Silicon Carbide Heating Element——Semiconductor high-temperature heating solution

A high-performance heating element designed for industrial heat treatment furnaces, semiconductor annealing equipment, new energy charging piles and medical sterilization systems. It adopts silicon carbide (SiC) single crystal substrate + diamond coating, suitable for 5kW-1MW power range, temperature resistance up to 1600℃ (short time), thermal conductivity ≥450W/m·K.

MOQ:1000PCS

Vorlaufzeit: 15-25 Tage

Standort der Fabrik: Zhongshan, Guangdong, China

Life appliances: high-end embedded coffee machines, molecular cooking tools, medical-grade sterilization equipment, air fryer ovens.

Industrial equipment: semiconductor sintering furnaces, photovoltaic glass coating heating systems, automobile exhaust catalytic heaters, aerospace thermal management modules.

Power Range:

Residential/Commercial: 500W–15kW (appliances, HVAC systems, water heaters).

Industrial: 15kW–100kW+ (furnaces, metalworking, chemical reactors).

Voltage Compatibility:

110V/220V single-phase AC or 380V–480V three-phase AC (global grid compatibility, error ≤±5%).

Material Properties:

Composition: High-purity silicon carbide (99.9%+ grade)

Thermal conductivity: 120–150 W/m·K (better than stainless steel).

Melting point: ~2700°C (preferable for extreme cold).

Resistance Range: 1Ω–100Ω (adjustable per application).

Operating Temperature:

Continuous: 800°C–1600°C (short-term peak: 2000°C for specialized models).

Abmessungen:

Rod/Tube Length: 100mm–5000mm (customizable bundling).

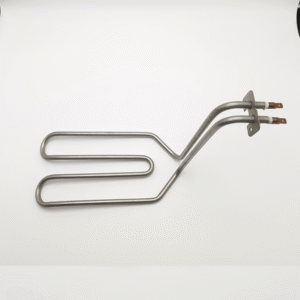

Diameter: Φ5mm–Φ200mm (spiral, U-shaped, or straight configurations).

Lebenserwartung:

50,000–200,000 hours (depends on temperature, duty cycle, and coating).

Resistance to Extreme Temperatures

Survives temperatures over 2000° C Nichrome’s ~1200°C is perfect for furnaces, aerospace, and metallurgy.

High Thermal Efficiency:

SiC’s low thermal mass enables quick heat transfer (30 seconds to reach 1000°C) with little energy loss.

Durability in Difficult Surroundings

Resists chemical exposure, acidic/alkaline environments, corrosion, and oxidation.

Low thermal expansion (3×10⁻⁶/°C) guarantees dimensional stability.

Energy Savings:

Direct heating with 10–30% higher efficiency than PTC/nichrome elements.

Smart Compatibility:

Works with PID controllers and IoT systems (supports variable frequency drives).

Safety Features:

Automatic overheat shutdown (≥1600°C) with CE/UL/ATEX certifications.

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.