|---|---|---|

| Yancheng DragonPower Electric Co., Ltd. | Silicon Carbide Heating Elements | 5.0 | High-temp (1600°C+), premium pricing, industrial use |

| Jiangsu Shazi Electric Appliance Co., Ltd. | Industrial Stainless Steel Tubular Elements | 5.0 | Mid-range, 230V, 5000W, cost-effective for bulk orders |

| Yancheng Dingming Electric Heating Technology Co., Ltd. | Custom Tubular Heaters | 4.9 | Single-unit availability, stainless steel, prototyping |

| Foshan Jinlan Heating Appliance Co., Ltd. | Bakery Oven Elements | Н/Д | Budget-friendly, low price per unit ($0.35), less documented specs |

| BEST ELECTRIC EQUIPMENT CO., LTD (Vietnam) | Industrial Finned Elements | Н/Д | 220V, 1000W, single-unit availability, stainless steel |

| Nicson Electroheat Technology Co., Ltd. | OEM Household Elements | Н/Д | Bulk MOQ 50 pcs, low price range, household focus |

| Zhengzhou Mingxin Electric Heating Material Co., Ltd. | U-Shape Molybdenum Disilicide Elements | 5.0 | Ultra-high temp (1800°C), specialized industrial applications |

Best-Selling Models

Best-selling heating elements in 2024 feature advanced materials and energy-efficient designs. Silicon carbide and stainless steel tubular elements remain popular for industrial and commercial appliances. Custom tubular heaters and bakery oven elements offer flexibility for specialized needs. Household appliances often use OEM elements for reliability and performance.

User Reviews and Ratings

User reviews highlight the strengths of trending heating elements in electric ranges. Retailers such as AJ Madison and Lowe’s report average ratings above 4.4 stars. Users praise modern appearance, convection and air-fry features, quick preheat times, and easy cleaning. Minor criticisms focus on build quality, such as flimsy storage drawers, rather than heating performance. Wi-Fi connectivity and smart controls receive positive feedback for convenience.

| Розничный торговец | Average Rating | Positive Feedback | Negative Feedback |

|---|---|---|---|

| AJ Madison | 4.5 stars | Modern appearance, convection & air-fry features, quick preheat | None specifically noted |

| The Home Depot | Not specified | Convection and air-fry settings, easy-to-clean tray | Flimsy storage drawer |

| Lowe’s | 4.4 stars | Modern design, easy cleaning, Wi-Fi connectivity | None specifically noted |

Note: Users consistently value heating elements that deliver reliable heat, energy efficiency, and modern features in their appliances.

Installation and Maintenance Tips for Oven Heating Elements

Installation Guidelines for Heating Elements

Professional vs. DIY Installation

Choosing between professional and DIY installation depends on the complexity of the oven and the user’s confidence. The table below compares both approaches:

| Аспект | Установка своими руками | Профессиональная установка |

|---|---|---|

| Average Time Required | 1 to 4 hours | 1 to 2 hours |

| Total Cost | Parts only ($10 to $50) | Parts + Labor ($150 to $600) |

| Гарантия | May void warranty | Usually includes warranty on parts & labor |

Professional installation offers faster service and warranty protection. Technicians use manufacturer-approved parts and possess expertise that can extend oven lifespan. DIY installation saves money and provides immediate repair if parts are available, but it carries risks such as safety hazards and potential warranty voidance. For gas ovens or complex issues, professional installation is recommended. DIY may suit standard electric ovens if the user follows safety guidelines.

Меры предосторожности

Safety remains critical during installation. Always disconnect power at the breaker panel and unplug the oven before starting. Double-check that the oven has no power by testing controls and indicator lights. Allow the oven and heating element to cool completely. Wear dry, heat-resistant gloves and safety glasses. Remove combustibles from the area. Inspect wiring for damage and use insulated tools. Take photos or label wires before disconnecting. After installation, restore power and test the new element before reassembling the oven. If unusual signs appear, such as flickering lights or burning odors, stop immediately and contact a professional.

Maintenance Best Practices for Heating Elements

Cleaning and Care Tips

Routine maintenance ensures optimal performance and extends the life of heating elements. Daily cleaning removes grease and food debris. Weekly deep cleaning of racks and trays prevents residue buildup. Monthly inspections of electrical connections and thermostat calibration help avoid power fluctuations. Annual professional inspections identify worn parts and ensure safety compliance.

Совет: Avoid continuous high-temperature operation without breaks. Prolonged empty oven burns can damage the heating element.

Troubleshooting Common Issues

Common problems include uneven heating, failure to heat, visible damage, or burning smells. To troubleshoot:

- Disconnect the oven from power before any repair.

- Inspect the heating element for cracks or burns.

- Test bake and broil modes to identify which element heats.

- Use an oven thermometer to check temperature accuracy.

- Test the temperature sensor with a multimeter.

- Inspect the control board and wiring for damage.

- Examine the oven door seal for gaps.

- Refer to the owner’s manual for model-specific tips.

- Seek professional help if repairs exceed your expertise.

When to Replace Heating Elements

Replace heating elements if you notice visible damage, persistent uneven heating, or slow preheating. Regular inspection helps identify aging or faulty components early. Using high-quality, heat-resistant elements and proper installation techniques supports reliable oven operation and prevents further damage.

Modern kitchens benefit from trending oven heating elements that deliver rapid heat-up, precise temperature control, and consistent cooking results. Advanced designs improve energy efficiency, reduce monthly costs, and support sustainability. Homeowners who upgrade enjoy enhanced food quality, smart home integration, and improved indoor air quality.

- Improved energy efficiency lowers utility bills

- Precise temperature control ensures better cooking

- Rapid heat-up saves time

- Smart features enable remote operation

- Sustainability efforts reduce environmental impact

Choosing the right heating element creates a comfortable, efficient, and future-ready kitchen.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the most energy-efficient oven heating element available today?

Induction and infrared heating elements lead in energy efficiency. These technologies transfer heat directly to cookware or food, reducing energy loss. Many modern ovens now feature these elements to help users lower utility costs and support sustainability goals.

How often should oven heating elements be replaced?

Most heating elements last between five and ten years. Replacement becomes necessary if users notice uneven heating, visible damage, or slow preheating. Regular inspection and proper maintenance extend the lifespan of these components.

Can users install oven heating elements themselves?

Many electric oven heating elements allow for DIY installation. Users should always disconnect power before starting. For gas ovens or complex repairs, professional installation ensures safety and maintains warranty coverage.

Are modern heating elements compatible with older ovens?

Compatibility depends on the oven’s model, wattage, and connector type. Users should check manufacturer specifications and part numbers. Some modern elements fit older ovens, but always verify before purchasing.

What safety features do trending oven heating elements offer?

Modern heating elements include overheat protection, child safety locks, and self-regulating technologies. These features help prevent accidents and ensure reliable operation in both residential and commercial kitchens.

How can users maintain oven heating elements for optimal performance?

Regular cleaning removes grease and food debris. Monthly inspections of electrical connections and thermostat calibration help maintain efficiency. Annual professional checks identify worn parts and ensure compliance with safety standards.

Do smart ovens require special heating elements?

Smart ovens often use advanced heating elements designed for rapid response and digital control. These elements support features like remote monitoring and precise temperature adjustments. Users should consult the oven’s manual for compatible replacement parts.

What are the signs of a failing oven heating element?

Common signs include uneven cooking, visible cracks or burns on the element, and longer preheating times. A burning smell or failure to reach set temperatures also indicates potential issues. Prompt replacement prevents further damage.