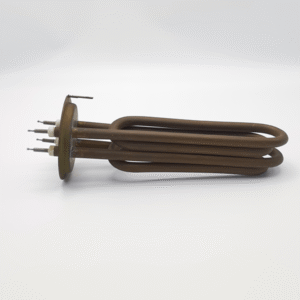

The electric heater heating element adopts high-purity nickel-chromium alloy heating wire and ceramic insulation skeleton, combined with a fully enclosed metal shell and anti-oxidation coating process, with high temperature resistance (600℃), corrosion resistance, excellent insulation and other characteristics, thermal efficiency ≥95%. Support single-end/dual-end power supply design, power coverage 1kW-30kW, adapt to PID intelligent temperature control (±2℃ accuracy), built-in anti-dry burning, overheating protection and leakage monitoring functions, life ≥80,000 hours. The product is CE, RoHS, UL certified, and can be customized in length, diameter and installation method. It is suitable for industrial ovens, pipeline heating systems and household appliances (air purifiers, heaters).

MOQ:1000PCS

Lead time:25days

Factory location: Zhongshan, Guangdong, China

Resistive Core:

For high-temperature durability, make these from nichrome (NiCr), Kanthal (FeCrAl), or silicon carbide (SiC).

When electricity flows through it, heat is produced.

Protective Sheath:

Insulation made of stainless steel, iron, or ceramic helps to keep water, air, or debris from touching.

Insulation layer:

Ceramic insulation or magnesium oxide (MgO) powder helps retain heat and stop electrical leaking.

| Type | Description | Applications |

|---|---|---|

| Coil Element | Helical wire coils (e.g., in space heaters). | Space heaters, hair dryers |

| Tubular Element | U-shaped tubes (e.g., in water heaters). | Water heaters, boilers |

| Cartridge Element | Cylindrical, sealed design (e.g., in furnaces). | Industrial furnaces, baseboard heaters |

| Finned Element | Coiled wire with fins for increased surface area (e.g., oil heaters). | Radiators, underfloor heating |

| Quartz Element | High-intensity quartz tube with halogen bulbs (instant heat). | Hair straighteners, portable heaters |

Residential:

Water heaters, electric stoves, space heaters, underfloor heating.

Commercial:

HVAC systems, industrial ovens, dryers.

Industrial:

Furnaces, boilers, metalworking equipment.

| Parameter | Typical Values | Importance |

|---|---|---|

| Power Rating | 500W–15,000W (depends on use case) | Determines heating capacity. |

| Voltage | 120V, 240V, or 480V | Must match power supply. |

| Resistance | Varies (e.g., 38Ω for 240V/1500W) | Affects power output. |

| Material | Nichrome (cost-effective), Kanthal (high temp) | Corrosion and heat resistance. |

| Max Temp | 600°C–1200°C (varies by material) | Critical for industrial use. |

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Get a custom quote in less than two days.