When you look for the most trusted heating element manufacturers in the market, you encounter names like Watlow, Chromalox, Tempco, Omega Engineering, Backer Group, Zoppas Industries, NIBE Element, Durex Industries, Tutco, and Thermowatt. Choosing a reputable manufacturer directly impacts safety, efficiency, and quality in your application. Top manufacturers deliver heating element solutions that meet strict quality and certification standards, ensuring reliable performance and long service life.

Trusted heating element brands stand out through:

- High-quality construction for improved safety and durability

- Advanced materials that support efficiency and consistent heat output

- Strong global presence and proven customer satisfaction

You benefit from precise temperature control, reduced maintenance, and long-lasting products when you select heating element manufacturers that prioritize quality and compliance.

What Makes a Heating Element Manufacturer Trusted?

Key Criteria for Reliable Heating Element Brands

Product Quality and Reliability in Heating Elements

When you select heating elements, you expect consistent performance and long service life. Reliable heating element manufacturers use advanced materials and strict quality production standards. This approach ensures high-quality heating elements that deliver precise temperature control in industrial and commercial applications. You benefit from reduced downtime and fewer replacements, which supports both safety and efficiency in your operations.

Industry Certifications and Compliance Standards

You should always look for heating element suppliers that comply with recognized industry standards. Certifications such as UL, ANSI, and NFPA demonstrate a manufacturer’s commitment to safety and quality. These certifications guarantee that heating elements meet legal and insurance requirements, reduce risks of fire or electrical shock, and ensure reliable operation in specific applications. Certified products also lower maintenance costs and improve operational efficiency.

Note: Trusted manufacturers often provide transparent documentation, custom engineering support, and references from successful projects.

Global Presence of Heating Element Manufacturers

A strong global presence signals that a manufacturer can support diverse industrial heating elements across multiple markets. When you choose a manufacturer with international reach, you gain access to a broad range of heating elements for specific applications, along with reliable after-sales service and replacement parts. This global support ensures you receive consistent quality and technical guidance, no matter where your application is located.

Customer Reviews and Brand Reputation

You can gauge a manufacturer’s reliability by examining customer reviews and their reputation in the market. Manufacturers with positive feedback often demonstrate a history of delivering quality products and responsive support. Case studies from industries such as automotive and food processing show how trusted brands improve efficiency, reduce downtime, and provide energy-efficient heating solutions for industrial and commercial applications.

Innovation and Technology in Heating Element Design

Innovation drives the development of energy-efficient heating and industrial heating elements. Leading manufacturers invest in research and development to create heating elements that offer precise temperature control and advanced safety features. For example, PTC heater elements self-regulate temperature, which enhances durability and supports energy-efficient heating in demanding applications. Manufacturers that prioritize technology help you achieve better performance and lower operational costs.

Why Trust Matters When Choosing Heating Elements

Trust plays a critical role when you select heating elements for industrial, commercial, or residential applications. Reliable manufacturers deliver products that meet strict safety and quality standards, ensuring your equipment operates efficiently and safely. In the automotive industry, for example, energy-efficient heating elements in seat warmers improve comfort and reduce energy use. In the food and beverage sector, flexible heaters and cast-in heaters help maintain material flow and minimize downtime, supporting long-term performance. When you choose a trusted manufacturer, you gain confidence in the quality, safety, and reliability of your heating solutions.

Top 10 Heating Element Manufacturers and Brands in 2025

Watlow Heating Elements

Company Overview

Watlow stands as a global leader in the design and manufacture of electric industrial heating elements. You find Watlow’s solutions in critical sectors, including energy processing, semiconductor, foodservice, and nuclear industries. The company operates with more than 4,000 employees and maintains a presence in 16 countries, ensuring you receive support and expertise wherever your applications require it.

Product Range and Applications

Watlow offers a comprehensive range of heating elements, including tubular, cartridge, flexible, and immersion types. You can use these products in high-power applications such as carbon recycling, ammonia production, and renewable energy generation. Watlow’s electric heaters also serve the pharmaceutical, automotive, and energy storage sectors. Their heating elements provide precise temperature control, making them ideal for sensitive processes and demanding environments.

Notable Features of Watlow Heating Elements

Watlow’s heating elements deliver uniform heat distribution and minimize the risk of hot spots. You benefit from advanced safety features and integrated thermal control systems. The company’s electric heating element designs support clean thermal solutions, helping you align with net-zero and sustainability goals. Watlow’s products meet rigorous industry certifications, including NQA-1 and ASME standards, which ensures safety and reliability in critical applications.

Key Strengths and Innovations

You gain access to industry-leading technology when you choose Watlow. The company’s HELIMAX system uses Continuous Helical Flow (CHF) technology, which eliminates dead zones and reduces fouling risks. The POWERSAFE system integrates medium voltage control and heating, supporting high-power applications. Watlow’s electric industrial heating elements offer precise surface temperature control, improving process efficiency and safety. The table below highlights Watlow’s key innovations and market impact:

| アスペクト | Evidence Detail |

|---|---|

| Technology Innovation | HELIMAX system uses Continuous Helical Flow (CHF) technology for uninterrupted heat flow, eliminating dead zones and hot spots, reducing fouling risks. |

| High Power Applications | Electric process heaters suitable for applications exceeding 100MW, including carbon recycling and ammonia production. |

| Integrated Systems | POWERSAFE system integrates medium voltage control and heating for high power applications. |

| Efficiency & Sustainability | Supports clean thermal solutions aligned with net-zero goals; energy-efficient electric thermal solutions for renewable power generation. |

| Certifications & Quality | Products meet NQA-1 and ASME Section I, III, VIII, IX standards, ensuring safety and quality in critical sectors like nuclear energy. |

| Market Presence & Innovation | Over 1,100 patents; global presence with sales offices in 16 countries; 4,000 employees and multiple manufacturing and technology centers worldwide. |

| Industry Applications | Serves semiconductor, pharmaceutical, energy processing, automotive, foodservice, nuclear, and energy storage sectors. |

| Thermal Control & Safety | Precise control of heating element surface temperature and power draw reduces risk and improves process efficiency. |

| 環境への影響 | Electric heaters provide uniform heat with smaller footprint and safer operation by eliminating fossil fuel burning, storage, or transport. |

Chromalox Heating Element Solutions

Company Overview

Chromalox has established itself as a pioneer in electric industrial heating elements and thermal solutions. You encounter Chromalox products in a wide range of industries, including oil and gas, chemical processing, power generation, and food production. The company’s global reach and commitment to innovation make it a preferred choice for industrial customers seeking reliable and efficient heating elements.

Product Range and Applications

Chromalox provides an extensive selection of heating elements, such as tubular, strip, band, and flexible heaters. You can apply these solutions in process heating, freeze protection, and temperature maintenance for pipelines, tanks, and vessels. Chromalox’s electric heaters also support applications in environmental chambers, ovens, and advanced manufacturing processes. Their products address both standard and custom requirements, ensuring you find the right fit for your specific needs.

Notable Features of Chromalox Heating Elements

You benefit from Chromalox’s focus on energy efficiency and reliability. The company incorporates advanced ceramics, polymers, and smart heating solutions into its product designs. These features enhance durability and performance, allowing you to achieve consistent results in demanding environments. Chromalox’s heating elements also support sustainability initiatives by reducing energy consumption and improving operational efficiency.

Key Strengths and Innovations

Chromalox stands out for its ongoing investment in technological advancements. The company leverages smart heating solutions and advanced materials to deliver superior performance. You gain access to products that emphasize energy efficiency, reliability, and long service life. Chromalox’s competitive strengths position it alongside other industry leaders, as the market increasingly values innovation and sustainability. The company’s broad product range and commitment to quality ensure you receive dependable solutions for diverse applications.

Tip: When you select Chromalox, you invest in heating elements designed for both current and future industrial challenges.

Tempco Electric Heating Element Corporation

Company Overview

Tempco Electric Heating Element Corporation has built a reputation for delivering high-quality heating elements for industrial, commercial, and OEM applications. You find Tempco’s products in industries such as plastics, packaging, food processing, and medical equipment manufacturing. The company’s customer-focused approach ensures you receive tailored solutions and responsive technical support.

Product Range and Applications

Tempco offers a wide variety of heating elements, including band, cartridge, strip, tubular, and flexible heaters. You can use these products in injection molding machines, extruders, ovens, and laboratory equipment. Tempco’s electric industrial heating elements support both standard and custom designs, allowing you to address unique application requirements. The company’s coil and immersion heaters provide efficient heat transfer for process heating and temperature maintenance.

Notable Features of Tempco Heating Elements

You benefit from Tempco’s emphasis on product quality and customization. The company uses advanced manufacturing techniques to produce heating elements that deliver consistent performance and long service life. Tempco’s coil heaters and flexible heating elements offer precise temperature control, supporting critical applications in manufacturing and research environments.

Key Strengths and Innovations

Tempco’s strengths lie in its ability to provide rapid prototyping, custom engineering, and technical support. You can rely on Tempco for heating elements that meet strict industry standards and certifications. The company’s focus on innovation ensures you receive solutions that adapt to evolving industry needs. Tempco’s electric industrial heating elements help you achieve energy efficiency, process reliability, and reduced maintenance costs.

Omega Engineering Heating Elements

Company Overview

Omega Engineering stands as a recognized leader in the field of process measurement and control. You encounter Omega’s heating elements in laboratories, manufacturing plants, and research facilities worldwide. The company has built its reputation on precision, reliability, and a commitment to advancing temperature control technology. Omega’s global presence ensures you receive technical support and product availability wherever your applications demand it.

Product Range and Applications

You can select from a broad portfolio of heating elements at Omega Engineering. The company offers cartridge, tubular, flexible, and immersion heaters, as well as specialized coil heating elements. These products serve a wide range of applications, including laboratory testing, semiconductor manufacturing, food processing, and environmental chambers. Omega’s heating elements also support temperature maintenance in tanks, pipes, and industrial ovens. You benefit from both standard and custom solutions that address unique requirements in your operations.

Notable Features of Omega Heating Elements

Omega’s heating elements deliver precise temperature control and rapid heat-up times. You gain from their use of high-quality materials, which ensures durability and consistent performance. The company’s coil heaters provide uniform heat distribution, making them ideal for applications that require tight temperature tolerances. Omega also integrates advanced safety features, such as thermal cutoffs and over-temperature protection, to support safe operation in demanding environments.

Key Strengths and Innovations

You experience Omega’s strengths through its focus on innovation and customer support. The company invests in research and development to introduce new heating element technologies, including energy-efficient designs and digital temperature controllers. Omega’s technical team assists you with product selection, customization, and troubleshooting. Their commitment to quality and continuous improvement positions Omega Engineering as a trusted partner for your heating applications.

Backer Group Heating Element Manufacturers

Company Overview

Backer Group operates as a global supplier of heating elements and thermal management solutions. You find Backer’s products in industries such as automotive, HVAC, renewable energy, and household appliances. The company’s extensive manufacturing network and engineering expertise allow you to access reliable heating solutions tailored to your specific needs.

Product Range and Applications

Backer Group offers a comprehensive selection of heating elements, including tubular, foil, flexible, and coil types. You can use these products in applications ranging from electric vehicles and battery systems to water heaters and industrial ovens. Backer’s coil heating elements support precise temperature control in laboratory and medical equipment. The company also provides custom heating solutions for specialized industrial processes, ensuring you meet your operational goals.

Notable Features of Backer Group Heating Elements

You benefit from Backer’s focus on quality, efficiency, and adaptability. The company uses advanced manufacturing techniques to produce heating elements that withstand harsh environments and frequent cycling. Backer’s coil heaters deliver rapid response and uniform heating, which improves process consistency. The company’s products often include integrated sensors and control systems, helping you optimize energy use and maintain safe operation.

Key Strengths and Innovations

Backer Group demonstrates strength through its commitment to research, development, and sustainability. You see this in their adoption of eco-friendly materials and energy-saving designs. The company’s global engineering teams collaborate to develop innovative heating solutions for emerging applications, such as electric mobility and smart home devices. Backer’s dedication to customer service and technical support ensures you receive guidance throughout your project lifecycle.

Zoppas Industries Heating Elements

Company Overview

Zoppas Industries brings a long-standing Italian industrial heritage to the heating elements market. You recognize the company for its strong emphasis on research and development, which drives continuous improvement in product quality and innovation. Zoppas Industries serves customers worldwide, offering solutions for both traditional and advanced applications.

Product Range and Applications

You can choose from a diverse array of heating elements at Zoppas Industries, including tubular, flexible, foil, and coil types. The company’s products support applications in household appliances, automotive systems, medical devices, and industrial equipment. Zoppas Industries also provides heating solutions for renewable energy, HVAC, and food processing sectors. Their coil heating elements deliver efficient and uniform heat, making them suitable for precise temperature control in sensitive applications.

Notable Features of Zoppas Heating Elements

Zoppas Industries integrates Industry 4.0 technologies, such as robotics and digital transformation, into its production processes. You benefit from their servitization strategies, which include a cloud platform for remote device communication and after-sales digital services. These features help you optimize product performance and maintain strong engagement with the company. Zoppas Industries’ customer-centric business model ensures you receive solutions tailored to your needs.

Key Strengths and Innovations

You experience Zoppas Industries’ strengths through their focus on anticipating market needs and enhancing product quality. The company’s investment in R&D leads to innovative heating elements that support advanced applications. Their use of digital platforms and remote monitoring services allows you to manage and optimize your heating systems efficiently. Zoppas Industries’ approach combines tradition with modern technology, providing you with reliable and forward-thinking heating solutions.

NIBE Element Heating Solutions

Company Overview

You encounter NIBE Element as a major global player in the electric heater element market. The company operates with a strong focus on sustainable energy solutions and technological expertise. NIBE Element maintains a significant presence in the European market and supports customers worldwide through an extensive distribution network. The company’s financial stability and operational effectiveness stand out, as highlighted by comprehensive financial reports and industry benchmarks.

Product Range and Applications

NIBE Element offers a broad portfolio of heating elements designed for diverse applications. You can select from tubular, cartridge, foil, and flexible heaters. These products serve industries such as HVAC, automotive, renewable energy, and household appliances. NIBE Element’s solutions address both standard and custom requirements, making them suitable for everything from water heaters and industrial ovens to advanced electric vehicle systems. The company’s heating elements support energy-efficient and reliable performance in demanding environments.

Notable Features of NIBE Heating Elements

You benefit from NIBE Element’s commitment to quality and innovation. The company’s heating elements deliver consistent heat output and long service life. Customers appreciate the clarity and consistency of NIBE’s product documentation, which helps you make informed decisions. The company provides prompt technical support and easy-to-understand infographics, which enhance your experience and satisfaction. NIBE Element’s focus on sustainable energy aligns with the growing demand for advanced, energy-efficient heating solutions.

NIBE Element’s strong distribution network and customer-centric approach ensure you receive reliable products and valuable support across multiple markets.

Key Strengths and Innovations

NIBE Element demonstrates strength through its extensive product portfolio and technological leadership. You see the company’s innovation in its ability to anticipate market trends and deliver advanced heating elements for new applications. Financial reports highlight NIBE’s profitability, asset turnover, and long-term solvency, reinforcing its reliability as a supplier. Customer feedback consistently praises the company’s responsiveness and comprehensive support. NIBE Element’s position as a key innovator in the market ensures you have access to cutting-edge solutions for your heating needs.

- NIBE Energy Systems is recognized for its technological expertise and broad product range.

- The company’s strong European presence and distribution network support reliable delivery and service.

- Market reports highlight NIBE’s role as a key innovator in energy-efficient heating solutions.

- Customer testimonials reflect high satisfaction with product clarity, support, and documentation.

Durex Industries Heating Elements

Company Overview

Durex Industries stands out as a leader in the design and manufacture of specialized heating elements. You find the company’s products in a wide range of industries, including medical devices, food processing, packaging, and semiconductor manufacturing. Durex Industries adopts a customer-centric approach, focusing on innovation and tailored solutions to meet specific industry requirements.

Product Range and Applications

You can choose from a comprehensive selection of heating elements at Durex Industries. The company specializes in silicone rubber heaters, flexible heating technologies, cartridge heaters, and immersion heaters. These products support applications in analytical instrumentation, aerospace, plastics processing, and industrial automation. Durex Industries offers both standard and custom heating elements, enabling you to address unique challenges in your operations.

Notable Features of Durex Heating Elements

Durex Industries emphasizes product innovation and customization. You benefit from their expertise in flexible heating technologies, which allow for precise temperature control and adaptability in complex applications. The company’s heating elements are engineered for durability and consistent performance, even in harsh environments. Durex Industries collaborates with customers to develop solutions that fit exact specifications, ensuring optimal results for your processes.

Key Strengths and Innovations

You experience Durex Industries’ strengths through its focus on innovation, partnerships, and customer satisfaction. The company leads the market in silicone rubber heaters and flexible heating solutions. Industry reports highlight Durex Industries’ adaptability and leadership in the electric heating element sector. The company’s strategies include expanding its product portfolio, forming strategic partnerships, and prioritizing tailored solutions for specific applications.

- Durex Industries specializes in silicone rubber heaters and flexible heating technologies.

- The company focuses on customization and customer-centric solutions.

- Strategic partnerships and innovation drive product development and market reach.

- Durex Industries maintains a strong presence in the industrial electric heating element market.

Tutco Heating Solutions Group

Company Overview

Tutco Heating Solutions Group has established itself as a significant competitor in the industrial heating market. You find Tutco’s products in packaging, HVAC, medical, and electronics industries. The company’s focus on innovation and operational efficiency makes it a preferred choice for manufacturers seeking reliable and cost-effective heating elements.

Product Range and Applications

Tutco offers a wide array of heating elements, including air heaters, flexible heaters, cartridge heaters, and custom assemblies. You can use these products in packaging machines, drying systems, laboratory equipment, and process heating applications. Tutco’s standardized heater configurations enable quick installation and integration across diverse manufacturing environments. The company’s solutions support both small and large-scale operations, making them suitable for a variety of applications.

Notable Features of Tutco Heating Elements

Tutco’s heating elements stand out for their durability, cost-effectiveness, and ease of installation. You benefit from products designed for quick replacement and minimal downtime. The company integrates smart technologies, such as IoT-enabled predictive maintenance, which enhances operational efficiency and reduces unexpected failures. Tutco’s focus on standardized designs allows you to streamline maintenance and improve productivity.

Key Strengths and Innovations

Tutco Heating Solutions Group demonstrates strength through innovation and market presence. The company has developed smart air heating systems with predictive maintenance capabilities, supporting real-time data analysis and optimized performance. Tutco holds an estimated 5-9% market share in the packaging machine heaters segment, reflecting its strong industry position.

| 会社名 | Estimated Market Share (%) |

|---|---|

| Watlow Electric | 15-20% |

| Tempco Electric Heater | 12-17% |

| クロマロックス | 10-14% |

| Backer Hotwatt | 8-12% |

| Tutco Heating Solutions | 5-9% |

| Other Companies | 40-50% |

You gain from Tutco’s commitment to providing economical and reliable heating elements, especially valued by small and medium-sized manufacturers. The company’s integration of smart technologies and focus on operational efficiency set it apart in the industrial heating market.

Thermowatt Heating Element Manufacturers

Company Overview

You encounter Thermowatt as a global leader in the design and production of electric heating elements. The company began operations in Italy and now serves customers in over 100 countries. Thermowatt focuses on delivering advanced thermal solutions for both residential and industrial markets. You see their products in water heaters, household appliances, and commercial equipment. The company invests heavily in research and development, which allows you to benefit from innovative technologies and reliable performance.

Product Range and Applications

Thermowatt offers a broad portfolio of heating elements. You can select from immersion heaters, tubular heaters, and flange heaters. These products support applications in water heating, washing machines, dishwashers, and industrial boilers. Thermowatt also provides custom solutions for OEMs, which helps you meet unique technical requirements. The company’s heating elements play a critical role in temperature regulation and energy efficiency across many sectors.

Note: Thermowatt’s product range covers both standard and tailor-made solutions, ensuring you find the right fit for your specific application.

Here is a quick overview of Thermowatt’s main product categories:

| 製品タイプ | Typical Application | Key Benefit |

|---|---|---|

| Immersion Heaters | Water heaters, boilers | 迅速な熱伝達 |

| Tubular Heaters | Ovens, dishwashers | Uniform temperature |

| Flange Heaters | Industrial tanks, process | Easy installation |

| Custom Solutions | OEM appliances | Application-specific design |

Notable Features of Thermowatt Heating Elements

You benefit from Thermowatt’s commitment to quality and safety. The company uses high-grade materials that withstand corrosion and high temperatures. Their heating elements feature advanced insulation, which improves energy efficiency and extends product life. Thermowatt integrates safety devices, such as thermal cut-offs and thermostats, to protect your equipment from overheating. You also gain from their focus on easy installation and maintenance, which reduces downtime and service costs.

- High resistance to corrosion and scaling

- Integrated safety features for reliable operation

- Energy-efficient designs that lower power consumption

- Compatibility with a wide range of appliances and systems

Key Strengths and Innovations

Thermowatt stands out for its continuous innovation and global reach. You see the company invest in automated manufacturing processes, which ensure consistent quality and fast delivery. Thermowatt leads the market in developing eco-friendly heating elements that support sustainability goals. The company’s R&D teams work on new materials and smart technologies, such as IoT-enabled temperature monitoring. You benefit from their expertise in both mass production and custom engineering, which allows you to address evolving industry needs.

Tip: When you choose Thermowatt, you access a partner with decades of experience and a strong focus on technological advancement.

Comparison Table: Leading Heating Element Brands and Manufacturers

Brand Overview and Key Attributes

When you compare leading heating element manufacturers, you see that each brand brings unique strengths to the heating element market. Companies like Watlow, Chromalox, and Tempco focus on innovation and product development. They often form strategic partnerships to deliver customized solutions for industries such as manufacturing, automotive, and electronics. You notice that cost reduction and new manufacturing techniques drive competition. Brands like Kanthal AB and Nippon Carbon Co., Ltd. invest in research and development to improve efficiency and performance. The market remains dynamic, with companies adapting to changing industry demands and focusing on premium-quality oven heating elements and other advanced products.

| ブランド | イノベーションフォーカス | Customization | Strategic Partnerships | Market Segment Leadership |

|---|---|---|---|---|

| ワトロー | 高い | はい | はい | Industrial, Energy |

| クロマロックス | 高い | はい | はい | Process, Power |

| Tempco | ミディアム | はい | はい | OEM, Plastics |

| Omega | 高い | はい | いいえ | Lab, Research |

| 支援者グループ | 高い | はい | はい | Automotive, HVAC |

| ゾッパス | 高い | はい | はい | Appliances, Medical |

| NIBE要素 | 高い | はい | はい | HVAC, Renewable |

| Durex | 高い | はい | はい | Medical, Packaging |

| Tutco | ミディアム | はい | はい | Packaging, HVAC |

| Thermowatt | 高い | はい | はい | Residential, Industrial |

You benefit from a competitive market where brands strive for excellence in quality and innovation.

Product Range: Oven Heating Element, Immersion Heating Elements, and More

You find that top heating element manufacturers offer a wide product range. Most brands provide oven heating element solutions, including both high-quality oven heating elements and premium-quality oven heating elements for industrial and commercial use. You also see immersion heating elements, cartridge heaters, flexible heaters, and custom assemblies. This variety allows you to select the right product for your application, whether you need precise temperature control in an oven or efficient heat transfer in a tank.

| ブランド | Oven Heating Element | Immersion Heating Elements | Flexible Heaters | Custom Solutions |

|---|---|---|---|---|

| ワトロー | はい | はい | はい | はい |

| クロマロックス | はい | はい | はい | はい |

| Tempco | はい | はい | はい | はい |

| Omega | はい | はい | はい | はい |

| 支援者グループ | はい | はい | はい | はい |

| ゾッパス | はい | はい | はい | はい |

| NIBE要素 | はい | はい | はい | はい |

| Durex | はい | はい | はい | はい |

| Tutco | はい | はい | はい | はい |

| Thermowatt | はい | はい | はい | はい |

You can rely on these brands for a complete selection of heating solutions, from standard oven heating elements to advanced custom designs.

Certifications, Global Reach, and Industry Focus

You should always consider certifications and global reach when choosing heating element manufacturers. Leading brands comply with international safety and environmental standards, such as the European Union’s Ecodesign Directive. They use advanced materials like silicon carbide and ceramics to meet strict energy efficiency and safety requirements. You see strong market presence in North America, Asia-Pacific, and Europe. Many manufacturers expand through local production and partnerships, adapting to regional needs and regulations.

- Brands demonstrate industry focus by meeting regulatory frameworks and adopting advanced technologies.

- Global reach includes significant presence in aerospace, defense, and electronics sectors.

- Manufacturers invest in local facilities and partnerships to serve diverse markets.

You gain peace of mind knowing that top brands prioritize quality, compliance, and global support.

How to Choose the Right Heating Element Manufacturer

Assessing Your Heating Element Application Needs

Industrial, Commercial, and Residential Heating Elements

You must first identify your application’s environment and requirements. Industrial heating elements serve demanding sectors such as oil and gas, chemical processing, and power generation. In these industries, you often use circulation heaters to preheat crude oil, support chemical reactions, or generate steam. You need to consider fluid properties, flow rates, and temperature requirements for optimal performance. Proper selection of electric industrial heating elements leads to energy efficiency, cost savings, and longer equipment lifespan. If you work in commercial settings, commercial heating elements provide reliable solutions for food service, packaging, or HVAC systems. Residential applications focus on safety, ease of use, and compatibility with household appliances.

Avoid common mistakes in heater selection to prevent inefficiency, equipment damage, and downtime. Tailor your choice to the specific applications and process demands.

Customization Options and Technical Support

You benefit from manufacturers that offer customization and technical support. Many industrial processes require heating elements designed for specific applications, such as unique shapes, wattages, or mounting options. Flexible heater elements, for example, use materials like silicone or polyurethane to deliver thermal stability and durability in automotive, aerospace, and medical devices. Technological advancements in electric heaters, such as new conductive materials, improve efficiency and adaptability. When you select a manufacturer with strong technical support, you gain access to expert guidance for installation, troubleshooting, and maintenance.

Evaluating Heating Element Brand Reputation and Support

Warranty, After-Sales Service, and Customer Care

You should always evaluate a manufacturer’s warranty and after-sales service. Reliable brands provide clear warranty terms and responsive customer care. This support ensures you receive timely replacements or repairs, minimizing downtime in industrial and specific applications. After-sales service often includes technical assistance, spare parts availability, and maintenance advice. Strong customer care reflects a manufacturer’s commitment to long-term partnerships.

Customer Feedback and Case Studies

You can learn from industrial case studies that showcase the performance of electric industrial heating elements in real-world scenarios. For example:

- Circulation heaters improve crude oil flow in oil and gas.

- Chemical processing plants use electric heaters for precise temperature control.

- Power generation facilities rely on industrial heating elements for steam systems.

These examples highlight the importance of matching heating element features to your process needs. Key evaluation criteria include cost, feasibility, energy efficiency, safety standards, and maintenance. Experts such as engineers and energy inspectors recommend using multi-criteria decision-making methods to rank manufacturers and ensure alignment with your industrial requirements.

Considering Cost, Value, and Long-Term Performance

You need to balance initial investment with long-term value. Some electric heaters and heating elements have higher upfront costs due to advanced materials or technology. However, these options often deliver better energy efficiency, durability, and lower operating expenses over time. For instance, a premium model with a stainless steel tank may cost more initially but reduce energy bills and maintenance needs.

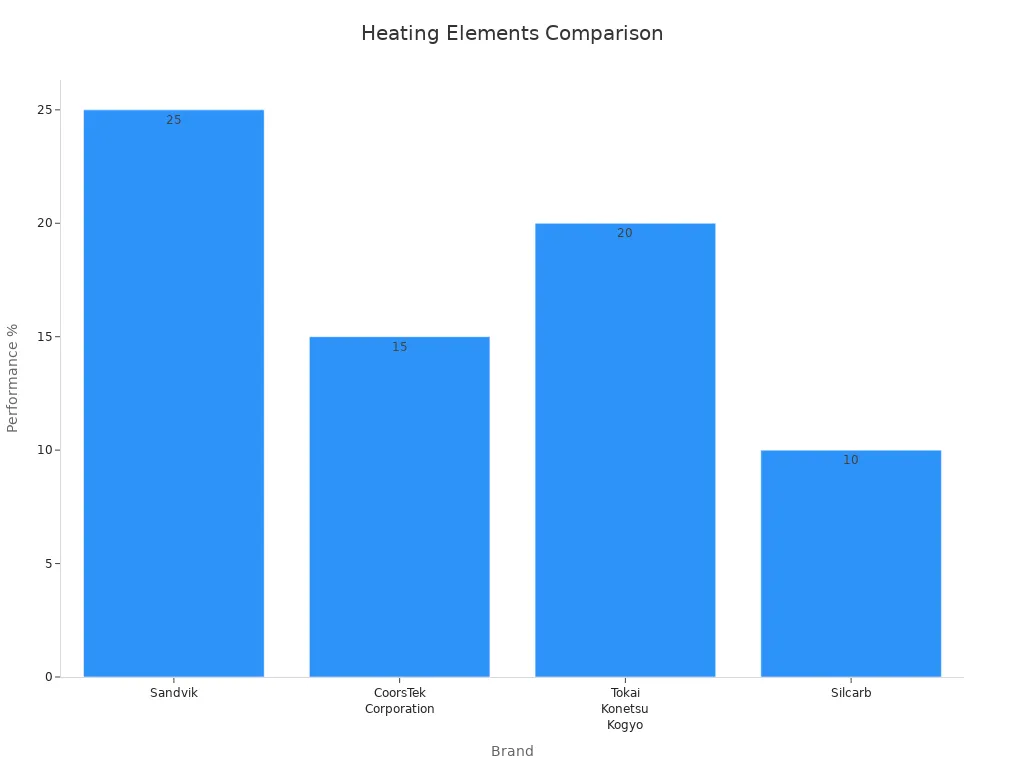

| ブランド | Key Innovation/Feature | Performance Improvement | Cost/Value Insight |

|---|---|---|---|

| Sandvik | New Silicon Carbide heating elements | Up to 25% better thermal conductivity | Higher initial cost, improved energy savings |

| CoorsTek Corporation | Upgraded SiC elements | ~15% reduction in energy consumption | Lower operational costs offset initial investment |

| Tokai Konetsu Kogyo | Longer operational life elements | 20% performance increase in extreme conditions | Extended lifespan adds value despite higher upfront cost |

| Silcarb | Improved resistance to thermal shock | 10% longer lifespan, higher reliability | Durability contributes to cost savings over time |

| I Squared R Element Co., Inc. | Enhanced temperature uniformity for precision | Improved heat distribution | Ideal for aerospace precision applications, supporting value through performance reliability |

You see that innovation drives value through efficiency and lifespan, not just price. When you choose a manufacturer, consider how their products align with your specific applications and long-term goals.

Key Differentiators Among Top Heating Element Brands

Innovation and R&D in Heating Element Technology

You see that innovation drives the heating element industry forward. Leading brands invest heavily in research and development to create advanced products that meet new market demands. Companies focus on integrating sensors and smart technologies into heating elements. These features allow you to benefit from diagnostics, faster maintenance, and precise temperature control in your applications.

Manufacturers also develop new materials, such as ceramics and carbon fiber, to improve energy efficiency and product lifespan. The rise of electric vehicles and renewable energy systems increases the need for energy-efficient heating solutions. You notice that some brands use artificial intelligence to support smart temperature control and predictive maintenance. This trend helps you optimize energy use and reduce downtime.

- Integration of sensors and smart technologies enables advanced diagnostics.

- New materials like ceramics and carbon fiber improve efficiency and durability.

- AI and smart controls support predictive maintenance and energy optimization.

- R&D investment responds to market challenges, such as raw material supply and regulatory changes.

- Customization for medical and industrial applications continues to grow.

Sustainability and Environmental Responsibility in Heating Element Manufacturing

Sustainability shapes the strategies of top heating element manufacturers. You find that companies assess the life cycle environmental impact of their products. Electric air source heat pumps and direct electric heaters now offer the lowest environmental impact among heating technologies. Manufacturers work to reduce greenhouse gas emissions by developing products that support net zero goals.

Current gas boilers emit about 220 grams of CO2 per kilowatt-hour, while hydrogen boilers with carbon capture can lower this to 64 grams. By 2050, a net zero heating mix could cut emissions by up to 95% per kilowatt-hour. You benefit from these efforts when you choose brands that prioritize energy efficiency and environmental responsibility.

- Life cycle assessments guide product development for lower emissions.

- Electric heating solutions support decarbonization and sustainability.

- Manufacturers invest in eco-friendly materials and production methods.

- Companies align with global sustainability targets and regulations.

Tip: When you select a brand with strong sustainability credentials, you help reduce your carbon footprint and support a cleaner future.

Regional Strengths and Specializations of Heating Element Manufacturers

You notice that regional strengths influence the specialization of heating element manufacturers. Europe leads the market with strong demand and advanced manufacturing, especially in countries like Germany, Italy, and France. North America maintains a significant presence, while Asia Pacific shows rapid growth due to technological advancements in Japan, South Korea, and China.

The following table highlights regional insights:

| Region | Countries Included | Market Insights |

|---|---|---|

| Global | 該当なし | Market size $2.86B (2021), projected $5.52B (2032), CAGR 6.17% |

| North America | United States, Canada | Significant market presence |

| Europe | Germany, UK, France, Italy, Spain | Leading region with strong demand and manufacturing |

| Asia Pacific | Japan, South Korea, China, Australia | Growing market with technological advancements |

| South America | Brazil, others | Increasing demand and usage |

| Middle East | Saudi Arabia, others | Emerging market |

| Africa | 該当なし | Emerging market |

Manufacturers in Europe and South America often focus on customization and environmental friendliness. In Asia Pacific, you find rapid adoption of advanced technology and cost-effective solutions. North American brands emphasize quality and a wide range of industrial applications.

- European brands excel in quality and eco-friendly design.

- Asian manufacturers lead in technology and affordability.

- North American companies focus on industrial performance and reliability.

Selecting a trusted heating element manufacturer ensures you receive safe, efficient, and long-lasting products. The top 10 brands deliver proven reliability and advanced technology, helping you achieve better performance in your applications. When you understand key performance metrics and consult qualified experts, you make informed decisions that improve equipment efficiency. Always prioritize quality, technical support, and brand reputation to maximize value and minimize risks in your heating solutions.

よくあるご質問

What certifications should you look for in heating elements?

You should look for certifications like UL, CE, and ISO 9001. These certifications confirm that the heating elements meet safety, quality, and performance standards. Always check the manufacturer’s documentation for proof of compliance.

How do you choose the right heating element for your application?

You need to consider your application’s temperature range, environment, and power requirements. Review the manufacturer’s product specifications. Consult technical support if you have unique needs or require custom solutions.

How often should you replace heating elements?

You should replace heating elements when you notice reduced performance, visible damage, or inconsistent heating. Regular inspections help you catch problems early. Always follow the manufacturer’s maintenance guidelines for best results.

Can you use industrial heating elements in residential appliances?

You should not use industrial heating elements in residential appliances. Industrial elements often require higher voltages and have different safety standards. Always select elements designed for your specific appliance and application.

What are the most common types of heating elements?

You will find several types, including tubular, cartridge, flexible, and immersion heaters. Each type serves different applications. For example, immersion heaters work well in tanks, while cartridge heaters fit into drilled holes.

Why does brand reputation matter when selecting heating elements?

Brand reputation signals consistent quality, safety, and support. Trusted brands invest in research, meet industry standards, and provide reliable customer service. You reduce risks and improve performance by choosing a reputable manufacturer.