When you manage a modern restaurant kitchen, you rely on plate heaters and commercial food warmer units to ensure every dish reaches your guests at the perfect temperature. Top choices include the Avantco HPG-4000, Cuisinart CB-30P1, Wilprep 1200W commercial food warmer, and Cadco or Waring hot plate models. The Cuisinart CB-30P1 stands out with a 4.3-star user rating and over 1,000 units sold last month, making it a trusted electric burner for busy chefs.

| Модель | User Rating (Stars) | Number of Reviews | Units Sold Last Month | Цена |

|---|---|---|---|---|

| Cuisinart CB-30P1 | 4.3 | 4,200+ | 1,000+ | $53.99 |

You gain efficiency and reliability with these electric commercial food warmer and burner solutions.

Why Plate Heaters and Commercial Food Warmers Matter

Impact on Food Quality

You know that maintaining food quality is essential in every restaurant kitchen. Plate heaters and commercial food warmer units help you keep dishes at the right temperature, preserving texture and flavor. When you serve food at the correct temperature, you prevent rapid cooling that can lead to soggy or dried-out meals. Consistent heat also protects against bacterial growth, which is critical for food safety. In fact, maintaining temperatures above 140°F ensures that your dishes remain safe and appetizing. Advanced systems, such as sensor-based controls, automatically adjust heating to maintain precise temperatures. This technology reduces the risk of overheating or underheating, which can compromise both food quality and food safety. Regular maintenance, like monitoring water levels and cleaning, further supports optimal performance and compliance with food safety standards.

Tip: Precision temperature control systems can reduce energy consumption by up to 30%, helping you maintain food quality while saving on utility costs.

Enhancing Service Efficiency

You streamline your kitchen workflow when you use a commercial food warmer. These units allow you to hold multiple items at safe temperatures, so your staff can focus on preparation and plating. By keeping food ready for service, you reduce wait times and improve the pace of your kitchen. Remote monitoring systems let you control temperatures from a distance, which boosts operational efficiency. Insulated doors and compact electric countertop units minimize heat loss and maximize energy efficiency. You also benefit from reduced waste, as proper temperature control prevents food quality degradation. Well-maintained warmers avoid unnecessary overheating, which further improves energy efficiency and supports food safety compliance.

- The global market for energy-efficient food warming systems is projected to reach USD 4.1 billion by 2032, driven by technology and food safety emphasis.

- Sensor-based controls and remote monitoring systems enhance operational efficiency and reduce food safety risks.

- Different commercial setups, such as steam tables and hot holding cabinets, improve efficiency by reducing access time and enabling portability.

Customer Satisfaction and Experience

You deliver a better dining experience when you serve meals at the ideal temperature. Approximately 75% of consumers consider food temperature essential for meal satisfaction. Reliable plate heaters and commercial food warmer units help you meet these expectations. When you maintain food quality and ensure food safety, you build trust with your guests. In healthcare and hospitality, upgraded kitchen equipment, including food warmers, is critical for enhancing meal service quality. Compliance with food safety regulations also protects your reputation and reduces the risk of foodborne illnesses. As energy-efficient warming technologies continue to grow, you can improve both customer satisfaction and operational sustainability.

Key Criteria for Choosing Plate Heaters

Capacity and Size

You need to match the burner capacity and size to your kitchen’s workflow. Compact single-burner electric models work well in small kitchens or for tasks like warming sauces. Multi-burner units offer greater flexibility and capacity, which suits high-volume restaurants. Portability matters for food trucks and catering operations, so lightweight electric burners with sturdy handles make transport easy. Adjustable thermostats and advanced temperature control features allow you to manage food quality across different dishes.

| Evaluation Criteria | Details / Numerical Standards | Application Context |

|---|---|---|

| Burner Count | Single or double burner | Small kitchens, multitasking |

| Wattage Range | 750–1800 watts | Light to intensive cooking |

| Диапазон температур | 100°F–572°F | Gentle warming to searing |

| Size & Portability | Compact or large units | Food trucks, cafes, commercial kitchens |

| Durability & Safety | Stainless steel, auto shut-off, non-slip feet | Commercial and mobile use |

| Контроль температуры | Adjustable, manual/digital | Consistent results |

You should consider the available space and the number of dishes you need to keep warm. Plate heat exchangers provide a smaller footprint and greater scalability than traditional designs, making them ideal for kitchens with limited space.

Heating Speed and Performance

Heating speed directly impacts your kitchen’s efficiency. You want a burner that reaches the desired temperature quickly and maintains it with precise temperature control. Performance tests show that increasing the diameter of the heating rod in electric plate heaters improves airflow and reduces surface temperature spikes. Larger diameter rods can boost comprehensive performance by up to 95% compared to smaller models.

- Increasing heating power enhances overall performance, but a larger heating rod diameter has a greater effect on heating speed.

- Under the same heat flux, larger rod diameters deliver higher efficiency and faster heating.

- Steady-state power percentages and input power levels help you compare how quickly different burner models reach optimal temperatures.

You should look for electric burners that offer rapid heat-up times and stable temperature control. This ensures you maintain food quality and keep up with service demands.

Энергоэффективность

Energy efficiency remains a top priority in modern restaurant kitchens. Plate heat exchangers can deliver up to five times higher energy efficiency than shell-and-tube designs. Electric burners with advanced temperature control systems help you reduce utility costs while maintaining consistent food quality. Materials like copper and aluminum provide high thermal conductivity, which improves heat transfer and reduces energy waste.

You benefit from models that allow easy maintenance, such as plate-and-frame designs, which support long-term efficient operation. Flexible capacity adjustment lets you add or remove plates to match your current needs, optimizing both power usage and performance.

Tip: Choose electric burners with automatic shut-off and programmable temperature control to maximize energy savings and safety.

Durability and Build Quality

You need plate heaters that withstand daily use in a demanding restaurant environment. Build quality directly affects long-term performance and food safety. Manufacturers test plate heaters for thermal stability, insulation effectiveness, and the ability to maintain high temperatures over extended periods. The following table summarizes key findings from durability assessments:

| Аспект | Observations / Results |

|---|---|

| Maximum temperature reached on steel plate after 4 hours | ~549 °C (below target 600 °C due to heat loss) |

| Time to reach stable max temperature | At least 4 hours |

| Temperature difference above and below steel plate | ~142 °C (indicating heat loss challenges) |

| Heater temperature maintenance | 600 °C maintained for 3 hours in experiment |

| Insulation thickness impact | Increased insulation thickness (from 5 mm to 107 mm) improved max temperature from 398 °C to 678 °C in simulation |

| Build plate max temperature in current system | 374 °C (37.7% below target 600 °C) |

| Simulation vs. experimental temperature differences | 37 °C to 75 °C due to assumptions in convection, emissivity, and material properties |

| Insulation material (Cermex BK2100SW) performance | Simulated max temperature below insulation ~537 °C at 52% heater power, close to experimental results |

You benefit from models that use advanced insulation and robust materials. These features help maintain consistent temperature control and support food safety by reducing heat loss. Manufacturers also use accelerated artificial aging tests to predict the durability of coatings and components. These tests simulate over 10 years of use, helping you select equipment that will last and continue to meet food safety standards. Combining different verification methods and analyzing material degradation ensures that your plate heater will perform reliably throughout its service life.

Особенности безопасности

You must prioritize safety features when choosing plate heaters for your kitchen. Integrated safety mechanisms protect both your staff and your customers. Incidents involving heating appliances, such as carbon monoxide poisoning from gas units, highlight the need for built-in safety systems. Regulatory agencies have found that warnings and maintenance alone do not eliminate hazards. Modern plate heaters include features like automatic shut-off, overheat protection, and blocked vent switches. These design elements help prevent accidents and support food safety by ensuring that equipment operates within safe temperature ranges.

Failures in heat exchangers have led to catastrophic events, including fires and toxic releases. Investigations recommend inherently safer designs and rigorous hazard analysis. You should look for plate heaters that meet or exceed industry safety certifications. These certifications confirm that the equipment has passed strict testing for temperature control, electrical safety, and food safety compliance. By choosing models with advanced safety features, you reduce risks and create a safer kitchen environment.

Note: Always verify that your plate heater carries recognized safety certifications and includes essential safety features. This step is crucial for food safety and regulatory compliance.

Ease of Use and Controls

You need plate heaters that offer intuitive controls and straightforward operation. Simple interfaces allow your staff to adjust temperature control settings quickly, which helps maintain food safety during busy service periods. Digital displays, programmable timers, and clear indicator lights make it easy to monitor and adjust heating levels. These features reduce the risk of user error and help you deliver consistent results.

Many modern plate heaters include preset temperature control options for different dishes. This function streamlines workflow and ensures that food safety standards are met with every use. Easy-to-clean surfaces and removable drip trays simplify daily maintenance. When you choose equipment with user-friendly controls, you empower your team to focus on quality and efficiency.

- Look for models with large, clearly labeled dials or touch panels.

- Choose units with audible alerts for temperature changes or safety warnings.

- Select plate heaters with quick-access cleaning features to support food safety.

Maintenance and Cleaning

Proper maintenance and cleaning routines keep your plate heaters and holding cabinets running efficiently. You protect your investment and ensure food safety when you follow a consistent schedule. Start by unplugging all equipment before cleaning. This step prevents electrical hazards and keeps your staff safe.

You should clean the surfaces of your plate heaters daily. Use a soft cloth and a mild detergent to wipe away food residue and grease. Avoid abrasive pads, which can scratch the surface and reduce the lifespan of your equipment. For holding cabinets, remove all trays and racks before cleaning. Wash these components separately with warm, soapy water. Dry them thoroughly before placing them back inside.

Tip: Schedule a deep cleaning for your holding cabinets at least once a week. This practice helps prevent the buildup of grime and bacteria.

Inspect the heating elements on your plate heaters regularly. Look for signs of wear, such as discoloration or uneven heating. If you notice any issues, replace the element promptly to maintain consistent performance. For holding cabinets, check the door seals and hinges. Damaged seals can cause heat loss and reduce energy efficiency. Lubricate hinges as needed to ensure smooth operation.

You should also pay attention to ventilation. Dust and debris can accumulate in vents and fans, leading to overheating. Use a vacuum or a soft brush to clean these areas every month. This step helps your equipment maintain optimal airflow and prevents unexpected shutdowns.

Create a maintenance log for your kitchen. Record each cleaning session and any repairs or part replacements. This log helps you track the condition of your plate heaters and holding cabinets over time. It also supports compliance with health and safety regulations.

| Задача по обслуживанию | Frequency | Tools Needed |

|---|---|---|

| Surface cleaning | Daily | Soft cloth, detergent |

| Deep cleaning (cabinets) | Weekly | Soapy water, sponge |

| Heating element check | Monthly | Visual inspection |

| Ventilation cleaning | Monthly | Vacuum, brush |

| Seal and hinge inspection | Monthly | Lubricant, cloth |

By following these steps, you extend the life of your plate heaters and holding cabinets. You also create a safer and more efficient kitchen environment.

In-Depth Reviews of the Best Plate Heaters

Best Overall Plate Heater: Avantco HPG-4000

Pros

- You benefit from a robust stainless steel construction that withstands daily commercial use.

- The unit features a high-wattage electric burner, delivering rapid heat-up and consistent temperature maintenance.

- Adjustable temperature controls allow you to fine-tune the heat for different dishes, supporting both delicate and hearty menu items.

- The spacious surface accommodates multiple plates, making it suitable for busy service periods.

- Safety features, such as overheat protection and non-slip feet, help you maintain a secure kitchen environment.

Cons

- The larger footprint may not fit well in compact kitchens or food trucks.

- The higher power consumption can increase your utility costs if you do not monitor usage closely.

- The unit requires regular cleaning to prevent buildup on the heating surface.

Ideal Use Cases

You should choose the Avantco HPG-4000 if you operate a mid- to high-volume restaurant that demands reliable plate heaters. This model excels in environments where you need to keep several plates warm simultaneously, such as banquet halls, hotel kitchens, or catering operations. The adjustable controls and durable build make it a versatile choice for a range of cuisines and service styles.

Best for High Volume Kitchens: Wilprep 1200W Commercial Food Warmer

Pros

- Сайт Wilprep 1200W commercial food warmer uses a stainless-steel U-shaped heating tube. You get rapid and uniform heating, which keeps dishes fresh and ready for extended periods.

- You can precisely control the temperature from 0°F to 200°F using the built-in ThermoProbe and control knob. This flexibility supports a wide variety of food types.

- Superior heat retention comes from an insulating ceramic fiber layer. You maintain warmth efficiently and minimize electricity consumption.

- The large 12×20 inch countertop design fits GN 1/1 pans, giving you generous storage and service capacity.

- ETL certification and high-grade stainless steel construction ensure reliability, corrosion resistance, and easy maintenance.

Cons

- The unit’s size may limit placement options in smaller kitchens.

- The initial investment is higher than some entry-level electric burner models.

- You need to monitor water levels and clean the unit regularly to maintain optimal performance.

Ideal Use Cases

You should select the Wilprep 1200W commercial food warmer if you manage a high-volume kitchen, such as a cafeteria, buffet, or institutional dining facility. The large capacity and precise temperature control make it ideal for holding multiple dishes at safe serving temperatures throughout long service periods. The robust construction and energy-efficient design support continuous operation in demanding environments.

Tip: For best results, use the Wilprep with compatible GN 1/1 pans to maximize storage and streamline your workflow.

Best for Energy Efficiency: Electric Infrared Hot Plate

Pros

- Infrared technology allows you to convert nearly 100% of electricity into heat, minimizing energy waste.

- You can achieve up to 30% greater energy efficiency compared to traditional heating systems. The direct heat transfer targets plates and food, not the surrounding air.

- The electric infrared hot plate outperforms fan and radiant heaters in both energy consumption and heat output.

- You can pair this hot plate with renewable energy sources, such as solar panels, for near carbon-neutral operation on sunny days.

- Over a 10-year period, you may realize heating cost savings of up to 60%.

Cons

- Real-world power consumption varies depending on room size, insulation, and external temperature.

- The lack of a specific energy efficiency rating for this model can make direct comparisons challenging.

- You may need to adjust your workflow, as infrared burners heat differently than conventional electric burners.

Ideal Use Cases

You should consider the electric infrared hot plate if you prioritize sustainability and long-term cost savings. This model suits restaurants aiming to reduce their carbon footprint or those with access to renewable energy. The efficient burner design works well in kitchens where energy costs are a concern and where you want to maintain consistent plate temperatures with minimal waste.

Note: For optimal efficiency, use the infrared hot plate in well-insulated spaces and monitor your power usage regularly.

Best Budget Option: Cuisinart CB-30P1 Cast-Iron Single Burner

Pros

You gain significant value with the Cuisinart CB-30P1 Cast-Iron Single Burner. This electric burner offers a compact design that fits easily on any countertop. The heavy-duty cast-iron plate distributes heat evenly, so you achieve consistent results with every use. You can adjust the temperature using a simple control knob, which gives you flexibility for different cooking and warming tasks. The indicator lights show when the burner is on or ready, which helps you manage your workflow safely. The non-slip feet keep the unit stable during busy service hours. Cleaning is straightforward because the smooth surface wipes clean with minimal effort.

- Compact size saves space in crowded kitchens.

- Durable cast-iron plate ensures even heating.

- Adjustable temperature control supports a range of dishes.

- Indicator lights improve safety and usability.

- Non-slip feet provide stability on any surface.

- Easy-to-clean design reduces maintenance time.

Cons

You may find some limitations with this electric burner. The single-burner configuration restricts you to one task at a time, which can slow down your workflow during peak hours. The heat-up time is slower compared to high-wattage commercial plate heaters. The unit lacks advanced features such as digital temperature displays or programmable timers. The power cord length may limit placement options in larger kitchens. The cast-iron surface requires regular cleaning to prevent residue buildup.

- Single burner limits multitasking.

- Slower heat-up compared to commercial models.

- No digital controls or timers.

- Shorter power cord may restrict placement.

- Requires frequent cleaning for optimal performance.

Ideal Use Cases

You should choose the Cuisinart CB-30P1 if you operate a small café, food truck, or need a backup burner for your main kitchen. This model works well for warming sauces, holding side dishes, or preparing single servings. You benefit from its portability and ease of use when you need an extra electric burner for catering events or pop-up kitchens. The affordable price makes it a smart choice for startups or kitchens with limited budgets. You can also use it as a dedicated warming station for desserts or appetizers during busy service periods.

Tip: Use the Cuisinart CB-30P1 as a supplemental burner during high-volume events to keep your workflow smooth and efficient.

Best for Compact Spaces: Best Portable Electric Burners (Cadco/Waring)

Pros

You maximize your workspace with the best portable electric burners from Cadco and Waring. These models feature slim profiles and lightweight construction, so you can move them easily between prep stations or service areas. The electric heating elements deliver rapid and reliable performance, making them suitable for both cooking and warming. You can select from single or double burner configurations to match your kitchen’s needs. The stainless steel housing resists corrosion and stands up to daily use. Simple controls allow you to adjust the temperature quickly, which helps you maintain precise heat for a variety of dishes. The compact footprint fits on crowded countertops or in mobile setups.

- Slim, lightweight design enhances portability.

- Electric elements provide fast, consistent heating.

- Available in single or double burner options.

- Durable stainless steel construction.

- Easy-to-use temperature controls.

- Fits in tight spaces or mobile kitchens.

Cons

You may encounter some drawbacks with these portable electric burners. The smaller size limits the number of pans you can use at once. The surface area may not accommodate large pots or multiple dishes. Some models lack advanced safety features such as automatic shut-off or overheat protection. The power output is lower than that of full-size commercial plate heaters, which can affect performance during peak service. The cord length may also restrict placement in larger kitchens.

- Limited cooking surface for large pans.

- Fewer advanced safety features.

- Lower power output than commercial units.

- Cord length may limit flexibility.

- Not ideal for high-volume, continuous use.

Ideal Use Cases

You should select Cadco or Waring portable electric burners if you need flexible heating solutions in a compact kitchen. These models excel in food trucks, concession stands, or as temporary stations during catering events. You can use them to keep sauces, soups, or side dishes warm without taking up valuable counter space. The best portable electric burners also serve as excellent backup units during equipment maintenance or unexpected surges in demand. Their portability allows you to adapt quickly to changing kitchen layouts or service requirements.

Note: For best results, use portable electric burners in well-ventilated areas and monitor them during extended use to ensure safety.

Comparison Table of Top Plate Heaters and Hot Plates

Key Features Overview

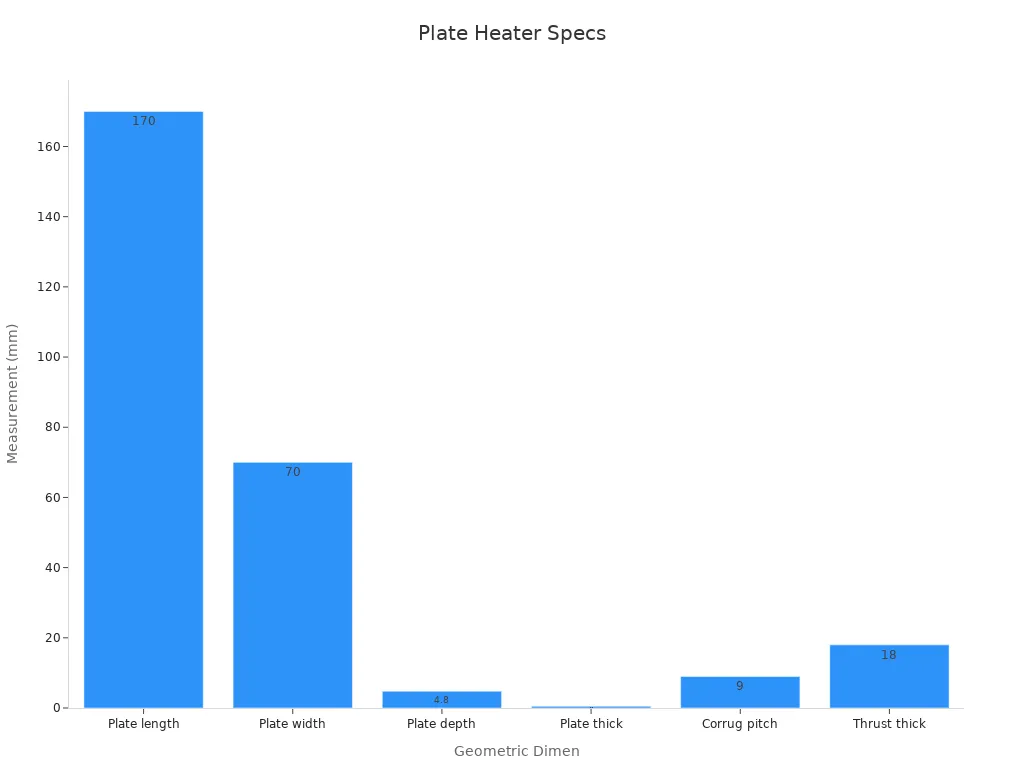

When you compare plate heaters and hot plates for your restaurant, you need to focus on technical specifications that impact daily operations. The following table summarizes essential features and dimensions that influence heat transfer, durability, and usability:

| Feature/Specification | Value/Description |

|---|---|

| Number of plates | 28 corrugated plates |

| Plate length (L) | 170 mm |

| Plate width (W) | 70 mm |

| Plate depth (2bc) | 4.8 mm |

| Plate thickness (δ) | 0.5 mm |

| Cumulative heat transfer area (A) | 0.378 m² |

| Surface enlargement ratio | 1.13 |

| Corrugation angle (β) | 60 degrees |

| Corrugation pitch (t) | 9 mm |

| Thrust plate minimum thickness | 18 mm |

| Gasket technology | Three-channel gasket |

| Bolt and support length ratio | 1.6 times the assembly components length |

| Materials | As per technical specification document EK.1 |

You benefit from these geometric and material specifications because they ensure stable heat transfer and operational reliability. The chart below visually represents the geometric measurements, helping you understand the scale and proportions of a typical plate heater:

Modern plate heaters offer several advanced features:

- You maintain consistent temperature across the entire surface, which prevents dew condensation and frost.

- High transparency (over 98% transmittance) supports applications where visibility matters.

- You can apply these heaters to flat, curved, or semi-circular surfaces.

- Customizable maximum generated temperatures reach up to 350 °C, depending on the substrate.

- Even heat distribution eliminates visibility flaws and ensures uniform heating.

You also gain from active temperature control systems, which use non-contact sensors for precise regulation. Some models reach up to 400 °C and offer rapid heating rates, up to 30 °C per minute. Environmental controls, such as heated purge gas, prevent sample degradation and support food safety. Smart design features, like interchangeable geometries and integrated sensors, further enhance operational flexibility.

Performance and Value Comparison

You need to evaluate plate heaters and commercial food warmer units not only by their technical features but also by their real-world performance and value. Several factors influence your decision:

- Different models use materials like copper or polypropylene. Copper provides high thermal conductivity and durability, but comes at a higher cost and environmental impact. Polypropylene is more affordable and recyclable, but less efficient.

- Double-glazing collectors achieve about 17.3% efficiency, outperforming single glazing at 14.6%. Polypropylene collectors reach only 8.1% efficiency.

- High-quality materials, such as tempered glass and selective coatings, maintain efficiency over time, justifying a higher initial investment.

- Seasonal and geographical factors affect performance, so you should adapt your choice to local conditions.

- Economic and technical key performance indicators (KPIs) help you optimize your selection for both cost and operational needs.

- Environmental sustainability assessments highlight the trade-offs between efficiency and ecological footprint.

You can use new evaluation methods, such as FTDPD and ΔP, to assess the cost-effectiveness and efficiency of your plate heater or hot plate. These methods allow you to test under various conditions with fewer resources, reducing both evaluation costs and time.

Tip: When you select a commercial food warmer or electric burner, consider not only the upfront price but also the long-term savings from higher efficiency and lower maintenance needs. High-quality materials and advanced temperature control systems often deliver better value over the lifespan of your equipment.

By comparing these features and performance metrics, you ensure that your kitchen operates efficiently, safely, and sustainably.

Practical Tips for Buying and Using Plate Heaters

Assessing Your Kitchen’s Needs

You should start by evaluating your kitchen’s unique requirements before selecting a plate heater or burner. Every kitchen operates differently, so a careful assessment helps you choose equipment that supports food safety and efficiency. Consider these steps:

- Review your daily kitchen operations to spot bottlenecks or inefficiencies that affect service speed or food safety.

- Gather feedback from your staff through interviews or surveys. They often notice workflow issues that impact temperature control and food safety.

- Use workflow mapping tools, such as flowcharts or simulation software, to visualize how dishes move from preparation to service.

- Study your kitchen layout. Focus on the work triangle, zone planning, and space-specific solutions to optimize movement and reduce staff fatigue.

- Align your kitchen design with your cuisine type and service style. Quick service restaurants may need different burner setups than full-service establishments.

- Make small adjustments, like rearranging equipment or adjusting station heights, to improve comfort and efficiency.

- Cross-train your staff and streamline your supply chain. These steps can indirectly influence how well your burner and electric equipment fit your workflow.

- Evaluate your kitchen size, power requirements, and cooking volume. This information guides you in selecting the right electric burner or portable electric burners.

- Integrate technology, such as kitchen display systems or digital checklists, to improve communication and workflow.

By following these steps, you ensure that your plate heater supports both food safety and operational efficiency.

Installation Best Practices

Proper installation of your plate heater or electric burner is essential for safe and efficient operation. You should always read the manufacturer’s instructions before starting. Place your burner on a stable, heat-resistant surface away from flammable materials. Ensure there is enough space around the unit for ventilation and easy access. Position the burner close to your main prep or plating area to minimize movement and maintain temperature control.

Check that your electrical outlets meet the power requirements of your burner. Avoid using extension cords, as they can cause overheating and pose a food safety risk. Secure all cords to prevent tripping hazards. If you install multiple burners, keep them spaced apart to prevent overheating and allow for safe cleaning. For portable electric burners, choose locations that allow for quick relocation if your workflow changes.

Tip: Schedule a professional inspection of your kitchen’s electrical system before installing new electric burners. This step helps you avoid power overloads and supports food safety compliance.

Daily Operation Tips

You can maximize the performance and lifespan of your plate heater by following a few daily practices. Always preheat your burner before placing plates or food on it. This step ensures consistent temperature control and supports food safety. Use the adjustable controls to set the correct temperature for each dish. Monitor the burner during service to prevent overheating or underheating.

Clean the surface of your burner after each use. Remove food residue and spills to maintain hygiene and prevent buildup that can affect food safety. Inspect the heating elements regularly for signs of wear or damage. Replace any faulty parts immediately to avoid disruptions in service.

Rotate your burners if you use multiple units. This practice distributes wear evenly and extends the life of your equipment. Keep a log of cleaning and maintenance activities. This record helps you track performance and supports food safety audits.

Note: Consistent cleaning and careful monitoring of your electric burner help you maintain high standards of food safety and service quality.

Cleaning and Maintenance Guidelines

You maintain high standards of food safety when you follow a strict cleaning routine for every burner and holding cabinets in your kitchen. Start each day by wiping down the burner surfaces with a soft, damp cloth. Remove any food residue or grease immediately to prevent buildup that can compromise food safety. For holding cabinets, empty all trays and racks before cleaning. Wash these components with warm, soapy water and dry them thoroughly before returning them to service.

A weekly deep cleaning schedule helps you extend the life of your burner and holding cabinets. Unplug each burner before cleaning to avoid electric shock. Use a non-abrasive cleaner on the burner surface and check for any signs of wear or discoloration. Inspect the power cords for fraying or damage, as this can pose a risk to both food safety and kitchen operations. For holding cabinets, clean the door seals and hinges to ensure a tight fit and efficient heat retention.

Tip: Keep a maintenance log for each burner and holding cabinets. Record every cleaning session and any repairs. This habit supports food safety audits and helps you track equipment performance.

Monthly, check the heating elements in your burner for signs of uneven heating or corrosion. Replace any faulty parts promptly to maintain consistent temperature control. Clean the ventilation areas of your holding cabinets to prevent dust buildup, which can affect both performance and food safety. Always use manufacturer-recommended cleaning products to avoid damaging sensitive components.

A clean burner and well-maintained holding cabinets not only support food safety but also improve energy efficiency and reduce the risk of equipment failure during peak service.

Safety Precautions

You protect your staff and guests by following essential safety precautions when operating any burner or holding cabinets. Safety audits highlight several hazards, including burns from high temperatures, electric shock from damaged cords, and fire risks—especially with older burner models. Always select equipment certified by recognized testing laboratories, such as UL or other NRTL marks. Inspect each burner before use and remove any damaged units from service.

The table below summarizes key safety guidelines for burner and holding cabinets operation:

| Category | Key Findings and Guidelines |

|---|---|

| Hazards | Burns (up to 500°C), electric shock, fire risks |

| Equipment Selection | Use only NRTL-certified burners; inspect before use; remove damaged units |

| Operation Controls | Keep cords away from hot surfaces; turn off when not in use; minimize unattended heating; use medium heat settings |

| Engineering Controls | Use thermostat controls; clamp probes securely; consider blast shields for hazardous operations |

| Administrative Controls | Monitor temperature; use timers; label controls; never leave heating unattended |

| PPE | Wear lab coat, safety glasses, heat-resistant gloves, closed-toe shoes |

| Known Safety Issues | Older models may lack temperature feedback; moisture or corrosives increase risk |

| Best Practices | Assess hazards before heating; avoid heating closed systems without pressure controls; use secondary containment for flammables |

You should always use heat-resistant, crack-free glassware with your burner. Make sure the burner surface exceeds the size of the vessel to prevent spills. Never leave a burner or holding cabinets unattended during operation. Keep all cords away from hot surfaces and ensure the area around each burner remains clear of flammable materials.

Wear appropriate personal protective equipment, including heat-resistant gloves and closed-toe shoes, when handling hot plates or trays from holding cabinets. Regularly review your kitchen’s safety protocols and update them as new equipment or procedures are introduced. By following these guidelines, you create a safer environment and uphold the highest standards of food safety in your restaurant.

You now have a clear overview of the best plate heaters and commercial food warmers for modern restaurant kitchens. Focus on models like the Avantco HPG-4000, Wilprep 1200W, Cuisinart CB-30P1, and Cadco/Waring burners. Prioritize these features:

- Rapid, even heating

- Durable construction

- Energy efficiency

- User-friendly controls

Select a plate heater that matches your kitchen’s workflow and volume. The right choice will help you deliver consistent quality and keep your service running smoothly.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the main benefit of using a plate heater in a restaurant kitchen?

You keep food at the ideal serving temperature. This helps you maintain food quality and safety. Warm plates also prevent dishes from cooling too quickly, which improves your guests’ dining experience.

How do you choose the right size plate heater for your kitchen?

You should assess your kitchen’s space and service volume. Select a model that fits your countertop and matches your average number of plates per service. Compact units work well for small kitchens, while larger models suit high-volume operations.

Are plate heaters energy efficient?

Many modern plate heaters use advanced insulation and temperature controls. You can reduce energy waste by choosing models with automatic shut-off and programmable settings. Energy-efficient designs help you lower utility costs and support sustainability goals.

How often should you clean your plate heater?

You should clean the surface daily and perform a deep cleaning weekly. Regular maintenance prevents residue buildup and supports food safety. Always unplug the unit before cleaning to avoid electrical hazards.

Can you use a plate heater for other tasks besides warming plates?

Yes, you can use some plate heaters to keep side dishes, sauces, or appetizers warm. Always check the manufacturer’s guidelines to ensure safe and proper use for different food items.

What safety features should you look for in a plate heater?

Look for automatic shut-off, overheat protection, and non-slip feet.

Choose models with safety certifications from recognized testing agencies.

These features help you protect your staff and maintain a safe kitchen environment.

Do portable electric burners work well for catering or food trucks?

You benefit from their compact size and easy transport. Portable electric burners provide reliable heat for off-site events, food trucks, or pop-up kitchens. Always ensure you have access to proper electrical outlets for safe operation.