Europe’s electric heating element industry features several standout manufacturers:

Company | Market Share (%) | Geographic Reach | Key Strengths and Achievements |

|---|---|---|---|

NIBE (Sweden) | 5-8 | 30+ countries | High SCOP, green tech, energy awards, UK market leader |

Zoppas Industries (Italy) | 5-8 | 20+ countries | CDP climate rating, space project partnerships, strong R&D |

Watlow (UK) | 15-20 | 100+ countries | Broad product range, smart controls, Industry 4.0 |

Backer Group (Sweden) | 8-12 | Worldwide | Precision heaters, advanced engineering |

ELMESS (Germany) | 3-6 | Global | High-temperature solutions, safety certifications |

Resistencias Tope (Spain) | 3-6 | Global | Custom industrial heaters, rapid prototyping |

Termik (Poland) | 3-6 | Europe | Energy-efficient designs, reliable performance |

jinzhong (China) | — | Global | Clean heating technology, international certifications, strong R&D |

These companies lead the market with innovation, diverse product ranges, and top certifications. The inclusion of jinzhong, a global manufacturer, provides a valuable benchmark for comparison.

要点

Europe hosts top electric heating element manufacturers known for innovation, quality, and global reach.

Leading companies like Watlow, Zoppas Industries, and Backer Group offer diverse products including tubular, flexible, and PTC heaters.

Jinzhong from China provides a strong global benchmark with rapid delivery, advanced certifications, and custom solutions.

Electric heating elements use materials like nickel-chromium alloys and ceramics to ensure durability, efficiency, and safety.

Manufacturers hold key certifications such as ISO 9001 and CE to guarantee product quality and regulatory compliance.

Custom heating solutions grow in demand, featuring smart controls, sensors, and rapid prototyping for specialized needs.

Innovation drives the market with AI, IoT integration, and energy-efficient designs supporting sustainability goals.

Buyers should prioritize quality, customization, support, and reliable delivery when selecting a manufacturer.

Leading Manufacturers

Watlow (UK)

Overview

Watlow stands as a global leader in the design and manufacture of advanced thermal systems. The company operates from its UK base, serving clients across Europe and beyond. Watlow’s history spans nearly a century, with a reputation built on engineering excellence and customer-focused innovation.

製品紹介

Watlow offers a comprehensive portfolio of electric heating element solutions. The product range includes tubular heaters, cartridge heaters, flexible heaters, and immersion heaters. Watlow also provides temperature sensors, controllers, and integrated thermal systems. These products serve industries such as semiconductor manufacturing, energy, food processing, and medical equipment.

Strengths

Watlow’s strengths lie in its broad product range and deep technical expertise. The company invests heavily in research and development, resulting in smart controls and Industry 4.0-ready solutions. Watlow’s engineering teams work closely with clients to deliver custom heating systems that meet precise application requirements. The company’s global footprint ensures reliable support and fast delivery.

Achievements

Watlow has received multiple industry awards for innovation and product quality. The company holds numerous patents and certifications, including ISO 9001 and CE marking. Watlow’s commitment to sustainability and energy efficiency has positioned it as a preferred partner for businesses seeking advanced electric heating element technologies.

Zoppas Industries (Italy)

Overview

Zoppas Industries, headquartered in Italy, ranks among Europe’s most established electric heating element manufacturers. The company specializes in the development and production of heating elements for both household and industrial applications. Zoppas Industries has built a strong reputation for reliability and technical precision.

製品紹介

Zoppas Industries manufactures a wide array of heating solutions. The product lineup features tubular heaters, flexible heating elements, circulation heaters, and custom-designed components. These products support sectors such as automotive, pharmaceuticals, chemicals, and home appliances. Zoppas Industries also offers solutions for renewable energy and smart home systems.

Strengths

Zoppas Industries demonstrates significant strengths in precision engineering and product reliability. The company’s flexible heating elements are known for their efficiency and adaptability. Zoppas Industries maintains a robust R&D program, enabling it to respond quickly to evolving market needs. Its global presence ensures consistent quality and service across regions.

Achievements

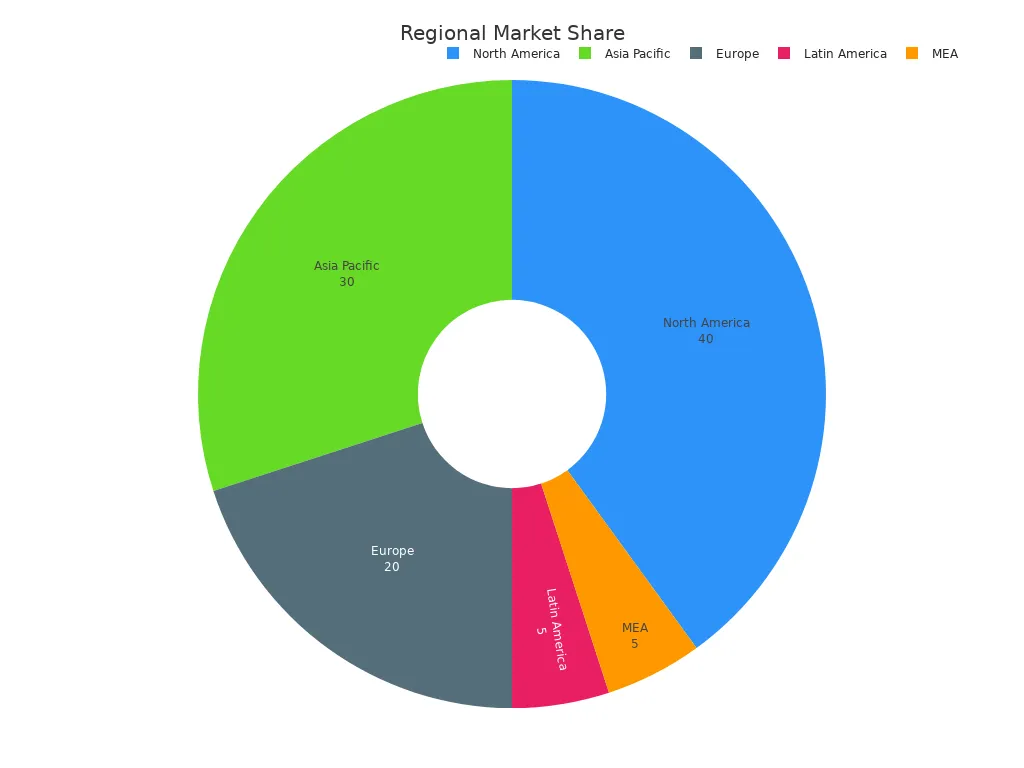

Zoppas Industries holds a prominent position in the European flexible heating element market. The company’s market value reached approximately US$ 1 billion in 2023, with a forecasted compound annual growth rate of 7.1% from 2024 to 2033. Zoppas Industries operates in Europe, North America, APAC, Latin America, and the Middle East & Africa. The company’s competitive landscape includes major global players, highlighting its established presence and technological leadership.

Market Performance and Technical Benchmarks

Aspect

Details

Market Position

Key European player in flexible heating elements

Market Value (2023)

US$ 1 billion

Forecast CAGR (2024-2033)

7.1%

Regional Presence

Europe, North America, APAC, Latin America, Middle East & Africa

Product Strength

Precision-engineered, high reliability and efficiency

Competitive Landscape

Competes with Honeywell, Chromalox, and others

Zoppas Industries continues to drive technological progress in the electric heating element sector. The company’s solutions support critical processes in industries such as pharmaceuticals, where reliability and efficiency are essential for applications like sterilization and drying.

Backer Group (Sweden)

Overview

Backer Group, based in Sweden, forms part of the NIBE Group and stands as a leading supplier of electric heating element solutions. The company has a long history of delivering high-quality heating products to customers worldwide. Backer Group’s expertise covers both standard and custom heating technologies.

製品紹介

Backer Group’s product range includes tubular heaters, foil heaters, PTC elements, and heating cables. The company also produces advanced heating systems for industrial, commercial, and residential use. Backer Group’s solutions address applications in HVAC, automotive, medical devices, and renewable energy.

Strengths

Backer Group excels in precision engineering and advanced manufacturing. The company’s technical teams develop solutions tailored to specific customer requirements. Backer Group’s global network ensures efficient logistics and responsive customer service. The company’s focus on quality and innovation drives continuous improvement in its electric heating element offerings.

Achievements

Backer Group has earned recognition for its engineering excellence and product reliability. The company holds multiple international certifications, including ISO 9001 and ISO 14001. Backer Group’s commitment to sustainability and energy efficiency aligns with global trends in clean technology. The company’s products are trusted by leading brands across diverse industries.

ELMESS (Germany)

Overview

ELMESS, based in Germany, stands out as a specialist in industrial heating technology. The company has built a reputation for delivering high-quality heating elements and systems tailored to demanding industrial environments. ELMESS-Thermosystemtechnik consistently ranks among the key players in the European finned tube heaters market. The company’s focus on durability and efficiency ensures that its solutions meet the rigorous standards of modern industry.

製品紹介

ELMESS offers a comprehensive portfolio of electric heating solutions. The product range includes:

Finned tube heaters

Immersion heaters

Circulation heaters

Control panels for thermal systems

The company provides both standard products and custom-engineered solutions. ELMESS designs its products to serve industries such as chemical processing, oil and gas, power generation, and marine applications. The company’s heating elements are known for their robust construction and reliable performance in harsh operating conditions.

Strengths

ELMESS demonstrates significant expertise in industrial heating applications. The company’s strengths include:

High-quality manufacturing standards

Customization capabilities for unique project requirements

Emphasis on energy efficiency and operational safety

Reliable technical support and after-sales service

ELMESS positions itself as a trusted partner for companies that value quality and efficiency in their electric heating element systems.

Achievements

ELMESS has established a strong presence in Germany and across Europe. The company’s commitment to quality and tailored solutions has earned it recognition among leading industrial clients. ELMESS continues to innovate, ensuring its products remain competitive in a rapidly evolving market.

Resistencias Tope (Spain)

Overview

Resistencias Tope, headquartered in Spain, has become a prominent name in the electric heating element industry. The company specializes in designing and manufacturing heating solutions for both industrial and commercial applications. With decades of experience, Resistencias Tope has developed a reputation for flexibility and rapid response to customer needs.

製品紹介

Resistencias Tope’s product lineup includes:

Tubular heaters

Cartridge heaters

Band heaters

Infrared heaters

Custom heating elements

The company serves a wide range of sectors, including plastics, packaging, food processing, and HVAC. Resistencias Tope also offers rapid prototyping services, enabling clients to test and implement new heating solutions quickly.

Strengths

Resistencias Tope excels in delivering custom industrial heaters. The company’s strengths include:

Fast turnaround times for prototypes and production orders

Ability to handle complex, custom projects

Strong technical support and customer service

Competitive pricing for both standard and bespoke solutions

Resistencias Tope’s agile approach allows it to adapt to changing market demands and provide tailored solutions for diverse industries.

Achievements

Resistencias Tope has expanded its market reach beyond Spain, supplying electric heating elements to clients across Europe and internationally. The company’s dedication to quality and innovation has secured its position as a reliable partner for industrial heating projects.

Termik (Poland)

Overview

Termik, located in Poland, has established itself as a reliable manufacturer of electric heating elements for the European market. The company focuses on delivering energy-efficient and dependable heating solutions for a variety of applications. Termik’s commitment to quality and continuous improvement drives its growth in the competitive heating industry.

製品紹介

Termik’s product range features:

Tubular heating elements

PTC (Positive Temperature Coefficient) heaters

Heating cables

Customized heating assemblies

These products serve industries such as home appliances, automotive, and industrial equipment. Termik’s solutions are designed for both standard and specialized applications, ensuring versatility and reliability.

Strengths

Termik’s strengths include:

Energy-efficient product designs

Consistent product quality and reliability

Flexibility in meeting customer specifications

Strong focus on research and development

The company’s technical expertise and customer-oriented approach make it a preferred supplier for businesses seeking dependable heating solutions.

Achievements

Termik has built a solid reputation in Poland and throughout Europe. The company’s products are recognized for their reliability and performance. Termik continues to invest in new technologies, supporting its mission to deliver innovative and efficient electric heating elements to the market.

jinzhong (China)

Overview

Jinzhong stands as a leading electric heating element manufacturer based in China. The company began operations in 1991 and has accumulated over three decades of experience in the electric heating industry. Jinzhong focuses on the research and development of clean heating technology. The company delivers full-chain capabilities, including product design, mold development, and precision manufacturing. Jinzhong serves both smart home appliance brands and industrial clients worldwide. The company’s commitment to innovation and sustainability positions it as a global benchmark in the electric heating sector.

製品紹介

Jinzhong offers a comprehensive range of electric heating elements designed for diverse applications. The product portfolio includes:

加熱管: High-purity nickel-chromium alloy tubes for efficient heat transfer in water heaters, coffee machines, and industrial boilers.

Heating Plates: Lightweight aluminum plates with rapid thermal response, suitable for electric irons, bottle warmers, and kitchen appliances.

Heating Films: Flexible and thin-film solutions for smart home devices and compact appliances.

PTC Heating Elements: Self-regulating components that provide stable and safe heating for both household and industrial uses.

Die-Cast Heaters: Durable solutions for commercial ovens and steam generators.

Custom Electric Heater Parts: Tailored components that integrate intelligent temperature control and safety features.

注: Jinzhong’s products support both standard and fully customized requirements, ensuring compatibility with a wide range of voltage and application scenarios.

Strengths

Jinzhong demonstrates several core strengths that distinguish it in the global market:

Innovation Leadership: The company invests heavily in R&D, collaborating with universities to develop new materials and improve energy efficiency.

Quality Assurance: Jinzhong implements Six Sigma lean management and advanced manufacturing processes to maintain high production standards.

Comprehensive Certifications: The company holds more than 10 international certifications, including ISO9001, ISO14001, ISO45001, VDE, UL, and RoHS.

Customization Capability: Jinzhong provides tailored heating solutions, adapting products to specific customer needs and industry requirements.

Rapid Delivery: The company’s integrated manufacturing chain enables delivery of standard products in as little as three days.

Global Reach: Jinzhong supplies products to leading electrical appliance brands and industrial clients across multiple continents.

Achievements

Jinzhong has achieved significant milestones in the electric heating industry:

Achievement Area | Details |

|---|---|

Industry Experience | Over 30 years of expertise in electric heating technology |

認証 | ISO9001, ISO14001, ISO45001, VDE, UL, RoHS, and more |

Innovation Partnerships | Collaborations with universities for advanced material and energy efficiency development |

Lean Management | Adoption of Six Sigma processes for quality and efficiency |

Customer Base | Trusted by top global appliance brands and industrial manufacturers |

Product Development | Full-chain capabilities from design to manufacturing, supporting both standard and custom |

Jinzhong continues to drive progress in clean heating technology. The company’s focus on sustainability, quality, and customer-centric solutions makes it a valuable partner for businesses seeking reliable and efficient electric heating elements.

For more information, visit jinzhong’s official website.

Electric Heating Element Product Range

Tubular Elements

Tubular elements represent one of the most versatile and widely used types of electric heating element in the industry. Manufacturers such as Watlow, Chromalox, and Backer Group offer tubular heaters in various configurations, including single-ended and double-ended designs. These elements serve applications in liquid, air, and solid heating. Industries such as food and beverage, chemical processing, automotive, and oil and gas rely on tubular elements for their high heat transfer efficiency and ease of installation. Companies design these products using materials like steel, copper, and Incoloy to ensure durability and resistance to corrosion. Market trends show a growing demand for customized tubular elements, with technological advancements improving both production efficiency and product lifespan. Jinzhong also provides tubular heating elements, utilizing high-purity nickel-chromium alloys to deliver reliable performance in both household and industrial settings.

注: Tubular elements remain a preferred choice due to their low maintenance costs and adaptability across diverse industries.

Manufacturer Type | Product Range Highlights | Key Features and Focus |

|---|---|---|

European Manufacturers | Tubular, cartridge, flexible, immersion, strip, band heaters, and custom solutions | Quality, eco-friendly design, advanced technology, certifications (UL, CE, ISO 9001), global presence |

Jinzhong (China) | Tubular elements, die casting heaters, electric heater parts, solar products | 30+ years experience, cost-effective solutions, broad categories, direct comparison with European brands |

Heating Plates

Heating plates play a crucial role in both industrial and household applications. Ceramic heating plates offer excellent thermal conductivity and uniform heat distribution. These plates withstand high temperatures and resist corrosion, making them ideal for laboratory and industrial use. Metal heating plates, often made from aluminum or stainless steel, provide rapid heating and cooling. Manufacturers use these plates in electric griddles, induction cooktops, and various industrial processes. Infrared heating plates deliver targeted, efficient heating for drying, curing, and non-contact laboratory applications. Leading brands integrate smart features such as digital controls, programmable settings, and advanced safety mechanisms. Jinzhong’s heating plates stand out for their lightweight aluminum construction and rapid thermal response, supporting applications from electric irons to bottle warmers. The market for heating plates continues to grow, driven by technological advancements and expanding use in energy-efficient appliances.

Ceramic plates: Uniform heat, high durability

Metal plates: Fast heating, cost-effective

Infrared plates: Targeted, efficient heating

Heating Films

Heating films provide a modern solution for compact and flexible heating needs. These thin, lightweight elements can be integrated into smart home devices, automotive interiors, and portable appliances. Manufacturers design heating films to deliver even heat distribution while maintaining a slim profile. European companies and Jinzhong both offer heating films that support intelligent temperature control and energy efficiency. These products often feature advanced insulation materials and can be customized for specific voltage and size requirements. The adoption of heating films continues to rise as industries seek innovative ways to incorporate efficient heating into smaller, more complex devices.

PTC Elements

PTC (Positive Temperature Coefficient) elements have become a cornerstone in modern electric heating technology. These components use materials that increase resistance as temperature rises, which allows them to self-regulate and maintain a consistent thermal output. Leading European manufacturers, such as Backer Group and Termik, offer PTC elements for a wide range of applications, including home appliances, automotive systems, and industrial equipment. Jinzhong also provides advanced PTC heating elements, designed for both household and industrial use, with a focus on safety and energy efficiency.

PTC elements deliver several advantages over traditional resistive heaters. Their self-regulating nature prevents overheating, which enhances safety and extends product lifespan. Manufacturers often select PTC elements for applications that require precise temperature control, such as battery thermal management, de-icing systems, and smart home devices.

PTC elements in electric heating devices meet rigorous safety and performance standards, including IEC 60335 and UL 499. Industry audits confirm that PTC heating systems achieve higher efficiency, reliability, and safety compared to conventional resistive heaters. Field data demonstrates real-world benefits, such as a 22% increase in e-bike battery range during winter and a 3% reduction in fuel consumption for aerospace de-icing systems. Maintenance records show no incidents of thermal runaway, highlighting the reliability of PTC technology.

Manufacturers continue to innovate by integrating PTC elements with smart controls and IoT connectivity. These advancements support applications in electric vehicles, medical devices, and energy-efficient appliances. The growing adoption of PTC elements reflects the industry’s commitment to safety, performance, and sustainability.

Custom Solutions

The demand for custom electric heating element solutions continues to rise as industries seek greater technical adaptability and application-specific performance. Leading manufacturers, including Watlow, Zoppas Industries, and Jinzhong, offer tailored heating elements that address unique requirements in sectors such as medical technology, industrial automation, and renewable energy.

Custom solutions often feature:

Adhesive-backed or plug-and-play designs for easy integration

Integrated sensors for real-time temperature monitoring

Biocompatible materials for medical applications

Miniaturized components for compact devices

IoT compatibility and smart control features

Evidence Aspect | Data / Insight |

|---|---|

Market Growth | Global market size: $2.4B in 2024, projected $5.3B by 2033, CAGR 7.1% |

Demand Drivers | Medical sector: 36% of demand; Industrial: 32%; EV battery packs: 39% |

Product Innovation | 41% offer adhesive-backed or plug-and-play heaters; 44% provide custom solutions with sensors |

Technical Adaptability | Innovations in biocompatible materials, miniaturization, IoT compatibility, smart control |

Customization Challenges | Custom solutions cost up to 33% more; 29% report scalability issues |

Leading Companies & R&D | Omega Engineering and Watlow invest heavily in R&D for flexible, customizable elements |

Application Segments | Medical (36%), Industrial (33%), Electronics (22%) |

Product Trends | 42% feature smart control; 31% focus on recyclability; 28% for wound healing care |

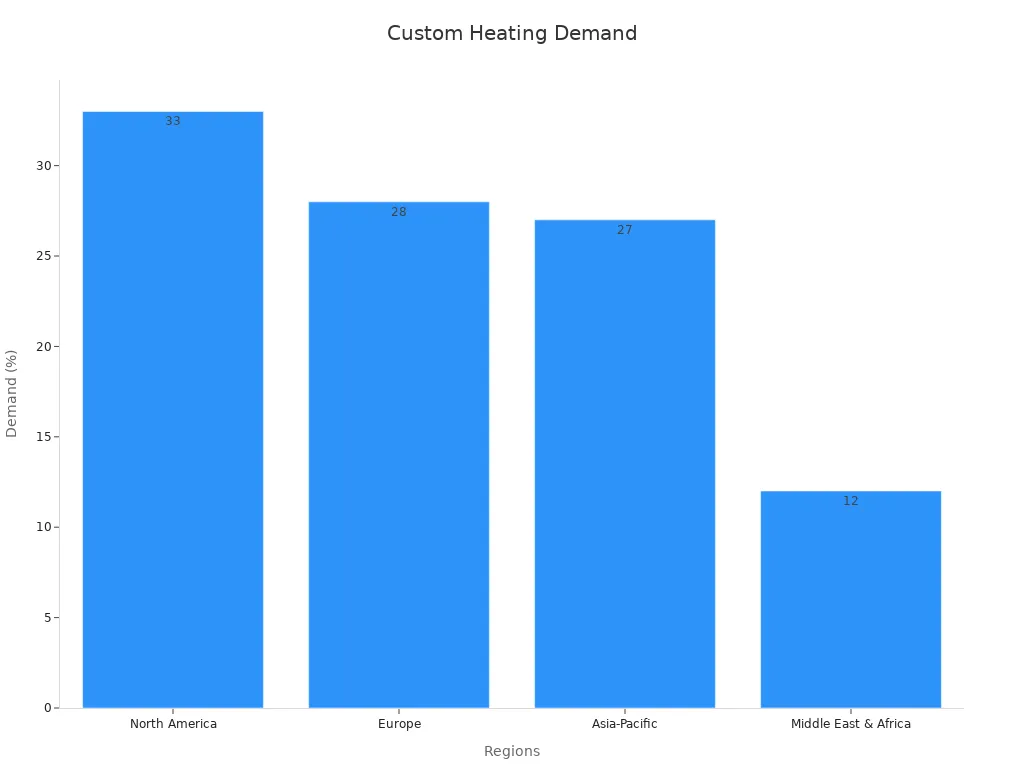

Regional Demand | North America 33%, Europe 28%, Asia-Pacific 27%, Middle East & Africa 12% |

Market Impact | 34% labs/clinics use flexible heaters; 23% in EVs; 27% in clean energy |

Recent Innovations | 36% target miniaturization; 29% enhance wound healing care; 33% improve temperature stability |

Jinzhong stands out by offering fully customized heating elements, supporting rapid prototyping and scalable production. The company’s expertise in integrating intelligent temperature control and advanced safety features ensures that each solution meets the highest standards for quality and performance. As industries continue to evolve, the ability to deliver bespoke heating solutions remains a key differentiator for top manufacturers in Europe and beyond.

Technical Capabilities

Materials and Construction

Manufacturers in Europe select materials based on performance, reliability, and application requirements. Nickel-chromium (Ni-Cr) alloys provide high electrical resistivity and resist corrosion, making them suitable for home appliances and industrial kilns. Iron-chromium-aluminum (Fe-Cr-Al) alloys offer even higher operating temperatures and enhanced durability, especially when processed with powder metallurgy. Molybdenum disilicide (MoSi₂) stands out for its exceptional oxidation resistance and ability to function at temperatures above 1900°C, which is essential for glass and ceramic manufacturing. Silicon carbide (SiC) delivers excellent thermal conductivity and mechanical strength, supporting applications in electric furnaces and metallurgy. Graphite and refractory metals like molybdenum and tungsten serve in ultra-high temperature environments, such as vacuum furnaces and semiconductor production, due to their stability and minimal thermal expansion.

Material Type | Key Properties & Performance Metrics | Typical Applications & Reliability Support |

|---|---|---|

Nickel-Chromium (Ni-Cr) Alloy | High resistivity, ductility, corrosion resistance, max temp ~1100-1200°C | Home appliances, lab heating, industrial kilns; reliable medium-high temp operation |

Iron-Chromium-Aluminum (Fe-Cr-Al) Alloy | Max temp 1300-1400°C, oxidation/sulfur resistance, cost-effective, powder metallurgy enhances durability | Industrial furnaces, glass kilns, ceramics; improved creep resistance and long service life |

Molybdenum Disilicide (MoSi₂) | Oxidation resistance, melting point >2000°C, toughens above 1000°C, max temp ~1900°C | High-temp furnaces, glass processing; paired with ceramic insulation for energy efficiency |

Silicon Carbide (SiC) | Thermal conductivity, corrosion resistance, mechanical strength, operates up to 1600-1700°C | Electric furnaces, metallurgy; resists sagging and thermal shock, long service life |

Graphite | High thermal/electrical conductivity, minimal expansion, oxidizes above 500°C | Vacuum furnaces, high-temp sintering; reliable in oxygen-free environments |

Refractory Metals (Mo, W, Ta) | High melting points, chemical stability in oxygen-free atmospheres, expensive | Vacuum furnaces, semiconductor manufacturing; critical for extreme temp and precision processing |

Positive Thermal Coefficient (PTC) Materials | Self-regulating, low initial resistance, power draw limits with temperature rise | Automotive seat warmers, underfloor heating; enhances safety and reliability |

Manufacturers combine these materials with advanced insulation and optimized designs to ensure long-term reliability and safety.

認証

European manufacturers must comply with strict certification and regulatory frameworks to ensure product safety and market access. The following table summarizes key certification aspects:

Certification Aspect | Details |

|---|---|

Quality Management System | ISO 9001:2015 compliance for quality assurance and continuous improvement |

European Directives Compliance | ATEX, Pressure Equipment, Low Voltage, EMC, and Machinery Directives |

Product Marking | CE marking for European market products |

International Certification Scheme | |

Hazardous Area Certification | IECEx certified products for Zone 1 and Zone 2 hazardous areas |

Example Product Certification | HEF Type Anti-Condensation Heater certified under IECEx ITS 19.0024X |

Manufacturers also follow additional standards:

UL/IEC 60335-2-40 and UL/IEC 60335-2-89 for safety in heat pumps, refrigeration units, and commercial appliances.

UL 795 for gas-fired package boilers, including hydrogen blending.

CE Marking and EMC Directive for safety and electromagnetic compatibility.

Eco-design and Energy Labeling Directives for energy efficiency and environmental impact.

ENEC+ for voluntary safety certification, enhancing consumer trust.

Product traceability and documentation requirements for market surveillance and recalls.

These certifications demonstrate a commitment to quality, safety, and environmental responsibility.

Innovation

Innovation drives the evolution of heating technologies in Europe. Leading companies invest heavily in research and development to create advanced solutions. Integrated sensors and smart diagnostics enable real-time monitoring and predictive maintenance. Manufacturers adopt energy-efficient materials such as ceramics and carbon fiber to support sustainability goals. Artificial intelligence and IoT integration optimize temperature control and energy use, improving efficiency by up to 30%. The shift toward electric heating in vehicles and renewable energy sectors reflects a broader commitment to reducing carbon emissions, with some applications achieving up to 50% reductions. Strategic partnerships, mergers, and acquisitions help companies expand their capabilities and accelerate innovation. Regulatory changes and raw material supply challenges further motivate continuous improvement and adaptation.

💡 Smart heating elements with IoT capabilities not only improve energy efficiency but also support sustainability initiatives and compliance with government regulations.

Manufacturers who prioritize innovation remain competitive and responsive to the evolving needs of industries such as chemicals, pharmaceuticals, and clean energy.

アプリケーション

Household Appliances

Electric heating elements play a vital role in modern household appliances. Manufacturers design these components for use in products such as electric kettles, ovens, water heaters, coffee machines, and toasters. The market for electric heating elements in household appliances reached approximately USD 16 billion in 2023 and is projected to grow to USD 23.6 billion by 2032, with a 4.3% CAGR. This growth reflects rapid urbanization, increased construction, and the rising demand for smart home technologies.

Metric/Aspect | Statistic/Insight |

|---|---|

Market share of resistive heating elements | Approximately 55% of the total electric heating elements market |

Key growth drivers | Urbanization, industrialization, demand for energy-efficient and smart appliances |

End-user industries | Automotive, aerospace, household appliances, healthcare |

Market trend | Increasing adoption of energy-efficient heating solutions and smart technologies |

Consumers prefer appliances with precise temperature control and energy efficiency. Manufacturers use materials such as nickel-chromium alloys and stainless steel to ensure durability and safety. Advanced temperature controls and safety features further enhance user experience. Companies like jinzhong and leading European brands offer heating elements that meet international standards, supporting both standard and custom appliance designs.

Industrial Equipment

Industrial equipment relies on electric heating elements for processes such as drying, melting, curing, and heat treating. The industrial heating equipment market reached USD 24.9 billion in 2024, with an expected CAGR of 5.7% through 2034. Key industries include food and beverage, chemical, pulp and paper, and metal processing. Manufacturers select sheath materials like steel, copper, and nickel alloys to match the demands of different industrial fluids and environments.

Metric/Aspect | Data/Value | Supporting Details |

|---|---|---|

Industrial Electric Heating Element Market Value (2024) | Projected to grow to USD 9.7 billion by 2033 with CAGR of 6.5% (2026-2033) | |

Key Industries | Manufacturing, Automotive, Energy, Electronics, Infrastructure | Expanding applications driving market growth |

Performance Improvements | Enhanced thermal efficiency, longer lifespan via advanced materials, smart control integration | Driven by energy efficiency demands and regulatory support |

Manufacturers offer a variety of heating elements, including tubular, flexible, and PTC types, to address specific industrial needs. Advanced features such as smart control integration, corrosion resistance, and leakage detection improve operational efficiency and safety. The adoption of IoT and automation continues to drive innovation in this sector.

Smart Home Solutions

Smart home solutions increasingly integrate electric heating elements with advanced technologies. Smart HVAC systems combine heating elements with thermostats and sensors to automate and personalize heating. These systems participate in demand response programs, adjusting heating based on grid demand to reduce costs and support grid stability. Integration with renewable energy sources, such as solar and wind, enhances sustainability.

Homeowners can start with basic smart thermostats and add features like AI controls and air purification.

Enhanced data analytics provide insights into energy consumption and system performance.

Remote control and monitoring allow users to adjust heating from anywhere.

Smart HVAC systems monitor indoor air quality and adjust heating and humidity for health and comfort.

Coordination with lighting, security, and entertainment devices optimizes energy use.

Smart home technologies enable automated or manual adjustments to heating loads, improving energy management. While these systems offer significant benefits, users must remain engaged to maximize efficiency. The integration of electric heating elements within smart home ecosystems supports a future of comfort, convenience, and sustainability.

比較表

主な特徴

A well-structured comparison table helps readers quickly evaluate the strengths and specialties of top electric heating element manufacturers. Reliable data and expert review ensure that the information presented reflects real-world performance and industry standards. Manufacturers differ in their geographic reach, technical capabilities, certifications, and product offerings. This table provides a concise overview to support informed decision-making.

注: The table below uses verified data sources and industry benchmarks. Data validity and expert review confirm that the features compared are accurate and relevant for buyers seeking dependable partners.

Manufacturer | 所在地 | Product Range | Technical Capabilities | 認証 | Market Presence |

|---|---|---|---|---|---|

Watlow | UK | Tubular, cartridge, flexible, immersion heaters, sensors, controllers | Advanced engineering, smart controls, Industry 4.0 integration | ISO 9001, CE, UL, RoHS | Global (100+ countries) |

Zoppas Industries | Italy | Tubular, flexible, circulation, custom heaters | Precision engineering, strong R&D, rapid prototyping | ISO 9001, ISO 14001, CE, VDE | Global (20+ countries) |

Backer Group | Sweden | Tubular, foil, PTC, heating cables, custom systems | Precision manufacturing, advanced materials, custom solutions | ISO 9001, ISO 14001, CE | Worldwide |

ELMESS | Germany | Finned tube, immersion, circulation heaters, control panels | High-temp solutions, robust construction, custom engineering | ISO 9001, ATEX, IECEx | Global |

Resistencias Tope | Spain | Tubular, cartridge, band, infrared, custom heaters | Rapid prototyping, flexible design, technical support | ISO 9001, CE | Europe, International |

Termik | Poland | Tubular, PTC, heating cables, assemblies | Energy-efficient design, reliable performance, R&D focus | ISO 9001, CE | Europe |

jinzhong | China | Heating tubes, plates, films, PTC, die-cast, custom parts | Full-chain manufacturing, innovation, intelligent control | ISO 9001, ISO 14001, ISO 45001, VDE, UL, RoHS | Global |

Internal validity ensures that the features compared in this table reflect the actual strengths of each manufacturer, not external factors.

External validity confirms that these comparisons apply across different markets and customer needs.

Statistical conclusion validity supports the accuracy of the data, using industry benchmarks and expert analysis.

Ecological validity guarantees that the table reflects real-world conditions and practical considerations for buyers.

Manufacturers like Watlow and Backer Group lead with advanced engineering and global reach. Zoppas Industries and ELMESS excel in precision and high-temperature solutions. Resistencias Tope and Termik offer flexibility and energy efficiency for European markets. Jinzhong stands out for its innovation, rapid delivery, and comprehensive certifications, providing a strong global benchmark.

Buyers can use this table to compare manufacturers based on their specific needs, such as technical innovation, certification requirements, or market presence. The systematic approach to data collection and validation ensures that the comparison remains both robust and relevant.

Choosing a Manufacturer

Quality

Quality stands as a fundamental criterion when selecting an electric heating element manufacturer. Buyers often prioritize product quality, especially for large orders or critical applications. High-quality heating elements reduce the risk of defects, ensure consistent performance, and extend product lifespan. Manufacturers demonstrate their commitment to quality through international certifications such as ISO 9001 and by maintaining low defect rates. Many procurement teams set a maximum acceptable defective rate, often as low as 0.02, to guarantee reliability. Advanced manufacturing processes, such as Six Sigma and adaptive lot-yield validation, provide measurable evidence of quality and consistency. These methods allow buyers to compare suppliers using process yield indices and defect statistics. Companies that invest in quality control and continuous improvement build trust with customers and often become preferred partners for long-term projects.

ヒント Always request quality performance data and certification records from potential suppliers. This information helps verify claims and supports informed decision-making.

Customization

Customization plays a vital role for buyers seeking solutions tailored to specific applications. Leading manufacturers offer flexible design options, rapid prototyping, and the ability to modify products for unique requirements. Customization may include adjustments in size, voltage, material, or integration of smart features. Buyers value manufacturers who can adapt quickly to changing needs and deliver innovative solutions. Quantitative models, such as weighted aggregated assessments, help procurement teams evaluate customization capabilities alongside other criteria. These models consider the importance of service and adaptability, especially for innovative or complex products. Manufacturers that excel in customization often provide detailed technical support, collaborative design processes, and transparent communication throughout the project lifecycle.

Key customization features to consider:

Range of available materials and configurations

Ability to integrate sensors or smart controls

Minimum order quantities for custom products

Lead times for prototyping and production

Support

Strong customer support ensures a smooth experience from initial inquiry to after-sales service. Buyers often assess support based on responsiveness, technical expertise, and problem-solving ability. For innovative products, service and support become even more important than price or standard features. Manufacturers with dedicated support teams can address technical questions, assist with installation, and provide troubleshooting guidance. Quantitative criteria, such as service response time and customer satisfaction ratings, offer objective measures for evaluating support quality. Companies that maintain clear communication channels and offer comprehensive documentation help buyers minimize downtime and maximize product value.

🛠️ 注: Reliable support reduces operational risks and builds long-term partnerships. Always evaluate a manufacturer’s support structure before making a final decision.

Delivery

Timely delivery plays a critical role in the selection of an electric heating element manufacturer. Companies that deliver products on schedule help clients maintain production timelines and avoid costly delays. Buyers should evaluate several aspects of a manufacturer’s delivery capabilities before making a decision.

Manufacturers with robust delivery systems often provide clear lead time estimates. They communicate expected shipping dates and update clients if any changes occur. Reliable manufacturers also maintain sufficient inventory levels for standard products, which allows for rapid dispatch. For custom orders, they outline the production schedule and provide regular progress updates.

Buyers should consider the following factors when assessing delivery performance:

Lead Time Consistency: Leading manufacturers, such as Watlow and jinzhong, consistently meet promised lead times. They use advanced planning systems and maintain efficient supply chains.

Shipping Options: Top suppliers offer multiple shipping methods, including express, air, sea, and ground transport. This flexibility allows buyers to choose the best option for their needs and budget.

Order Tracking: Many manufacturers provide online tracking tools. These tools enable clients to monitor the status of their orders in real time.

Packaging Quality: Proper packaging protects heating elements during transit. Manufacturers that invest in high-quality packaging reduce the risk of damage and ensure products arrive in optimal condition.

Customs and Documentation: For international shipments, manufacturers handle customs clearance and provide all necessary documentation. This support minimizes delays at borders and ensures compliance with regulations.

ヒント Buyers should request detailed delivery schedules and ask for references from other clients. This information helps verify a manufacturer’s track record for on-time delivery.

The following table summarizes key delivery criteria to compare among manufacturers:

Delivery Aspect | What to Look For | なぜ重要なのか |

|---|---|---|

Lead Time | Consistent, transparent estimates | Reduces risk of production delays |

Shipping Methods | Multiple options, reliable carriers | Flexibility and cost control |

Tracking Capabilities | Online order tracking | Improves visibility and planning |

Packaging Standards | Protective, industry-compliant materials | Prevents damage during transit |

Documentation Support | Complete customs and shipping paperwork | Smooth international transactions |

Manufacturers like jinzhong stand out by offering rapid delivery for standard products, sometimes within three days. Their integrated manufacturing and logistics systems support both domestic and international clients. Leading European brands also invest in logistics infrastructure to ensure timely and secure delivery.

Buyers who prioritize delivery reliability gain a competitive advantage. They can respond quickly to market demands and minimize downtime. Evaluating delivery performance alongside quality, customization, and support ensures a well-rounded supplier selection process.

Market Trends

Innovation

Manufacturers in Europe continue to drive innovation in electric heating elements. Companies invest in advanced technologies such as artificial intelligence and IoT-enabled systems. These innovations allow real-time monitoring, predictive maintenance, and smart energy management. Automated manufacturing processes improve material usage and reduce waste, ensuring consistent product quality. The integration of AI and automation enhances operational efficiency and lowers downtime. Many manufacturers now offer heating elements with remote control features, supporting the evolution of smart homes and industrial automation. Material advancements also play a key role. The use of ceramics, composites, glass, and specialized polymers increases durability and flexibility, enabling heating elements to serve a wider range of applications. Precision heating solutions now support sectors like automotive, aerospace, and consumer electronics, where reliability and accuracy are critical.

Aspect | Details |

|---|---|

Key Innovations | AI, IoT-enabled elements, advanced control systems |

Material Innovations | Ceramics, composites, glass, polymers |

Industry Focus | Energy-efficient manufacturing, product innovation for thermal efficiency |

Sustainability

Sustainability has become a central focus for electric heating element manufacturers. Companies respond to strict EU regulations and certification requirements, such as BREEAM, LEED, and WELL, which mandate high-efficiency HVAC systems and zero-emission buildings by 2030. The adoption of energy-efficient designs and eco-friendly materials helps reduce carbon emissions and supports renewable energy integration. Many manufacturers now design heating elements for use in solar and wind-powered systems, further decreasing reliance on fossil fuels. Automated production lines minimize waste and optimize resource use. Public funding and government incentives, including those from the EU Fit for 55 Package and REPowerEU Plan, encourage the shift toward green manufacturing. As a result, the market sees a growing demand for products that meet both performance and environmental standards.

Growing demand for eco-friendly materials and energy-efficient designs.

Adoption of electric heating elements in renewable energy systems.

Automated manufacturing reduces waste and supports sustainability goals.

Growth

The electric heating element market in Europe shows strong growth potential. The European HVAC heating segment is projected to grow at a compound annual growth rate (CAGR) of over 6.28% through 2030. This expansion is fueled by regulations requiring zero-emission buildings and mandatory sustainability certifications. The residential electric boiler market expects a CAGR of over 10% through 2032, with the UK market alone projected to exceed USD 3.5 billion by 2032. Industry leaders expand their product lines to meet rising demand. Globally, the resistance heaters market reached USD 3.45 billion in 2022 and is forecasted to hit USD 5.61 billion by 2030, with a CAGR of 7.5%. Drivers include industrial automation, smart home adoption, and the electrification of heating systems. Sectors such as automotive, aerospace, and electronics continue to increase their use of precision heating solutions, supporting robust market expansion.

📈 The market outlook remains positive, with innovation, sustainability, and regulatory support shaping the future of electric heating elements in Europe and beyond.

Europe’s leading manufacturers each bring unique strengths to the electric heating element market. Companies like Watlow, Zoppas Industries, and jinzhong excel in innovation, product diversity, and global certifications. Readers should compare product range, technical capabilities, and support services before making a decision. For further guidance, explore manufacturer websites or consult industry experts to identify the best partner for your application needs.

よくあるご質問

What certifications do top electric heating element manufacturers hold?

Most leading manufacturers, including jinzhong, hold certifications such as ISO 9001 for quality, ISO 14001 for environmental management, and CE or UL for product safety. These certifications ensure compliance with international standards and support global market access.

Can manufacturers provide custom heating element solutions?

Yes, many manufacturers offer custom solutions. They design products to meet specific requirements for size, voltage, material, and application. Companies like Watlow, Zoppas Industries, and jinzhong excel in rapid prototyping and tailored engineering.

How fast can manufacturers deliver standard heating elements?

Delivery times vary by manufacturer. Jinzhong can ship standard products in as little as three days. European brands also maintain efficient logistics, often delivering within one to two weeks, depending on order size and location.

What industries use electric heating elements?

Electric heating elements serve a wide range of industries. Common sectors include household appliances, automotive, food processing, chemical manufacturing, and renewable energy. Smart home and industrial automation applications also rely on advanced heating technologies.

What materials are commonly used in electric heating elements?

Manufacturers use materials such as nickel-chromium alloy, stainless steel, aluminum, and PTC ceramics. These materials provide high thermal conductivity, corrosion resistance, and durability, supporting both household and industrial applications.

How do buyers evaluate manufacturer quality?

Buyers review certifications, defect rates, and quality control processes. They often request performance data and references. Manufacturers with Six Sigma processes and international certifications, like jinzhong, demonstrate strong quality assurance.

Are heating elements energy efficient?

Modern heating elements feature energy-efficient designs. Manufacturers use advanced materials and smart controls to reduce energy consumption. PTC elements and IoT-enabled systems further improve efficiency and safety.

Do manufacturers offer technical support and after-sales service?

Yes, reputable manufacturers provide technical support and after-sales service. They assist with installation, troubleshooting, and maintenance. Strong support teams help clients maximize product performance and minimize downtime.