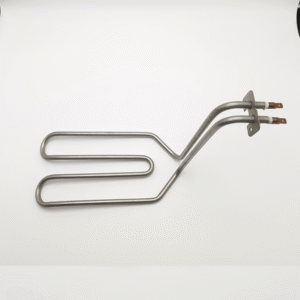

The die-cast heater accessories are made of high-precision die-cast aluminum alloy technology. The surface anodizing treatment improves wear resistance and corrosion resistance. It is suitable for high temperature (50℃-300℃) and high pressure environment. The integrated heat dissipation structure design optimizes heat conduction efficiency, supports IPX7 waterproof and dustproof and anti-dry burning protection, meets the industrial-grade high-intensity and high-frequency continuous working requirements, and has a lifespan of more than 30,000 hours.

Minimum order quantity: 1000

Delivery time: 15-25 days

Factory location: Zhongshan, Guangdong, China

Coffee machine steam module housing, electric water heater heating cavity, industrial oven heat dissipation components, medical sterilization equipment heater housing, laboratory constant temperature water bath housing, new energy battery module constant temperature housing, hotel commercial electric tea stove components

Rapid Heating: Aluminum alloy housing allows 3minute boiling of 1.5L water in 1500W kettles.

Stable Temperature Control: For coffee machines (90-105°C extraction), nickelchromium cores guarantee ±3°C variance.

CorrosionResistant: Anodized surfaces reduce limescale accumulation, therefore lowering maintenance in humid kitchens.

Lightweight Design: 30% lighter than stainless steel, decreasing device weight for portable devices like mini kettles.

Customizable dimensions fit kettles, coffee machines, and electric pots with little changes.

Energy efficient: With thermal efficiency of at least 92%, power use is lowered by 15-20% compared with conventional heating element housing.

Durable Longevity: Perfect for high-frequency blender and electric pot use, resists 8000-15000 hours of cyclic heating.

Builtin thermal cutoffs (autoshutoff at >350°C) help to avoid dry burning in bottle warmers and teapots.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.