Die-cast parts are made of high-precision die-casting technology and aluminum alloy. The surface is anodized to enhance wear resistance and corrosion resistance. It is suitable for high temperature (50℃-300℃) and high pressure environment. The integrated heat dissipation structure design improves heat conduction efficiency, supports IPX7 waterproof and dustproof and anti-dry burning protection, and meets the industrial-grade high-intensity and high-frequency continuous working requirements.

Minimum order quantity: 1000

Delivery time: 15-25 days

Factory location: Zhongshan, Guangdong, China

Coffee machine steam module housing, electric water heater heating cavity, industrial oven heat dissipation components, medical sterilization equipment heater accessories, laboratory constant temperature water bath housing, new energy battery module constant temperature housing, hotel commercial electric tea stove components, mold constant temperature control housing, smart wearable device temperature control housing.

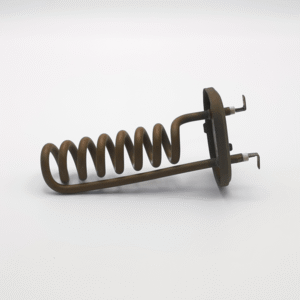

High resistivity (1.01.5 μΩ·m) from nickelchromium alloy (Cr20Ni80) heating cores guarantees consistent heating; diecast aluminum alloy (A356/6061) with thermal conductivity ≥200 W/(m·K) assures quick heat transfer.

MultiDevice Compatibility: Precisioncast measurements (length: 100-600mm; width: 40-150mm) match common household appliances—electric kettles (boiling), coffee machines (brewing), and blenders (hot blending).

Optimized casting design removes cold spots, which is essential for consistent performance in soy milk makers (grinding/heating) and electric pots (stewing).

Resistance to Corrosion: In high-moisture surroundings (e.g., damp kitchens), anodized or ceramic-coated surfaces lower limescale adhesion by 40%, therefore increasing lifespan.

Overheat Protection:Integrated thermal cutoff switches autoshutdown at >350°C, therefore avoiding dry burning and guaranteeing safe operation in teapot and bottle warmers.

Thermal efficiency of at least 92% lowers electricity use by 15-20% against conventional heating components (e.g., 1.5L water boils in 35 minutes with 1500W models).

Aluminum’s density of 2.7 g/cm³ cuts component weight by 30% over stainless steel, making it perfect for portable devices such mini kettles and little coffee machines.

Thermal expansion matching (aluminum + nickelchromium) guarantees 8,000–15,000 hours of stable performance under intense frequency use (daily two-hour run, for example).

Standardized Tolerances: ±0.5mm dimensional stability promotes OEM and aftermarket replacements with little tweaking.

For large-scale OEM orders, diecasting technology helps to lower production costs while preserving precision, therefore helping it to be competitive.

Nếu bạn có thể cung cấp thông tin chính xác về thông số nhu cầu, chúng tôi có thể gửi báo giá cho bạn sớm nhất trong vòng 24 giờ.

Đây là danh sách những câu hỏi thường gặp của khách hàng. Chúng tôi sẽ trả lời ngắn gọn từng câu hỏi, bao gồm các khía cạnh như sản phẩm, chất lượng và dịch vụ. Nếu quý khách có thắc mắc khác, vui lòng để lại tin nhắn để được tư vấn. Xin chân thành cảm ơn.

Chúng tôi là một nhà máy sản xuất có năng lực sản xuất độc lập, với 30 năm kinh nghiệm trong lĩnh vực R&D và sản xuất phụ kiện sưởi điện, năng suất sản xuất hàng năm trên 5 triệu bộ, hỗ trợ tùy chỉnh OEM/ODM và cung cấp dịch vụ kiểm tra video thực tế tại nhà máy.

Chúng tôi hỗ trợ thử nghiệm mẫu miễn phí, và cước phí phải được thanh toán trước (thu khi giao hàng). Các mẫu thông thường được giao trong vòng 7-10 ngày làm việc, kèm theo báo cáo thử nghiệm SGS và bảng thông số hiệu suất.

Phản hồi trực tuyến từ 8:30 đến 17:30 các ngày làm việc. Trong trường hợp khẩn cấp, bạn có thể gửi yêu cầu công việc qua trang web chính thức. Chúng tôi cam kết phản hồi kỹ thuật trong vòng 2 giờ và cung cấp giải pháp trong vòng 48 giờ.

Chúng tôi có hai cơ sở sản xuất tại Trung Sơn và Vũ Hồ, với sản lượng hàng tháng hơn 3 triệu sản phẩm, được trang bị dây chuyền dập hoàn toàn tự động và xưởng lắp ráp tự động. Thời gian giao hàng tiêu chuẩn là 15 ngày, đơn hàng tùy chỉnh được giao trong vòng 30 ngày. Chúng tôi hỗ trợ cung cấp theo lô.

Có chứng nhận ISO9001/14001, CE (EU), ETL (Bắc Mỹ), RoHS (bảo vệ môi trường), sản phẩm chống cháy nổ được chứng nhận kép ATEX/IECEx và đáp ứng các quy định REACH.

Cung cấp các sản phẩm cho các thương hiệu hàng đầu thế giới như Philips, Midea, Supor, Delonghi, BSH và SEB Group, được sử dụng trong các dự án cao cấp như máy pha cà phê, bàn là điện, máy lọc nước và hệ thống sưởi năng lượng mặt trời, và có thể cung cấp danh sách tham khảo về các khách hàng tương tự.

Nhận báo giá tùy chỉnh trong vòng chưa đầy hai ngày.