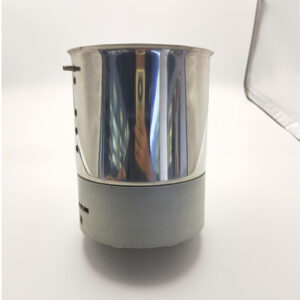

Our factory specializes in the production of heating elements and temperature control components for electric milk frothers, suitable for manual/automatic milk frothers, handheld coffee machines and other equipment. Made of food-grade 304 stainless steel and high-temperature resistant ceramic coating, it is corrosion-resistant and non-sticky, supports rapid heating and precise temperature control (30℃-100℃ multi-speed adjustment), and meets the refined needs of milk foaming, coffee foaming, etc. Integrated PID temperature control chip and double safety protection (anti-dry burning, overheating power off) to ensure operational stability. Modular design is suitable for mainstream brand models, easy to install and simple to maintain.

MOQ:1000PCS

Lead time:15-25days

Factory location: Zhongshan, Guangdong, China

Our electric heating components are core elements in milk frothers and coffee machines, designed to precisely heat milk to optimal temperatures (typically 60–70°C for velvety microfoam or 40–60°C for gentle warming) and maintain consistent heat during frothing or coffee preparation. They ensure smooth, stable foam texture and enhance beverage quality while preventing overheating or scorching, critical for professional barista-grade results in home or commercial settings.

| Parameter | Specification Range | Customization Options |

|---|---|---|

| Power Rating | 50W–500W (standard); up to 1000W for high-performance frothers | Adjustable to match frother motor/wattage limits |

| Operating Voltage | 110V/220V AC (standard); 12V/24V DC available for battery-powered or portable models | Custom voltage for global market compatibility |

| Dimension Range | Diameter: 20mm–60mm; Thickness: 1.0mm–3.0mm; Shape: annular, spiral, or custom contour | Compact designs to fit narrow frother chambers |

| Material | Food-grade 304 stainless steel (standard); 316 stainless steel for acidic milk (e.g., almond/oat milk) | Polished/matte finish for easy cleaning |

| Temperature Range | Ambient (20°C) to max 90°C (continuous operation, auto-shutoff at 90°C) | Low-temp variants (max 70°C) for delicate foams |

| Control Compatibility | Compatible with external thermistors (±2°C) or integrated sensors (±1°C) | Custom interfaces (e.g., PWM, app-connected) |

We offer tailored solutions, including dimensions, power, material grade, and interface design, to align with specific frother structures (e.g., handheld frothers, espresso machine integrated units) while maintaining safety, efficiency, and brand compatibility.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.