When you choose a hot tub heater, focus on heater element quality. High-performance hot tub heater elements, crafted from titanium or Incoloy, resist corrosion and scale buildup. Good heater elements from brands like Balboa, Gecko, and HydroQuip stand out for their durability and energy efficiency. You avoid common problems, such as electrical failures, corrosion, or flow errors, by selecting the right heater element for your hot tub. Fast heating and fewer breakdowns help you enjoy your spa with confidence.

What Makes a Hot Tub Heater Element Effective?

Key Performance Features of a Hot Tub Heater

Fast Heating Capability

You want your hot tub to reach the perfect temperature quickly. A high-quality hot tub heater delivers fast heating capability, so you spend less time waiting and more time relaxing. The best heater elements use advanced materials and precise engineering to transfer heat efficiently into the water. Industry experts recommend checking the electrical resistance and amp draw of your heater element. For example, a 4.0 to 5.5 kW element should have 9–12 ohms resistance and draw 15–25 amps at 240 volts. These values ensure your heater element can deliver rapid heat without overloading your system.

| Performance Metric | Expected Value / Description |

|---|---|

| Electrical Resistance | 9–12 ohms (for 4.0 to 5.5 kW heater elements) |

| Kontinuität | Good continuity (no breaks in circuit) |

| Amp Draw at 240 volts | 15-25 amps (normal range) |

Konstante Temperaturregelung

Reliable temperature control keeps your hot tub comfortable and safe. A stable heater element maintains your chosen temperature, preventing sudden drops or spikes. Consistency depends on both the quality of the element and the control system. You should test your heater regularly with a multi-meter to confirm it operates within the recommended range. Proper water chemistry and flow also help your heater maintain steady heat output.

Durability and Longevity in Heater Elements

Korrosionsbeständigkeit

Durability starts with corrosion resistance. You expose your hot tub heater element to water, chemicals, and minerals every day. Materials like titanium and Incoloy resist corrosion and mineral buildup, which extends the life of your heater. Titanium, in particular, prevents scale formation and withstands harsh environments, making it a top choice for long-term performance.

Tip: Always balance your water chemistry to protect your heater element from corrosion and scale.

Build Quality

Build quality affects how long your heater element lasts. Look for elements that meet recognized safety and performance standards. For example, UL 1563 sets strict requirements for electric spas and hot tubs, including heater elements. This standard covers electrical safety, heating function control, and fire risk reduction. Choosing a heater element that meets these standards ensures you get a product designed for safety and reliability.

- UL 1563 covers:

- Heating function control

- Electrical shock and fire risk reduction

- Component safety

Energy Efficiency in Hot Tub Heater Elements

Energieaufnahme

Energy efficiency matters for both your wallet and the environment. The Department of Energy (DOE) sets minimum thermal efficiency standards for pool and hot tub heaters. The current standard for gas-fired heaters is 82% thermal efficiency, increasing to 84% in 2028. Electric resistance heaters, common in hot tubs, consume more energy than heat pumps. You should choose a heater element that balances power and efficiency for your needs.

| Aspekt | Einzelheiten |

|---|---|

| Product Scope | Pool heaters for pools, spas, and hot tubs |

| Current Standard (2019) | Gas-fired heaters: 82% minimum thermal efficiency |

| New Standard (2028) | Electric heaters included; gas: 84% minimum TE |

| Efficiency Metric | Integrated Thermal Efficiency (TEI) |

Wärmespeicherung

Efficient heater elements not only generate heat quickly but also retain it. Good insulation and proper installation help your hot tub maintain temperature with less energy use. When your heater element holds heat well, you reduce energy waste and keep your spa ready for use at any time.

Types of Hot Tub Heater Elements That Work Best

When you select a heater element for your hot tub, you face several choices. The most common materials include titanium, Incoloy, and stainless steel. Each type offers unique benefits and drawbacks. Understanding these differences helps you choose the best option for your spa heater.

Titanium Hot Tub Heater Elements

Titanium heater elements have become a top choice for many hot tub owners. You often find them in high-end spa heater elements because of their impressive performance in harsh environments.

Pros of Titanium

- You benefit from exceptional corrosion resistance. Titanium withstands exposure to saltwater, brine, and aggressive chemicals.

- The material remains lightweight and robust, making it easy to handle during installation.

- Titanium heater elements resist erosion and scale buildup, which extends their lifespan.

- You can use them in high-temperature and high-pressure settings without worrying about rapid wear.

Anmerkung: Tubular heater elements, especially single-ended types, dominate the market for compact heating applications like hot tubs. Titanium versions offer both efficiency and durability.

| Material | Hauptvorteile |

|---|---|

| Titan | Lightweight, robust, highly resistant to corrosion and erosion; ideal for saltwater and harsh environments |

Cons of Titanium

- You may encounter scale buildup if you have hard water or use saltwater sanitation. This reduces heat output and can cause element failure.

- Improper installation, such as bending terminals, can fracture seals and allow water intrusion.

- Operating the heater element without enough cooling water leads to rapid burnout.

- Nuisance tripping of high limit switches can occur due to low water flow, incorrect voltage, or faulty wiring.

- Titanium heater elements often cost more than other types.

Tip: Maintain proper water chemistry and flow to prevent scale buildup and premature failure of your titanium heating element.

Incoloy Hot Tub Heater Elements

Incoloy heater elements offer a balance between performance and cost. You see them frequently in both residential and commercial spa heater applications.

Pros of Incoloy

- Incoloy provides excellent resistance to oxidation and corrosion, even in extreme conditions.

- You can use these elements in acidic or alkaline water without rapid deterioration.

- Many Incoloy heater elements feature ceramic coatings, which further enhance durability and protect against wear.

- The material handles high temperatures well, making it suitable for demanding spa environments.

| Material | Hauptvorteile |

|---|---|

| Incoloy | Excellent resistance to oxidation and corrosion; suitable for acidic/alkaline water; often paired with ceramic coatings for extra durability |

Cons of Incoloy

- Incoloy does not match titanium’s resistance to saltwater corrosion. You may see faster wear in saltwater spas.

- Scale buildup remains a concern, especially if you neglect water chemistry.

- Incoloy heater elements can develop pinholes from corrosion over time, leading to electrical shorts.

- You must ensure proper installation and avoid dry firing, as overheating can damage the element.

Note: Heating elements made from Incoloy and ceramic-coated materials typically last between 3 bis 10 Jahre, depending on usage and care.

Stainless Steel Hot Tub Heater Elements

Stainless steel heater elements remain a popular choice for many spa owners. You often find them in budget-friendly spa heater elements and replacement parts.

Pros of Stainless Steel

- Stainless steel offers strong durability and resists corrosion in most water conditions.

- The material forms a self-healing rust layer, which helps protect the element from further damage.

- You can use stainless steel heater elements in hard water and high-temperature environments.

- These elements are widely available and usually cost less than titanium or Incoloy options.

| Material | Hauptvorteile |

|---|---|

| Rostfreier Stahl | Strong, durable, resists corrosion and high temperatures; self-healing rust layer; suitable for hard water |

Cons of Stainless Steel

- Stainless steel does not perform as well as titanium or Incoloy in saltwater or highly corrosive environments.

- You may notice a shorter lifespan if you use your hot tub frequently or have poor water chemistry.

- Stainless steel heater elements are more prone to scale buildup, which reduces heat transfer efficiency.

- You must clean and maintain these elements regularly to maximize their service life.

Tip: Proper maintenance and selecting the right material based on your water chemistry are critical for maximizing the performance and durability of your spa heater elements.

Ceramic-Coated Heater Elements

Ceramic-coated heater elements have gained popularity in the spa industry. You often see them in modern hot tubs because they combine the benefits of metal cores with a protective ceramic layer. This design helps you achieve reliable performance, especially if you want to extend the life of your heater element.

Pros of Ceramic-Coated Elements

You get several advantages when you choose a ceramic-coated heater element for your hot tub:

- Superior Corrosion Protection: The ceramic coating acts as a barrier between the metal core and the water. You reduce the risk of corrosion, even if your water contains high levels of minerals or chemicals.

- Improved Scale Resistance: The smooth ceramic surface makes it harder for scale and mineral deposits to stick. You spend less time cleaning and more time enjoying your spa.

- Enhanced Durability: Ceramic-coated elements resist pitting and surface damage. You can expect a longer service life compared to standard metal elements.

- Stable Heat Transfer: The ceramic layer helps distribute heat evenly across the surface. You avoid hot spots and maintain consistent water temperature.

Tip: If you use a saltwater system or have hard water, ceramic-coated heater elements can help you minimize maintenance and extend the lifespan of your spa equipment.

| Merkmal | Benefit for You |

|---|---|

| Corrosion Protection | Less risk of rust and chemical damage |

| Scale Resistance | Fewer mineral deposits, easier cleaning |

| Dauerhaftigkeit | Longer-lasting performance |

| Wärmeverteilung | Even water temperature, no hot spots |

Cons of Ceramic-Coated Elements

Despite their strengths, ceramic-coated heater elements have some drawbacks you should consider:

- Higher Initial Cost: You may pay more upfront for a ceramic-coated heater element than for a standard stainless steel option.

- Potential for Coating Damage: If you handle the element roughly during installation, the ceramic layer can crack or chip. Damaged coatings expose the metal core, which increases the risk of corrosion.

- Limited Repair Options: Once the ceramic coating wears away or gets damaged, you cannot repair it. You must replace the entire heater element to restore full protection.

- Compatibility Issues: Not all hot tubs support ceramic-coated elements. You should check your spa’s specifications before making a purchase.

Note: Always follow the manufacturer’s installation guidelines to prevent accidental damage to the ceramic coating.

Ceramic-coated heater elements offer a strong balance of protection and performance. You benefit most from these elements if you want to reduce maintenance and maximize the lifespan of your hot tub’s heating system.

Top-Rated Hot Tub Heater Elements and Brands

Best Overall Hot Tub Heater Elements

Balboa Titanium Heater Element Review

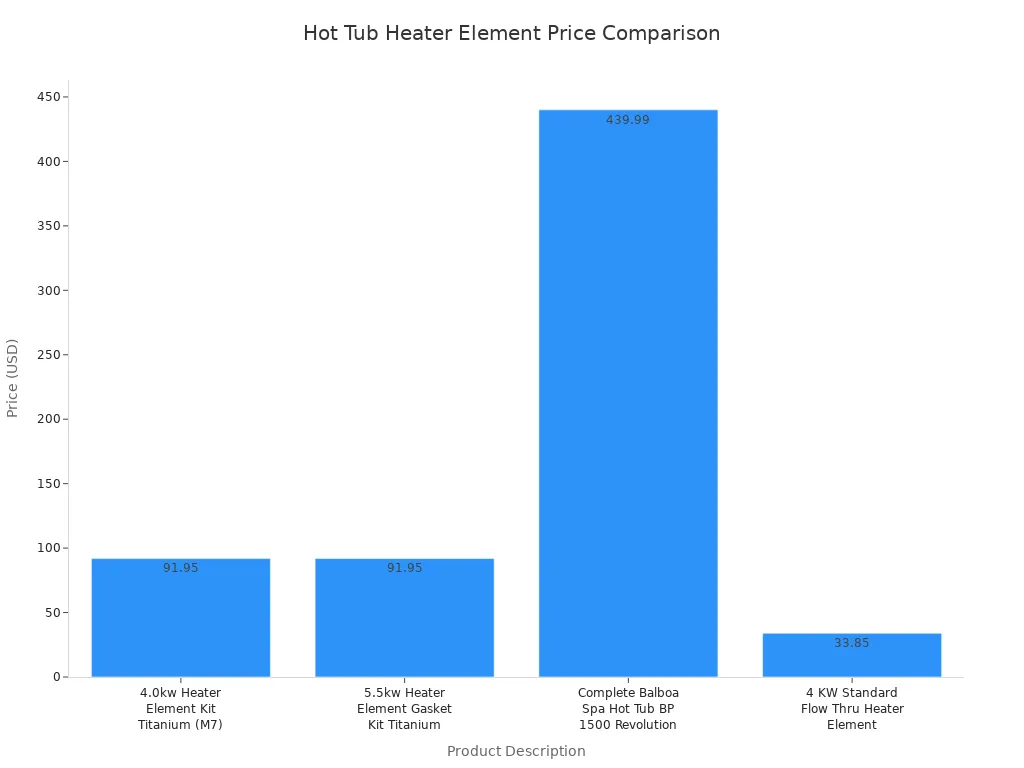

You can rely on the Balboa Titanium Heater Element for consistent performance and long-term durability. This heater element uses titanium, which resists corrosion and scale buildup. You benefit from fast heating and stable temperature control. The Balboa Titanium Heater Element fits many modern hot tubs and meets strict safety standards. Professional installers often recommend Balboa for its reliability and ease of installation. The price for a 4.0kw titanium kit typically ranges from $89.95 to $93.95, offering you a balance between quality and value.

Gecko Flo-Thru Heater Element Review

The Gecko Flo-Thru Heater Element stands out for its efficient heat transfer and robust construction. You get a heater element that works well with a variety of spa heater systems. Gecko uses advanced materials, including titanium and Incoloy, to ensure longevity. The Flo-Thru design allows water to pass directly over the heating coil, which improves efficiency and reduces energy waste. You can find a standard 4 KW flow-thru element for as low as $33.85, making it an accessible choice for many hot tub owners.

| Product Description | Brand(s) | Price Range (USD) | Anmerkungen |

|---|---|---|---|

| 4.0kw Heater Element Kit with Titanium | Balboa, Gecko, HydroQuip | $89.95 – $93.95 | Discounted from MSRP ~$130-$135 |

| 4 KW Standard Flow Thru Heater Element | Gecko, HydroQuip, Spa Builders | $33.85 | Discounted from RRP $69.95 |

Best Budget-Friendly Heater Element Options

HydroQuip Universal Heater Element Review

HydroQuip offers a universal heater element that meets industry safety and performance standards. You receive a product that is ETL tested to UL 1563 and UL 1081. The HydroQuip element features a stainless steel or Incoloy core, providing solid resistance to corrosion. You can install this heater element in most hot tub models, and it comes at a competitive price point. The 4 KW standard flow-thru element is available for $33.85, making it a cost-effective solution for routine replacements.

SpaBuilders Stainless Steel Heater Element Review

SpaBuilders provides a stainless steel heater element designed for affordability and reliability. You benefit from a self-healing rust layer that protects the element in hard water environments. SpaBuilders heater elements are compatible with many spa heater systems and are easy to install. The price remains budget-friendly, and you can expect dependable performance for everyday use.

| Heater Series | Price (Starting at) | Plumbing Size | Sicherheitszertifizierungen | Wesentliche Merkmale | Garantie |

|---|---|---|---|---|---|

| Megatrol Series | $269.95 | 2″, 2½”, or 3″ | ETL tested to UL 1563 & UL 1081 | Titanium corrosion-proof manifold, GFI failure protection | 5-year no-fault (with air bleeder) |

| FlexiTrol Series | $274.95 | 2″ | ETL tested to UL 1563 & UL 1081 | Stainless steel seamed heater manifold, 800 Incoloy element | Not specified |

| PowerMaster Series | $319.95 | 2″ | ETL tested to UL 1563 & UL 1081 | Stainless steel seamed heater manifold, 800 Incoloy element | Not specified |

Best Heater Elements for Saltwater Hot Tubs

Balboa Titanium Saltwater Heater Element Review

If you own a saltwater hot tub, you need a heater element that withstands salt exposure. The Balboa Titanium Saltwater Heater Element uses high-grade titanium, which resists corrosion from salt and harsh chemicals. You can expect a longer lifespan and fewer maintenance issues. Many high-end hot tubs include this type of heater element to ensure reliable operation in saltwater systems.

Therm Products Titanium Heater Element Review

Therm Products manufactures titanium heater elements specifically for saltwater and demanding environments. You benefit from advanced corrosion resistance and stable heat output. These heater elements help you avoid premature failure caused by saltwater corrosion. Always check your warranty terms, as some manufacturers may limit coverage if you use aftermarket saltwater systems.

- Saltwater hot tubs require heater elements made from corrosion-resistant materials such as titanium or high-grade stainless steel.

- Saltwater can accelerate corrosion in metal components, so you should always choose heater elements designed for this environment.

- Some manufacturers may void warranties if you install non-factory saltwater systems.

| Brand/Manufacturer | Notable Heater Elements / Models | Key Features / Notes |

|---|---|---|

| Pentair | MasterTemp 125 Spa Heater | Advanced technology, durable, efficient electric spa heater |

| Raypak | E3T Digital Spa Electric Heaters (5.5kW, 18kW, 27kW) with Titanium Heat Elements | Reliable, energy-efficient, digital control |

| Coates Heater Company | 5.5kW 240V Electric Heater Elements (e.g., 20005061) | Threaded elements, widely used in spa heaters |

| Hayward | 5.5kW C-Spa Heater Element (CZXELE7623) | Trusted brand, electric spa heater elements |

| Waterway Plastics | Various spa heater components | Commonly used by professionals |

Tip: Always confirm compatibility and warranty terms before installing a new heater element in your saltwater hot tub.

How to Choose the Right Heater Element for Your Hot Tub

Selecting the right heater element for your spa system requires careful attention to compatibility, environmental factors, and installation practices. You ensure reliable performance and safety by following a systematic approach.

Check Hot Tub Heater Compatibility

Matching Size and Shape

You must verify that the new heater element matches the physical dimensions and mounting style of your existing unit. Heater elements may appear similar, but brands often use unique designs. Always check the length, diameter, and connection type before purchasing. This step prevents installation issues and ensures a secure fit.

Spannungs- und Wattanforderungen

You need to confirm that the voltage and wattage of the replacement heater element align with your hot tub’s specifications. Even if two elements look identical, differences in kilowatt rating or voltage can affect heating speed and energy consumption. Using the wrong rating may cause slow heating, higher electricity bills, or even damage to your equipment.

- Review the following before buying a replacement:

- Style of the element

- Kilowatt (KW) rating

- Voltage (e.g., 120V or 240V)

- Connection or mounting type

Tip: Compatibility checks help you avoid costly mistakes and ensure your heater element operates safely and efficiently.

Consider Your Hot Tub’s Environment

Saltwater vs. Freshwater

Saltwater systems accelerate corrosion in heater elements due to high salt concentrations and elevated temperatures. You should choose corrosion-resistant materials, such as titanium, for saltwater environments. These materials withstand chemical stress and reduce the risk of premature failure. Freshwater systems allow for more flexibility in material choice, but regular maintenance remains essential.

Indoor vs. Outdoor Use

Outdoor hot tubs require heater elements with robust electrical safety features and corrosion resistance. Exposure to weather and moisture increases the risk of electric shock. You must select components that meet safety standards and have appropriate ingress protection ratings. Indoor installations face fewer environmental hazards, but you should still prioritize quality and safety.

Installation Considerations for Heater Elements

DIY vs. Professional Installation

You may consider installing a heater element yourself, but professional installation offers several advantages. Technicians ensure proper wiring, secure connections, and compliance with safety codes. If you choose the DIY route, follow manufacturer instructions closely and double-check all connections.

Safety Precautions

Installation mistakes can lead to heater failure or safety hazards. Review the table below for common errors and how to avoid them:

| Common Installation Mistake | So vermeiden Sie |

|---|---|

| Operating heater element without adequate water flow | Clean filters, check water level, and clear blockages before operation |

| Scale buildup on heater element | Use sequestering agents and maintain low alkalinity (70-80 ppm) |

| Loose or oxidized electrical connections | Ensure all wiring is tight, clean, and undamaged |

| Faulty pressure switch or ignoring flow sensors | Test and maintain pressure switches; do not bypass unless testing |

| Incorrect voltage or power surges | Verify voltage supply and use surge protection |

Anmerkung: Regular cleaning, balanced water chemistry, and routine inspections help prevent most heater element failures.

Maintenance Tips for Long-Lasting Hot Tub Heater Elements

Regular Cleaning of Heater Elements

Removing Scale and Debris

You extend the life of your heater element by removing scale and debris regularly. Start by draining your hot tub and turning off the power. Apply a quality scale remover to the heater area and use a soft brush or sponge to scrub away mineral deposits. For hard-to-reach spots, a toothbrush works well. After cleaning, wipe down all surfaces to remove residue. Use a line flush product to clean internal plumbing and heater elements, which helps eliminate hidden buildup. Cleaning filters after scale removal prevents redepositing debris into the system.

Reinigungshäufigkeit

Manufacturers recommend a consistent cleaning schedule to prevent heater failure. Clean your filters monthly and perform a full drain and scrub every three to four months. Weekly surface cleaning of the shell and jets with mild, pH-neutral cleaners keeps your system running smoothly. Deep cleaning and draining the hot tub quarterly, including chemical flushing of plumbing, helps maintain optimal heat transfer and reduces the risk of failure.

Tip: Regular cleaning not only improves heat efficiency but also reduces the need for frequent repair.

Preventing Corrosion in Hot Tub Heater Elements

Water Chemistry Balance

Proper water chemistry protects your heater element from corrosion. Test your water weekly to monitor pH, alkalinity, and sanitizer levels. Keep pH between 7.4 and 7.6, and alkalinity between 80 and 120 ppm. Balanced water chemistry prevents both corrosion and scale, which are leading causes of heater failure. Use chlorine, bromine, or mineral systems to sanitize the water and perform shock treatments periodically to remove contaminants.

Using Protective Coatings

In high-salt or coastal environments, you benefit from applying corrosion-resistant coatings to metal parts. A well-fitted, insulated cover shields your heater from debris, UV damage, and heat loss. Regularly rinse the tub and inspect components for signs of wear. Professional maintenance checks help you identify early signs of corrosion and schedule timely repair before major failure occurs.

Troubleshooting Common Hot Tub Heater Issues

Identifying Heating Problems

You may notice your heater shutting down, producing no heat, or running too often. These issues often result from low water flow, dirty filters, or trapped air. Water leaking near the heater area can signal loose plumbing unions. Electrical shorts, often caused by corrosion or water intrusion, may trip the GFCI breaker. Use an ohm meter to test resistance; a reading outside the 9–12 ohms range suggests a problem. Always check for proper water level and ensure the heater is fully submerged to avoid dry firing and premature failure.

Quick Fixes

To address common problems, follow these steps:

- Open and lock slice valves to ensure proper water flow.

- Clean or replace filters to maintain efficient heat transfer.

- Prime the system to remove air bubbles.

- Inspect and tighten plumbing unions to stop leaks.

- Test high limit switches and thermostats for continuity.

- If you detect a problem, schedule a professional repair promptly to prevent further damage.

Anmerkung: Preventative maintenance, including regular cleaning and water chemistry checks, reduces the risk of heater failure and costly repair.

When and How to Replace Your Hot Tub Heater Element

Signs Your Heater Element Needs Replacing

Slow Heating

You may notice your hot tub takes much longer to reach the desired temperature. Water that feels lukewarm or does not heat at all often points to a faulty heater element. If you see frequent tripping of breakers or error codes related to heating, these are strong indicators of heater element failure. Sometimes, thermostat or circulation pump issues can cause similar symptoms, but heater element failure remains a primary suspect when heating is inadequate.

- Water remains lukewarm or cold despite running the heater.

- Breakers trip or error codes appear during heating cycles.

- The hot tub struggles to maintain set temperatures.

Sichtbare Schäden oder Korrosion

Physical inspection can reveal clear signs that you need to replace the heater element. Look for visible wear, corrosion, or mineral buildup on the element. These issues reduce heating efficiency and can lead to complete failure. If you see holes or damage in the element sheath, the element is beyond repair.

- Corrosion or mineral deposits cover the heater element.

- Holes or cracks appear in the element sheath.

- GFCI tripping occurs, which often signals a short caused by water intrusion or corrosion.

Tip: Use an ohm meter to test the heater element after disconnecting power. Acceptable resistance readings range from 9 to 12 ohms. Readings outside this range indicate a problem.

Step-by-Step Guide to Installing a Replacement Spa Heater Element

Tools and Materials Needed

Before you begin, gather the following:

| Tool/Material | Zweck |

|---|---|

| Replacement heater element | Matches your hot tub’s specifications |

| Wrenches & Screwdrivers | Remove and secure hardware |

| Multimeter | Test voltage and resistance |

| Teflon tape (if needed) | Ensure watertight seal |

| Towels/Bucket | Catch residual water |

Safe Removal and Installation

Follow these steps to ensure a safe and effective process when installing a replacement spa heater element:

- Turn off power at the circuit breaker to prevent electrical shock.

- Drain the hot tub below the heater element level.

- Entfernen Sie die Zugangsplatten, um an die Heizeinheit zu gelangen.

- Carefully disconnect electrical connections, noting wire colors and terminals.

- Remove mounting hardware and extract the old heater element.

- If required, wrap Teflon tape around the threads of the new element.

- Insert and align the new heater element into the housing.

- Secure mounting hardware firmly.

- Reconnect electrical connections, matching wire colors and terminals.

- Use a multimeter to verify proper voltage and resistance.

- Close and seal access panels.

- Refill the hot tub with water.

- Restore power and monitor the heater element to confirm proper operation.

Note: Always follow your manufacturer’s guidelines and consult the hot tub manual for specific instructions and safety precautions.

By recognizing the signs of heater element failure and following these steps, you ensure your hot tub heats efficiently and safely.

You achieve the best results when you select a hot tub heater made from durable materials like titanium or Incoloy. Trusted brands such as Balboa, Gecko, and HydroQuip deliver proven reliability. To keep your hot tub running smoothly, follow a regular maintenance schedule and replace components as needed. Investing in quality ensures you enjoy a warm, relaxing soak every season.

Tip: Regular care extends the life of your equipment and helps you avoid unexpected repairs.

FAQ

What is the average lifespan of a hot tub heater element?

You can expect most hot tub heater elements to last between 3 and 10 years. Lifespan depends on water chemistry, usage frequency, and material quality. Regular maintenance extends service life.

Can you replace a hot tub heater element yourself?

You can replace a heater element if you have basic electrical skills and follow safety guidelines. Always turn off power and consult your hot tub’s manual. If unsure, hire a professional.

How do you know if your heater element is failing?

You may notice slow heating, lukewarm water, or frequent breaker trips. Visible corrosion or mineral buildup also signals failure. Use a multimeter to check resistance for confirmation.

Which heater element material works best for saltwater hot tubs?

You should choose titanium heater elements for saltwater systems. Titanium resists corrosion from salt and chemicals, providing longer service life and fewer maintenance issues.

How often should you clean your hot tub heater element?

You should clean your heater element every three to four months. Regular cleaning prevents scale buildup and improves heating efficiency. Always follow manufacturer recommendations for best results.

What safety precautions should you take during installation?

Always disconnect power before starting. Wear insulated gloves and use proper tools. Double-check all electrical connections. If you feel unsure, contact a licensed technician for installation.

Does water chemistry affect heater element performance?

Yes, water chemistry plays a critical role. Balanced pH and alkalinity prevent corrosion and scale. Test your water weekly to keep your heater element in top condition.

Are ceramic-coated heater elements compatible with all hot tubs?

Not all hot tubs support ceramic-coated elements. You should check your spa’s specifications before purchasing. Consult your manufacturer or dealer for compatibility information.