You can identify issues with your oven element without special training. If you notice your oven not heating as it should, you may have a faulty heating element. Use a visual inspection and a multimeter to check for problems. This process helps you decide if you need oven repair or a simple replacement. Pay close attention to the oven element’s condition to keep your appliance working safely.

Understanding the Oven Element and Why Ovens Stop Heating

Was ist ein Ofenelement?

You rely on the oven element as the main source of heat in your electric oven. Manufacturers design different elements for specific cooking tasks. The table below outlines the main types and their functions:

| Backofenelement | Location in Oven | Main Function Description |

|---|---|---|

| Bake element | Bottom of oven cavity | Provides heat primarily for baking and roasting. |

| Broil element | Top of oven cavity | Supplies direct, intense heat used for broiling. |

| Convection element | Near convection fan | Works with the fan to circulate hot air evenly, enhancing convection cooking by providing additional heat. |

Each oven element uses a resistive coil, often made from nickel-chrome alloys, to generate heat. You can find the bake element at the bottom, the broil element at the top, and the convection element near the fan if your oven supports convection cooking.

How the Oven Element Heats Your Oven

The oven element heats your oven by converting electrical energy into heat. Here is how the process works:

- Electrical current flows through the resistive coil inside the element.

- The resistance in the coil causes it to heat up quickly.

- The element emits radiant heat, which warms the air and surfaces inside the oven.

- In convection ovens, a fan circulates the hot air, ensuring even cooking.

- The oven’s thermostat monitors the temperature and cycles the element on and off to maintain the set heat level.

Tip: The combination of radiant and convective heat ensures your food cooks evenly and efficiently.

You benefit from this design because it provides reliable, consistent heat for baking, roasting, and broiling. The oven element’s placement and function help prevent overcooking or undercooking.

Common Reasons for Oven Not Heating

You may encounter an oven not heating for several reasons. Appliance repair professionals often identify these common causes:

- Faulty heating elements are the most frequent reason for electric ovens not heating.

- Damaged temperature sensors can prevent the oven from reaching or maintaining the correct temperature.

- Power supply issues, such as tripped breakers or faulty wiring, can interrupt the oven’s operation.

- Miscalibrated thermostats may cause inaccurate temperature readings.

- In gas ovens, faulty igniters or gas line problems can stop the oven from heating.

If you notice your oven not heating, start by checking the oven element and temperature sensor. For complex electrical or gas issues, you should contact a professional to ensure safe and proper repairs.

Signs of a Faulty Heating Element

Visual Signs Your Oven Element Is Failing

Cracks, Blisters, and Burn Marks

You can often spot a faulty heating element by looking for visible damage. Examine the oven element closely. Cracks, blisters, or burn marks on the surface signal that the part has worn out or failed. These marks show that the element has overheated or suffered electrical damage. If you see any of these signs, you should stop using the oven until you address the problem.

Tipp: Always check the element when the oven is cool to avoid burns.

Element Not Glowing Red or Orange

A healthy oven element glows bright orange or red within ten minutes of turning on the oven. If the element stays dark or only heats in certain spots, you likely have a faulty element. This lack of color means the element cannot conduct electricity properly. You may also notice that the oven takes longer to preheat or does not reach the set temperature.

| Sign | Was es bedeutet |

|---|---|

| No glow or partial glow | Internal break or electrical fault in the element |

| Uneven color along element | Inconsistent heating, possible internal damage |

Performance Issues When Cooking

Uneven or Incomplete Cooking

You might notice uneven cooking if your oven has a malfunctioning heating element. Food may come out undercooked in some areas and overdone in others. Hot and cold spots inside the oven often result from a faulty heating element. You may also find that cooking times increase gradually, which means the oven is not heating as it should.

- Food cooks unevenly with hot and cold spots.

- Baking results become inconsistent.

- Dishes take longer than usual to finish.

Unusual Noises or Smells

A faulty heating element can cause strange noises or smells during operation. Listen for popping or buzzing sounds when the oven is on. These noises may indicate electrical arcing or a break inside the element. Burning odors or smoke can signal a malfunctioning heating element or wiring problem. If you detect these signs, turn off the oven and inspect the element before using it again.

Higher Energy Bills and Other Clues

You may see your energy bills rise if the oven struggles to maintain temperature. A faulty heating element forces the appliance to work harder, using more electricity. Some digital ovens display error codes, such as F1 or F2, which point to heating element faults. Repeated tripping of circuit breakers can also suggest electrical issues related to the oven element. Excessive dirt or buildup inside the oven can damage the element and reduce performance.

Anmerkung: If you notice any of these signs, you should test the oven element to confirm the problem.

Safety Precautions Before Oven Repair

Before you begin any oven repair or testing, you must take safety seriously. Working with electrical appliances like ovens exposes you to risks such as electric shock, burns, and even fire. Many home repair attempts result in injuries or long-term health effects. Over 14% of DIY appliance repairers experience lasting health issues, and 19% require medical attention due to accidents. You can avoid these risks by following strict safety procedures.

Turning Off Power to the Oven

You must always disconnect the oven from its power source before starting any inspection or repair. This step protects you from electrical shock and prevents accidental activation of the oven while you work. Follow these steps to ensure your safety:

- Turn off the power at the circuit breaker that supplies electricity to your oven. If your oven plugs into an outlet, unplug it completely.

- For hardwired ovens, switch off the dedicated circuit breaker in your electrical panel.

- Use a multimeter to verify that no power remains at the oven terminals. This step confirms that the appliance is safe to touch.

- Wear insulated gloves and rubber-soled shoes to reduce the risk of shock.

- Never touch electrical components with wet hands or while standing on a wet surface.

Tipp: For gas ovens, also shut off the gas supply by closing the gas shut-off valve before you begin any work.

Wenn Sie bemerken flickering lights, buzzing sounds, or frequent breaker trips, stop immediately and call a professional. These warning signs indicate deeper electrical problems that require expert attention.

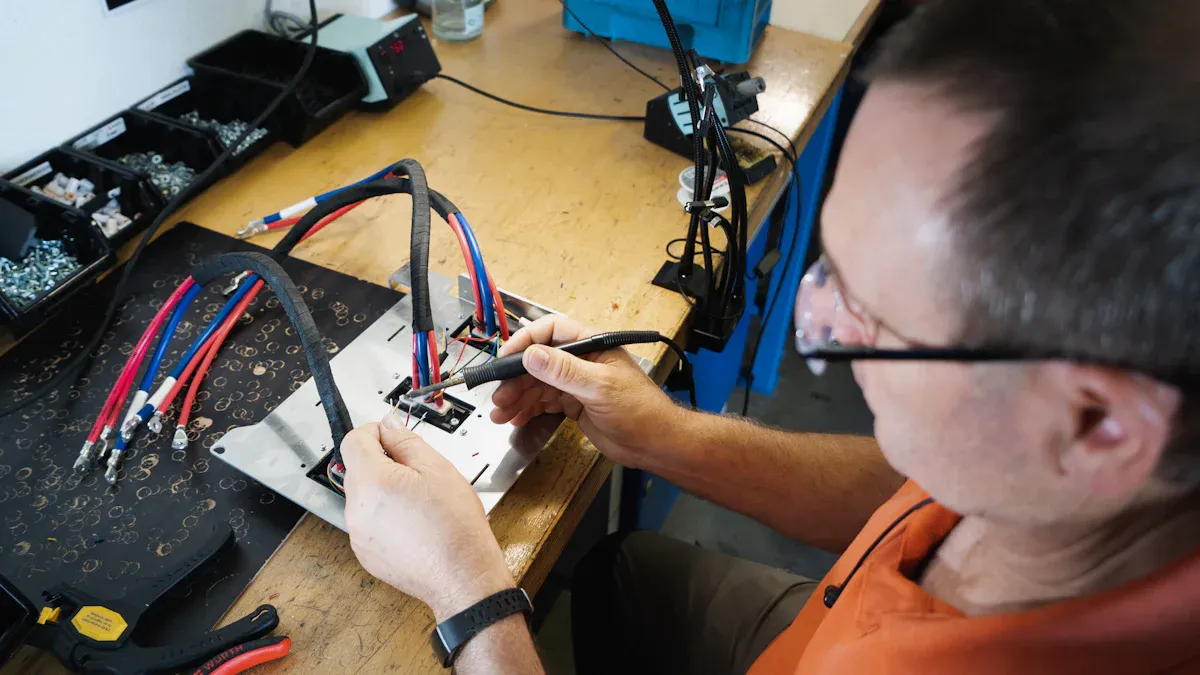

Gathering Tools for Testing

You need the right tools to safely test your oven element. Using proper equipment not only makes the job easier but also reduces the risk of injury or damage.

Multimeter and How to Use It

A multimeter is the essential tool for testing oven elements. You use it to measure resistance (ohms) and check for continuity in the element. Knowing how to use a multimeter helps you determine if the element is working or needs replacement. Here’s what you should do:

- Set your multimeter to the resistance (Ω) or continuity setting.

- Touch the probes to the terminals of the oven element.

- If the multimeter shows a reading within the expected range, the element has continuity and is likely functional.

- If the multimeter displays no reading or infinite resistance, the element is faulty.

You should always check the power supply before using the multimeter. Make sure the oven is completely disconnected. If you are unsure how to use a multimeter, consult the device manual or seek guidance from a professional. Practice using the multimeter on a known working circuit to build confidence.

Weitere hilfreiche Hilfsmittel

Besides the multimeter, you need a few more tools and safety items for a successful repair:

| Werkzeug | Purpose/Use |

|---|---|

| Multimeter | Measure resistance to test element continuity |

| Schraubendreher | Remove mounting screws or covers |

| Safety gloves | Protect hands from sharp edges and shocks |

- Wear dry, heat-resistant gloves and safety glasses to protect yourself from burns and debris.

- Allow the oven and element to cool completely before handling.

- Remove any combustibles from the area to reduce fire risk.

- Inspect cords and check the wires for damage before starting work.

- Use GFCI-protected outlets near water sources and test them regularly.

Anmerkung: Taking photos or notes of wiring before disassembly helps you reassemble the oven correctly.

By following these safety precautions and using the right tools, you can test your oven element with confidence. If you ever feel unsure or encounter warning signs, contact a certified technician. Professional repair ensures your safety and protects your appliance warranty.

How to Check the Bake Element Visually

Accessing the Oven Element Safely

You must follow a careful process to access the oven element without risking injury or damaging your appliance. Manufacturers recommend a series of steps to ensure your safety and the effectiveness of your inspection. Here is a clear, step-by-step guide:

- Disconnect the oven from its power source by unplugging it or switching off the circuit breaker. This step prevents electrical hazards.

- Confirm that the oven is completely powered off. Test the controls and displays to ensure no live current remains.

- Allow the oven and the heating element to cool down fully. You avoid burns by waiting until all parts reach room temperature.

- Open the oven door and remove all oven racks. This action gives you clear and unobstructed access to the bake element.

- Remove any covers, panels, or shields that protect the element. Use a screwdriver to unscrew fasteners as recommended by the manufacturer.

- Wear personal protective equipment. Dry, heat-resistant gloves and safety glasses protect you from burns and debris.

- Clear the oven area of any combustibles. Inspect the wiring for visible damage before you proceed.

- Never inspect or touch the element while it is hot. Always ensure a safe environment by following these precautions.

Tipp: Always keep your workspace organized and free from clutter. This habit reduces the risk of accidents during your inspection.

What to Look for During Inspection

Once you have safe access, you can check the bake element for signs of damage or malfunction. A thorough visual inspection helps you identify problems early and decide if you need to replace the element.

Signs of Physical Damage

You should look closely at the bake element for any physical defects. Experts recommend checking for the following indicators:

- Cracks or breaks along the length of the element.

- Blistering or bubbling on the surface, which often results from overheating.

- Burn marks or scorch marks that suggest electrical faults.

- Any visible separation or deformation of the element.

If you notice any of these signs, the element has likely failed and needs replacement. Physical damage often leads to uneven heating or complete loss of function. You protect your oven and ensure safe operation when you address these issues promptly.

Burn Marks or Discoloration

Burn marks and discoloration provide strong clues about the health of your bake element. When you check the bake element, pay attention to these details:

- The element should glow bright orange within ten minutes of heating. If it fails to glow or only glows in certain spots, this indicates damage.

- Scorch marks, dark spots, or areas with unusual color changes signal overheating or electrical problems.

- Excessive dirt or buildup on the element can also impair performance. Clean the element gently if you see debris, but do not use abrasive tools.

Anmerkung: Uneven or absent glowing is a primary sign of a failing element. If you see these symptoms, you should replace the bake element before using the oven again.

A careful inspection allows you to catch problems early. You maintain your oven’s performance and safety when you regularly check the bake element for these visual indicators.

How to Test the Oven Element with a Multimeter

Testing your oven element with a multimeter gives you a clear answer about its condition. You can follow a systematic approach to ensure safety and accuracy. This process helps you confirm whether the heating element is the cause of your oven’s issues.

Removing the Oven Element

You must remove the oven element before testing it with a multimeter. Appliance repair manuals recommend the following steps for safe removal:

- Unplug the oven or switch off the circuit breaker. This step prevents electrical shock.

- Wait until the oven cools completely. You avoid burns by working with a cold appliance.

- Gather your tools: a Phillips or flathead screwdriver, needle-nose pliers, gloves, a flashlight, and a multimeter.

- Open the oven door and take out the racks to access the heating element.

- Use the screwdriver to remove the screws that secure the element.

- Gently pull the element forward to expose the wiring.

- Disconnect the wires attached to the element using pliers. Take a photo or make a note of the wire positions for reassembly.

- Insulate any exposed wires with electrical tape or shrink tubing after disconnecting.

- Always follow your oven manufacturer’s manual for model-specific instructions and safety warnings.

Tipp: Use insulated tools and wear rubber-soled shoes for extra protection. Always verify that the power is off with a voltmeter before touching any internal parts.

Setting Up and Using the Multimeter

You need to set up the multimeter correctly to get an accurate reading. This tool measures resistance and checks for continuity in the oven element.

- Place the oven element on a non-conductive surface, such as wood or concrete.

- Plug the black probe into the black socket and the red probe into the red socket on the multimeter.

- Set the multimeter to the lowest ohms (Ω) setting or to continuity mode (often marked with a sound wave symbol).

- Calibrate the multimeter by touching the two probes together. A reading below 1.0 confirms the device works properly.

- Touch the probes to the two terminals of the oven element. Make sure the probes and terminals do not touch each other.

Continuity Testing Explained

Continuity testing checks if electricity can flow through the oven element. When you use the multimeter in continuity mode, a working element will cause the device to beep or display a resistance value. If you hear no beep or see an infinite reading, the element has failed.

- A good oven element typically shows a resistance between 16 and 50 ohms, depending on its wattage and voltage.

- For example, a 1500-watt element at 240 volts should measure around 38.4 ohms.

- Infinite resistance means the element is broken and cannot conduct electricity.

- Near-zero resistance suggests a short circuit, which is rare but dangerous.

| Oven Element Specification | Spannung (V) | Power (W) | Calculated Resistance (Ohms) | Interpretation |

|---|---|---|---|---|

| Standard Bake Element | 240 | 2600 | ~22 | Functional element resistance |

| High Power Element | 240 | 3600 | ~16 | Functional element resistance |

| Low Power Element | 240 | 1500 | ~38.4 | Functional element resistance |

Anmerkung: Always measure resistance with the element disconnected from the oven and wiring.

Interpretieren von Multimeterergebnissen

You interpret the multimeter reading by comparing it to the expected resistance range:

- 0–50 ohms: The element is functional and has good continuity.

- Above 50 ohms or infinite: The element is faulty and needs replacement.

- No beep in continuity mode: The circuit is open, and the element cannot heat.

If you get a reading close to the calculated value for your element’s wattage and voltage, you can trust that the element works. If the reading is far outside this range, you should replace the element.

If you see a reading of ‘1’ or ‘OL’ (over limit) on the multimeter, the element is open and broken.

What to Do If the Element Fails the Test

If your oven element fails the continuity test, you must take action to restore your oven’s performance and safety.

- Replace the oven element if the multimeter shows infinite resistance or no continuity.

- Do not use the oven with a faulty element. Continued use can cause uneven cooking or damage other components.

- If you replace the element and the oven still does not heat, check the wiring and circuit boards for faults.

- If you feel unsure about testing or replacing the element, contact a professional appliance repair technician.

- Always prioritize safety. Improper repairs can lead to electrical hazards or void your appliance warranty.

Alarm: Never attempt to operate your oven with a failed heating element. Immediate replacement ensures safe and reliable cooking.

What Your Test Results Mean for Oven Repair

Good vs. Faulty Heating Element

You can interpret your test results by comparing them to clear standards. A good oven heating element will pass both visual and electrical checks. Follow these steps to distinguish between a functional and a faulty element:

- Inspect the element for cracks, breaks, or burn marks. Any physical damage means the element is faulty.

- Use a multimeter to check for continuity. A good element will show continuity, while a faulty one will not.

- Observe how the oven performs. A working element heats evenly and allows the oven to reach and maintain the set temperature. A faulty element causes uneven heating, hot spots, or prevents the oven from reaching the desired temperature.

- If you suspect complex electrical issues beyond the heating element, seek professional oven repair.

A clear test result helps you decide if you need to replace the element or look for other causes.

Troubleshooting If the Oven Is Still Not Heating

Sometimes, you replace the heating element, but the oven still does not heat. In this case, you need to take additional troubleshooting steps. Use this checklist to guide your next actions:

- Check the power supply voltage. Make sure the oven receives the correct voltage (240V for electric ovens).

- Test the thermal fuse with a multimeter. Replace it if it is blown.

- Inspect all wiring connected to the element or igniter for damage or burns. Repair or replace any damaged wires.

- Test the new heating element with a multimeter to confirm it is not defective.

- Check related components in the circuit path, such as the thermal fuse and high limit switch, for continuity.

- Inspect wiring for open or damaged connections that could interrupt the circuit.

- Verify the relay board operation, especially the bake element relay. Sparks during the original element failure can damage relay contacts or solder joints.

- Use a wiring diagram to confirm the circuit path. Make sure no relay contacts or switches prevent current flow.

- If the relay clicks but the element does not heat, suspect a faulty relay or damaged relay board. Consider replacing the relay board.

- If all above components test fine, consider the control board as a possible failure point.

Always turn off power before testing any components. This step protects you from electrical shock.

If you have a gas oven, check the igniter. A faulty igniter can prevent the oven from heating. You should check the igniter for visible damage, test it with a multimeter, and listen for the sound of the igniter clicking or glowing when you turn on the oven. If the igniter does not work, replace it to restore proper function.

When to Check the Bake Element or Other Parts

After you confirm the bake element works, you need to check other oven components if the oven still does not heat. Start with the oven control thermostat, temperature sensor, electronic control board, and fuses. This stepwise approach ensures you identify the true cause of the problem. If you have a gas oven, always check the igniter as part of your troubleshooting process. The igniter plays a key role in lighting the burner and allowing the oven to heat. If you find the igniter is not working, replace it before moving on to more complex oven repair steps.

Tip: Systematic troubleshooting saves time and prevents unnecessary part replacements. Always check the igniter and related components before replacing the control board.

Next Steps If You Find a Faulty Heating Element

How to Replace the Oven Element Yourself

You can replace a faulty oven element with basic tools and careful attention to detail. Most major appliance brands recommend a straightforward process. Begin by disconnecting the oven from its power source to ensure safety. Remove the old element by unscrewing it and gently pulling it away from the oven wall. Take note of the wire positions before disconnecting them. Attach the wires to the new element in the same configuration. Secure the new element with screws, then restore power and test the oven by setting it to a high temperature. Some smoke from the protective coating is normal during the first use. Once you confirm the element heats properly, replace any covers and return the oven racks.

Tipp: Always match the new element to your oven’s model number for compatibility and safety.

Here is a quick step-by-step summary:

- Disconnect power to the oven.

- Remove the old element and note wire positions.

- Attach wires to the new element.

- Secure the element with screws.

- Restore power and test the oven.

- Replace covers and racks after testing.

When to Call a Professional for Oven Repair

You should consider professional repair in several situations. If your oven is under warranty, using an authorized technician helps maintain coverage. Manufacturers often require professional service for warranty compliance. Electrical issues, such as tripped breakers or burning smells, pose safety hazards and need expert handling. Gas ovens present additional risks, including gas leaks and ignition failures, which require specialized knowledge and tools. Complex mechanical problems or repairs involving heavy appliances also call for professional attention.

| Repair Type | Cost Range (Including Parts & Labor) | Part Cost Range | Labor Cost Range (per hour) |

|---|---|---|---|

| Heating Element Replacement | $150 – $450 | $15 – $100 | $50 – $200 |

| General Oven Repair | $100 – $600 | Variiert | $50 – $200 |

Professional labor costs often range from $50 to $200 per hour. While replacing an oven element yourself can save on labor, hiring a professional ensures safety and proper diagnosis, especially for gas ovens or complex electrical issues.

Alarm: Always consult a professional if you feel unsure or encounter hazards during any repair.

Preventing Future Oven Not Heating Issues

You can extend the life of your oven and reduce future problems by following a regular maintenance schedule. Clean the oven interior and remove food debris daily. Inspect door gaskets and seals to prevent heat loss. Each week, deep clean racks and trays, and check the heating element for signs of damage or uneven heating. Monthly, inspect electrical connections and test the thermostat. For gas ovens, check connections and pilot lights for leaks. Schedule a comprehensive inspection with a professional at least once a year.

| Inspection Frequency | Recommended Tasks for Oven Elements and Safety Devices |

|---|---|

| Daily | Clean interior, check for obvious issues |

| Weekly | Deep clean racks, inspect elements |

| Monatlich | Inspect electrical connections, test thermostat |

| Jährlich | Professional inspection, replace worn parts |

Anmerkung: Regular cleaning, prompt repairs, and annual professional inspections help prevent costly breakdowns and keep your oven running efficiently.

Testing your oven element at home is a straightforward process when you use the right tools and follow safety steps. If you find a faulty heating element, you can often replace it yourself, but professional repair remains available for complex issues. Regular checks and maintenance offer several long-term benefits:

- Du extend the lifespan of oven elements by up to 30%.

- You reduce fire hazards by removing grease and debris.

- You prevent unexpected breakdowns and higher energy costs.

- You maintain warranty coverage and ensure safe operation.

Consistent care keeps your oven working safely and efficiently for years.

FAQ

How often should you test your oven element?

You should test your oven element once a year or whenever you notice heating issues. Regular checks help you catch problems early and keep your oven working safely.

Can a faulty igniter cause oven heating problems?

Yes, a faulty igniter can prevent your oven from heating. If your oven uses gas, the igniter must glow hot enough to light the burner. If the igniter fails, your oven will not heat properly.

What is the difference between a bake element and an igniter?

A bake element heats electric ovens directly. An igniter works in gas ovens by lighting the gas burner. If the igniter does not function, the oven cannot produce heat.

How do you know if the igniter needs replacement?

You may notice the oven does not heat, or you hear no click or see no glow from the igniter. If you test the igniter with a multimeter and find no continuity, you should replace it.

Can you replace an igniter yourself?

You can replace an igniter if you follow safety steps and use the correct part for your oven model. Always disconnect power and gas before starting. If you feel unsure, contact a professional.

Why does the oven element fail more often than the igniter?

The oven element faces constant high temperatures and electrical stress, which can cause it to wear out faster. The igniter also fails over time, but the element usually shows visible damage first.

What should you do if both the element and igniter seem fine, but the oven still does not heat?

You should check other components, such as the thermostat, control board, or wiring. Sometimes, a problem with the igniter circuit or a blown fuse can stop the oven from heating.

Tip: Always consult your oven’s manual for troubleshooting steps and safety information.