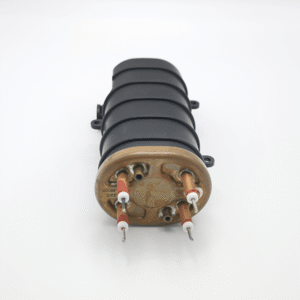

Aluminum Heating Element for Convector——High thermal conductivity and lightweight convection heating solution

Fin-type heating elements designed for home heaters, commercial industrial HVAC systems and cold chain equipment are made of aviation-grade 6063-T5 aluminum alloy + anodized insulation coating, suitable for 500W-15kW power range, temperature resistance up to 250℃ (short time), thermal conductivity ≥200W/m·K.

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

Home appliances: electric heaters, air conditioning convection heating modules, instant heaters.

Industrial equipment: industrial HVAC systems, agricultural greenhouse hot air circulation equipment, drying equipment

Power range:

Household: 800W–2500W (small convector, electric heater)

Industrial: 2500W–15kW (commercial HVAC system, industrial oven convection heating module)

Working voltage: 110V/220V single-phase AC or 380V three-phase AC (global power grid compatible, error ≤±5%).

Resistance value: 3Ω–25Ω (accurately matched by voltage and power, error ≤±3%).

Working temperature: Continuous and stable operation 150°C–280°C (short-term tolerance of 350°C, anodized layer protection).

Material:

Base material: aviation-grade aluminum alloy (6063-T5, thermal conductivity ≥200W/m·K, lightweight design).

Surface treatment: anodized layer (thickness 20μm, corrosion resistance, wear resistance, salt spray resistance test ≥300 hours).

Optional coatings: PTFE (acid and alkali resistant, oil resistant) or ceramic coating (high temperature resistant up to 500°C).

Dimensions:

Total length: 150mm–1200mm, fin spacing 5mm–30mm (customized spacing and density are supported).

Substrate thickness: 3mm–10mm, fin thickness 0.8mm–2mm.

Service life: 15,000–50,000 hours (based on operating temperature and heat dissipation conditions, anti-oxidation coating extends life).

Customizable services: support power, voltage, fin shape adjustment, optional explosion-proof certification, integrated NTC sensor, etc.

Extreme heat dissipation and thermal efficiency:

The X-shaped cross-fin structure optimizes the airflow path through CFD, and the heat convection efficiency is increased by 45%, and the heat exchange rate under forced air cooling is ≥92%.

The thermal conductivity of aluminum alloy is 5 times that of steel, and the volume is reduced by 60% at the same power, which is suitable for compact convector design.

High temperature stability:

The anodized layer can withstand long-term operation at 280°C, and its anti-oxidation performance is 3 times higher than that of ordinary aluminum, preventing high-temperature oxidation failure.

Quick response and energy saving:

Lightweight design (density 2.7g/cm³) + low heat capacity characteristics, heating to 150°C within 30 seconds, supporting high-frequency start and stop (energy efficiency ratio increased by 20%).

Corrosion resistance enhancement:

Anodized layer + optional PTFE coating (resistant to pH 1–14), suitable for coastal high salt fog, chemical environment or humid places.

Structural strength optimization:

Integrated die-casting molding process, mechanical vibration fatigue life ≥ 100,000 times (passed GB/T 2423.56 vibration test).

Intelligent compatibility:

Supports PWM power regulation and NTC temperature sensor integration, and is suitable for IoT intelligent temperature control system (remote adjustment of wind speed/temperature).

Global adaptability:

Compatible with 110V–480V voltage, supports CE, UL, RoHS, ISO 9001 certification, and adapts to European, American/Asian industrial standards.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.