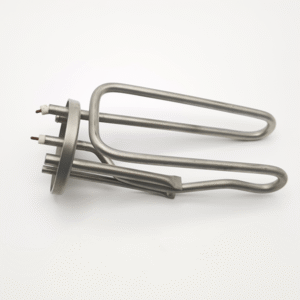

The heating element for deep fryers uses a stainless steel (316L) tube body combined with a nickel-chromium alloy resistance wire, with a multi-layer ceramic insulation coating on the surface, an integrated PID temperature control module and an NTC temperature sensor, supporting high-temperature rapid response (heating to 180°C in 3 seconds), energy efficiency ≥95%, an operating temperature range of 80°C–300°C, and adaptable to wide voltage (110V–240V) and power customization (1500W–6000W). The anti-grease coating design reduces carbon deposition, has IPX7 waterproof, anti-dry burning protection and automatic power-off functions, and the surface anodizing treatment enhances corrosion resistance. The service life exceeds 50,000 hours, complies with EU CE and North American UL certification, and meets the high-frequency frying needs of the catering industry.

MOQ:1000PCS

リードタイム:25日

工場所在地中国広東省中山市

Commercial fryers (such as French fries machines/chicken steak machines), deep fryers in restaurant chains, continuous frying equipment in food processing plants, air fryer modules for hotels/bakers, industrial oil bath reactors, laboratory high-temperature frying test systems, cold chain fryer preheating units, gas/electromagnetic dual-mode frying equipment, marine ship kitchen heating systems, and aerospace food processing equipment.

Power range: 1500W~6000W (customizable, suitable for high-frequency requirements of commercial fryers and industrial oil bath reaction scenarios)

Working voltage: 100V~240V AC/DC (wide voltage design, compatible with global voltage standards)

Resistance value: 0.5Ω~50Ω (matched by voltage and power, supports customization of stainless steel tube body)

Working temperature: 80°C~300°C (nickel-chromium alloy is resistant to high temperature oxidation, heats up to 180°C in 3 seconds)

Material: stainless steel 316L tube body, nickel-chromium alloy resistance wire, multi-layer ceramic insulation layer (customizable anodized surface treatment)

Dimensions: length 500mm~3m, diameter 8mm~30mm (supports threaded interface and special-shaped processing)

Service life: 50,000~80,000 hours (anti-oxidation coating + anti-dry burning design, suitable for continuous high-temperature operation)

Extremely fast heat conduction: adopts the core structure of electric heating tube (stainless steel tube body + nickel-chromium alloy), heats up to 180°C in 3 seconds, and is suitable for high-frequency frying in commercial fryers.

Industrial-grade temperature resistance: supports continuous operation at 300°C, the ceramic insulation layer is thermally shock-resistant, and meets the requirements of boiler heating systems and oil bath reactors.

IPX7 waterproof: fully sealed design combined with anti-oil coating, suitable for kitchen/ship humid environments, and meets CE/UL certification standards.

Energy-saving and high-efficiency: energy efficiency ≥ 95%, multi-layer ceramics reduce energy consumption, reduce the operating costs of catering equipment, and adapt to the energy-saving needs of electric heating units.

Flexible adaptation: threaded interface supports quick installation, meets non-standard scenarios such as air fryers/cold chain preheating, and is compatible with customized solutions for tubular heating elements.

Safety redundancy: dual protection of anti-dry burning + automatic power off, adapted to chain restaurant/aerospace equipment safety standards.

Long-lasting and durable: 316L stainless steel is corrosion-resistant, and anodizing treatment extends life by 50%, reducing maintenance frequency.

Fast delivery: standardized production line mass production, orders completed in 25 days, adapted to commercial equipment bulk procurement needs.

正確な需要パラメータ情報をご提供いただければ、最短で24時間以内にお見積もりをお出しできます。

我々は、独立した生産能力を持つソース工場であり、電熱アクセサリーのR&Dと製造で30年の経験を持ち、500万セット以上の年間生産能力、OEM / ODMのカスタマイズをサポートし、工場の実生活のビデオ検査サービスを提供しています。

無料サンプルテストに対応しており、運賃は前払い(配達時に徴収)です。従来のモデルは、SGS試験報告書および性能パラメータ表とともに7~10営業日でお届けします。

営業日8:30~17:30までオンライン対応。お急ぎの場合は、公式ウェブサイトから作業依頼を送信してください。2時間以内に技術的な回答を提供し、48時間以内にソリューションを提供することをお約束します。

中山と蕪湖に2つの生産拠点があり、月産300万個以上で、全自動プレスラインと自動組立工場を備えています。標準製品の納期は15日で、カスタマイズ注文は30日以内に納品されます。バッチ供給にも対応しています。

ISO9001/14001、CE(EU)、ETL(北米)、RoHS(環境保護)の認証を取得し、防爆製品はATEX/IECExの二重認証を受けており、REACH規制にも適合しています。

Philips、Midea、Supor、Delonghi、BSH、SEB Groupなどの世界的な一流ブランドにサービスを提供し、製品はコーヒーメーカー、電気アイロン、ウォーターディスペンサー、太陽熱暖房システムなどのハイエンドプロジェクトで使用されています。