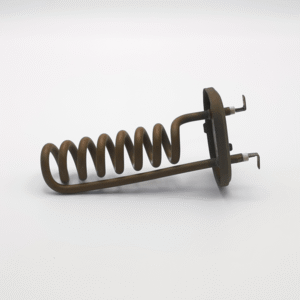

Metal Heating Plate——High-performance heating solutions

Metal heating plates are widely used in industrial, medical, laboratory and consumer fields. Their core performance depends on material selection, surface treatment and temperature control technology.

MOQ:1000PCS

リードタイム:25日

工場所在地中国広東省中山市

Home appliances: electric kettle, coffee machine, health pot, electric pressure cooker, air fryer.

Industrial equipment: commercial oven hot air module, laboratory constant temperature reactor, food processing drying equipment, heater heating module.

Material and structure:

Stainless steel (304/316): corrosion-resistant, high temperature resistant (800°C), polished or matte surface, suitable for food and medical equipment.

Aluminum substrate (anodized): thermal conductivity 237 W/(m·K), lightweight, surface anti-oxidation coating, suitable for small household appliances.

Nickel-chromium alloy (NiCr): temperature resistance 1200°C, strong oxidation resistance, high resistivity, suitable for industrial high temperature scenes.

Composite metal plate: stainless steel + aluminum layer (composite thermal conductivity), taking into account strength and thermal efficiency.

Household model: 500W–2000W (electric kettle, air fryer, coffee machine, etc.).

Commercial/industrial model: 2000W–10,000W (industrial oven, metal heat treatment equipment).

Working voltage:

Standard voltage: 110V/220V AC (error ±5%), compatible with global power supply.

Low voltage adaptation: 12V–48V DC (vehicle/portable device).

Temperature control:

PID algorithm: temperature control accuracy ±1°C, supports program heating (such as gradient heating).

Sensor type: K-type thermocouple (wide temperature range -50°C–1300°C) or PT100 platinum resistance (high precision).

Temperature range: room temperature +10°C to 1000°C (depending on the material).

寸法:

Shape: flat, curved, customized (suitable for pot bottom, oven cavity, etc.).

Thickness: 1mm–10mm (ultra-thin design suitable for compact space, thick plate for industrial equipment).

Safety protection:

Anti-dry burning: Automatically cut off the power when the temperature is greater than the set value by 10°C (such as setting 300°C, the actual 310°C triggers protection).

Overload protection: Automatically reduce the power when the current exceeds the limit, adapting to short circuit or external device abnormality.

Explosion-proof design(industrial grade): Passed CE/ATEX certification, suitable for flammable and explosive environments.

Life and reliability:

Conventional models: 5,000–15,000 hours (calculated based on 8 hours of continuous use per day).

Industrial-grade models: 10,000–20,000 hours (enhanced heat dissipation and anti-oxidation coating).

Core advantages

Durability and broad-spectrum adaptability:

Stainless steel material: acid and alkali resistant, wear resistant, suitable for food processing and medical sterilization equipment.

Nickel-chromium alloy: high temperature resistant (1200°C), anti-oxidation, suitable for extreme environments such as metallurgy and glass sintering.

High-efficiency thermal conductivity and uniform temperature:

Aluminum-based composite board: Surface temperature uniformity ≤±5°C, thermal efficiency of more than 90%.

Stainless steel heat sink: Reduce the risk of local overheating through heat conduction optimization design.

Precise temperature control and intelligence:

Supports multi-segment programming (such as heating → constant temperature → cooling), suitable for laboratory gradient reaction or industrial annealing process.

PID dynamic adjustment: Suitable for high-frequency temperature change scenarios (such as PCR amplification, material heat treatment).

Safety and easy maintenance:

Anti-corrosion coating (such as Teflon): Suitable for strong acid/alkali environment (laboratory/chemical industry).

Modular design: Convenient replacement of heating elements, reducing maintenance costs.

Lightweight and structural strength:

Aluminum substrate: Low density (2.7g/cm³), 40% lighter than stainless steel, suitable for portable devices.

Stainless steel frame: Shock-resistant, suitable for industrial vibration environment (such as heating of automotive parts).

Environmental protection and energy saving:

High heat recovery efficiency (metal has fast heat conduction) and complies with EU RoHS/REACH environmental protection standards.

正確な需要パラメータ情報をご提供いただければ、最短で24時間以内にお見積もりをお出しできます。

我々は、独立した生産能力を持つソース工場であり、電熱アクセサリーのR&Dと製造で30年の経験を持ち、500万セット以上の年間生産能力、OEM / ODMのカスタマイズをサポートし、工場の実生活のビデオ検査サービスを提供しています。

無料サンプルテストに対応しており、運賃は前払い(配達時に徴収)です。従来のモデルは、SGS試験報告書および性能パラメータ表とともに7~10営業日でお届けします。

営業日8:30~17:30までオンライン対応。お急ぎの場合は、公式ウェブサイトから作業依頼を送信してください。2時間以内に技術的な回答を提供し、48時間以内にソリューションを提供することをお約束します。

中山と蕪湖に2つの生産拠点があり、月産300万個以上で、全自動プレスラインと自動組立工場を備えています。標準製品の納期は15日で、カスタマイズ注文は30日以内に納品されます。バッチ供給にも対応しています。

ISO9001/14001、CE(EU)、ETL(北米)、RoHS(環境保護)の認証を取得し、防爆製品はATEX/IECExの二重認証を受けており、REACH規制にも適合しています。

Philips、Midea、Supor、Delonghi、BSH、SEB Groupなどの世界的な一流ブランドにサービスを提供し、製品はコーヒーメーカー、電気アイロン、ウォーターディスペンサー、太陽熱暖房システムなどのハイエンドプロジェクトで使用されています。