The microwave heating tube adopts magnetron or solid-state radio frequency (2.45GHz/915MHz) technology, combined with high-temperature resistant ceramic or stainless steel cavity, supports high-frequency electromagnetic field energy conversion, achieves fast and uniform heating (30 seconds to 150℃), energy efficiency ≥92%, adapts to wide power (1000W–10kW) and customized frequency. The surface has multi-layer metal shielding coating, with IPX6 waterproof, overheating and electromagnetic leakage prevention functions, complies with CE/FCC/GB certification, meets the needs of continuous high-frequency microwave heating, and has a lifespan of more than 30,000 hours.

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

Household microwave ovens, built-in ovens, commercial food thawing machines.

Power range: 100W–30 kW (adjustable, appropriate for domestic microwaves ranging from 30 kW to industrial ones).

Operating frequency is 2.45GHz (standard ISM band) or 915MHz (industrial/high-power uses).

Input voltage—110V/220V–480V AC ( single-phase or three-phase, internationally compatible).

Output power stability: ±5% (precision control for regular heating).

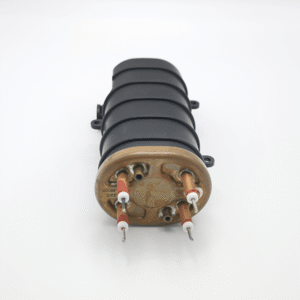

Magnetron uses tungsten for the cathode, copper for the anode, and high-purity alumina ceramic for the housing.

Waveguide: Corrosion-resistant, aluminium alloy or stainless steel optimised for 2.45GHz/915MHz.

Efficiency: ≥92% (electric microwave radiation’s energy conversion).

Operating temperature: -40°C to 250°C ( Continuous duty with cooling devices).

Lifespan (Dependent on cooling efficiency and usage intensity): 5,000–20,000 hours

Magnetron:

Generates microwave energy via electron resonance in a strong magnetic field.

Features a ceramic insulator to withstand high voltages (up to 20kV).

Cooling System:

Air-cooled or liquid-cooled (Forced-air fans or coolant circulation for heat dissipation).

Waveguide:

Directs microwaves into the cavity, minimizing energy loss (<3% reflection loss).

Safety Features:

Overheat protection, door interlock switches, and leakage detection (<5mW/cm² per FDA/IEC standards).

Rapid Heating:

Heats materials uniformly in seconds (e.g., drying food in 1/10th the time of convection ovens).

Energy Efficiency:

No need for preheating; targets water/molecule vibration directly, reducing 30% energy waste.

Process Control:

Programmable power modulation for batch or continuous processing (e.g., pharmaceutical drying).

Versatility:

Compatible with metals (induction limits apply) and non-conductive materials (ceramics, plastics).

Space-Saving Design:

Compact form factor for integration into industrial lines or countertop appliances.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.