You demand reliable heat in your industrial processes or home appliances. An infrared élément chauffant delivers immediate and consistent warmth, making it a trusted choice for both professionals and homeowners. Many Fabricants d'éléments chauffants, y compris Chauffage électrique Jinzhong, design products that excel in performance and durability. When you select éléments chauffants pour appareils ménagers, you benefit from advanced engineering that ensures steady output and long service life.

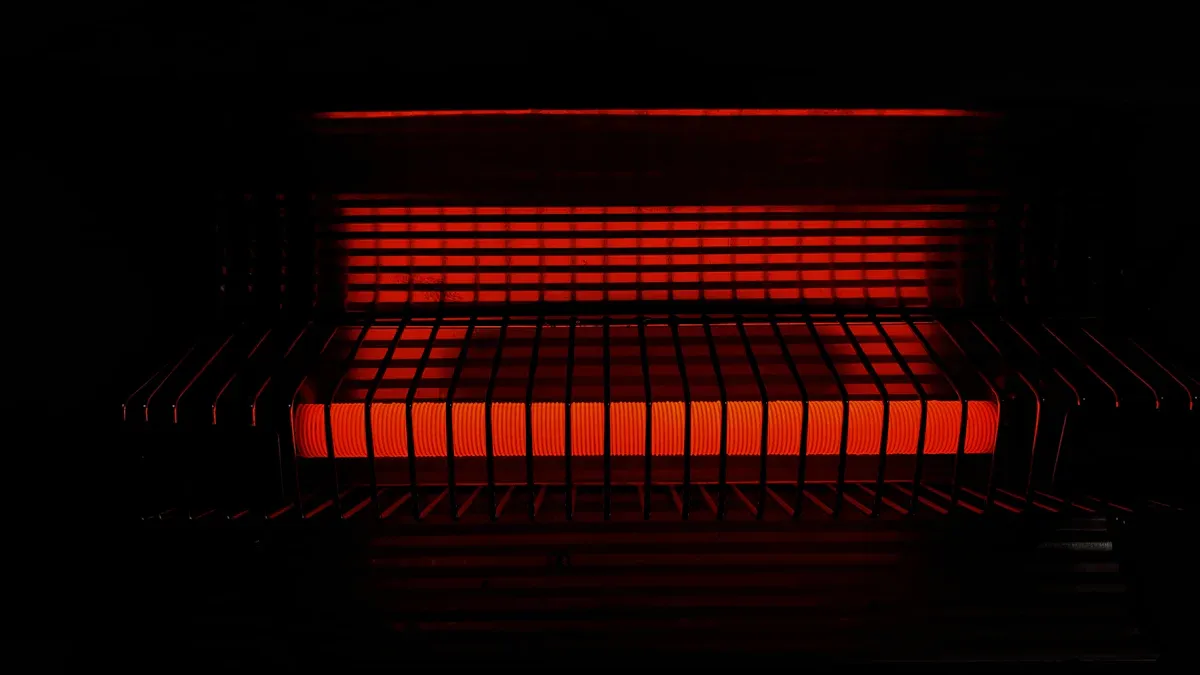

Infrared Heating Element Mechanism

Infrared Radiation and Heat Transfer

How Infrared Heating Element Emits Energy

You benefit from a heating solution that uses fundamental scientific principles to deliver warmth. An infrared heating element emits energy through radiant heating, which transfers energy via electromagnetic waves. This process warms objects and people directly, rather than heating the air around them. The Stefan–Boltzmann Law explains that as the temperature of the heating element rises, the amount of radiant heat it emits increases rapidly. Emissivity also plays a crucial role. Surfaces with higher emissivity, such as darker materials, absorb and emit infrared radiation more effectively.

Tip: Direct exposure to the infrared heating element ensures you receive the most efficient warmth, since infrared radiation travels in straight lines and requires a clear line-of-sight.

- Radiant Heating: Transfers energy through electromagnetic waves, warming objects directly.

- Stefan–Boltzmann Law: Radiant heat output increases dramatically as the element’s temperature rises.

- Emissivity: Darker surfaces absorb and emit infrared radiation more efficiently.

- Line-of-Sight: Direct exposure is essential for effective heating.

- Absorption and Re-radiation: Heated surfaces store energy and gradually release it, enhancing overall warmth.

The wavelength of infrared radiation also affects how efficiently heat transfers to different materials. For example, water and PVC absorb medium-wave infrared radiation best, while metals reflect most medium and far-infrared energy. The efficiency of your infrared heating element depends on matching its emission spectrum to the absorption characteristics of the target material.

| Type de matériau | Peak Absorption Wavelength (μm) | Efficiency Relation |

|---|---|---|

| Water | 3 | Better absorbed by medium-wave infrared heaters |

| PVC | 3.5 | Better absorbed by medium-wave infrared heaters |

| Metals | Short-wave range | High reflectivity in medium and far infrared |

Infrared radiation falls into three categories: Near-IR (0.75–1.4 µm), Mid-IR (1.4–3 µm), and Far-IR (3–1000 µm). The energy output of your heating element changes with its temperature and the type of lamp or emitter used.

Direct Radiant Heat Delivery

You experience immediate warmth because the infrared heating element delivers heat directly to surfaces and people. Unlike convection heaters, which rely on air circulation, infrared heaters focus energy precisely where you need it. This direct approach minimizes heat loss and ensures that you feel the effects almost instantly. When you use an infrared heating element, you notice that objects in the room retain heat and gradually release it, maintaining a comfortable environment even after the heater switches off.

Consistent Heat Output Features

Stable Temperature Regulation

You rely on stable temperature regulation for both comfort and process control. Infrared heating elements excel in this area due to their advanced materials and design. For example, ceramic and quartz elements maintain consistent heat output even under continuous operation. Aluminum and stainless steel components maximize radiant heat transmission and reduce energy waste. These materials ensure that your infrared heating element delivers steady warmth without frequent fluctuations.

| Matériau | Properties | Benefits for Heat Output |

|---|---|---|

| Aluminium | High reflectivity, lightweight, corrosion-resistant | Maximizes radiant heat transmission |

| Acier inoxydable | Durable, resistant to high temperatures | Reduces heat loss and energy waste |

| Céramique | Good heat resistance, stable at high temps | Maintains consistent heat output |

| Quartz | Excellent thermal properties, lightweight | Efficient heat emission, quick response |

| Gold/Ruby Coatings | Enhanced reflectivity, precision heating | Concentrates heat output for specific needs |

You also benefit from the unique ability of infrared heating panels to store heat in surfaces. When these panels emit heat onto objects, those objects retain warmth and radiate it back into the room. This lingering heat effect enhances comfort and reduces the need for continuous operation, saving energy over time.

Fast Response to Power Changes

You need a heating solution that responds quickly to changes in power. Infrared heating elements provide rapid heat-up times and immediate adjustments to temperature settings. Carbon fiber elements offer quick heating and energy efficiency. Halogen and quartz tube designs deliver consistent and focused heat output, allowing you to control the environment with precision. This fast response ensures that you always have the right amount of heat exactly when you need it.

- Carbon Fiber: Quick heating, energy efficient.

- Halogen: Rapid heat-up, high intensity.

- Quartz Tube: Consistent, focused heat output.

With these features, your infrared heating element adapts to your requirements, whether you need instant warmth or precise temperature control for sensitive applications.

Reliability of Infrared Heating Element

Rapid Heating Capabilities

Instant Warmth Generation

You expect your heating system to deliver warmth quickly, especially in demanding environments. An infrared heating element excels in this area by reaching its operating temperature in just a few minutes. Unlike traditional convection radiators, which may require up to half an hour to become fully effective, infrared panels typically heat up within 3 to 5 minutes. This rapid response ensures you experience immediate comfort and efficient process control.

| Technologie de chauffage | Average Time to Reach Operating Temperature |

|---|---|

| Infrared Panels | 3 to 5 minutes |

| Traditional Convection Radiators | Up to 20-30 minutes |

You gain a clear advantage with this fast heat-up time, making infrared heating elements ideal for both residential and industrial applications where time and efficiency matter.

Minimal Heat Loss During Operation

You want your heating solution to maximize energy use and minimize waste. Infrared heating elements achieve near 100% efficiency by delivering radiant heat directly to objects and surfaces, not just the air. This direct transfer reduces energy loss and ensures that almost all the energy consumed translates into usable warmth.

| Heating Type | Efficacité | Heat Loss Characteristics |

|---|---|---|

| Chauffages infrarouges | Near 100% | Minimal heat loss, heats objects directly |

| Conventional Heaters | Less efficient | Significant energy loss through ducts and insulation |

Note: By choosing an infrared heating element, you reduce unnecessary energy consumption and benefit from a more sustainable heating method.

Even Heat Distribution

Uniform Surface Coverage

You need consistent warmth across every part of your space. Infrared heating elements provide uniform heat distribution by emitting targeted radiation that penetrates surfaces directly. This method avoids the uneven heating often seen with other technologies.

| Characteristic | Description |

|---|---|

| Targeted Radiation | Infrared wavelengths penetrate surfaces directly, heating them uniformly without relying on air. |

| No ‘Hot Spots’ | Quartz tubes distribute heat evenly, preventing uneven heating that can occur with other elements. |

- Professional-grade infrared heaters use engineered reflectors to enhance heat distribution.

- Radiant heat spreads naturally, ensuring gradual temperature transitions.

Infrared heaters warm objects directly, not just the air, which reduces energy loss and maximizes efficiency. This focused approach ensures even warmth across all surfaces.

Elimination of Cold Spots

You often encounter cold spots with conventional heating systems. Infrared heating elements solve this problem by emitting radiant heat that warms objects and surfaces directly. You can position these heaters strategically to target specific cold areas, providing direct and concentrated warmth. This method minimizes energy loss and ensures effective heating, even in the coldest spots.

- Infrared heaters emit radiant heat that warms objects and surfaces directly.

- You can position them to target specific cold areas for direct, concentrated heat.

- This approach minimizes energy loss and ensures effective warming of even the coldest spots, enhancing overall temperature uniformity.

Durable Design and Materials

Longevity of Infrared Heating Element

You want a heating solution that stands the test of time. A well-manufactured infrared heating element can last from 15 to 20 years under normal operating conditions. Heavy-duty commercial models may exceed 25 years. Infrared panels typically last around 20 years, with some models reaching up to 30 years depending on quality. High-quality ceramic heating elements can operate for several thousand hours, with some exceeding 10,000 hours.

- Infrared panels are expected to last around 20 years.

- Lifespan can vary from 10 to 30 years based on quality.

- Heavy-duty commercial models may exceed 25 years.

- High-quality ceramic elements may exceed 10,000 hours of operation.

Resistance to Environmental Stress

You need a heating element that performs reliably in challenging environments. Manufacturers use advanced materials to ensure durability and resistance to environmental stress. Historically, ceramic materials provided high-temperature resistance. Modern designs now favor quartz for its superior durability and efficiency. Quartz resists high temperatures and enhances the overall performance of the infrared heating element.

| Composant | Material Description |

|---|---|

| Insulator | High thermal shock resistance ceramic material |

| Resistance wire | High quality Ni80Cr20 |

| Glaze Layer | Good radiation metal oxide materials with additives |

- Quartz is resistant to high temperatures.

- It offers superior properties compared to ceramic.

- It enhances the overall efficiency of infrared heating.

Tip: By selecting an infrared heating element constructed with these advanced materials, you ensure long-term reliability and consistent performance, even in demanding settings.

Infrared Heating Element vs. Other Heating Methods

Comparison with Electric Heaters

Reliability in Maintaining Temperature

You notice a clear difference in how infrared heaters and electric heaters maintain temperature. Infrared heaters provide instant warmth by directly heating objects and people. This method leads to less energy waste and faster comfort. Electric heaters warm the air, which can result in uneven temperature distribution and slower heating times. You experience more consistent and reliable heat with infrared technology because it does not rely on air movement. Infrared heaters convert nearly all electricity into heat, so you reach your desired temperature quickly and maintain it with minimal fluctuation.

Differences in Energy Consumption

You want a heating solution that keeps energy costs low. Infrared heating systems deliver targeted radiant heat, allowing you to feel warmer at lower wattages. Electric heaters use convection to warm the air, which requires more energy and can be less efficient in larger or drafty spaces.

| Méthode de chauffage | Consommation d'énergie |

|---|---|

| Infrared Heating | Lower wattage, more efficient due to direct radiant heating |

| radiateurs électriques | Higher wattage, relies on convection, less efficient |

- Infrared systems generally consume less energy overall.

- Electric heaters require higher electricity inputs to heat the air sufficiently.

- Infrared heating works best in well-insulated spaces.

Comparison with Gas Heating

Safety and Consistency Factors

You prioritize safety in your heating choices. Infrared heaters feature no open flames, enclosed burner heads, and low surface temperatures. These design elements make them suitable for family-friendly and public spaces. Gas heating systems can pose risks such as combustion hazards and gas leaks. Infrared heaters also offer immediate warmth and low emissions, making them compatible with solar panels. Gas systems may produce higher emissions and require careful monitoring for safety.

- Infrared heaters are energy efficient and provide immediate warmth.

- They have low emissions and work well with renewable energy sources.

- Gas heating systems may involve higher emissions and safety concerns.

Maintenance and Upkeep

You benefit from straightforward maintenance with infrared heating. Gas heating systems require regular attention to keep them running safely and efficiently.

- Oil the fan to prevent damage.

- Inspect pipes for leaks to maintain efficiency.

- Check gaskets to prevent leakage.

- Analyze valves to ensure correct positioning.

- Clean exhaust systems to avoid debris build-up.

- Perform periodic cleaning of components to remove dust and soot.

- Clean heat exchangers and burners annually.

- Inspect and replace filters as needed.

- Lubricate supply fan motor and blower bearings.

- Inspect and clean the burner to ensure efficiency.

Infrared heating elements need less frequent maintenance, which saves you time and reduces long-term costs.

Comparison with Radiant Floor Heating

Installation and Performance

You consider installation and performance when choosing a heating system. Infrared panels mount on walls or ceilings, offering a simple setup. Infrared heating film installs beneath floors or ceilings, which is more complex. Infrared panels reach higher surface temperatures (80°C to 120°C), providing quick heating. Heating film operates at lower temperatures (35°C to 55°C), delivering gentle warmth. Infrared panels suit smaller spaces needing targeted heat, while heating film works best for whole-room heating in new builds.

- Infrared panels: Wall or ceiling mounting, quick heating, targeted warmth.

- Heating film: Underfloor installation, gentle warmth, ideal for new construction.

Suitability for Different Environments

You match your heating system to your environment for best results.

| Heating System | Best Suited Environments |

|---|---|

| Infrared Heating | Large, high-ceiling environments, commercial spaces, outdoor areas |

| Radiant Floor Heating | Residential interiors where comfort underfoot is prioritized |

You select infrared heating for large or commercial spaces and radiant floor heating for residential comfort.

Benefits of Infrared Heating Element

Energy Efficiency Advantages

Lower Operating Expenses

You can significantly reduce your heating costs by choosing an infrared heating element. This technology delivers heat directly to objects and people, which means less energy waste and lower utility bills. Studies show that infrared heaters can achieve fuel cost savings of up to 50% compared to traditional heating methods. You can set your thermostat lower and still feel comfortable, which further reduces expenses. Two-stage infrared systems can decrease energy costs by an additional 12%.

- An evaluation of infrared two-stage heating systems versus forced air systems shows a 24% improvement in efficiency.

- Reports indicate annual fuel savings as high as 50%.

- Analyses in industry journals report savings between 33% and 50% compared to unit heaters.

You can see the difference in operating costs in the table below:

| Technologie de chauffage | Operating Cost (per hour) | Efficiency (%) | Notes supplémentaires |

|---|---|---|---|

| Infrared Heating | 5p | 90% | Directly warms objects, leading to lower energy costs |

| Traditional Electric | 10p – 35p | Varies | Less efficient due to convection heating |

| Chauffage au gaz | Higher overall costs | Varies | Fluctuating prices and maintenance required |

Reduced Environmental Footprint

You help protect the environment when you use infrared heating. These systems run on electricity, which increasingly comes from renewable sources. In places like the UK, a large share of electricity now comes from wind and solar power, which lowers the carbon footprint of heating. Infrared heating elements use less energy because they heat objects directly, not the air. This results in fewer carbon emissions. Traditional gas systems rely on fossil fuels, which have a much higher environmental impact. Infrared heating also minimizes air movement, which reduces dust and allergens and helps maintain better indoor air quality.

Aspects de sécurité

No Open Flame Risks

You avoid the dangers of open flames when you choose infrared heating. These systems provide direct, focused heat without producing harmful byproducts. You can safely use them in environments with flammable materials. Infrared heating elements operate without open flames, which significantly reduces the risk of ignition. Traditional heaters can create ignition sources and dangerous situations. Infrared heaters do not produce fumes, smoke, or odors, making your space safer and more comfortable.

| Certification | Description |

|---|---|

| CSA Group Standards | For Canada |

| FM Approval | For fire safety |

| UL Certifications | For electrical and heating products |

| UL1030 | Sheathed Heating Elements |

| UL499 | Electric Heating Appliances |

| UL508A | Control Panel Certification |

| ISO 9001:2015 | Quality management certification |

Safe-to-Touch Surfaces

You benefit from safer surfaces with infrared heating. Many models feature low surface temperatures, which reduces the risk of burns. The design eliminates moving parts and open elements, making these heaters suitable for homes, offices, and public spaces.

Tip: Always check for safety certifications like UL or FM Approval to ensure your heater meets the highest safety standards.

Maintenance Simplicity

Easy Cleaning and Care

You save time on maintenance with infrared heating. Regularly inspect and clean the vents to prevent obstructions. Check wiring connections for security and damage. Maintain proper mounting by tightening screws and replacing damaged ones. Follow the manufacturer’s guidelines for best results. Conduct a full inspection before the heating season to address any issues early.

Fewer Replacement Needs

You experience fewer breakdowns and replacement needs with an infrared heating element. The design has no moving parts and uses durable materials, which means less wear and tear. You spend less on repairs and replacements over the life of the system.

Addressing Common Concerns About Infrared Heating Element

Reliability Over Time

Expected Lifespan of Infrared Heating Element

You want your heating investment to last. The expected lifespan of an infrared heating element depends on several factors. High-quality materials and careful design play a major role in durability. When you follow the manufacturer’s maintenance guidelines, you can extend the life of your heater. Usage patterns also matter. Taking recommended breaks and using the correct power supply help prevent unnecessary wear. The table below highlights the main factors that influence long-term reliability:

| Facteur | Description |

|---|---|

| Quality of Materials | High-quality materials ensure durability and prevent malfunctioning of heating elements. |

| Heating Element Design | The design and construction of the heating element affect its reliability and heat output consistency. |

| User Maintenance | Proper care and adherence to guidelines can significantly extend the lifespan of the heating pad. |

| Usage Patterns | Recommended usage breaks help prevent wear and tear on heating elements. |

| Power Supply and Voltage | Correct voltage and power supply compatibility are crucial to avoid damage to internal components. |

Note: You can maximize the lifespan of your heater by following the manufacturer’s recommendations and using the correct voltage.

Performance in Harsh Conditions

You may need your heater to perform in challenging environments. Many modern heaters use rugged stainless steel construction and sealed combustion designs. These features provide reliability in harsh conditions. You can expect your heater to withstand wind, rain, and cold temperatures. Infrared heat technology warms solid surfaces, so it remains effective even in windy areas. Moisture resistance and weatherproofing protect the heater in wet conditions. Optimized ignition systems ensure reliable operation in sub-zero temperatures.

- All-weather performance, including wind, rain, and cold

- Rugged stainless steel and sealed combustion for durability

- Effective heating in windy environments

- Moisture-resistant and weatherproof design

- Reliable ignition in sub-zero climates

Troubleshooting and User Questions

Resolving Common Issues

You might encounter occasional issues with your heater. Most problems have simple solutions. If you notice no heat production, check the power supply, plug, and circuit breaker. For inconsistent heating, adjust the thermostat, clean the heater, and ensure nothing blocks the airflow. Unusual noises often result from loose parts or debris. Inspect and clean the vents, and lubricate moving parts if needed.

- No heat: Check power, plug, cord, outlet, circuit breaker, remote batteries, manual switch, and thermostat.

- Inconsistent heating: Adjust placement, thermostat, and clean regularly.

- Unusual noises: Inspect for loose parts, clean vents, and lubricate mechanisms.

Ensuring Consistent Heat Output

You want steady warmth from your heater. Place your infrared heating element in an open area, away from obstructions. Clean the unit regularly to prevent dust buildup. Set the thermostat to your desired temperature and check it periodically. Follow the manufacturer’s care instructions to maintain optimal performance.

Tip: Regular cleaning and proper placement help ensure your heater delivers consistent, reliable heat.

Real-World Applications of Infrared Heating Element

Utilisations industrielles

Manufacturing and Processing

You rely on precise, efficient heating in manufacturing. An infrared heating element delivers high radiant efficiency, making it ideal for curing composites, forming automotive parts, and thermoforming food packaging. You can achieve consistent results with minimal power degradation, even after thousands of operational hours. The table below highlights key industrial applications and their performance metrics:

| Application | Performance Metrics |

|---|---|

| Curing composites | Radiant efficiency >95% |

| Forming and bonding automotive components | Power degradation ≤5% after 10,000 operational hours |

| Testing heat shields on spacecraft | Surface temperature uniformity (±5% tolerance) |

| Drying concrete | |

| Thermoforming food packaging |

You see these elements in action across large manufacturing facilities, vehicle plants, and process heating environments. Their ability to provide direct, uniform heat ensures high-quality output and energy savings.

Quality Control Environments

You need stable temperatures for quality control. Infrared heating elements maintain tight tolerances, which is essential for testing heat shields or drying coatings. You benefit from surface temperature uniformity, which supports reliable product testing and consistent results.

Residential and Commercial Applications

Home Heating Solutions

You want comfort and efficiency at home. Infrared heating elements provide direct warmth in living rooms, garages, and workshops. You can use them for both small and large spaces, including central heating systems. Their ability to heat objects and people directly means you feel warmer faster, even in drafty environments.

- Living rooms and bedrooms

- Garages and workshops

- Central heating for homes

Office and Retail Spaces

You create comfortable environments in offices, retail stores, and public venues. Infrared heating works well in gyms, health centers, and indoor sports courts. You also see these systems in restaurants, cafes, and outdoor terraces, where they deliver targeted warmth without heating unused air.

- Office buildings and retail spaces

- Restaurants and large cafes

- Outdoor event spaces and terraces

Note: Infrared heaters function effectively in both enclosed and open environments, making them highly versatile for commercial use.

Specialized Uses

Medical and Laboratory Equipment

You depend on precise temperature control in medical and laboratory settings. Infrared heating elements support targeted heat therapy, arthritis pain relief, and laboratory processes that require exact temperatures. Hospitals and research facilities use these systems for their reliability and safety.

Food Service and Hospitality

You improve food quality and safety in kitchens and hospitality venues. Infrared heating elements help extend bread shelf life, enhance the appearance of instant meals, and prevent overheating during chocolate processing. You also find them in food packaging and drying applications, where they deliver rapid, uniform heating.

| Domaine d'application | Description |

|---|---|

| Bread shelf life extension | Reduces mold, extends shelf life by 3-4 days |

| Chocolate processing | Ensures exact temperatures, prevents overheating |

| Instant meals | Enhances breadcrumb coatings without overcooking |

| Industrial drying | Precision drying, curing, and coating in various applications |

| Medical and laboratory equipment | Targeted heat therapy, precise temperature control |

You benefit from energy savings, fast response times, and improved product quality in these specialized industries.

You gain a dependable heating solution when you choose an infrared heating element. This technology stands out for delivering steady, reliable heat in many environments. Advanced engineering ensures energy efficiency and long-lasting performance. You invest in a system that offers both immediate comfort and long-term value.

Tip: Consider this option for applications where consistent heat and durability matter most.

FAQ

How quickly does an infrared heating element warm up?

You experience almost instant heat. Most infrared heating elements reach full temperature within 3 to 5 minutes. This rapid response ensures you feel warmth right away, making them ideal for spaces where immediate comfort matters.

Are infrared heating elements safe to use around children and pets?

You can safely use infrared heating elements in homes with children and pets. Most models feature cool-to-touch surfaces and no exposed flames. Always follow manufacturer guidelines for placement and operation.

What maintenance do infrared heating elements require?

You need minimal maintenance. Regularly dust the surface and check for any visible damage. Inspect wiring connections once a year. Always unplug the unit before cleaning. Refer to your user manual for specific care instructions.

Can you install infrared heating elements yourself?

You can install many infrared panels yourself using basic tools. Wall or ceiling mounting usually requires a drill and screwdriver. For complex systems or hardwiring, consult a licensed electrician to ensure safety and compliance.

How energy efficient are infrared heating elements compared to other heaters?

You benefit from high energy efficiency. Infrared heating elements convert nearly all electricity into usable heat. You often use less energy than with traditional convection heaters, which lose heat through air movement.

Tip: Lower energy use means reduced utility bills and a smaller environmental footprint.

Do infrared heating elements work well in large or open spaces?

You achieve effective heating in large or open areas. Infrared heaters warm objects and people directly, not just the air. For best results, position multiple units to cover the entire space and avoid cold spots.

What environments are best suited for infrared heating elements?

You find infrared heating elements ideal for homes, offices, warehouses, and outdoor patios. They perform well in both enclosed and open environments. Always choose a model rated for your specific application.