When you select a hot tub heating element, you invest in performance, safety, and long-term reliability. The right material, such as titanium, resists corrosion and chemical damage, ensuring your element lasts longer. Build quality and advanced safety features protect your spa and household appliance heating elements from premature wear. Heating element manufacturers like Jinzhong Electric Heating focus on insulation, smart controls, and energy-saving technologies to maximize heat efficiency. Consider the table below to see how each feature impacts lifespan and performance.

| Feature | Description | Impact on Lifespan and Performance |

|---|---|---|

| High-performance titanium heaters | Stronger, resists chemicals | Extends lifespan, reduces replacement frequency |

| POLI-MAX™ Insulation | Superior heat retention | Improves energy efficiency, reduces workload |

| Smart Touch Controls | Programmable, precise temperature management | Reduces unnecessary operation, saves energy |

Key Features of a Quality Hot Tub Heating Element

Material Selection

Stainless Steel, Incoloy, and Titanium Options

When you choose a spa heater, the material of the element plays a critical role in its performance and lifespan. Stainless steel, Incoloy, and titanium are the most common materials used in spa heater elements. Stainless steel offers solid durability for standard water conditions. Incoloy, an alloy with high nickel content, provides enhanced resistance to corrosion, making it suitable for spas with fluctuating water chemistry. Titanium stands out for its exceptional resistance to harsh chemicals and saltwater, making it the preferred choice for marine environments and high-end spa heater applications. You should always match the material of your heater to your spa’s water type and usage patterns to maximize longevity.

Corrosion and Scale Resistance

Corrosion and scale can quickly degrade a hot tub heating element. Incoloy and titanium elements resist chemical attack and mineral buildup much better than standard metals. This resistance means your spa heater will maintain efficient heat transfer and require fewer replacements. If you operate your spa heater in areas with hard water or use saltwater systems, selecting a titanium element ensures the best protection against scale and corrosion. You will notice fewer interruptions and more consistent heat output over time.

Build and Design Standards

Precision Manufacturing and Element Thickness

The build quality of a spa heater directly impacts its durability and efficiency. Precision manufacturing ensures each element meets strict tolerances for size and shape, which leads to reliable performance. The thickness of the element, especially when made from titanium alloy, adds significant durability. Thicker elements withstand harsh conditions and resist wear, resulting in a longer service life and fewer replacements. You benefit from a spa heater that maintains strong heating performance, even in cold temperatures.

Tip: Always check your spa heater’s specifications for element thickness and material type before purchasing a replacement.

Surface Area and Heat Transfer Efficiency

A well-designed spa heater element maximizes surface area to improve heat transfer. More surface area allows the element to distribute heat evenly throughout the water, reducing hot spots and improving comfort. Efficient heat transfer also means your spa heater uses less energy to reach and maintain the desired temperature. You save on utility costs while enjoying a consistently warm spa experience.

| Specification | Typical Values / Examples |

|---|---|

| Voltage Ratings | Commonly 240V, sometimes 120V |

| Wattage (Power) Ratings | Typically 4.0 kW to 5.5 kW for residential hot tubs |

| Amp Draw at 240V | Between 15 to 25 amps for 4.0 to 5.5 kW elements |

| Resistance | Usually 9 to 12 ohms for these wattages |

| Materials Used | Incoloy (high corrosion resistance), Titanium (lighter, marine environments) |

| Common Brands | Balboa, Gecko, HydroQuip, Pentair, Raypak, Hayward |

You should always consult your spa heater’s manual and match voltage, wattage, and material type to the original equipment. This practice ensures safe operation and optimal heat performance.

Electric spa heaters dominate the market due to their reliability and ease of installation. Manufacturers have focused on improving heater materials to combat corrosion, rather than changing the fundamental design.

Essential Safety Features

Overheat Protection Mechanisms

Safety is paramount when you operate a spa heater. Modern spa heater elements include advanced temperature control systems with automated shut-off mechanisms. These systems monitor water temperature and immediately stop heating if unsafe conditions arise. Overheat protection prevents burns, equipment damage, and reduces the risk of fire. Redundant sensors and control circuits add another layer of safety, ensuring your spa heater element shuts off above certain temperature thresholds or when the spa is inactive.

Grounding and Electrical Safety

Proper electrical safety features protect you and your equipment. Spa heaters require dedicated circuits sized according to manufacturer specifications, often around 50 amps. Ground Fault Circuit Interrupter (GFCI) protection is mandatory for all spa heater installations. GFCI breakers quickly cut power during electrical faults, preventing shock hazards. You must use weatherproof disconnect switches within sight of the spa but at a safe distance for emergency shut-off. All wiring should be rated for moisture resistance and outdoor use. Licensed electricians should handle installation to ensure compliance with the National Electrical Code and local regulations. Regular testing of GFCI devices keeps your spa heater operating safely.

Note: Always prioritize professional installation and regular safety checks for your spa heater to maintain code compliance and protect your investment.

Hot Tub Heating Element Performance and Efficiency

Fast and Even Water Heating

Watt Density and Power Ratings

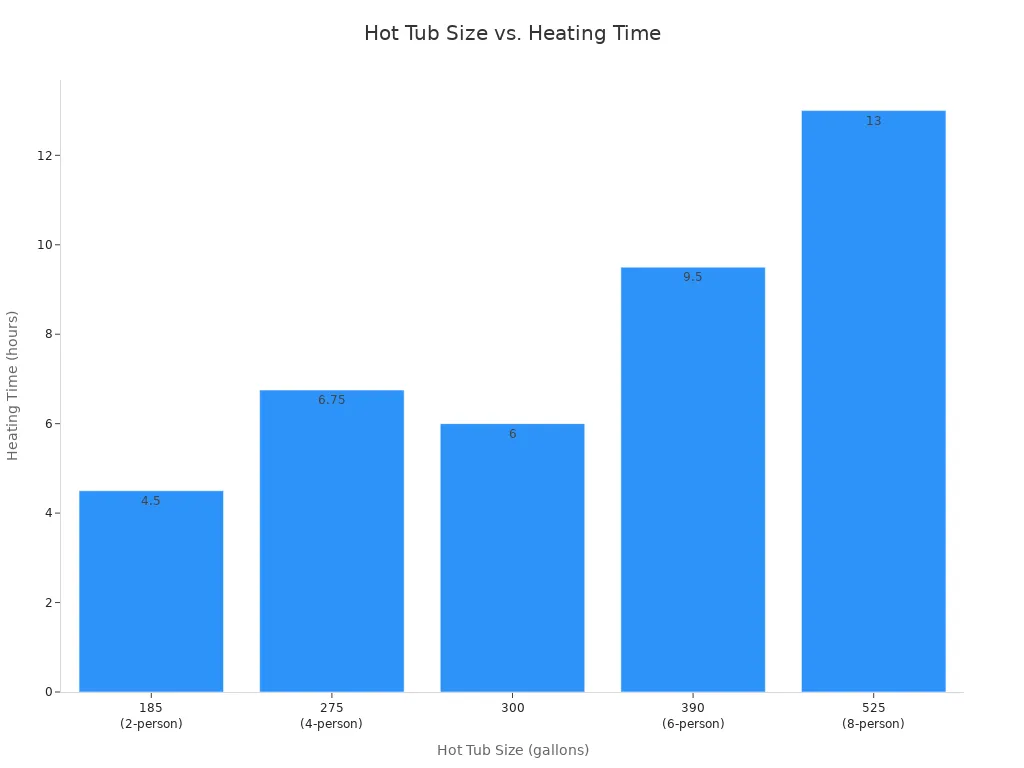

When you select a spa heater, watt density and power ratings directly influence how quickly your hot tub reaches the desired temperature. A high-quality heater with the right watt density delivers efficient performance without causing premature wear. Most residential spa heater elements operate between 3 kW and 5.5 kW. This power range allows you to heat water at a rate of 3 to 6°F per hour. For example, if you start with water at 50°F, you can expect your spa heater to reach 100°F to 104°F in about 4 to 8 hours. Larger tubs or colder weather may extend this time, sometimes up to 12 hours for the initial heating cycle.

| Hot Tub Size (gallons) | Heater Power (kW) | Approximate Heating Time to 100-104°F |

|---|---|---|

| 185 (2-person) | 3 | About 4.5 hours |

| 275 (4-person) | 3 | About 6.75 hours |

| 300 | 5 | About 6 hours |

| 390 (6-person) | 3 | About 9.5 hours |

| 525 (8-person) | 3 | About 13 hours |

You should always match your spa heater’s power rating to your tub size and usage needs. This ensures you get fast, reliable heating without overloading your electrical system.

Consistent Heat Distribution

A well-designed spa heater provides even heat distribution throughout the water. This prevents hot or cold spots and creates a comfortable soaking experience. The element’s surface area and placement inside the spa heater chamber play a crucial role. When you use a heater with optimized design, you achieve uniform water temperature and reduce the risk of overheating specific areas. Consistent heat also helps maintain water chemistry, which protects your spa heater from scale and corrosion.

Energy Consumption and Savings

Energy-Efficient Technologies

Modern spa heater systems incorporate advanced technologies to minimize energy use. Features like full or partial foam insulation, high-density thermal covers, and programmable controls help you reduce heat loss and lower utility bills. Some spa heater models use low-energy circulation pumps, heat recycling, and pump shrouds to transfer warmth back into the water. These innovations decrease the workload on your heater and extend its lifespan.

- Standard hot tubs consume 5 to 6 kWh daily, costing about $22.50 to $30 monthly.

- Energy-efficient spa heater models can cut monthly energy costs to $10 to $15.

- Key energy-saving features include:

- Full or partial foam insulation

- Thick thermal covers

- Floating thermal blankets

- Programmable pumps and filtration cycles

| Component | Power Consumption (Watts) | Estimated Energy Use (kWh/hour) |

|---|---|---|

| Water Heater | 1,500 to 6,000 | 1.5 to 6.0 |

| Circulation Pump | Approximately 1,500 | 1.5 |

| Jets & Air Blower | 500 to 1,000 | 0.5 to 1.0 |

| Lighting & Controls | 50 to 200 | 0.05 to 0.2 |

Impact on Utility Costs

Choosing an energy-efficient spa heater can lead to significant annual savings. Proper insulation, high-density foam covers, and smart controls can reduce energy consumption by 30-40%. Maintaining your spa heater at an optimal temperature (100-102°F) and using programmable settings provide immediate savings. For a medium-sized hot tub, you might see annual running costs drop from $240-$360 to much lower amounts with these improvements. Over time, these savings add up, making your investment in a quality spa heater both practical and economical.

Tip: Regularly check your spa heater for scale buildup and maintain water chemistry. This keeps your heater running efficiently and prevents unnecessary energy waste.

Longevity and Durability of Hot Tub Heating Elements

Resistance to Mineral Buildup and Scale

Importance of Water Chemistry Management

You play a crucial role in extending the life of your hot tub heating element by managing water chemistry. Balanced water prevents corrosion and scale, which are the leading causes of element failure. If you allow acidic water to persist, the element may rust and break down rapidly. Hard or basic water encourages mineral deposits, which insulate the element and reduce heat transfer. When you maintain proper pH and calcium hardness, you protect the element from these threats. Most heating elements last between 7 to 10 years with consistent water care, but neglect can shorten this lifespan to just a few years.

Tip: Test your water weekly and adjust pH and alkalinity to recommended levels. This simple habit keeps your element working efficiently.

Self-Cleaning and Protective Coatings

Manufacturers design some elements with self-cleaning features and protective coatings to resist scale and corrosion. Titanium elements excel in harsh environments, including saltwater spas, because they naturally resist mineral buildup. Ceramic-coated elements offer a smooth surface that discourages deposits and enhances corrosion protection. These innovations help you maintain efficient heating and reduce the need for frequent cleaning. Stainless steel elements, while durable, require more attention to prevent scale accumulation. If you choose an element with advanced coatings, you spend less time on maintenance and enjoy stable performance.

| Material Type | Scale Resistance | Maintenance Needs | Typical Lifespan |

|---|---|---|---|

| Titanium | Excellent | Low | 7-10 years |

| Ceramic-Coated | Very Good | Low | 7-10 years |

| Stainless Steel | Moderate | Moderate | 5-8 years |

Wear, Tear, and Lifespan

Signs of Element Degradation

You should watch for clear signs that your heating element is wearing out. Reduced heating efficiency, longer heat-up times, and cold spots in the water often indicate mineral buildup or corrosion. If you notice visible rust, discoloration, or scale on the element, it may be time for replacement. Electrical issues, such as tripped breakers or error codes, can signal internal damage. Regular inspection helps you catch problems early and avoid unexpected downtime.

How Quality Extends Service Life

Choosing a high-quality element and maintaining it properly ensures long-lasting performance. Corrosion-resistant materials like titanium and copper reduce the risk of premature failure. Routine cleaning, balanced water chemistry, and timely filter changes protect the element from contaminants and electrical hazards. You should circulate water daily and schedule preventive maintenance inspections to identify issues before they escalate. These practices collectively extend the service life of your element, keeping your hot tub comfortable and reliable.

Note: Daily water circulation for at least 20 minutes helps filter out particles and bacteria, safeguarding your element from buildup and malfunction.

Installation Best Practices for Hot Tub Heating Elements

Proper Electrical Wiring and Connections

Secure Connections and Correct Torque

You must prioritize secure electrical connections when installing a replacement spa heater element. Tight terminal connections prevent overheating and circuit failure. Use copper wire types such as THHN, THWN, or XHHW for durability and conductivity. Select wire size based on amperage—6-gauge wire for 50 amps and 4-gauge for 60 amps. Always pull wires through conduit using fish tape and wire-pulling lubricant to avoid damage. Make sure to use flex conduit inside the equipment bay for flexibility and ease of future electrical repairs.

Tip: Never fish wires around energized circuits or into the electrical service panel. This practice reduces the risk of electric shock and damage.

Safe Fastening and Leak Prevention

Proper fastening of unions and fittings is essential for leak prevention. Hand-tighten plastic unions only to avoid breakage. Replace gaskets or O-rings if leaks persist. Waterproof electrical connections protect against short circuits and corrosion. Avoid using extension cords and ensure a dedicated circuit for your hot tub heater replacement. Always consult local authorities for permits and code requirements before installation.

Recommended Electrical Wiring Standards Table

| Standard/Practice | Description |

|---|---|

| NEC Compliance | Follow National Electrical Code strictly |

| GFCI Protection | Install GFCI breaker for safety |

| Dedicated Circuit | Prevent overloads and ensure proper grounding |

| Waterproof Connections | Protect against moisture and corrosion |

| Disconnect Switch | Install near hot tub for emergency shut-off |

Leak and Pressure Testing

Gasket and Seal Integrity

Inspect all gaskets and seals after installing a replacement. Pumps, heater unions, valves, and jets are common leak sources. Signs of leaks include water under the pump, rust on the motor, or rust on heater tubes. Replace degraded O-rings and gaskets to maintain system integrity. Use specialized repair kits for glued plumbing parts before considering full replacement.

Pressure Testing Procedures

Pressure testing ensures the system holds up under operating conditions. Turn off power and close gate valves on both sides of the heater and pump. Remove and inspect union fittings for leaks. Increase pressure in 10 PSI increments, waiting 10 minutes at each stage. Charge the system to 200% of operating pressure for flexible pipes and 300% for rigid PVC. Monitor for leaks at peak pressure for at least 10 minutes. Reduce pressure to 150% and maintain for 24 hours. If you notice any pressure drop, conduct further leak detection. Always wear comprehensive safety gear during pressure testing.

Note: Never exceed the maximum operating pressure of pipe material. Secure all plugs and testers to prevent accidents.

Professional vs. DIY Installation

When to Hire an Electrician

You should hire a licensed electrician for any electrical repairs involving 240V connections. Professional installation ensures compliance with electrical codes, proper wiring, and plumbing integrity. Manufacturers often require professional installation to maintain warranty coverage. Professionals handle permits, site preparation, and full system setup, preventing common mistakes that compromise safety and reliability.

Common DIY Mistakes to Avoid

DIY installation may seem cost-effective, but it carries risks. Common mistakes include designing a hot tub too large for the heater capacity, rushing plumbing joints, and not reading instructions carefully. These errors can cause leaks, electrical errors, and damage to control boards. Forcing pipes at incorrect angles or not keeping pipes perpendicular leads to poor alignment and sealing issues. DIY installations often lack warranty support, leaving you responsible for costly repairs and replacement.

Callout: Professional installers provide ongoing support, warranty protection, and peace of mind. You reduce the risk of electrical hazards, leaks, and premature heating element failure by choosing expert installation.

Maintenance and Care for Hot Tub Heating Elements

Routine Inspection and Testing

Visual Checks for Damage or Corrosion

You should inspect your hot tub heating element regularly to catch early signs of wear. Look for discoloration, rust, or scale buildup on the element surface. These issues often indicate corrosion or mineral deposits, which can reduce heating efficiency. If you notice any holes or pitting, plan for a replacement soon. Routine inspections help you maintain optimal performance and prevent unexpected breakdowns.

Tip: Schedule monthly visual checks for your element, especially if you use your hot tub frequently. Professional inspection and component testing, including heating elements, is recommended at least once a year.

Using a Multimeter for Functionality Testing

Testing spa heater elements with a multimeter ensures your system operates safely and efficiently. Always disconnect power before you begin. Set your multimeter to measure resistance (Ohms) and place the probes on the two terminals of the element. A healthy element typically shows a resistance between 9 and 12 ohms. If you see a very low reading, the element may have a short circuit. A very high or infinite reading suggests an open circuit, meaning the element needs replacement. You should also test for shorts to ground by measuring resistance between a terminal and the metal sheath. An infinite reading means no short; any other result indicates a faulty element.

Steps for heater element testing:

- Disconnect all electrical power to the hot tub.

- Use a multimeter to measure resistance between the two heater element terminals.

- Confirm a reading between 9 and 12 ohms.

- Test for shorts to ground.

- If the element tests good, continue testing associated heater components such as the high limit switch and thermostat.

Note: Poor water chemistry and operating the heater without water flow can damage the element. Always ensure proper water circulation before testing the heater element.

Water Chemistry and Treatment

Balancing pH and Alkalinity

Maintaining balanced water chemistry protects your hot tub heating element from damage. Aim for a pH range of 7.4 to 7.6 and alkalinity between 80 and 120 ppm. Low pH causes corrosion, while high pH leads to scale buildup. Alkalinity acts as a buffer, stabilizing pH and reducing the risk of rapid changes. You should test your water weekly and adjust chemicals as needed to keep these levels within the recommended range.

| Parameter | Ideal Range | Effect on Element |

|---|---|---|

| pH | 7.4–7.6 | Prevents corrosion/scale |

| Alkalinity | 80–120 ppm | Buffers pH, prevents damage |

Preventing Scale and Corrosion

You can prevent scale and corrosion by monitoring sanitizer levels and following manufacturer instructions when adding chemicals. Regular maintenance, including cleaning the filter and flushing plumbing, complements water chemistry management. Neglecting these tasks accelerates wear and reduces the lifespan of your element. Balanced water chemistry ensures your heating element operates efficiently and lasts longer.

Cleaning and Replacement Guidelines

Safe Cleaning Methods

Clean your heating element gently to avoid damage. Use a soft brush or cloth to remove scale and debris. Avoid harsh chemicals or abrasive tools, which can scratch the element surface and reduce its effectiveness. If you notice stubborn deposits, soak the element in a mild vinegar solution before rinsing thoroughly. Always ensure the element is dry before reinstalling.

When and How to Replace the Element

Replace the element if you observe visible damage, persistent heating issues, or failed heater element testing. Turn off all power and drain the hot tub before starting. Remove the old element carefully, following the manufacturer’s instructions. Install the new element, ensuring secure connections and proper sealing to prevent leaks. After replacement, test the heater element and associated components to confirm proper operation.

Callout: Regular inspection, testing the heater element, and water chemistry management help you avoid costly repairs and extend the life of your hot tub heating element.

Choosing the Right Hot Tub Heating Element

Compatibility with Hot Tub Models

Sizing, Wattage, and Power Requirements

Selecting the correct spa heater for your hot tub requires careful attention to specifications. You must verify that the heating element’s wattage, voltage, and physical dimensions match your spa’s requirements. Most residential spa heaters operate at either 110V/120V or 220V/240V, depending on the size and power needs of your system. You should always check your local power supply and spa wiring before purchasing a replacement. Matching the heating capacity to your spa’s water volume and usage frequency ensures efficient performance. If you live in a colder climate or use your spa frequently, you may need a higher wattage spa heater to maintain comfortable temperatures.

Tip: Choose a spa heater with a temperature range between 35°C and 45°C for optimal safety and comfort.

You also need to consider the material of the spa heater element. Stainless steel offers corrosion resistance, while copper provides efficient heat transfer. Nickel-chromium alloys deliver high heat resistance and longevity. Select the material that best fits your water chemistry and durability needs.

Matching Brands and Control Systems

Compatibility extends beyond physical specifications. You must ensure that the spa heater matches your hot tub’s brand and control system. Some spa heaters are universal, while others are brand-specific. Always check if your spa heater integrates with your control panel and thermostat. Accurate thermostat control, ideally with ±1°C precision, helps you maintain your desired water temperature. If you choose a heater from a different brand, confirm that it fits your plumbing and electrical connections.

Checklist for Compatibility:

- Verify wattage, voltage, and dimensions

- Select material based on water chemistry

- Match heating capacity to spa size and climate

- Ensure brand and control system compatibility

- Inspect for corrosion or damage before installation

Evaluating Brands, Warranties, and Support

Trusted Manufacturers and Reviews

You benefit from choosing a spa heater from a reputable manufacturer. Brands like Nordic Hot Tubs, Vita Spas, Sundance Spas, and HotSpring Spas have established themselves through durable designs and reliable performance. Nordic Hot Tubs offers affordability and robust construction, with components tested for durability. Vita Spas provides luxury features and a steel frame for added strength. Sundance Spas and HotSpring Spas deliver high durability and innovative features, supported by strong warranties and customer service.

| Brand | Reliability & Durability | Warranty & Support | Customer Support Notes |

|---|---|---|---|

| Sundance Spas | High durability; lasts 15+ years with care | Strong warranties | Reliable customer service |

| HotSpring Spas | Durable with innovative features | Strong warranty support | Highly rated after-sales service |

| Vita Spas | Durable construction with galvanized steel frame | Long-term shell warranties; component warranties vary | Good warranty coverage |

| Cal Spas | Well-established brand with diverse models | Generally strong warranty protection | Some reported delays in parts and service |

| DreamMaker Spas | Budget-friendly; rotomolded construction | Mixed feedback on heating and pump durability | Some customer issues reported |

| Nordic Hot Tubs | Affordable with robust design | Industry-leading warranties including 5-year heater warranty | Strong warranty coverage |

Note: Reliable spa heaters depend on quality design, durable materials, and comprehensive warranty and service plans.

Warranty Coverage and Return Policies

Warranty coverage plays a vital role in your long-term satisfaction. You should look for spa heaters with strong warranties, such as five-year heater warranties or lifetime shell warranties. These warranties protect you from unexpected repairs and replacement costs. Brands with consistent service plans and local dealer support resolve issues quickly, whether you face pump problems or electrical faults. Always review the return policy before purchasing a spa heater. A clear and fair policy ensures you can address any compatibility or performance concerns without hassle.

Callout: Choose a spa heater from a trusted brand with proven warranty coverage and responsive customer support. This decision safeguards your investment and ensures reliable operation for years.

Troubleshooting Common Hot Tub Heating Element Problems

Diagnosing Heating Issues

No Heat, Inconsistent Heating, or Tripped Breakers

You may encounter several heating problems with your hot tub. The most common issue is no heat, which often means your heater is not heating at all. This can result from a burned-out coil, usually caused by dry firing when the heater operates without enough water. Reduced heat or not heating enough may signal scale buildup on the heater element, which insulates the coil and lowers efficiency. Tripped breakers, especially GFCI, often point to a short circuit from water intrusion or corrosion inside the heater sheath.

You should also watch for these signs:

- The heater is not heating at all after a refill, possibly due to airlocks or low water flow.

- The heater produces reduced heat, which may indicate a water flow problem or dirty filters.

- The breaker trips repeatedly, suggesting electrical faults or moisture in the wiring.

- Visible damage, such as melted coils or cracks, signals catastrophic heater failure.

Tip: Always keep the heater fully submerged during operation to prevent dry firing and premature failure.

Error Codes and What They Mean

Modern hot tubs display error codes to help you identify heating problems. Codes like “OH” or “HL” often mean the high limit switch has tripped, usually from overheating or low water flow. “FLO” indicates a water flow problem, which can prevent the heater from operating. “DR” or “DRY” means the heater is not heating at all due to insufficient water. If you see “SN” or “SENSOR,” the temperature sensor may be faulty, affecting heater performance.

You should consult your spa’s manual for specific error code meanings. These codes help you quickly pinpoint the source of no heat or not heating enough issues.

Solutions and Preventive Measures

Quick Fixes for Common Problems

You can resolve many heater issues with a few simple steps:

- Check the water level and top off if needed.

- Clean or replace dirty filters to restore proper flow.

- Reset the heater breaker or press the reset button on the control panel.

- Bleed air from the plumbing lines if you recently refilled the tub.

- Test the heater element with a multimeter. A reading outside 9-12 ohms means you need to repair or replace the element.

If the heater is still not heating at all, inspect for visible damage or corrosion. Replace the heater if you find cracks or melted areas.

Long-Term Prevention Strategies

You can prevent most causes of heater failure by following these best practices:

- Maintain balanced water chemistry. Keep pH between 7.4 and 7.6, and alkalinity between 100-150 ppm.

- Clean filters monthly and replace them annually.

- Inspect wiring and heater connections for corrosion or looseness.

- Ensure proper water flow to avoid overheating and dry firing.

- Use scale removers regularly if you have hard water.

Regular maintenance and prompt attention to heating problems will extend the life of your heater and reduce costly repairs.

You gain the most from your hot tub heating element when you focus on material quality, precise build, and robust safety features. Regular inspection and water care help you maintain optimal performance and extend service life. To maximize efficiency and longevity, follow these tips:

- Maintain proper water chemistry and clean filters regularly.

- Use high-quality covers and windbreaks to reduce heat loss.

- Upgrade to energy-efficient pumps and heaters when possible.

Consistent care and smart upgrades keep your hot tub running smoothly year-round.

FAQ

How often should you replace a hot tub heating element?

You should replace your hot tub heating element every 7 to 10 years. If you notice slow heating, visible corrosion, or frequent tripped breakers, consider replacement sooner.

Can you clean a heating element instead of replacing it?

You can clean minor scale or debris using a soft brush and mild vinegar solution. Avoid harsh chemicals. If you see deep corrosion or pitting, replacement remains the best option.

What causes a hot tub heating element to fail?

Common causes include poor water chemistry, scale buildup, dry firing, and electrical faults. Regular maintenance and proper water balance help prevent most failures.

How do you know if your heating element is bad?

You may notice no heat, inconsistent temperatures, or tripped breakers. Testing with a multimeter can confirm if the element has failed. Look for readings outside the 9–12 ohm range.

Is it safe to install a heating element yourself?

You can install a heating element if you have electrical experience and follow safety codes. For 240V systems, hiring a licensed electrician ensures compliance and safety.

Does water chemistry really affect heating element lifespan?

Yes. Unbalanced pH or high calcium levels cause corrosion and scale, which shorten the element’s life. Test and adjust your water weekly for best results.

What is the best material for a hot tub heating element?

Titanium offers the best resistance to corrosion and scale, especially in saltwater or harsh environments. Stainless steel and Incoloy also provide good durability for standard water conditions.