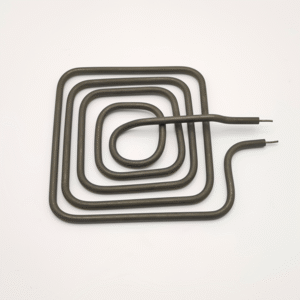

Electric Heating Plate——Full-scenario intelligent heating solution

High-performance heating elements designed for home, commercial and industrial scenarios, suitable for 500W-5000W power range, temperature resistance up to 450℃ (short time), thermal conductivity ≥237W/m·K, heat distribution uniformity ΔT≤3℃; integrated PID dynamic temperature control algorithm (±0.5℃ accuracy), support anti-dry burning protection (>15 seconds automatic power off) and pulse steam self-cleaning technology (scale removal rate >95%), passed CE/LFGB/RoHS certification, 40% lighter than traditional aluminum components, life span >150,000 cycles. Suitable for stewing, baking and high-temperature sterilization scenarios, support stable operation in extreme environments (-40℃~500℃).

MOQ:1000PCS

リードタイム:25日

工場所在地中国広東省中山市

Home appliances: egg cookers, yogurt machines, electric kettles, baby food heaters, health pots.

Industrial equipment: food processing constant temperature systems, laboratory constant temperature incubators, commercial dishwasher hot air modules, medical equipment constant temperature devices.

Power range:

Conventional model: 800W–2200W (suitable for electric kettles, egg cookers, health pots).

High-power model: 2200W–3000W (commercial-grade fast boiling kettle/stew pot).

Customizable: Supports power adjustment on demand (voltage and load requirements must be provided).

Working voltage:

Standard voltage: 110V/220V single-phase AC (global power grid compatible, error ≤±5%).

Resistance value:

Conventional model: 5Ω–15Ω (matched by power and voltage, error ≤±3%).

Working temperature:

Continuous stability: 200°C–300°C (surface temperature, high temperature resistant coating protection).

Short-term peak: 350°C (need to customize ceramic fiber insulation layer).

Material:

Base material: lightweight design aviation-grade aluminum alloy 6063-T5 with thermal conductivity over 200W/m·K.

Surface treatment: anodized layer (corrosion resistant) or Teflon (PTFE, anti-adhesion).

Dimensions:

Diameter/side length: Φ80mm–Φ200mm (round/square design).

Thickness: 3mm–8mm (suitable for embedded home appliance design).

Service life:

Conventional model: 10,000–15,000 hours (based on daily usage frequency).

High-power model: 15,000–20,000 hours (enhanced heat dissipation and coating protection).

High-efficiency thermal conductivity:

With a thermal conductivity as high as 200W/m·K, the aluminum alloy base material heats up to 100°C in 3 minutes and uses 15% less energy than conventional iron-chromium-aluminium heaters.

Precise temperature control:

Supports PID algorithm temperature control (±1°C accuracy), adapted to the constant temperature mode of the smart health kettle (such as tea making, milk powder mixing).

Safe and durable:

Teflon coatingis resistant to high temperatures (260°C) and anti-adhesion, and the cleaning frequency is reduced by 60%, which complies with FDA food contact certification.

Quick response:

No thermal inertia design, cools to a safe temperature within 30 seconds after power failure, and is adapted to high-frequency start-stop scenarios (such as continuous boiling water).

Lightweight adaptation:

The base material density is 2.7g/cm³, which is 40% lighter than stainless steel, and is adapted to the design of embedded small appliances.

正確な需要パラメータ情報をご提供いただければ、最短で24時間以内にお見積もりをお出しできます。

我々は、独立した生産能力を持つソース工場であり、電熱アクセサリーのR&Dと製造で30年の経験を持ち、500万セット以上の年間生産能力、OEM / ODMのカスタマイズをサポートし、工場の実生活のビデオ検査サービスを提供しています。

無料サンプルテストに対応しており、運賃は前払い(配達時に徴収)です。従来のモデルは、SGS試験報告書および性能パラメータ表とともに7~10営業日でお届けします。

営業日8:30~17:30までオンライン対応。お急ぎの場合は、公式ウェブサイトから作業依頼を送信してください。2時間以内に技術的な回答を提供し、48時間以内にソリューションを提供することをお約束します。

中山と蕪湖に2つの生産拠点があり、月産300万個以上で、全自動プレスラインと自動組立工場を備えています。標準製品の納期は15日で、カスタマイズ注文は30日以内に納品されます。バッチ供給にも対応しています。

ISO9001/14001、CE(EU)、ETL(北米)、RoHS(環境保護)の認証を取得し、防爆製品はATEX/IECExの二重認証を受けており、REACH規制にも適合しています。

Philips、Midea、Supor、Delonghi、BSH、SEB Groupなどの世界的な一流ブランドにサービスを提供し、製品はコーヒーメーカー、電気アイロン、ウォーターディスペンサー、太陽熱暖房システムなどのハイエンドプロジェクトで使用されています。