Specially designed for preparing ultrapure water in distilled water machines, it uses high-precision heating technology to evaporate and condense raw water, remove impurities and ions, and produce distilled water with a resistivity of ≥18 MΩ·cm, meeting the high-purity water needs in laboratories, medical treatment, pharmaceuticals and other fields.

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

Engineered for distilled water generation systems, high-performance electric heating components are intended to effectively convert water into purifying steam and condense it into high-purity distilled water. These optimized for durability, corrosion resistance, and energy efficiency components are essential for medical, laboratory, and industrial uses demanding ultra-pure water.

Operating at temperatures up to 1200°C, high resistivity and oxidation resistance nickel-chromium (NiCr) or iron-chromium-aluminum (FeCrAl) alloy.

Insulation: magnesium oxide (MgO) powder coating to guarantee thermal stability and prevent current leakage.

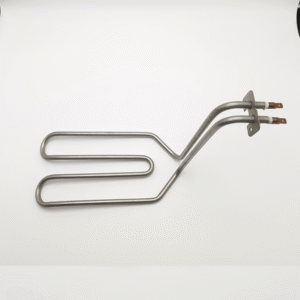

Stainless steel 304/316L enclosed with ceramic seals to resist corrosion and contamination .

Power Range: 500W–1500W (adjustable via thermostat) to match varying distillation demands .

Thermal Efficiency: ≥95% energy conversion rate, minimizing heat loss and operational costs .

Steam Generation: Rapid boiling of water (3–5L/hour) with minimal energy consumption .

Overheat Protection: Automatic shutdown at 120°C (adjustable) to prevent dry boiling or component damage .

Anti-Dry Burn: Built-in sensors detect low water levels and cut power to avoid overheating .

IPX4 Waterproof: Protection against splashing and humidity for safe operation in humid environments .

Voltage Compatibility: AC 110V–240V/DC 12V–48V for global use .

Mounting Designs: Vertical or horizontal configurations with flange or threaded interfaces .

Coating Options: Nano-ceramic or PTFE anti-scaling coatings to reduce maintenance frequency .

Produces 0 ppm distilled water for autoclaves, IV solutions, and sensitive experiments .

Eliminates 99.9% of contaminants (e.g., bacteria, heavy metals) via steam distillation .

Critical for battery manufacturing, pharmaceuticals, and electronics cleaning .

Compatible with high-purity water loops requiring continuous distillation.

Compact units for kitchens or clinics, combining energy efficiency with safety features .

Reduced Scaling: Anti-scaling coatings decrease limescale buildup by 60%, lowering maintenance needs .

Uniform Heating: Vertical steam pathways ensure consistent temperature distribution, minimizing hotspots .

Energy Savings: Optimized power consumption reduces operational costs by 20% vs. traditional elements .

Nếu bạn có thể cung cấp thông tin chính xác về thông số nhu cầu, chúng tôi có thể gửi báo giá cho bạn sớm nhất trong vòng 24 giờ.

Đây là danh sách những câu hỏi thường gặp của khách hàng. Chúng tôi sẽ trả lời ngắn gọn từng câu hỏi, bao gồm các khía cạnh như sản phẩm, chất lượng và dịch vụ. Nếu quý khách có thắc mắc khác, vui lòng để lại tin nhắn để được tư vấn. Xin chân thành cảm ơn.

Chúng tôi là một nhà máy sản xuất có năng lực sản xuất độc lập, với 30 năm kinh nghiệm trong lĩnh vực R&D và sản xuất phụ kiện sưởi điện, năng suất sản xuất hàng năm trên 5 triệu bộ, hỗ trợ tùy chỉnh OEM/ODM và cung cấp dịch vụ kiểm tra video thực tế tại nhà máy.

Chúng tôi hỗ trợ thử nghiệm mẫu miễn phí, và cước phí phải được thanh toán trước (thu khi giao hàng). Các mẫu thông thường được giao trong vòng 7-10 ngày làm việc, kèm theo báo cáo thử nghiệm SGS và bảng thông số hiệu suất.

Phản hồi trực tuyến từ 8:30 đến 17:30 các ngày làm việc. Trong trường hợp khẩn cấp, bạn có thể gửi yêu cầu công việc qua trang web chính thức. Chúng tôi cam kết phản hồi kỹ thuật trong vòng 2 giờ và cung cấp giải pháp trong vòng 48 giờ.

Chúng tôi có hai cơ sở sản xuất tại Trung Sơn và Vũ Hồ, với sản lượng hàng tháng hơn 3 triệu sản phẩm, được trang bị dây chuyền dập hoàn toàn tự động và xưởng lắp ráp tự động. Thời gian giao hàng tiêu chuẩn là 15 ngày, đơn hàng tùy chỉnh được giao trong vòng 30 ngày. Chúng tôi hỗ trợ cung cấp theo lô.

Có chứng nhận ISO9001/14001, CE (EU), ETL (Bắc Mỹ), RoHS (bảo vệ môi trường), sản phẩm chống cháy nổ được chứng nhận kép ATEX/IECEx và đáp ứng các quy định REACH.

Cung cấp các sản phẩm cho các thương hiệu hàng đầu thế giới như Philips, Midea, Supor, Delonghi, BSH và SEB Group, được sử dụng trong các dự án cao cấp như máy pha cà phê, bàn là điện, máy lọc nước và hệ thống sưởi năng lượng mặt trời, và có thể cung cấp danh sách tham khảo về các khách hàng tương tự.

Nhận báo giá tùy chỉnh trong vòng chưa đầy hai ngày.