When you select heating element materials for electric heaters or industrial heating elements, you want reliability and efficiency. The right material makes a difference. Nickel-chromium alloys, iron-chrome-aluminum, tungsten, molybdenum, and silicon carbide each offer unique advantages for types of heating elements. Materials with high electrical resistance and heat tolerance reduce premature failures. For example, scale buildup causes most heating element failures in American homes, but corrosion-resistant materials like stainless steel extend service life. You find these materials in everything from the heating element in electric iron to advanced industrial heating elements.

Essential Properties of Heating Element Materials

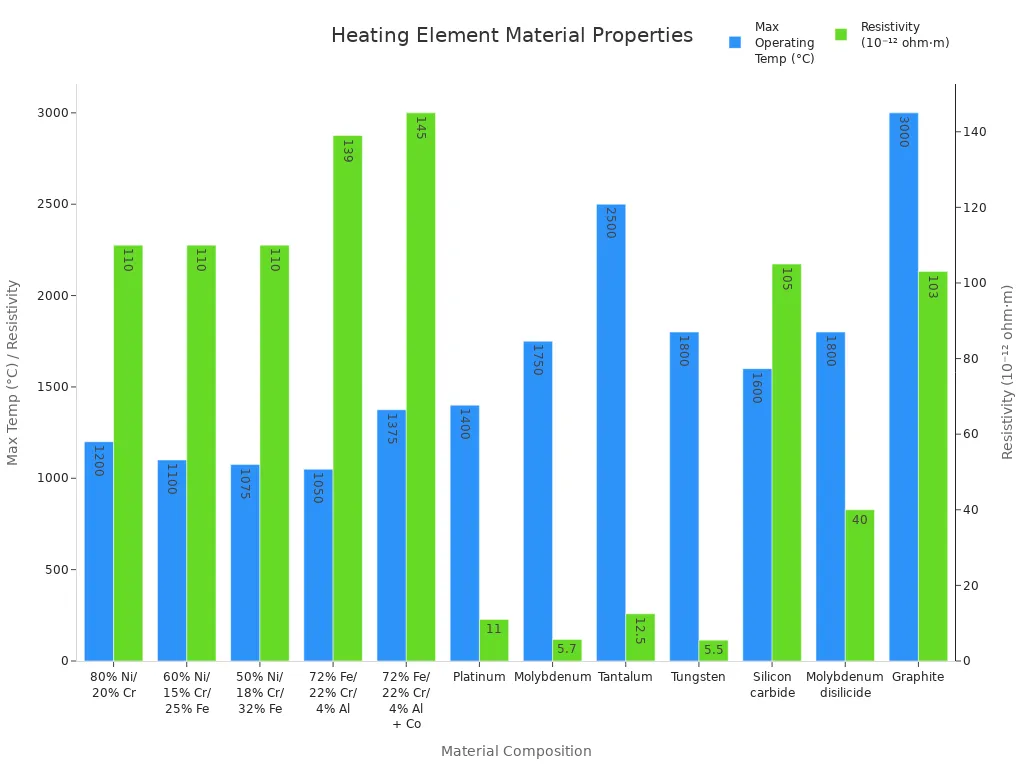

High Electrical Resistance

When you choose heating element materials, high electrical resistance stands out as a critical property. This characteristic allows electric heating elements to efficiently convert electrical energy into heat through Joule heating. Materials like nichrome and FeCrAl offer much higher resistivity than common metals such as copper. For example, nichrome alloys typically have a resistivity around 110 x10⁻¹² ohm·m, which ensures that your heating element generates significant heat for a given current. This efficiency means you get reliable performance and controlled heat output in devices ranging from toasters to industrial furnaces.

High resistance to oxidation and stable resistivity help maintain the efficiency and lifespan of heating elements, even under continuous use.

Typical Composition / Example | Max Operating Temperature (°C) | Resistivity (10⁻¹² ohm·m at 20°C) | |

|---|---|---|---|

Nickel-based alloys | 80% Ni / 20% Cr | 1200 | 110 |

Iron-based alloys | 72% Fe / 22% Cr / 4% Al | 1050 | 139 |

Refractory metals | Tungsten | 1800 | 5.5 |

Non-metallic materials | Silicon carbide | 1600 | 105 |

Heating element properties such as high resistivity and high resistance to oxidation ensure that your electrical heating elements remain efficient and durable, even at elevated temperatures.

Heat Tolerance and Melting Point

You need heating element materials that can withstand extreme temperatures without melting or degrading. The melting point and maximum operating temperature define the safe working range for high-temperature heating elements. Nichrome operates reliably up to 1200–1400°C, while FeCrAl alloys can reach 1400°C. Tungsten and molybdenum, both refractory metals, push these limits further, with melting points above 2600°C and maximum operating temperatures suitable for the most demanding applications. Silicon carbide and molybdenum disilicide also excel in high-temperature environments, making them ideal for industrial furnaces.

High resistance to oxidation and elevated melting points allow high-temperature heating elements to operate safely and efficiently in harsh industrial settings.

Материал | Максимальная рабочая температура (°C) | |

|---|---|---|

Nichrome | ~1400 | 1200 – 1400 |

FeCrAl | Н/Д | ~1400 |

Tungsten | 3422 | Up to ~3400 (vacuum/inert) |

Molybdenum | 2623 | Above 2000 |

Карбид кремния | Н/Д | ~1600 |

Selecting the right material ensures your heating element maintains structural integrity and performance, even in continuous high-heat operations.

Oxidation and Corrosion Resistance

You want your heating elements to last, especially in environments where air, moisture, or chemicals can cause rapid degradation. High resistance to oxidation is essential for maintaining the efficiency and safety of heating element materials. Nichrome and FeCrAl form protective oxide layers that shield the element from further oxidation, making them reliable for most applications. Silicon carbide and molybdenum disilicide offer even greater chemical stability and high resistance to oxidation, especially in extreme temperatures or corrosive atmospheres.

Metal/Alloy | Oxidation Resistance | Corrosion Resistance | Key Alloying Elements/Properties |

|---|---|---|---|

Stainless Steel (Alloy) | Good oxidation resistance at high temps | Good corrosion resistance due to chromium | Contains ≥10.5% chromium, nickel, molybdenum |

Nickel (Ni) (Alloy) | Exceptional oxidation resistance | Exceptional corrosion resistance | High strength, malleable, used in stainless steel and superalloys |

Silicon Carbide (SiC) | Excellent at high temperatures | Excellent chemical stability | Used in high-temperature heating elements |

Tungsten (W) | High heat resistance, oxidation resistant | Moderate corrosion resistance | Used in high-temperature, controlled atmosphere applications |

Tip: For electric heating elements exposed to harsh or oxidizing environments, always select materials with high resistance to oxidation. This choice extends the lifespan of your heating element and reduces maintenance needs.

High resistance to oxidation and corrosion ensures your heating element properties remain stable, even in challenging industrial or laboratory conditions. You benefit from longer service life, fewer failures, and safer operation when you select the right materials for your application.

Mechanical Strength and Durability

When you select a heating element, you need to consider mechanical strength and durability. These properties determine how well a material withstands physical stress, vibration, and repeated heating and cooling cycles. If you choose a material with high mechanical strength, you reduce the risk of breakage and extend the life of your heating element.

Silicon carbide heating elements stand out for their exceptional mechanical strength. Their covalent bonding structure resists deformation and mechanical shock, making them ideal for demanding environments.

This robust material reduces breakage and degradation, so you benefit from a service life that can be five to ten times longer than traditional metal heating elements.

Low thermal expansion in silicon carbide minimizes stress fractures during rapid temperature changes. You experience fewer failures and less downtime.

Because of these advantages, you replace silicon carbide elements less often and spend less time on maintenance. This durability lowers operational costs, especially in industrial settings.

Other materials, such as nichrome and FeCrAl, also offer good mechanical strength. However, they may not match the longevity of silicon carbide in harsh conditions. When you choose the right material for your application, you ensure reliable performance and reduce the frequency of replacements.

Tip: Always match the mechanical strength of your heating element material to the demands of your environment. This approach helps you avoid unexpected failures and costly repairs.

Cost and Availability

Cost and availability play a major role in your choice of heating element materials. You must balance performance, durability, and price to achieve the best results for your application. Stainless steel dominates the industrial heating element market, holding about 76% of the share. Its corrosion resistance and durability make it a top choice for industries like food processing and pharmaceuticals, even though it often costs more than other materials.

Nichrome continues to grow in popularity because it offers a strong balance between cost and performance. You get energy efficiency and reliability without a significant increase in expenses. Manufacturers and buyers face constant pressure to find cost-effective solutions, so they weigh the price of each material against its expected lifespan and maintenance needs.

Technological advancements and new materials have improved availability and reduced costs. You now have access to more energy-efficient and longer-lasting heating elements than ever before. However, using the wrong material can lead to expensive mistakes. For example, if you install a water-heating element in an oil system, you risk failure and contamination. This error can result in high costs for downtime, replacement parts, and extra labor.

When you evaluate heating element materials, always consider both the upfront cost and the long-term impact on your operations. The right material choice helps you maintain efficiency, safety, and profitability.

Nichrome Heating Elements

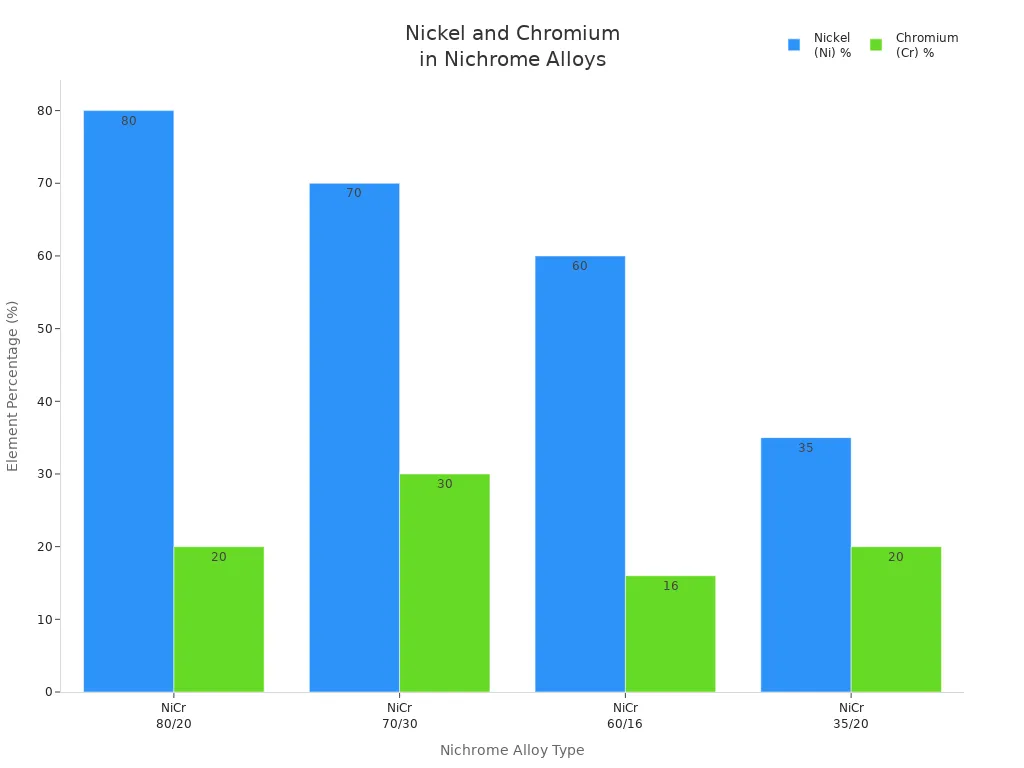

Composition of Nichrome

When you select a heating element alloy for electric heaters or industrial heating elements, Nichrome stands out as a reliable choice. This metal alloy consists mainly of nickel and chromium, with the most common ratio being 80% nickel and 20% chromium. Manufacturers may adjust the composition to suit specific heating element applications, but the NiCr 80/20 blend remains the industry standard due to its excellent performance.

Alloy | Nickel (Ni) % | Chromium (Cr) % | Iron (Fe) % |

|---|---|---|---|

NiCr 80/20 | 80 | 20 | Н/Д |

NiCr 70/30 | 70 | 30 | Н/Д |

NiCr 60/16 | 60 | 16 | 24 (approx) |

NiCr 35/20 | 35 | 20 | 45 (approx) |

You can see how the nickel and chromium content varies in different Nichrome alloys. The NiCr 80/20 composition delivers the best balance of electrical resistance, durability, and oxidation resistance for most heating element wire applications.

Properties of Nichrome Heating Element Materials

Nichrome heating element materials offer a unique combination of physical and chemical properties that make them ideal for demanding environments. You benefit from high electrical resistivity, which allows the heating element to generate heat efficiently. The chromium content forms a stable oxide layer when heated, protecting the metal alloy from oxidation and corrosion. This feature ensures long service life, even under continuous thermal cycling.

Property | Description / Value |

|---|---|

Composition | Approximately 80% nickel, 20% chromium |

Electrical Resistivity | |

Corrosion Resistance | High, due to chromium oxide layer |

Melting Point | ~1400°C |

Tensile Strength | 105,000 PSI |

Ductility | Good, allows wire to be coiled |

Stability at High Temperatures | Maintains strength and shape |

Oxidation Resistance | Excellent, forms protective oxide |

You can form Nichrome heating element wire into coils or other shapes without losing strength. Advanced manufacturing techniques, such as nanostructured designs and thin-film deposition, further improve heat distribution and efficiency. These innovations help you achieve uniform heating and reliable performance in both household and industrial heating elements.

Tip: The protective chromium oxide layer not only increases the lifespan of your heating element but also reduces maintenance needs in harsh environments.

Common Applications of Nichrome Heating Elements

You encounter Nichrome heating elements in a wide range of products, from household appliances to industrial heating systems. Its durability and consistent performance make it the preferred heating element alloy for many applications.

Application Category | Common Nichrome Heating Element Uses |

|---|---|

Household Appliances | Toasters, hair dryers, space heaters, ovens, ironing machines, water heaters, soldering irons |

Industrial Products | Furnaces, kilns, industrial heaters, metal sheathed tubular elements, cartridge elements, quartz tube heaters, infrared emitters, precision heating elements |

Other Uses | Electronic cigarettes (e-cigarettes), vaping devices |

You rely on Nichrome heating elements for their ability to withstand repeated heating cycles and maintain stable performance. In industrial heating elements, this material ensures efficient operation at high temperatures, reducing downtime and replacement costs. In household appliances, you benefit from rapid and even heating, which improves safety and user experience.

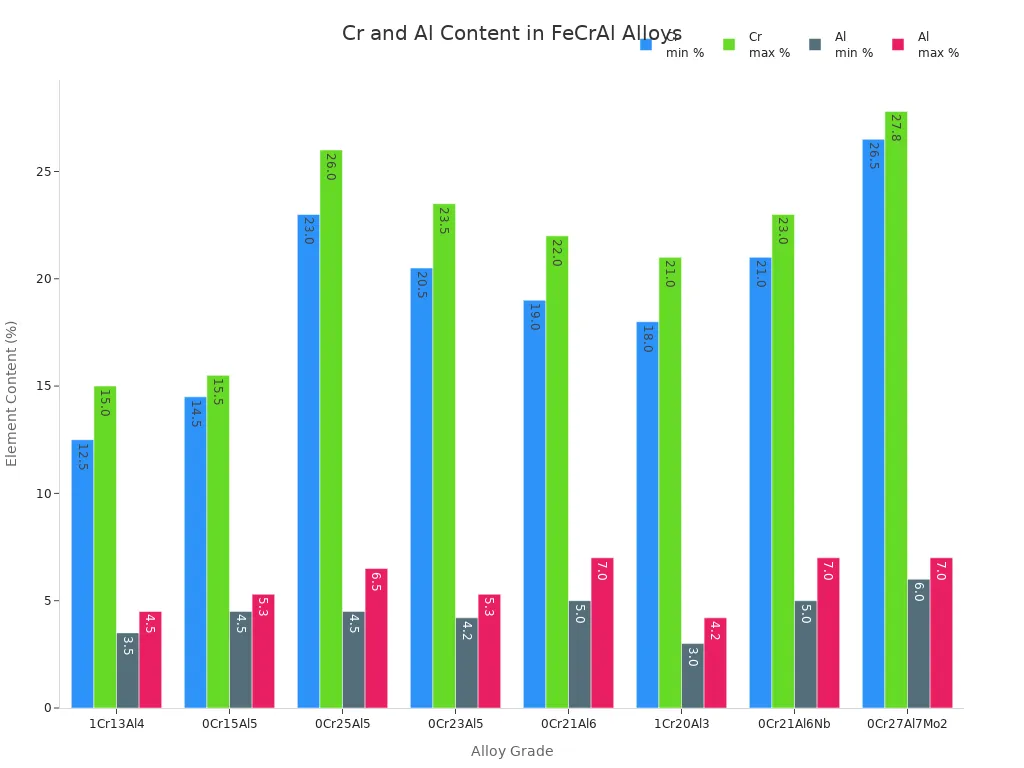

Iron-Chrome-Aluminum Heating Element Materials

What Is Iron-Chrome-Aluminum (FeCrAl)?

You often encounter Iron-Chrome-Aluminum (FeCrAl) alloys when you need reliable heating element materials for high-temperature applications. This alloy family combines iron, chromium, and aluminum as its primary components. Manufacturers adjust the composition to optimize performance for different heating element grades. The table below shows typical compositions for several FeCrAl alloys used in electric heaters and industrial heating elements:

Alloy Grade | C (max %) | P (max %) | S (max %) | Mn (max %) | Si (max %) | Cr (%) | Ni (max %) | Al (%) | Fe (balance) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|

1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | – | 3.5-4.5 | Balance | – |

0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | – | 4.5-5.3 | Balance | – |

0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Balance | – |

0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Balance | – |

0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Balance | – |

1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Balance | – |

0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Balance | Nb ~0.5% |

0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Balance | Mo 1.8-2.2% |

You can see that chromium and aluminum content varies across grades, which allows you to select the best material for your specific heating element needs.

Properties of FeCrAl Heating Elements

When you choose FeCrAl for your heating element, you gain several advantages over other materials. FeCrAl alloys deliver outstanding performance at high temperatures. You can operate these heating elements at temperatures up to 1400–1425°C, which exceeds the limits of most nickel-chromium alloys. The aluminum in FeCrAl forms a stable aluminum oxide (Al₂O₃) layer on the surface. This layer protects the material from oxidation and corrosion, even during continuous use.

The table below compares FeCrAl and Nichrome, two of the most common heating element materials:

Property | FeCrAl (Kanthal) | Nichrome |

|---|---|---|

Max Operating Temperature | Up to 1400-1425°C | Up to 1200°C |

Oxidation Resistance | Forms protective Al₂O₃ layer (superior) | Forms Cr₂O₃ layer (less robust) |

Lifespan | Longer due to enhanced oxidation resistance and stable resistivity | Shorter lifespan in high-temp environments |

Mechanical Strength | High tensile strength (500–800 MPa), good creep resistance up to ~1300°C | Softer, more malleable but less durable at high temps |

Electrical Resistivity | Higher (1.3–1.5 μΩ·m), stable over temperature | Lower, varies more with temperature |

Note: FeCrAl heating elements maintain stable resistance and mechanical strength, even after many heating and cooling cycles. This stability leads to a longer service life and fewer replacements.

You benefit from the high tensile strength and excellent creep resistance of FeCrAl, especially in demanding industrial heating elements. The material resists deformation and maintains its shape, even under heavy loads and high temperatures.

Typical Uses of FeCrAl Heating Element Materials

You find FeCrAl heating elements in many industrial and commercial applications where durability and high-temperature performance matter most. These materials excel in environments that require long service life and resistance to harsh conditions.

You use FeCrAl heating elements in immersion heating systems for molten metal, such as aluminum holding furnaces, degassing units, and die casting machines.

The material provides excellent shock resistance and stands up to aluminum alloying salts, which can damage other heating element materials.

FeCrAl radiant tubes serve in industrial heating, offering resistance to thermal shock, carburization, and distortion.

You can retrofit existing equipment with FeCrAl elements, thanks to their energy efficiency and through-the-wall mounting capability.

Furnace components made from FeCrAl deliver long life and high power ratings, making them ideal for continuous, high-demand operations.

When you select FeCrAl for your heating element, you ensure reliable performance in electric heaters, industrial heating elements, and specialized furnace systems. This choice helps you reduce downtime, lower maintenance costs, and achieve consistent results in your heating processes.

Tungsten Heating Elements

Tungsten’s Material Composition

You encounter tungsten as a pure metal in many high-temperature heating element applications. This material stands out because of its unique atomic structure and density. Tungsten has an atomic number of 74 and a density of 19.3 g/cm³, making it one of the heaviest and most robust metals you can use for heating element materials. Manufacturers often use tungsten in its pure form, but sometimes they add small amounts of potassium, thorium, or cerium to improve performance in specialized environments.

Note: Tungsten’s purity and high density contribute to its exceptional durability and thermal stability, which are essential for demanding industrial heating elements.

Properties of Tungsten Heating Elements

You benefit from tungsten’s remarkable properties when you need high-temperature heating elements. This metal offers the highest melting point among all metals, reaching approximately 3,422°C. Its low vapor pressure at elevated temperatures prevents material loss, even in vacuum or inert atmospheres. You also gain strong mechanical durability, as tungsten resists deformation under stress and maintains stability during repeated heating cycles.

Here is a summary of tungsten’s key properties:

Property | Описание |

|---|---|

High Melting Point | Withstands extreme heat without melting (~3,422°C) |

Low Vapor Pressure | Prevents evaporation and material loss at high temperatures |

High Tensile Strength | Maintains mechanical durability and resists deformation |

Electrical Resistivity | Converts electrical energy into heat efficiently |

Corrosion Resistance | Resists corrosion by molten alkali metals and steam |

Challenges | Brittle at room temperature, oxidizes above 500°C, needs vacuum/inert atmospheres |

You must take precautions when using tungsten heating elements. This material becomes brittle at room temperature and oxidizes rapidly above 500°C. To extend service life, you should operate tungsten heating elements in vacuum or inert gas environments and use controlled temperature ramping during startup.

Tip: Always use tungsten heating elements in controlled atmospheres to prevent oxidation and maximize durability.

Applications of Tungsten Heating Element Materials

You find tungsten heating elements in some of the most demanding industrial and research settings. Their ability to withstand extreme temperatures and maintain precise control makes them ideal for specialized applications.

Application Area | Описание |

|---|---|

Used in high-temperature furnaces for metal processing due to heat resistance and durability | |

Provide uniform, controlled heating for efficient thermal processing | |

Semiconductor Manufacturing | Used for heating elements and components that require stability and resistance to electromigration |

Serve as filaments in incandescent bulbs, leveraging high melting point and electrical resistance | |

Laboratory Equipment | Employed in devices needing precise temperature control, such as material science research |

Used in glass manufacturing and advanced ceramics production for their thermal stability |

You rely on tungsten heating elements for vacuum furnaces, semiconductor equipment, and laboratory devices that demand precise temperature control. In metallurgy, you use these materials for processing metals at extreme temperatures. Tungsten’s high melting point and resistance to corrosion make it a top choice for high-temperature heating elements in both research and industry.

Molybdenum Heating Element Materials

Molybdenum’s Composition

When you require heating element materials for extreme environments, molybdenum stands out for its purity and performance. Manufacturers produce molybdenum heating elements using high-purity molybdenum, with a typical purity level of at least 99.95%. This material conforms to ASTM B387 and ASTM B386 standards, ensuring consistent quality for demanding applications. You benefit from a density between 9.8 and 10.2 g/cc, which provides excellent mechanical strength and stability. The nearly pure molybdenum composition delivers high-temperature strength, low vapor pressure, and strong resistance to chemical corrosion in non-oxidizing environments. While you may encounter molybdenum disilicide (MoSi₂) heating elements for oxidation resistance, standard molybdenum heating elements rely on this high-purity metal to achieve reliable operation at temperatures up to 1900°C.

Note: The exceptional purity of molybdenum ensures that your heating element maintains its integrity and performance, even under the most challenging thermal conditions.

Properties of Molybdenum Heating Elements

You gain several advantages when you select molybdenum for your heating element. The following table highlights the key properties that influence its use in industrial heating elements and other high-temperature systems:

Property | Molybdenum (Mo) | Molybdenum Disilicide (MoSi₂) |

|---|---|---|

Maximum Operating Temp. | Up to 1900°C (requires vacuum atmosphere) | Up to 1850°C (oxidation resistant via SiO₂ film) |

Oxidation Resistance | Needs vacuum to prevent oxidation | High resistance due to protective SiO₂ glass film |

Electrical Conductivity | Moderate (34% IACS at 0°C) | Excellent electrical conductivity |

Теплопроводность | High (142 W/m·K at 20°C) | High thermal conductivity |

Mechanical Properties | Strong but brittle above 1900°C | Fragile with low mechanical shock resistance |

Application Environment | Vacuum furnaces, moderate temperature processes | High-temperature industrial heating in oxidizing atmospheres |

Thermal Stability & Cycling | Stable resistance, fast thermal cycling possible | Stable resistance, fast thermal cycling possible |

Limitations | Requires vacuum, brittle above max temp | Fragile, low shock resistance |

You notice that molybdenum offers high thermal conductivity and stable resistance, which supports rapid thermal cycling. However, you must operate these heating elements in vacuum or controlled atmospheres to prevent oxidation. Molybdenum disilicide provides an alternative for oxidizing environments, thanks to its protective silicon dioxide layer.

Uses of Molybdenum Heating Element Materials

You find molybdenum heating elements in a wide range of advanced industrial applications. Their unique properties make them indispensable in modern technology:

You use molybdenum heating elements in high-temperature industrial applications, such as vacuum furnaces for hardening and brazing, due to their high melting point and thermal stability.

Manufacturers produce these heating elements in various forms, including wire, rod, strip, and tubes, to match different heating element designs.

The excellent electrical conductivity and thermal properties of molybdenum make it ideal for use in vacuum atmospheres, where oxidation must be avoided.

Molybdenum disilicide heating elements offer oxidation resistance, rapid heating, low power consumption, and long service life, making them suitable for rapid thermal cycling and high-temperature environments.

You rely on molybdenum and its alloys as heating elements and structural materials in high-temperature furnaces, glass melting furnaces, and other components that demand high mechanical strength and resistance to ablation.

In the glass industry, you can use molybdenum as electrodes and structural parts, replacing more expensive materials like platinum and reducing production costs.

The stability and durability of molybdenum under vacuum or controlled atmospheres make it essential for modern industrial heating technologies.

Tip: Always match the heating element material to your process environment. Molybdenum excels in vacuum and controlled atmospheres, while molybdenum disilicide suits oxidizing conditions.

Silicon Carbide Heating Elements

What Is Silicon Carbide?

You encounter silicon carbide as a unique ceramic material used in advanced heating element designs. Manufacturers create these heating elements from high-resistance silicon carbide, specifically the alpha form. The process involves recrystallizing silicon carbide at elevated temperatures, which forms a dense lattice structure. This structure gives the material its strength and durability. The base material starts as green (beta) silicon carbide, a semiconductor with excess electrons that enhance electrical performance.

A typical silicon carbide heating element features a central hot zone and specialized cold ends. The cold ends contain silicon metal to lower resistance and keep temperatures manageable at the terminals. Aluminum coatings at the extreme ends provide reliable electrical connections. The result is a dense, self-bonded ceramic with tailored doping and coatings that optimize both electrical and thermal properties.

High-density structure (~2.4 g/cm³ or more)

Central hot zone for efficient heating

Cold ends with reduced resistance

Aluminum-coated contact surfaces for electrical connections

Note: The unique structure of silicon carbide heating elements allows you to achieve high performance and long service life in demanding environments.

Properties of Silicon Carbide Heating Elements

You benefit from several outstanding properties when you choose silicon carbide as your heating element material. This ceramic withstands extremely high temperatures, operating reliably from 1000°C up to 1600°C. At 1200°C, silicon carbide forms a protective oxide layer that shields the material from further oxidation. You gain excellent thermal conductivity, which ensures rapid and uniform heating.

Silicon carbide heating elements also resist thermal shock due to their low thermal expansion and high mechanical strength. The strong Si-C bonds in the crystal lattice prevent deformation and cracking, even during rapid temperature changes. You can rely on stable electrical resistance, which allows for precise temperature control over long periods.

High temperature capability (up to 1600°C)

Excellent thermal shock resistance

Strong chemical stability against acids, alkalis, and molten salts (up to 800°C)

High mechanical strength and hardness

Environmentally friendly and energy-efficient operation

Property | Benefit for Heating Elements |

|---|---|

High thermal conductivity | Rapid, uniform heating |

Low thermal expansion | Minimal deformation, high thermal shock resistance |

Chemical resistance | Withstands harsh environments |

Mechanical strength | Resists cracking and mechanical damage |

Tip: You can install and maintain silicon carbide heating elements easily, making them a practical choice for many industrial systems.

Applications of Silicon Carbide Heating Element Materials

You find silicon carbide heating elements in a wide range of high-temperature industrial applications. Their ability to operate at extreme temperatures and resist chemical attack makes them ideal for harsh environments. You often use these materials in furnaces for ceramics, glass, and metallurgy. They also serve in laboratory ovens, heat treatment equipment, and kilns.

Industrial furnaces for ceramics and glass production

Laboratory and research ovens

Heat treatment and sintering equipment

Metallurgical processing

Semiconductor manufacturing

You choose silicon carbide heating elements when you need reliable, long-lasting performance in settings where other materials might fail. Their combination of high temperature capability, chemical resistance, and mechanical durability ensures efficient operation and reduced maintenance.

Comparing Heating Element Materials

Side-by-Side Comparison of Heating Element Metals and Alloys

When you compare types of heating elements, you need to look at their core properties side by side. Each heating element material brings unique strengths to electric heaters and electric furnaces. The table below helps you quickly see how these materials perform in real-world applications:

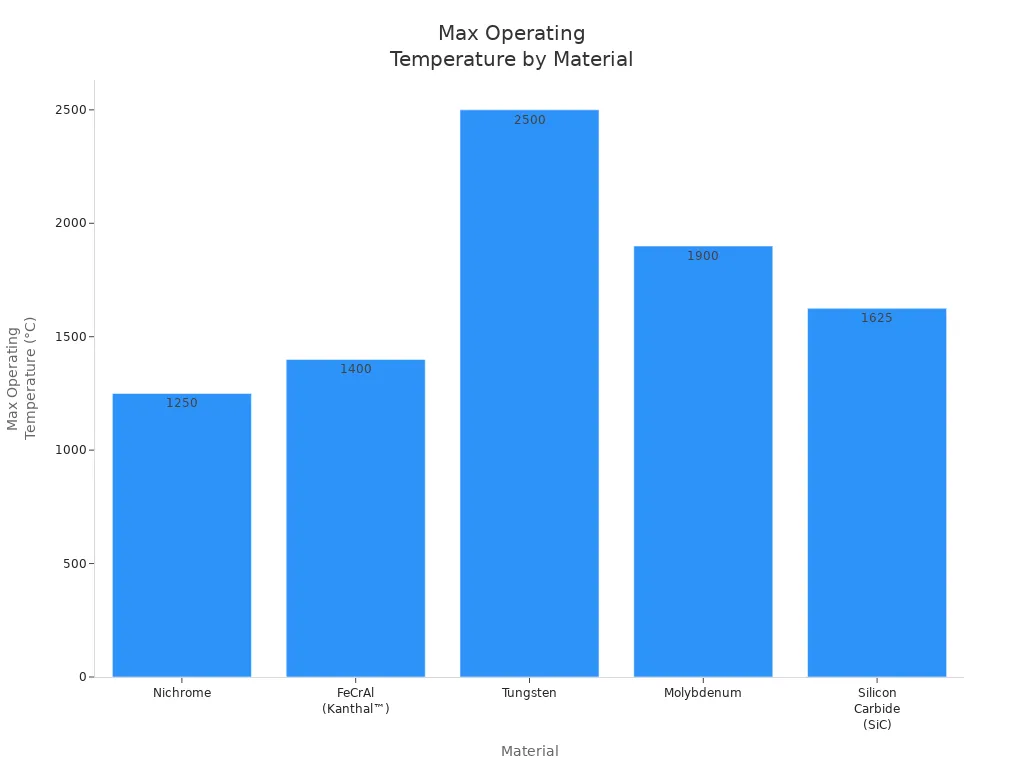

Материал | Resistivity & Corrosion Resistance | Max Operating Temperature | Key Characteristics & Applications |

|---|---|---|---|

Nichrome | High resistivity, good oxidation and corrosion | Up to 1250°C | Nickel-chrome alloy, widely used for moderate temperature heating elements |

FeCrAl (Kanthal™) | Good oxidation resistance via protective Al2O3 layer | Up to ~1400°C | Iron-chrome-aluminum alloy, lighter and longer life than Nichrome, used in higher temperature applications |

Tungsten | Very high melting point (~2500°C), high corrosion resistance | Up to ~2500°C | Refractory metal, used in controlled atmosphere high temperature applications |

Molybdenum | High melting point (~1900°C), high corrosion resistance | Up to ~1900°C | Refractory metal, suitable for vacuum or gas-protected high temperature furnaces |

Silicon Carbide (SiC) | Excellent thermal conductivity, forms protective SiO2 skin | Up to ~1625°C | Refractory ceramic, oxidation resistant in non-reducing atmospheres, brittle compared to metals |

You can see that Nichrome and FeCrAl serve best in moderate to high-temperature settings. Tungsten and molybdenum excel in extreme heat, especially in controlled atmospheres. Silicon carbide stands out for its thermal conductivity and oxidation resistance, but it is more brittle than metal options.

FeCrAl alloys can handle temperatures up to 1400°C and form a protective aluminum oxide layer that extends the life of the heating element. Silicon carbide is common in types of heating elements that reach up to 1600°C, offering both excellent thermal conductivity and oxidation resistance. Molybdenum disilicide, related to molybdenum, works well in extreme temperature applications up to 1800°C or higher. Nichrome is a cost-effective choice for lower temperature ranges. Tungsten and molybdenum are your best options for very high temperatures in electric furnaces with controlled atmospheres.

Tip: Always match the heating element material to your operating environment and temperature needs. This approach ensures safety, efficiency, and long service life.

Choosing the Right Heating Element Material

Selecting the right heating element materials depends on your specific requirements. You should consider the maximum temperature, resistance to oxidation, mechanical strength, and cost. For most household electric heaters, Nichrome offers a balance of performance and affordability. If you need longer life and higher temperature capability, FeCrAl is a strong choice.

For industrial electric furnaces that operate at extreme temperatures, tungsten and molybdenum provide unmatched durability. You should use these materials in vacuum or inert gas environments to prevent oxidation. Silicon carbide works well in high-temperature, non-reducing atmospheres, especially when you need fast, uniform heating.

When you evaluate types of heating elements, ask yourself these questions:

What is the maximum operating temperature?

Will the element face oxidizing or corrosive conditions?

Do you need high mechanical strength or flexibility?

What is your budget for initial cost and maintenance?

By answering these questions, you can select the best heating element for your application. The right choice improves efficiency, reduces downtime, and extends the lifespan of your equipment.

You have explored the essential metals and alloys that power modern heating technology. Nichrome, FeCrAl, tungsten, molybdenum, and silicon carbide each offer unique strengths, from high temperature resistance to outstanding durability. When you select the right material, you improve efficiency and extend equipment life. Always consider your application’s demands to ensure safe and reliable performance.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the most common metal used in heating elements?

You often find Nichrome as the most common metal for heating elements. Its high electrical resistance and oxidation resistance make it ideal for household appliances and industrial heaters.

Can you use stainless steel as a heating element?

You can use stainless steel for heating elements in some applications. It offers good corrosion resistance and durability. However, it does not match the efficiency or temperature tolerance of Nichrome or FeCrAl alloys.

Why do heating elements fail over time?

Heating elements fail due to oxidation, corrosion, or mechanical stress. Scale buildup and repeated heating cycles also shorten their lifespan. You can extend service life by choosing the right material for your environment.

How do you choose the right heating element material?

You should consider maximum operating temperature, resistance to oxidation, mechanical strength, and cost. Match the material to your application’s needs for best performance and safety.

Are ceramic heating elements better than metal ones?

Ceramic elements, such as silicon carbide, handle higher temperatures and resist corrosion. Metal elements, like Nichrome, offer flexibility and lower cost. Your choice depends on your temperature and durability requirements.

Can you repair a broken heating element?

You usually cannot repair a broken heating element. Replacement is the safest and most effective solution. Attempting repairs may cause safety risks or reduce efficiency.

What safety precautions should you follow with heating elements?

You should always disconnect power before handling heating elements. Avoid touching hot surfaces. Use proper insulation and follow manufacturer guidelines to prevent accidents.

Do heating element materials affect energy efficiency?

Yes, the material affects energy efficiency. High-resistance alloys like Nichrome convert electricity to heat more efficiently. Choosing the right material helps you save energy and reduce operating costs.