An electric heating element is a tool that turns electricity into heat. It does this using electrical resistance. You can find it in space heaters and big machines. Its main job is to give steady and useful heat for many uses.

Today, more people want these heating elements. In 2023, the market was worth $7.5 billion. By 2032, it might grow to $12.1 billion, rising 5.5% each year. This growth shows the need for smart and eco-friendly heating in homes, businesses, and factories.

Основные выводы

- Electric heating elements turn electricity into heat efficiently. They help lower energy costs.

- These elements are flexible and work in many areas, like homes or factories.

- Electric heating elements are safe. They don’t cause gas leaks or release harmful fumes.

- Picking the right element means looking at wattage, material, and size for your needs.

- Cleaning and checking for damage often can make them last longer.

What Are Electric Heating Elements?

Definition and Basic Concept

An electric heating element changes electricity into heat energy. It works by using electrical resistance. This happens when electricity meets resistance in the material, creating heat. Think of it as the main part of many heaters, like toasters or factory furnaces.

These elements give steady and easy-to-control heat. They are popular because they work well and can be used in many ways. For example, electric film heating systems are a type of these elements. In 2023, their market value was $1.2 billion. By 2032, it may grow to $2.5 billion. This is because people want heating that saves energy and cuts costs. This growth shows how important these elements are for saving energy and money.

Key Components of an Electric Heating Element

Electric heating elements have several important parts. Each part helps them work well. Here’s a simple look at these parts:

| Part Name | What It Does | Extra Info |

|---|---|---|

| Power Density | Shows heat made per square millimeter or inch | Lower density costs more but lasts longer than higher density. |

| Провод сопротивления | Thin, round wires that resist electricity, measured by wire size | Size is often checked using American Wire Gauge (AWG). |

| Resistance Ribbon | Flat wires with a rectangle shape | Heats faster and costs less due to its larger surface area. |

| Life Expectancy | Lasts 500 to 5000 hours based on how it’s used | Thinner wires or ribbons wear out faster at high heat. |

| Standardized Tests | Rules by ASTM International for testing heating materials | Special tests check how well materials handle heat over time. |

The resistance wire or ribbon is the main part that makes heat. The material, like nickel-chromium, affects how well it works and lasts. Power density shows how much heat it can make. Life expectancy tells how long it will last. Tests make sure these parts work well in different situations.

By learning about these parts, you can see how electric heating elements give accurate and efficient heat for many uses.

How Do Electric Heating Elements Work?

The Science Behind Heat Generation

Electric heating elements turn electricity into heat energy. This happens because of Джоулев нагрев, named after James Prescott Joule. When electricity moves through a material that slows it down, heat is made. Imagine water flowing through a tight pipe—it creates friction and heat. In the same way, resistance in the heating element makes warmth.

The material in the heating element is very important. Most are made from нихром, a mix of nickel and chromium. This material resists electricity well and handles high heat without breaking. It’s used in things like toasters, ovens, and big heaters because it lasts a long time.

Fun Fact: The glowing red wires in your toaster are электрические нагревательные элементы! They heat up because of resistance, turning bread into toast.

Electrical Resistance and Heat Transfer

Resistance is how electric heating elements make heat. It slows down electricity, like a roadblock. When electrons hit atoms in the material, they make heat. This heat spreads out and warms the area around it.

Three things affect how much heat is made:

- The material’s resistance: More resistance means more heat.

- The current flowing through the element: More current makes more heat.

- The time electricity flows: Longer use builds up more heat.

Heat moves in three ways: conduction, convection, and radiation. Most heating elements use conduction. Heat spreads from the element to nearby surfaces, like a stove or the air. Some, like infrared heaters, use radiation to warm objects directly.

Совет: Pick the right heating element for your needs. Infrared ones are good for focused heat, while convection ones warm bigger spaces.

These ideas show why electric heating elements work so well. They use science to give steady and easy-to-control heat for many uses.

Benefits of Electric Heating Elements

Energy Efficiency and Cost-Effectiveness

Electric heating elements use energy very efficiently. They turn almost all electricity into heat, wasting little energy. This helps lower your energy bills, making them a smart choice. Unlike older systems, they need less upkeep, saving money over time.

For instance, using electric heating at home can cut heating costs by 30%. They also control temperature well, avoiding overheating and saving more energy. With this technology, you get steady warmth while spending less.

Versatility in Applications

Electric heating elements can be used in many ways. They work in homes, factories, and other places. Here are some examples:

| Sector | Uses |

|---|---|

| Промышленный | Melting, drying, curing |

| Residential | Heating water and rooms |

| Коммерческий | Ovens, warmers, HVAC systems |

| Medical | Sterilizers, incubators |

| Agricultural | Greenhouse heating, pipeline de-icing |

| Electronics | Soldering, reflow ovens |

| Automotive | Drying and paint curing |

You can use them to heat greenhouses, sterilize tools, or warm your house. Their flexibility makes them useful in many industries.

Safety and Environmental Advantages

Electric heating elements are safer and better for the environment. They don’t have gas leaks or flames, making them safer to use. They also don’t release harmful gases, which helps the planet.

Studies show electric heating is cleaner than gas systems. For example:

- China’s Electric Heating Policy improved air for millions.

- But it raised carbon emissions to 101–162 megatons in 2015.

- By 2020, emissions could grow to 130–198 megatons.

Even with these issues, electric heating is still better for the environment than fossil fuels. Choosing them helps create a safer and greener future.

Types of Electric Heating Elements

Wire Heating Elements

Wire heating elements are very common in electric heaters. They use wires made from materials like nichrome to make heat. These wires are shaped into coils or stretched to spread heat better. The design depends on wire thickness, resistance, and coil size. Thin wires heat quickly but wear out faster. Thick wires last longer but need more energy.

Wire heating elements are used in many things like toasters, hair dryers, and factory furnaces. They can handle high heat, making them great for places needing steady warmth. Safety rules help improve their design and performance.

Керамические нагревательные элементы

Ceramic heating elements use ceramic materials to create heat. They spread heat evenly and work at lower temperatures than wire elements. This makes them good for things needing exact temperature control, like space heaters or medical tools.

Ceramic elements are strong and don’t crack with quick temperature changes. They save energy and last a long time, making them popular for homes and factories. Their design prevents overheating, making them safer to use.

Infrared Heating Elements

Infrared heating elements warm objects directly using radiation instead of heating air. They focus heat on specific spots, wasting less energy. Studies show their heat spreads in a curved pattern. For example, heat is strongest close to the heater and weaker farther away.

Infrared elements are great for jobs needing focused heat, like drying paint or warming outdoor areas. They heat quickly and are used in industries like car-making and construction. Designers use heat maps to make these systems work better.

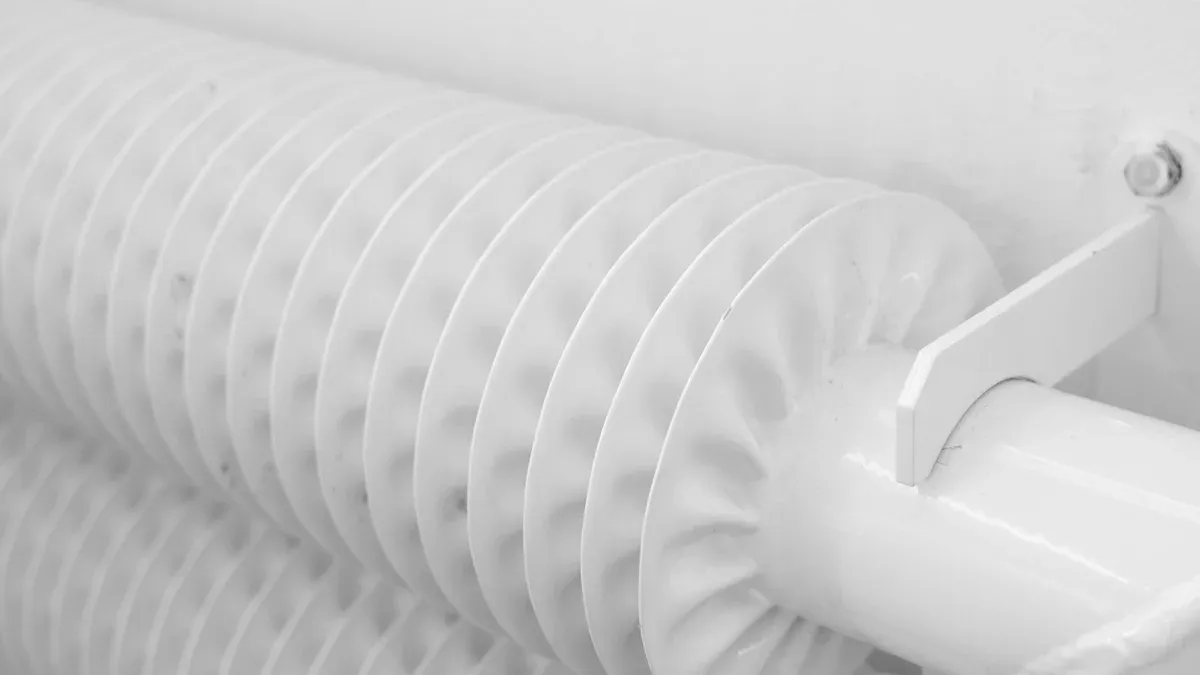

Tubular Heating Elements

Tubular heating elements are strong and work in many ways. They have a metal tube with a resistance wire inside. Around the wire is insulating material, like magnesium oxide. The metal tube keeps the parts safe and helps spread heat well.

These elements are used in many things. You can find them in water heaters, ovens, and factory machines. They are tough and handle high heat and rough conditions. This makes them great for hard jobs.

Did You Know? Tubular heating elements can be shaped into coils or loops. This lets them fit different heating needs, from simple to custom designs.

When picking a tubular heating element, think about the outer tube material, heat level, and where it will be used. Stainless steel and Incoloy are good choices. They don’t rust and work well with high heat.

Tubular heating elements save energy. They send heat straight to what they touch, wasting less energy. Whether you need to heat air, liquids, or solids, these elements work well and last long.

Knowing how tubular heating elements work helps you choose the right one. They show how electric heating can be both strong and efficient.

Applications of Electric Heating Elements

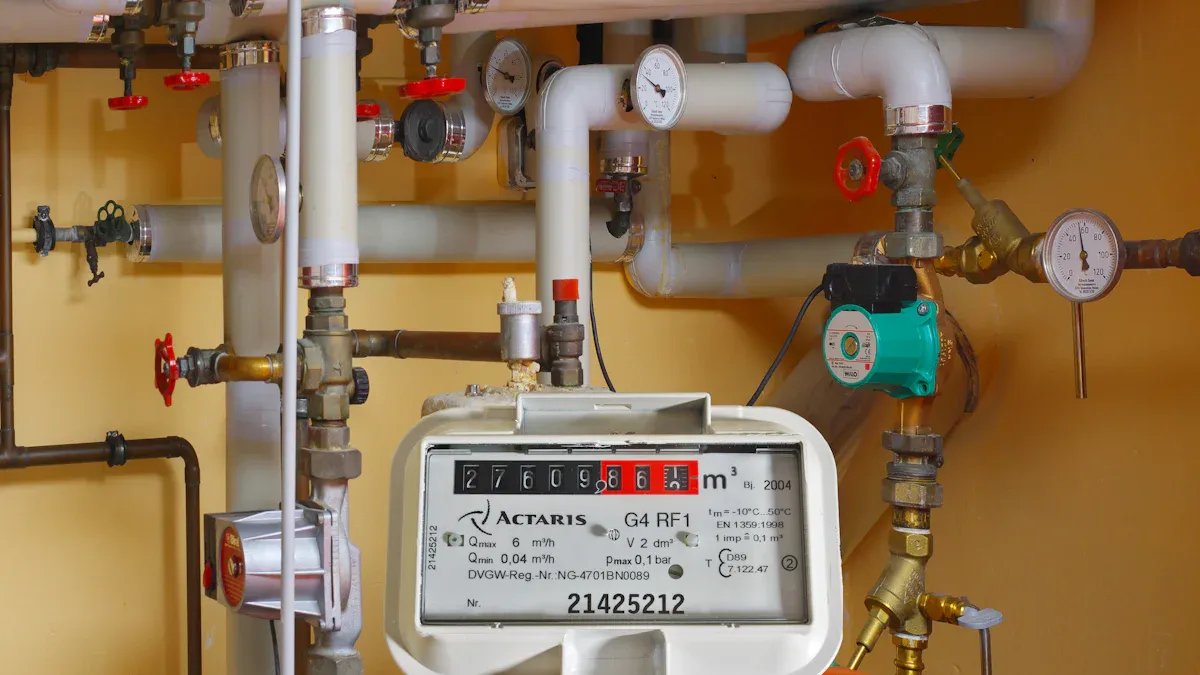

Residential Heating Systems

Electric heating elements help keep homes warm and cozy. They are found in water heaters, space heaters, and ovens. These elements give steady heat, making them a favorite for modern homes. With smart home tech, you can control them from anywhere to save energy.

The need for better home heating keeps growing. Energy-saving designs and smart tech are driving this change. For example, water heaters now use electric heating elements that need less energy but work just as well. This lowers your bills and helps the planet.

Industrial Processes

In factories, электрические нагревательные элементы are very important. They are used in making metal, shaping plastic, and processing food. These elements keep temperatures exact, which is key for quality and safety. For example, silicon carbide elements are great for metalwork because they handle heat changes well.

Manufacturing uses the most industrial heating elements, making up 44.3% of sales. Factories trust these elements because they are reliable and save money. In medicine, molybdenum disilicide elements melt glass at over 2000°C. These uses show how flexible and useful electric heating elements are.

| Тип нагревательного элемента | Industry Use | Main Benefits |

|---|---|---|

| Silicon Carbide Heating Elements | Metal Work | Handles heat changes, precise temperature |

| Molybdenum Disilicide Heating Elements | Glass Making | Works at 2000°C+, melts glass efficiently |

Consumer Appliances

Electric heating elements are in many gadgets you use daily. Toasters, coffee makers, washers, and dishwashers all rely on them. Energy labels on these items help you pick ones that use less power, saving you money.

Big appliances like fridges and washers use about 40% of home electricity. Choosing items with high energy grades can cut your energy use. For instance, “A” grade ovens use less power but still work great. This makes them a smart pick for eco-friendly buyers.

| Тип прибора | Average Energy Use (kWh) | Energy Grade |

|---|---|---|

| Стиральные машины | 0.1~0.5 kWh | B |

| Посудомоечные машины | 1.2~2.4 kWh | A |

| Электрические духовки | 2~4 kWh | A |

| Refrigerators | 0.3~1.6 kWh | C |

Совет: Choose appliances with energy labels to save power and help the environment.

Specialized Uses in Medical and Scientific Fields

Electric heating elements are very important in medicine and science. They give exact and steady heat, making them useful for special tasks. These elements help save lives and support amazing discoveries.

In medicine, they are used in tools like sterilizers and incubators. Sterilizers kill germs on surgical tools with high heat. Incubators keep a stable temperature for babies or lab samples. These devices need reliable heat, which electric heating elements provide well.

Science labs also use these elements for many jobs. Hot plates and furnaces heat chemicals during experiments. Advanced tools, like thermal analyzers, study how materials change with heat. These elements ensure experiments are accurate and repeatable.

Did You Know? Electric heating elements are key in PCR, a DNA test. This process helps scientists study genes and find diseases.

Cryogenic systems also rely on these elements. They stop frost or control temperatures in very cold places. Without them, many tools wouldn’t work right.

Electric heating elements are more than just parts. They are vital for healthcare and science. Their accuracy and flexibility make them essential in these fields.

How to Choose the Right Electric Heating Element

Things to Think About (e.g., Wattage, Material, Size)

Picking the right electric heating element needs careful thought. First, look at the wattage. More wattage means more heat but uses more energy. Small devices need less wattage, while factories may need more. Next, check the material. Нихром is strong and handles high heat well. But stainless steel or ceramic might work better for special jobs. Lastly, size is important. The element must fit the space and meet your heating needs.

Совет: Always read the manufacturer’s guide to make sure it fits your system.

Choosing the Right Element for Your Use

Different jobs need different heating elements. For homes, like in ovens or water heaters, pick ones that give steady heat. Factories need elements that handle very high heat and run for long hours. For medical or lab tools, accuracy is key. Use elements made for exact temperature control. Picking the right one helps it work better and last longer.

Keeping It in Good Shape

Taking care of your heating element makes it last longer. Check it often for damage like cracks or discoloration. Clean off dust or dirt that could lower its performance. How long it lasts depends on the material and where it’s used. If it’s in wet or harsh places, it might need a special coating. High-quality materials cost more but save money by lasting longer.

Примечание: Follow the maker’s care tips to keep your heating element working well for years.

Electric heating elements are important in today’s heating systems. They give reliable, efficient, and flexible heat for homes and industries. These elements turn electricity into heat with little energy waste, making them eco-friendly.

Here are reasons why they are becoming popular:

- Urbanization means more cities need better heating systems.

- Technological advancements help save energy and improve performance.

- Smart technologies connect heating to eco-friendly smart buildings.

Check out the many types of electric heating elements. Pick one that suits your needs and helps build a greener future. 🌱

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

How long do electric heating elements last?

How long they last depends on use and material. Most work for 500 to 5,000 hours. Cleaning and checking for damage can help them last longer. Strong materials like nichrome or stainless steel last the longest.

Can you use electric heating elements outside?

Yes, some types, like infrared or tubular ones, work outside. They handle weather changes and give focused heat. Always check the product details to make sure it’s safe for outdoor use.

How do you take care of an electric heating element?

Clean it often to remove dust and dirt. Look for cracks or color changes that show damage. Follow the maker’s instructions to keep it working well and lasting longer.

Are electric heating elements good at saving energy?

Yes, they turn almost all electricity into heat with little waste. Picking the right size and type for your needs saves energy and lowers costs.

What materials are used in electric heating elements?

Common materials are nichrome, stainless steel, and ceramic. Nichrome handles high heat and lasts long. Stainless steel resists rust, and ceramic controls heat well for delicate tasks.