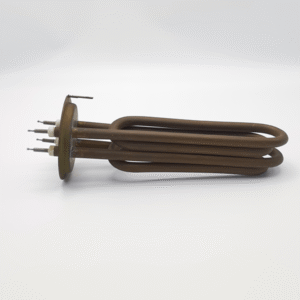

Aluminum Kettle Heating Plate – Lightweight and fast heating solution

The high-efficiency aluminum heating element designed for home, commercial and outdoor scenes is suitable for 800W-2500W power range, thermal conductivity ≥237W/m·K, temperature resistance up to 300℃ (short time), thermal response time ≤12 seconds; integrated PID dynamic temperature control algorithm (±0.5℃ accuracy), supports anti-dry burning protection (>10 seconds automatic power off) and pulse steam self-cleaning technology (scale removal rate >90%), passed CE/LFGB/RoHS certification, 40% lighter than traditional stainless steel heating plates, and life span >120,000 cycles. It is suitable for home fast heating, commercial multi-kettle parallel connection and outdoor emergency scenes, and supports stable operation in extreme environments (-20℃~450℃).

MOQ:1000PCS

Vorlaufzeit:25 Tage

Standort der Fabrik: Zhongshan, Guangdong, China

Home appliances: household electric kettles, instant hot water dispensers, health kettles, portable travel kettles.

Industrial equipment: commercial water boilers, hotel/hospital constant temperature kettles, laboratory high temperature cleaning equipment.

Leistungsbereich:

Conventional models: 800W–2200W (suitable for ordinary electric kettles and health kettles).

High-power models: 2200W–3000W (commercial-grade fast-boiling kettles).

Anpassbar: Unterstützt die bedarfsgerechte Leistungsanpassung (Spannungs- und Lastanforderungen müssen angegeben werden).

Betriebsspannung:

Standardspannung: 110 V/220 V einphasiger Wechselstrom (kompatibel mit dem weltweiten Stromnetz, Fehler ≤±5%).

Widerstandswert:

Conventional models: 5Ω–15Ω (matched by power and voltage, error ≤±3%).

Arbeitstemperatur:

Dauerhafte Stabilität: 200°C–300°C (Oberflächentemperatur, hochtemperaturbeständiger Beschichtungsschutz).

Kurzzeitige Spitze: 350 °C (Keramikfaser-Isolierschicht muss angepasst werden).

Material:

Aviation-grade aluminum alloy 6063-T5, thermal conductivity ≥ 200W/m·K, lightweight design, is the base material.

Surface treatment options include Teflon (PTFE, anti-adhesion) or anodized layer (thickness 15μm, corrosion-resistant).

Abmessungen:

Durchmesser/Seitenlänge: Φ80mm–Φ200mm (runde/quadratische Ausführung).

Thickness: 3mm–8mm (adapted to embedded pot bottom design).

Lebensdauer:

Herkömmliches Modell: 10.000–15.000 Stunden (basierend auf der täglichen Nutzungshäufigkeit).

Hochleistungsmodell: 15.000–20.000 Stunden (verbesserte Wärmeableitung und Beschichtungsschutz).

Hocheffiziente Wärmeleitfähigkeit:

With a thermal conductivity of up to 200W/m·K, the aluminum alloy base material heats up to 100°C in 3 minutes and uses 15% less energy than conventional iron-chromium-aluminum heaters.

Präzise Temperaturregelung:

Supports PID algorithm temperature control (±1°C accuracy), suitable for the constant temperature mode of smart health kettle (such as making tea, mixing milk powder).

Sicher und langlebig:

The anodized layer is resistant to salt spray corrosion (test ≥500 hours), with a lifespan extended by 30%, suitable for humid kitchen environments.

Schnelle Antwort:

No thermal inertia design, cools to a safe temperature within 30 seconds after power failure, and is suitable for high-frequency start-stop scenarios (such as continuous boiling water).

Easy to clean design:

Teflon coating resists scale/tea stain adhesion, reduces cleaning frequency by 60%, and complies with FDA food contact certification.

Leichtbauanpassung:

The substrate density is 2.7g/cm³, which is 40% lighter than stainless steel, and is suitable for embedded small appliance design.

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.