You rely on a heater coil whenever you want fast, reliable heating in your home or office. As electricity passes through the coil, the resistance inside the wire produces heat. This process makes heating coils essential for warming air or water in many devices. You experience this simple yet effective heating method every time you use an appliance with a heater coil. The design of heating coils ensures steady warmth in countless applications.

What Is a Heater Coil?

Basic Definition of a Heater Coil

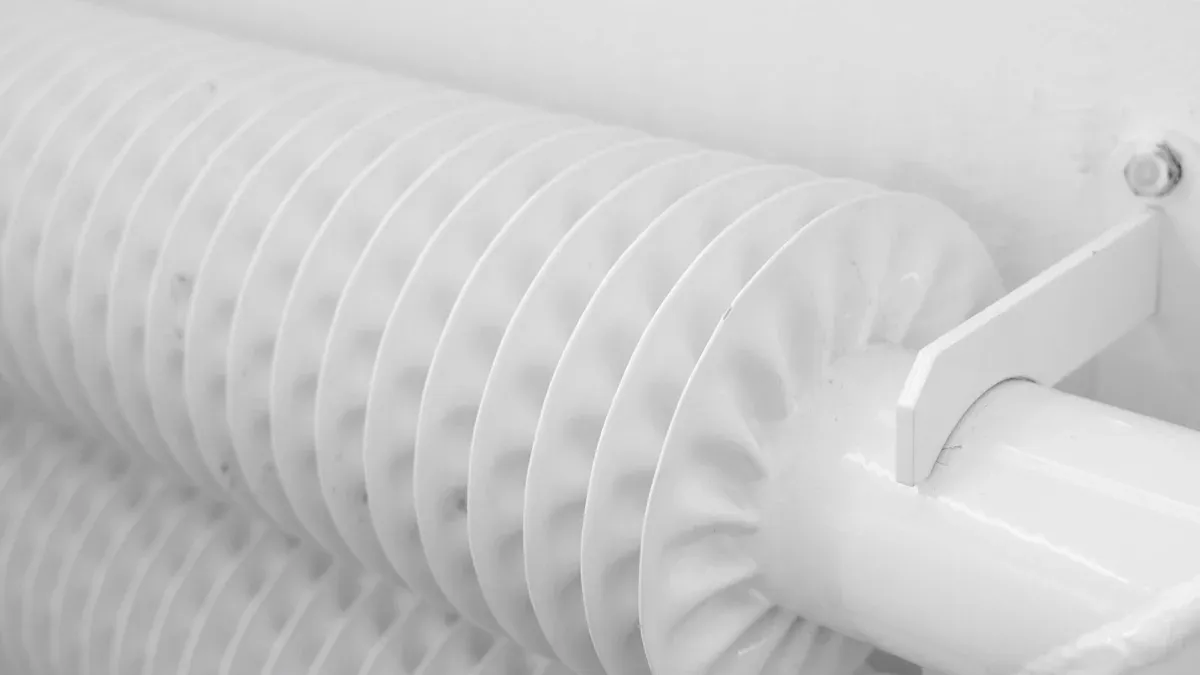

You encounter a heater coil whenever you use a device that needs to generate heat quickly and efficiently. In technical terms, a heater coil is an electric resistance element designed to provide supplemental reheat in HVAC systems or other appliances. Engineers construct these coils using nickel-chromium elements, arranging them to deliver specific heating capacities. You find these coils certified to UL standards, ensuring safety and reliability. Manufacturers integrate heater coils into terminal units or duct heaters, controlling them with contactors or SCR controllers to adjust heat output. Safety features, such as automatic and manual resets, prevent overheating. Airflow or fan switch relays ensure the coil operates only when safe airflow exists. This combination of construction, certification, and control defines a heater coil in engineering practice.

Common Materials Used in Heating Coils

Nichrome Wire in Heating Elements

You often see nichrome wire as the core material in a heating element. Nichrome, an alloy of about 80% nickel and 20% chromium, offers high resistivity and excellent oxidation resistance. This property allows the wire to heat up quickly and maintain performance over time. When you turn on an electric heating element, the nichrome wire resists the flow of electricity, causing it to heat up and radiate warmth.

Why These Materials Are Chosen for Heater Coils

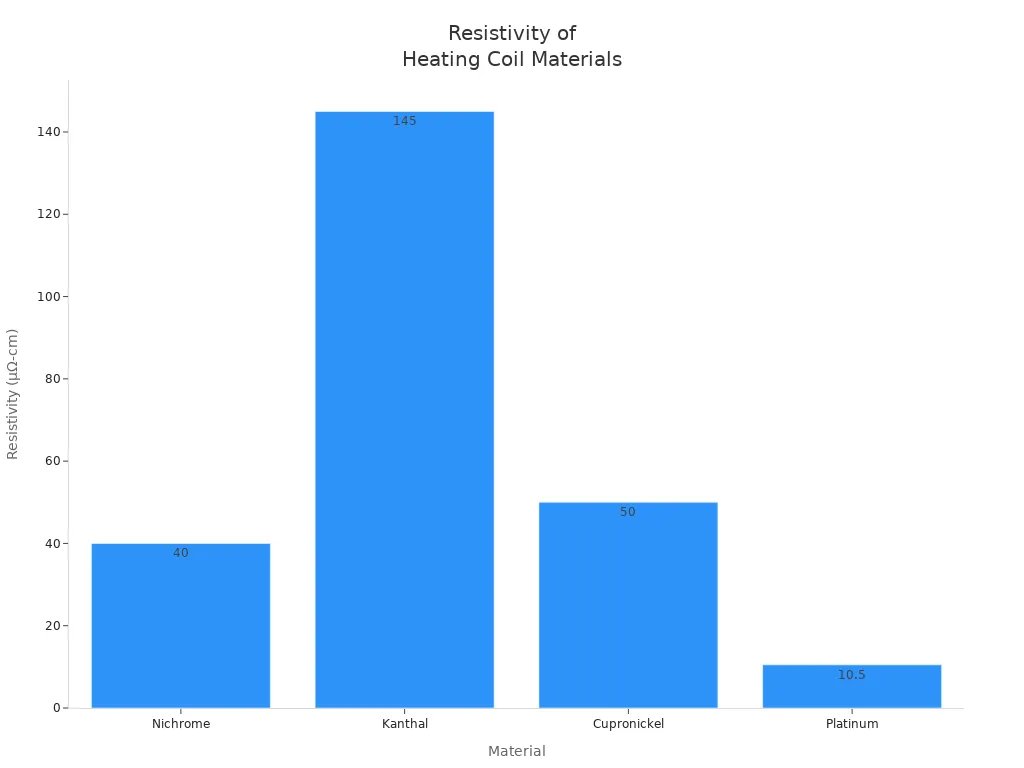

Engineers select materials for heating elements based on their ability to withstand high temperatures, resist oxidation, and maintain structural integrity. The table below compares the most common materials used in electric heating coils:

| Material | Composition | Resistivity (µΩ-cm) | Melting Point (°C) | Key Properties and Applications |

|---|---|---|---|---|

| Nichrome | ~80% Ni, 20% Cr | 40 | 1400 | High oxidation resistance; used in electric heaters and furnaces up to 1200 °C |

| Kanthal | ~72% Fe, 22% Cr, 5.8% Al | 145 | 1500 | Excellent oxidation resistance; operates up to 1400 °C; used in ceramic, steel, glass industries |

| Cupronickel | ~75% Cu, 23% Ni | 50 | 1280 | Good oxidation resistance; suitable for low-temperature heating up to 600 °C |

| Platinum | Pure Pt | 10.5 | 1768.3 | Noble metal; high resistivity and melting point; used in lab furnaces and resistance thermometers |

You benefit from these material choices because they ensure your heating element lasts longer and performs reliably, even under demanding conditions.

Where Heater Coils Are Found

Home Appliances Using Heating Coils

You interact with heating elements every day, often without realizing it. Common household appliances using electric heating coils include:

- Water heaters

- Electric cooktops and stoves

- Irons

- Toasters

- Hair dryers

- Electric ovens

- Electric kettles

- Space heaters

- Electric blankets

Each device relies on a heating element to convert electrical energy into heat, providing comfort and convenience in your daily routine.

Industrial Applications of Heating Coil Systems

In industrial settings, you find heating coil systems in a wide range of equipment. Manufacturing processes such as plastic molding, metalworking, and annealing use heating elements to reach precise temperatures. HVAC systems employ duct and pipe electric heating coils for climate control and energy efficiency. You also see heating elements in laboratory equipment, food service machines, and drying equipment. Cartridge heaters, a type of electric heating element, appear in medical devices, 3D printers, and plastic extruders. These applications highlight the versatility and importance of heating elements in both home and industry.

The Science Behind Heating Coil Systems

Electrical Resistance and Joule Heating

What Is Electrical Resistance in a Heating Element?

You encounter electrical resistance every time you use a heating element. Resistance describes how much a material opposes the flow of electric current. When you pass electricity through a conductor, such as a wire, the atoms inside the material slow down the movement of electrons. This opposition causes energy loss, which appears as heat. In a heating element, engineers select materials with high resistance, like nichrome, to maximize this effect. The formula for resistance is:

R = ρ × l / A

Where R is resistance, ρ is resistivity, l is length, and A is cross-sectional area.

A heating element with higher resistance produces more heat for the same amount of current. This principle allows you to control the amount of heat generated by adjusting the material, length, or thickness of the wire.

| Aspect | Explanation |

|---|---|

| Principle | Electrical energy converts to heat due to resistance when current passes through a conductor. |

| Formula | Heat generated (Power) = I² × R, where I = current, R = resistance. |

| Resistance Factors | Resistance (R) depends on resistivity (ρ), length (l), and cross-sectional area (A): R = ρ × l / A. |

| Resistivity Variation | Resistivity changes with temperature, usually increasing for metals; ρ_T = ρ_0 (1 + aT), where a is coefficient. |

| Material Requirements | High resistivity, high melting point, mechanical strength, oxidation resistance, and stable resistivity. |

| Heating Methods | Direct heating: workpiece carries current and heats up rapidly. Indirect heating: separate element heats workpiece via conduction, convection, radiation. |

| Applications | Industrial furnaces, electric heaters, ovens, and other heating devices. |

How Resistance Creates Heat in Heating Coils

When you turn on a device with a heating element, electrical current flows through the coil. The resistance in the coil material forces electrons to collide with atoms, transferring energy and causing the atoms to vibrate. This vibration produces heat. The amount of heat generated follows the I²R effect, where heat equals the current squared times the resistance. You see this in action in appliances like toasters, ovens, and industrial furnaces.

- Electrical resistance heating converts electrical energy into heat through materials with high resistance.

- Heat generated follows the I²R effect: Heat = Current² × Resistance.

- Common materials include nichrome and ceramics.

- Applications include industrial furnaces, electric heaters, toasters, and ovens.

- Advantages include high efficiency, precise temperature control, and low maintenance.

Joule heating explains this process. As current passes through the heating element, resistance causes energy dissipation. The heating effect does not depend on the direction of the current, so it works with both AC and DC power. The choice of material affects both efficiency and durability, which is why engineers use specific alloys for heating coils.

Simple Analogy: Water Flowing Through a Narrow Pipe

Imagine water flowing through a pipe. The pipe’s diameter and length represent resistance. If you use a narrow or long pipe, water flows more slowly, and pressure drops. In an electrical circuit, current acts like water, and voltage acts like pressure. When you force more current through a high-resistance heating element, the resistance acts like a constriction in the pipe. This restriction causes energy loss, which appears as heat in the coil.

Think of the heating element as a narrow section of pipe. As electricity (water) moves through, resistance (the narrowness) slows it down, and the energy lost turns into heat. This analogy helps you understand how heating coils work in everyday appliances.

Why the Heating Coil Gets Hot, Not the Connecting Wires

You may wonder why the heating coil glows red-hot, but the wires connecting it stay cool. The answer lies in the design and materials. Heating coils use materials with high resistance and are shaped to retain heat. The connecting wires, often made from copper, have low resistance and larger surface areas. These wires act as heat sinks, quickly dissipating any heat they absorb.

The geometry of the heating element also matters. The middle section of the coil heats up more because it loses heat less efficiently than the ends, which connect to bulkier wires. As the coil heats, its resistance increases, causing even more power to dissipate in the hottest part. This positive feedback loop continues until the coil reaches a stable temperature, balanced by heat loss to the surrounding air.

The connecting wires stay cool because they are designed to carry current efficiently without generating much heat. The heating coil, on the other hand, is engineered to maximize resistance and retain heat, making it the heart of any heating device.

How a Heating Element Converts Electricity to Heat

Electricity Entering the Heating Coil

When you switch on a device, electricity flows into the heating element through its terminals or wires. This creates a voltage difference, which sets up an electric field inside the coil. The electric field pushes electrons, causing them to move rapidly along the length of the heating element. As these electrons travel, they encounter the tightly packed atoms in the coil’s structure. Each collision between electrons and atoms transfers energy to the atoms, making them vibrate more intensely. These vibrations are what you feel as heat. This process, known as Joule heating, is the foundation of how heating elements work.

When you use an appliance with a heating element, you start a chain reaction: electricity enters, electrons move, and heat is produced almost instantly.

Resistance Slowing Down the Flow in the Heating Element

The material inside a heating element does not let electrons pass freely. Instead, it offers resistance, which acts like a barrier to the flow of current. As electrons try to move through the coil, they constantly bump into atoms. These microscopic collisions slow down the electrons and convert their kinetic energy into heat. The resistance in the heating element is carefully chosen to produce the right amount of heat for each application.

- The higher the resistance, the more heat the heating element generates.

- The resistance also limits the amount of current, protecting the device from overheating.

You can think of resistance as a speed bump for electrons. Each time an electron hits an atom, it loses some energy, which turns into heat. This is why the heating element gets hot while the connecting wires, which have much lower resistance, stay cool.

Energy Conversion: Electricity to Heat in Heating Coils

The entire process inside a heating element is a direct conversion of electrical energy into thermal energy. When you turn on a device, the current flows through the coil, and the resistance transforms the electrical energy into heat. This is the core principle behind every heating element you use, whether in a toaster, oven, or industrial heater.

Here is a simple step-by-step breakdown of the energy conversion process:

- You supply electricity to the heating element.

- The electric field inside the coil accelerates electrons.

- Electrons collide with atoms in the resistive material.

- Each collision transfers energy, causing atoms to vibrate.

- The increased vibration raises the temperature of the coil.

- The coil radiates heat, warming the surrounding air or material.

This process is highly efficient because almost all the electrical energy becomes heat. The design of the heating element ensures that you get reliable and consistent heating every time you use an appliance. The principle of resistance heating is what makes devices like space heaters, hair dryers, and electric kettles so effective.

Remember, the secret to how heating elements work lies in the resistance of the coil. The right material and design guarantee safe, efficient, and rapid heating for your needs.

The Heating Coil Warming Up

When you power on a device with a heating coil, you set a rapid transformation in motion. The coil begins to warm almost instantly as electrical energy flows through its resistive material. You notice the coil’s temperature rising, sometimes glowing red or orange in high-powered appliances. This visible glow signals intense heat production and efficient energy conversion.

The temperature a heating coil reaches depends on several factors, including the material, design, and the amount of electrical power supplied. You can observe a wide range of operating temperatures in different applications:

- E-cigarette heating coils often operate between 145°C and 334°C under typical wet conditions. When the coil dries out, temperatures can spike dramatically, sometimes reaching 322°C to 1008°C. Coil design and power settings play a significant role, with some coils peaking at 460°C even when wet.

- Hot water coils in HVAC systems usually run with supply temperatures from 49°C (120°F) to 82°C (180°F). Domestic hot water heating coils typically stay between 49°C (120°F) and 60°C (140°F). Industrial heating coils may start at 38°C (100°F) and climb much higher, depending on the process requirements.

Tip: Always check the manufacturer’s specifications for safe operating temperatures. Exceeding these limits can damage the coil or reduce its lifespan.

As the coil heats up, you may notice a delay before the surrounding air or water feels warm. The coil must first reach its target temperature, then transfer heat to its environment. The process involves three main steps:

- Initial Heating: The coil absorbs electrical energy and begins to warm. The temperature rises quickly due to the high resistance of the coil material.

- Stabilization: The coil approaches its designed operating temperature. Heat loss to the surrounding air or water balances the heat generated by electrical resistance.

- Heat Transfer: The coil maintains a steady temperature, radiating or conducting heat to the medium it is designed to warm.

You benefit from this rapid and controlled heating process in many everyday appliances. The coil’s ability to reach and maintain precise temperatures ensures consistent performance, whether you are boiling water, drying clothes, or heating a room.

Remember, the heating coil’s temperature and performance depend on both its design and how you use the appliance. Proper operation keeps the coil efficient and extends its service life.

How Heating Coils Transfer Heat to Air and Water

Heating Air in Everyday Appliances

Heating coils play a crucial role in warming air inside many household devices. When you turn on a space heater or hair dryer, you activate a heating coil system that quickly raises the temperature of the air around it. The process begins as electrical current passes through a high-resistance wire, usually made of nichrome. This resistance causes the wire to heat up rapidly.

Space Heaters with Heating Elements

In a space heater, you find electric heating coils positioned in front of a fan. The fan blows air directly over the hot coils. As the air moves across the surface, it absorbs heat and spreads warmth throughout the room. You can adjust the temperature by changing the power setting, which controls how much current flows through the coil. Most space heaters include safety features that shut off the coil if it gets too hot, protecting you and your home.

- Electrical current heats the coil.

- A fan circulates air over the coil.

- Warm air fills the room, providing comfort.

- Built-in sensors prevent overheating.

Hair Dryers Using Heating Coils

Hair dryers use a similar principle. Inside the dryer, electric heating coils heat up when you switch it on. A small fan pulls in cool air and pushes it over the coils. The air picks up heat and exits the nozzle, allowing you to dry your hair quickly and efficiently. You control the temperature and airflow with simple switches. The design ensures that the heating element never overheats, thanks to automatic shut-off systems.

Tip: Always keep the air vents on your hair dryer clear. Blocked vents can cause the heating coil to overheat and reduce the lifespan of your appliance.

Heating Water with Heating Coil Systems

Heating coils also excel at transferring heat to water. You see this in electric kettles and water heaters, where the coil sits directly in contact with the water.

Electric Kettles and Their Heating Elements

In an electric kettle, the heating element sits at the base, submerged in water. When you turn on the kettle, the coil heats up almost instantly. The water molecules near the coil gain energy through direct contact, causing them to move faster and eventually boil. This direct heat transfer mechanism makes electric kettles highly efficient. Most of the electrical energy converts to heat, with minimal loss.

Water Heaters with Heating Coils

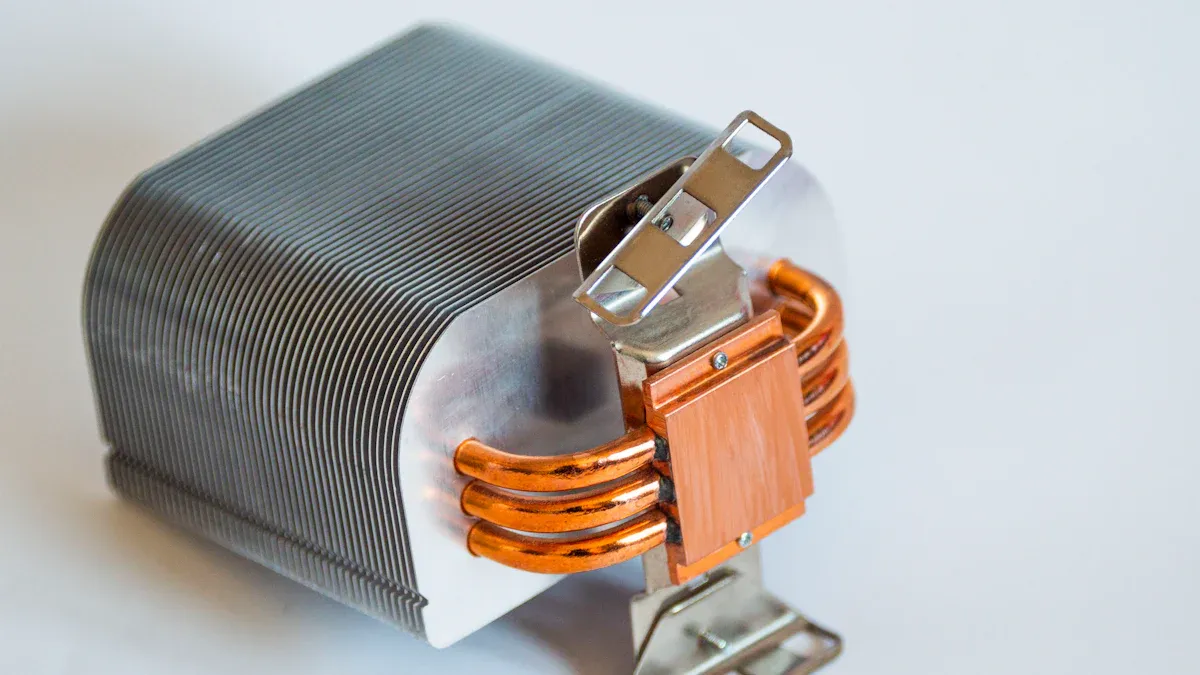

A water heater heating element works in much the same way. The coil, often made from a durable alloy, sits inside the tank. As electricity flows through the coil, it heats up and transfers energy to the surrounding water. Conduction moves heat from the coil to the water, while convection currents distribute the warmth evenly throughout the tank. The design of electric heating coils maximizes surface area, ensuring rapid and uniform heating.

Note: Modern water heaters use insulation and automatic shut-off features to prevent energy waste and overheating.

How Warmth Spreads from the Heating Coil

The heat transfer mechanism in household appliances relies on three main processes: conduction, convection, and radiation. Each method plays a role in how warmth moves from the coil to the environment.

| Heat Transfer Method | Description | Example in Household Appliances |

|---|---|---|

| Conduction | Heat moves directly from the hot coil to a solid surface in contact with it. Efficiency depends on material and contact quality. | Electric ovens heating metal walls and racks |

| Convection | Heat warms the air or fluid around the coil, which circulates to spread warmth. Often enhanced by fans to speed distribution. | Space heaters and electric furnaces blowing warm air |

| Radiation | The coil emits infrared heat energy that travels through air without direct contact. | Feeling warmth near a glowing electric coil |

You experience conduction when the coil touches water or metal surfaces. Convection occurs as air or water moves past the coil, carrying heat away. Radiation lets you feel warmth even if you do not touch the coil directly. In every hvac system, these methods combine to deliver efficient and reliable heating.

Remember: The effectiveness of a heating coil system depends on how well it uses conduction, convection, and radiation to transfer heat where you need it.

Everyday Examples of Heating Coils in Action

Toasters and Their Heating Elements

You interact with a heating element every time you make toast. Inside a toaster, you find thin wires made from nichrome, a material chosen for its high resistance and ability to withstand repeated heating cycles. When you push down the lever, electricity flows through these wires. The heating element glows red, reaching temperatures of several hundred degrees Celsius. This intense heat emits infrared radiation, which browns and crisps the surface of your bread.

The toasting process relies on precise timing. A built-in timer or a bi-metallic strip monitors the heat and cuts power to the heating element once your toast reaches the desired shade. You can adjust the darkness by changing the toasting time. In toaster ovens, both upper and lower heating elements work together to distribute heat evenly, usually at settings around 450°F (232°C). The result is consistent browning, whether you prefer a light golden slice or a deep, crunchy finish.

Tip: For even toasting, place bread slices in the center of the rack and avoid overcrowding the slots.

Ovens with Heating Coils

You depend on heating coils every time you bake, roast, or broil food in an electric oven. The oven heating element serves as the main source of heat, converting electrical energy into thermal energy through resistance. Most electric ovens feature two heating elements: a baking element at the bottom and a broil element at the top. When you set the oven temperature, electricity flows to these elements, causing them to heat up and warm the oven cavity.

The oven heating element provides dry, consistent heat, which is ideal for crisping and browning. Some ovens include a convection fan that circulates hot air, ensuring even cooking throughout the cavity. The temperature sensor inside the oven monitors the heat and cycles the heating elements on and off to maintain your chosen temperature. This system allows you to achieve reliable results, whether you are baking bread or broiling steak.

- Baking element: Located at the bottom, used for most cooking tasks.

- Broil element: Positioned at the top, delivers intense heat for browning and searing.

- Convection fan: Circulates air for uniform heat distribution.

Clothes Dryers Using Heating Coil Systems

You rely on a heating element every time you dry laundry in an electric dryer. The dryer uses either resistance wire heating elements or PTC (Positive Temperature Coefficient) heaters to warm the air. As the drum tumbles your clothes, the heating element raises the air temperature inside the drum. This hot air absorbs moisture from the fabrics, causing it to evaporate efficiently.

The tumbling action ensures that every item comes into contact with the heated air, improving both heat transfer and drying performance. Most dryers balance the characteristics of the heating element and airflow to optimize drying time and energy use. Some models use PTC heaters for a constant surface temperature, while others use resistance wire elements for faster heating. The system monitors temperature and moisture levels to prevent overheating and protect your fabrics.

Note: Clean the lint filter regularly to maintain airflow and ensure the heating element operates efficiently.

Car Defrosters and Heating Elements

When you drive on a cold morning, you often face fogged or frosted windows. Car defrosters rely on heating elements to clear your view and keep you safe. You find two main types of defrosters in most vehicles: front and rear systems. Each uses a different method to remove condensation, frost, and ice from your windows.

The front defroster connects to your car’s heating, ventilation, and air conditioning (HVAC) system. When you activate it, warm air blows onto the windshield and side windows. This warm air melts frost and prevents new ice from forming. The system often turns on the air conditioning automatically. This step dehumidifies the air, which helps clear condensation faster. You may notice that the front defroster takes a few minutes to work well. The engine must warm up before it can supply enough heat to the air.

The rear defroster works differently. You see thin lines embedded in the rear window glass. These lines are electric heat grids. When you press the rear defrost button, electricity flows through these grids. The resistance in the wires generates heat, which melts frost and ice almost immediately. You do not need to wait for the engine to warm up. The rear defroster provides rapid results, especially in icy or snowy conditions.

Tip: Start your engine and let it run for a few minutes before driving. This practice ensures that the defroster clears your windows completely and improves visibility.

You can use a scraper or a de-icer spray along with the defroster for even faster results. This combination removes thick ice and stubborn frost more efficiently. The defroster system keeps your windows clear and helps prevent dangerous driving conditions.

Here’s a quick overview of how car defrosters and heating elements work:

- Front defrosters use the HVAC system to blow warm, dry air onto the windshield and side windows.

- Rear defrosters use electric heating grids embedded in the glass to melt frost and ice instantly.

- The air conditioning system often runs with the defroster to remove moisture from the air.

- Letting your engine warm up improves the effectiveness of the front defroster.

- Using manual tools like scrapers can speed up the process.

You depend on these heating elements every winter. They ensure you have a clear view of the road, keeping you and your passengers safe. Understanding how defrosters work helps you use them more effectively and maintain your vehicle’s comfort and safety.

Safety and Efficiency of Heating Coil Systems

Built-In Safety Features in Heating Elements

Modern heating coils include several built-in safety features to protect you and your home. Manufacturers design these systems to prevent overheating, fire hazards, and electrical accidents. You benefit from these features every time you use an appliance with a heating coil system.

Thermostats in Heating Coil Systems

Thermostats play a key role in maintaining safe temperatures. You set your desired temperature, and the thermostat monitors the coil. If the temperature rises above the set point, the thermostat interrupts the electrical flow. This action prevents overheating and keeps your hvac system running safely. Many thermostats now include digital controls, allowing you to program heating schedules and monitor performance remotely.

Automatic Shut-Off for Heating Coils

Automatic shut-off features add another layer of protection. If your heater tips over or reaches a dangerous temperature, sensors trigger an immediate shutdown. You find these features in space heaters, furnaces, and other appliances. Some common safety mechanisms include:

- Tip-over protection

- Overheat protection sensors

- Thermal cut-off systems

- Limit switches

- Air pressure switches

These systems work together to ensure your heating coils operate only under safe conditions. You also see safety certifications like UL or CSA marks, which confirm that the product meets strict safety standards.

Tip: Always look for appliances with built-in safety features and proper certifications for peace of mind.

Tips for Safe Use of Heating Coils at Home

You can further improve safety by following best practices when using heating coils in your hvac system or household appliances:

- Schedule professional installation and annual maintenance for all heating appliances.

- Keep flammable materials away from heaters and furnaces.

- Never leave space heaters unattended.

- Install and maintain carbon monoxide and smoke detectors near heating equipment.

- Follow manufacturer instructions for installation, use, and maintenance.

- Avoid using extension cords as permanent power sources for heaters.

- Childproof appliances and educate children about the dangers of heating elements.

You should also use heat-resistant wiring insulation and ensure all metal parts are properly grounded. These steps help prevent electrical shocks and reduce the risk of fire.

Note: Regular maintenance keeps your hvac system and heating coils working safely and efficiently.

How Efficient Are Heating Coils?

Heating coils convert nearly all the electrical energy they receive into heat. This high efficiency means you get rapid and reliable warmth from your hvac system or appliance. However, the overall efficiency of a heating coil system depends on how well the heat spreads throughout your space. For example, convector heaters distribute heat more evenly and reduce heat loss, especially near windows, compared to baseboard or radiant heaters.

Recent advancements in heating coil design have improved both efficiency and safety. Manufacturers now use advanced materials like silver-plated copper and aluminum to enhance conductivity and durability. Smart digital controls, IoT integration, and adaptive algorithms allow you to monitor and adjust your heating remotely. These innovations help you save energy and extend the life of your hvac system.

While heating coils offer high energy conversion, you should consider the total cost of operation. Electric resistance heating is simple and affordable to install but can be expensive to run as a primary heat source. Heat pumps and hybrid systems, although more costly upfront, provide greater long-term savings due to their higher efficiency.

If you want to maximize efficiency, choose a heating coil system with advanced controls and proper heat distribution for your space.

Common Questions and Misconceptions About Heating Coils

Do Heating Coils Use a Lot of Electricity?

You might wonder if heating coils consume excessive electricity. The answer depends on the appliance and how long you use it. Heating coils in household devices like space heaters and toasters draw significant power compared to many other appliances. For example, a typical space heater uses between 750 and 1500 watts, while a toaster operates at around 1150 watts. The table below gives you a practical overview:

| Appliance Type | Typical Wattage Range (Watts) | Estimated Cost per Hour (¢) |

|---|---|---|

| Space Heaters | 750 – 1500 | 7.5 – 15 |

| Toasters | Around 1150 | About 11.5 |

If you run a space heater for an hour, you can expect it to cost between 7.5 and 15 cents, depending on your local electricity rates. Toasters cost about 11.5 cents per hour, but you usually use them for only a few minutes at a time. While heating coils are efficient at converting electricity to heat, they do use more power than many other household devices. You should always consider usage time and energy costs when choosing how to heat your space.

Tip: Use heating appliances with built-in thermostats or timers to manage electricity consumption efficiently.

Can Heating Coils Burn Out?

Heating coils can burn out over time, especially if you use them frequently or under harsh conditions. Several factors contribute to coil failure:

- Faulty wiring, such as frayed wires or loose connections, can cause the coil to fail.

- Corrosion from humidity or chemicals weakens the metal, leading to premature burnout.

- System strain, including continuous operation, clogged filters, or blocked vents, forces the coil to work harder and shortens its lifespan.

- Normal wear and tear gradually degrades the coil material.

- Lack of regular maintenance increases the risk of sudden breakdowns.

You may also encounter issues like tripped circuit breakers, blown fuses, or malfunctioning thermostats, which can prevent the coil from heating properly. Regular inspections and cleaning help extend the life of your heating elements and keep your appliances running safely.

Note: If you notice uneven heating, strange smells, or visible damage, turn off the appliance and consult a professional before further use.

Are All Heating Elements the Same?

Not all heating elements are created equal. You will find significant differences in material, design, and application. Manufacturers use various alloys and configurations to match specific needs. For example, nickel-chromium alloys work well in high-temperature devices like toasters and furnaces because they resist oxidation and last longer. Copper-nickel alloys suit low-temperature applications such as electric blankets due to their corrosion resistance.

You also see differences in how heating elements transfer heat and how they are mounted inside appliances. The table below summarizes key distinctions:

| Element Type | Wire Mounting | Heat Transfer Mode(s) | Typical Materials | Typical Applications |

|---|---|---|---|---|

| Embedded | Wire embedded in insulation | Conduction only | Kanthal® D, Nikrothal® 80 | Cartridge heaters, refrigerators |

| Supported | Wire coil supported at many points | Conduction, Convection, Radiation | Kanthal® AF, Nikrothal® 80 | Heating cables, baseboard heaters |

| Suspended | Wire suspended between points | Convection, Radiation | Nikrothal® 80, Nikrothal® 60 | Open coil heaters, furnaces |

You should select a heating element based on the required temperature, durability, and efficiency for your specific application. Understanding these differences helps you choose the right appliance and maintain it properly.

Remember: The right heating element ensures safe, efficient, and reliable performance in your home or workplace.

Heater coils generate heat by converting electricity into warmth through resistance. You benefit from this simple science every time you use a household appliance.

1. Coil heaters rely on resistance heating, where current passing through a wire produces heat. 2. Factors like wire thickness, length, and insulation affect efficiency. 3. Safety features—such as insulation, thermostats, and thermal cutoffs—protect you from hazards. 4. Regular maintenance ensures safe and efficient operation.

Understanding how heating coils work helps you use appliances safely and efficiently. Next time you turn on a heater, you can appreciate the straightforward science behind the warmth.

FAQ

What happens if a heating coil breaks?

You will notice the appliance stops producing heat. The coil cannot conduct electricity when broken. You should replace the coil or consult a technician. Never attempt to repair a broken coil yourself.

Can you touch a heating coil when it is off?

You should avoid touching heating coils, even when off. Residual heat can cause burns. Some coils retain heat for several minutes after use. Always let the coil cool completely before handling.

Why do heating coils sometimes glow red?

You see the coil glow red when it reaches high temperatures. The metal emits visible light as it heats up. This glow indicates efficient energy conversion and proper operation.

How long do heating coils usually last?

You can expect most heating coils to last several years with normal use. Lifespan depends on usage, maintenance, and material quality. Regular cleaning and proper operation extend coil life.

Are heating coils safe for children and pets?

You must keep children and pets away from exposed heating coils. Direct contact can cause burns. Use appliances with safety covers or automatic shut-off features for added protection.

Can you clean a heating coil?

You can clean some heating coils, but always follow manufacturer instructions. Unplug the appliance first. Use a soft brush or cloth. Never use water on electrical components.

Do heating coils work with both AC and DC power?

You can use heating coils with both AC and DC electricity. The coil produces heat from electrical resistance, regardless of current type. Always check the appliance’s specifications before use.

What should you do if a heating coil smells strange?

You should turn off the appliance immediately. A strange smell may indicate dust, debris, or overheating. Let the coil cool, then inspect for visible issues. If the smell persists, contact a professional.