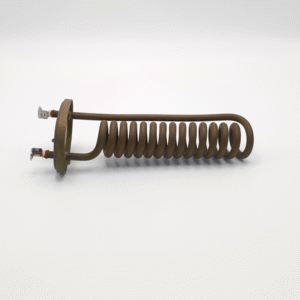

Milk Heater Heating Plate——Food-grade precise temperature control heating solution

The heating element is specially designed for milk heating equipment (such as pasteurizers, milk bar equipment, and dairy production lines). It uses food-grade 316L stainless steel + nano-ceramic coating, is suitable for a power range of 500W-3000W, has a temperature resistance of 150℃ (short time), and a heat distribution uniformity of ΔT≤2℃; it integrates a PID dynamic temperature control algorithm (±0.5℃ accuracy), supports anti-dry burning protection (automatic power off in >15 seconds) and pulse steam self-cleaning technology (milk scale removal rate >99%), and has passed CE/LFGB/RoHS certification, and is suitable for home, commercial and industrial dairy processing scenarios.

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

Home appliances: bottle sterilizer, constant temperature milk mixer, portable milk heating cup, coffee milk foam heating pad.

Industrial equipment: laboratory constant temperature water bath device, medical equipment constant temperature disinfection system, dairy product processing pretreatment equipment.

Material and structure:

304 stainless steel substrate: corrosion-resistant, rust-proof, surface polished (easy to clean), suitable for containers such as bottles and glasses.

Insulation design: ceramic fiber insulation layer (surface temperature ≤60°C, anti-scalding).

Power range:

Conventional model: 300W–800W (suitable for 200ml–500ml bottles, pasteurization or constant temperature heating).

Portable model: 200W (USB-C power supply, suitable for car/travel, battery life 6 hours).

Temperature control:

PID algorithm: temperature control accuracy ±0.5°C, support multi-stage temperature control (such as pasteurization 40°C→60°C→85°C).

Preset mode: breast milk heating (40°C), yogurt fermentation (42°C), brewing milk powder (70°C).

Dimensions and specifications:

Shape: round/square (fits the bottom of standard baby bottles, diameter 5–8cm).

Heating area: diameter 6cm–8cm (covers the bottom of the baby bottle).

Thickness: 1.5mm–3mm (ultra-thin design, portable for desktop/car).

Safety protection:

Anti-dry burning: automatic power off when temperature > set value 10°C (such as stopping heating after the water in the baby bottle is dried up).

Anti-overflow design: automatic power reduction when detecting boiling liquid to prevent milk from overflowing.

Tip-off: automatic power off when tilt angle > 15° (fits car use).

Life and reliability:

Regular models: 5,000–8,000 hours (calculated based on 3 uses per day).

Precise temperature control:

Multi-stage programming: supports pasteurization (62°C/30 minutes), breast milk storage (4°C refrigeration), and milk preparation (70°C).

Real-time display: The LED screen displays the current temperature and mode, which is suitable for night feeding without turning on the light.

Safety and anti-scalding:

Insulation layer: Surface temperature ≤60°C to avoid accidental scalding (especially suitable for families with children).

Double insurance: temperature fuse + automatic power off, in line with GB 4706.1 home appliance safety standards.

Efficient heating:

300W model: heats 200ml of cold water to 40°C in 3 minutes without overheating risk.

Pasteurization mode: 60°C constant temperature for 10 minutes, kills harmful bacteria and retains nutrients.

Easy to clean and maintain:

Detachable design: The heating plate is separated from the base and supports dishwasher cleaning.

Teflon coating (ceramic substrate): no residue, resistant to milk scale and milk stains.

Quiet operation:

Fanless design, suitable for use in the baby room at night.

Multi-scene adaptation:

Bottle heating: suitable for standard bottles.

Yogurt machine compatible: with glass jar, 42°C constant temperature fermentation for 8 hours.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.