You have a broken dryer 電熱線. This repair presents a clear choice based on cost. A professional will replace the part for $150 to $350. You can do it yourself for the part’s price, typically $20 to $80. Many owners, about 65%, try the DIY route first. Sourcing the correct Heating Element is key. Leading 発熱体メーカー, like 金中電熱, specialize in various 家電製品の加熱素子, influencing availability and price. Understanding these factors helps you make a cost-effective decision.

Cost Breakdown: Parts vs. Labor

The total expense for your repair splits into two main categories: the price of the new part and the cost of professional labor. You can control the final bill by understanding how each component contributes to the overall price. This breakdown will help you see where your money goes.

Heating Element Part Costs

The heating element itself is surprisingly affordable. However, the price varies based on your dryer’s brand, the type of element, and where you buy it.

Standard Electric Dryer Elements

You will find that most standard electric dryers from brands like Whirlpool, Maytag, GE, and Kenmore use common heating elements. These parts are widely available and are the most budget-friendly option. You can typically purchase a standard dryer heating element for $20 to $50. Their simple, effective design makes them a staple in the appliance repair world.

Premium Brand Elements (LG, Samsung, Bosch)

You should expect a higher part cost if you own a premium or smart dryer. Brands like LG, Samsung, and Bosch often use proprietary designs or integrate the element with other sensors. This complexity increases the manufacturing cost. A replacement element for these models usually falls in the $50 to $100+ range.

Heating Element Assembly Kits

Sometimes, buying just the element coil is not enough. A heating element assembly kit provides a more comprehensive solution. These kits bundle the heating element with related components that often fail at the same time, such as the high-limit thermostat and thermal fuse. While the initial cost is higher, a kit can save you from a second repair down the road.

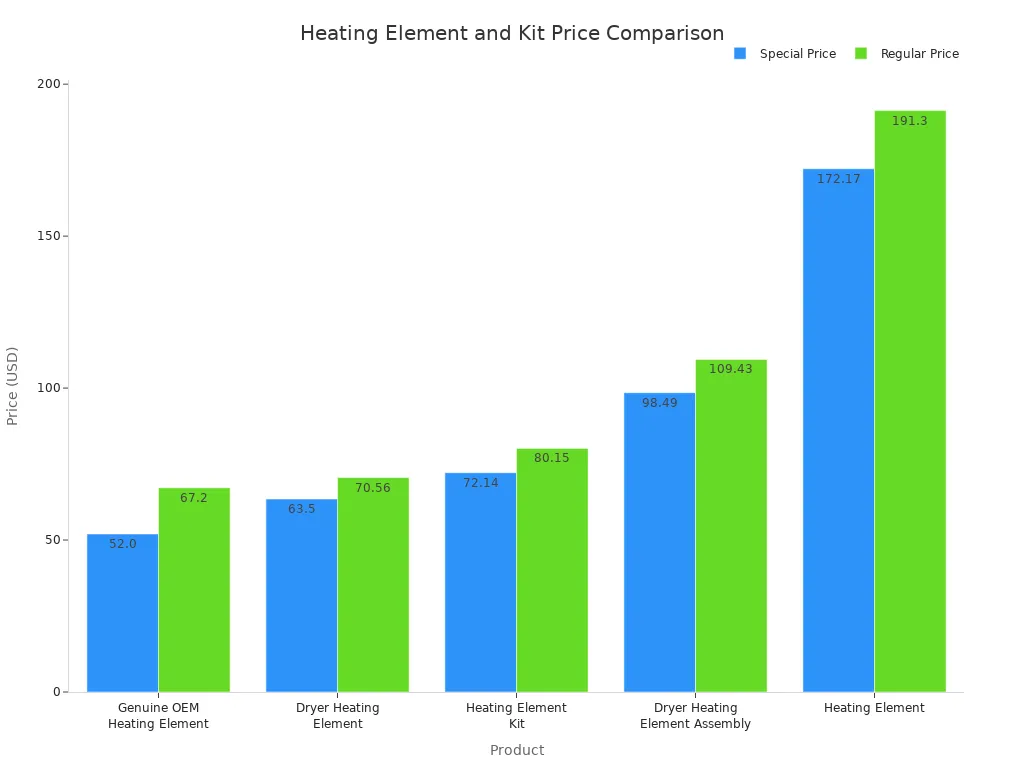

| 説明 | Special Price | Regular Price |

|---|---|---|

| Genuine OEM Heating Element | $52.00 | $67.20 |

| Dryer Heating Element | $63.50 | $70.56 |

| Heating Element Kit | $72.14 | $80.15 |

| Dryer Heating Element Assembly | $98.49 | $109.43 |

| 加熱エレメント | $172.17 | $191.30 |

The chart below visualizes how these prices compare, showing that kits and assemblies represent a larger upfront investment for greater peace of mind.

Where to Purchase Parts

You have several options for sourcing a new heating element:

- Local Appliance Part Stores: These stores offer expert advice and let you get the part immediately.

- Online Retailers: Websites like Amazon, RepairClinic, and PartSelect offer competitive pricing and a vast selection.

- Manufacturer’s Website: Buying directly from the manufacturer guarantees you get a genuine OEM (Original Equipment Manufacturer) part.

Professional Labor Costs

Hiring a qualified technician adds a significant labor cost to your bill. This fee covers the technician’s expertise, time, and business overhead.

Average Hourly Rates vs. Flat Fees

Appliance repair companies use two main pricing structures. Some charge an hourly rate for their work. Data from multiple sources shows the national average for an appliance technician is quite consistent.

| ソース | Average Hourly Wage |

|---|---|

| ZipRecruiter | $24.00 |

| BLS | $24.35 |

However, it is more common for companies to charge a flat fee for a standard repair like a heating element replacement. This fee typically ranges from $100から$250 and covers the entire labor portion of the job, regardless of how long it takes.

The Initial Service Call & Diagnostic Fee

Nearly every appliance repair company charges a service call fee. This upfront charge, usually between $75 and $125, covers the technician’s travel time and the initial work to diagnose the problem.

プロのアドバイス Most reputable companies will waive or apply the diagnostic fee toward the total repair cost if you decide to proceed with their service. Always ask about this policy when you book the appointment.

Emergency or After-Hours Surcharges

Your laundry rarely breaks on a convenient schedule. If you need a repair on a weekend, holiday, or outside of standard 9-to-5 business hours, you should anticipate an emergency surcharge. This extra fee can add $50 to $150 or more to your final bill.

Key Factors That Influence the Total Cost

The initial $150 to $350 professional repair estimate is a helpful starting point. However, several key variables can push your final bill to the lower or higher end of that spectrum. Understanding these factors gives you a more accurate picture of your potential expense. The specific details of your appliance and location play a significant role in the total repair cost.

Dryer Type: Electric vs. Gas

The single most important factor influencing your repair is whether your dryer is electric or gas-powered. This distinction changes the complexity, safety, and cost of the job.

Why Electric Dryers Are Cheaper to Repair

You will find that repairing an electric dryer is almost always less expensive. The heating system is simple. It consists of the heating element coil, thermostats, and fuses. A technician can diagnose and replace the element relatively quickly, which keeps labor charges down. The parts are also common and affordable, making this a straightforward and budget-friendly repair.

The Added Complexity of Gas Dryers

A gas dryer does not use a heating element in the same way an electric model does. Instead, it uses a gas burner assembly to generate heat. This system includes an igniter, flame sensor, and gas valve coils. These components are more complex and expensive than a simple electric coil.

⚠️ Safety Alert: Never DIY a Gas Dryer Repair Working with gas lines and combustion systems poses a serious risk of gas leaks, fire, or carbon monoxide poisoning. You should always hire a licensed and insured professional for any gas dryer repair. The increased labor cost ensures the job is done safely and correctly.

Dryer Brand and Model

Your dryer’s brand and specific model directly impact both part availability and price. Parts for common, mass-market brands are much easier and cheaper to find than those for high-end or older machines.

Common Brands (Whirlpool, Maytag, GE)

You benefit from economies of scale if you own a dryer from a popular brand like Whirlpool, Maytag, or GE. Manufacturers produce millions of these units, so replacement parts are widely available and competitively priced.

- A heating element for a Whirlpool dryer can cost around $40.80.

- A similar part for a メイタグ dryer might be priced at $43.96.

- GE dryer parts show significant price variation. A simple restring kit can be about $48.79, while a complete heater and housing assembly can cost over $250.

High-End and Smart Dryers

Premium brands like Bosch, Miele, Samsung, and LG often feature advanced technology, such as steam functions and smart diagnostics. These dryers use proprietary parts that are more complex and manufactured in smaller quantities. As a result, you should expect the heating element assembly for these models to be more expensive and potentially harder to source quickly.

Part Availability for Older Models

You might face a challenge if your dryer is over 10-15 years old. Manufacturers eventually discontinue parts for older models. While you can sometimes find a compatible part from a third-party supplier, a rare or out-of-production heating element can be very expensive if you find one at all. This scarcity can sometimes make a repair impractical.

Geographic Location

Where you live has a direct and significant effect on the labor portion of your repair bill. Appliance repair rates are not standardized across the country.

Urban vs. Rural Labor Rates

Labor rates are typically higher in major metropolitan areas. This difference reflects the higher cost of living and increased operational expenses (rent, fuel, insurance) for businesses in large cities. Technicians in urban centers must charge more to maintain a profitable business.

Regional Cost of Living Impact

While technicians in rural areas may have a lower hourly rate, you could face other charges. If local repair services are scarce, you might have to pay a higher travel fee for a technician coming from a neighboring town. This trip charge can sometimes offset the savings from a lower hourly rate, making location a crucial factor in your final repair cost.

Accessibility of the Unit

You might not think about your dryer’s location until it needs a repair. The ease with which a technician can access and work on your appliance directly impacts the labor time. More time and difficulty for the technician translate to a higher repair bill for you.

Stacked Washer/Dryer Units

You have a stacked washer and dryer to save space. This convenient setup, however, complicates repairs. A technician cannot simply access the back of the dryer. The repair process becomes much more involved.

First, the technician must safely unstack the dryer. This task often requires two people to prevent injury or damage to the appliances. The process involves:

- Disconnecting the dryer’s power and vent.

- Carefully lifting the heavy dryer off the washing machine.

- Moving the dryer to an open area with enough room to work.

This initial step alone can add significant time to the job. If the repair company charges hourly, you are paying for two technicians during the unstacking and restacking process. Even with a flat-fee repair, the company will factor this extra labor into your quote. Expect the cost to be $75 to $150 higher for a stacked unit compared to a standard, side-by-side installation.

Installations in Tight Closets

Your dryer may be tucked away in a small laundry closet or a narrow hallway. This installation creates a challenging work environment. A technician needs space to pull the unit out, disconnect it, and open its panels. A cramped space adds time and risk to the repair.

A technician working in a tight space must be extra careful. They need to avoid scratching floors, denting walls, or damaging the appliance itself. This slow, deliberate work adds to the total labor time.

The technician must first maneuver the dryer out of the closet completely. This step can be difficult if utility connections are short or the space is extremely limited. The entire repair—from diagnosis to reassembly—happens in a hallway or adjacent room. The technician then has to carefully slide the unit back into place and reconnect everything. This extra maneuvering adds a minimum of 30-60 minutes to the job, increasing your final cost.

How to Know If Your Heating Element Is Bad

Before you can decide whether to repair or replace your dryer, you must confirm the heating element is the actual problem. Several symptoms point to a bad element, but you should also rule out other common issues to avoid a costly misdiagnosis.

Telltale Symptoms of a Failing Element

You can often identify a failing element by observing your dryer’s performance. These signs indicate a problem with the heating system.

Dryer Tumbles But Produces No Heat

This is the most classic symptom. You hear the dryer running, and the drum is spinning, but the air inside remains cold. Your clothes tumble for an entire cycle without getting warm or dry.

Clothes Are Still Damp After a Full Cycle

You may notice a gradual decline in performance. If your clothes consistently come out damp after a standard cycle, the element might be failing. It may not be producing enough heat to evaporate the moisture effectively.

Dryer Overheats or Shuts Off Mid-Cycle

A faulty element can sometimes short-circuit against the metal housing. This can cause the dryer to get excessively hot, tripping the high-limit thermostat and shutting the machine off as a safety measure.

A Distinct Burning Smell

You might notice a sharp, metallic, or electrical burning odor. While a new dryer heating element can produce a slight smell during its first use, a persistent burning odor in an older machine is a red flag. This smell can be caused by several issues:

- Lint Buildup: Lint can accumulate on the element and ignite, causing a burning smell.

- Worn Drive Belt: A slipping or frayed belt can create friction and a burning rubber odor.

- Failing Motor: A struggling motor can produce an electrical burning smell.

- Element Malfunction: The element itself can break and arc, creating a distinct odor.

Ruling Out Other Common Problems First

A no-heat problem is not always caused by the element. You should investigate these other potential culprits before buying a new part.

Check for a Clogged Dryer Vent

A blocked vent restricts airflow, preventing heat from drying your clothes and causing the dryer to overheat. This can blow the thermal fuse. You should clean your vent line annually. If you hire a professional, you can expect to pay between $103 and $185 for the service.

Test the Thermal Fuse

The thermal fuse is a safety device that cuts power to the heating circuit if the dryer overheats. A clogged vent is the most common reason for a blown fuse. You can test the fuse for continuity with a multimeter. If it has blown, you must replace it. The part itself is inexpensive, but it is often sold in kits with other thermostats.

Inspect the High-Limit and Cycling Thermostats

These thermostats regulate the temperature inside the drum. If one fails, it can prevent the element from turning on or cause it to shut off prematurely. Like the thermal fuse, you can test these parts for continuity.

Verify the 240V Power Supply

Electric dryers require a 240-volt outlet. If one of the two circuit breakers trips, the dryer may still tumble with 120 volts, but it will not have the 240 volts needed to power the heater. You should check your home’s electrical panel to ensure both breakers are on.

How to Test the Heating Element

After ruling out other issues, you can perform two simple tests on the element itself.

Safety First: Always unplug your dryer from the wall outlet before opening the cabinet to perform any tests or repairs.

Performing a Visual Inspection for Breaks

Once you access the element, you can often see the problem. Look closely at the coils. A functional element will have a continuous, unbroken coil. You should look for any visible breaks, gaps, or dark, burnt-looking spots on the wire.

Using a Multimeter for a Continuity Test

A visual inspection is not always enough. You should use a multimeter set to the ohms (Ω) setting to test for electrical continuity. Touch one probe to each terminal on the element. A good element will show a reading between 9 and 12 ohms. If the multimeter reads infinity (OL) or zero, the element is bad and needs to be replaced.

The “Hidden Costs”: Related Parts That Often Fail

When your dryer’s heating element fails, you might think replacing that single part will solve the problem. However, a bad element is often a symptom of a larger issue. You should understand that other components likely failed alongside it or caused the initial failure. Addressing these related parts at the same time can save you from a repeat repair and additional expenses down the road.

Why One Failure Can Cause Others

Appliance components work together in a delicate system. The failure of one part can trigger a chain reaction, leading to a cascading failure of other related components.

The Domino Effect of Overheating

The most common cause of this domino effect is overheating, usually from poor airflow. A clogged vent restricts airflow. This forces your dryer to work much harder and leads to overheating. This excessive heat puts immense strain on all the electrical components in the heating circuit. The thermal fuse is designed to blow during an overheating event as a safety measure, shutting down the heating system. The constant high temperatures can also wear out the thermostats and cause the heating element itself to fail prematurely.

Thermal Fuse Replacement

The thermal fuse is a critical safety component in your dryer. You should think of it as a small, one-time-use electrical fuse.

Function and Average Cost

The thermal fuse protects your home from a potential fire. If the temperature inside your dryer gets dangerously high, the fuse blows and cuts all power to the heating circuit.

- Function: A single-use safety device that breaks the electrical circuit during a major overheating event.

- Important Note: A blown fuse is a symptom, not the root cause. You must find and fix the overheating issue (like a clogged vent) or the new fuse will blow immediately.

- Average Part Cost: The fuse itself is very inexpensive, typically costing $5 to $15. You will often find it bundled in a kit with the high-limit thermostat.

High-Limit Thermostat Replacement

The high-limit thermostat works with the thermal fuse, but it serves a different purpose. It is a key part of the normal heating cycle.

Function and Average Cost

This thermostat acts as a safety switch that regulates the dryer’s maximum operating temperature. It cycles the heating element on and off to maintain a consistent temperature and prevent minor overheating during a normal cycle. If it fails, it can either prevent the element from heating at all or allow the dryer to get too hot, which then blows the thermal fuse. To fix the issue, you must replace the faulty thermostat.

The average cost for a new high-limit thermostat is between $15 and $30. Buying it in a kit with the thermal fuse is often the most cost-effective option.

Cycling Thermostat Replacement

The cycling thermostat is the primary regulator of your dryer’s temperature. You can think of it as the command center for the heating system. It constantly monitors the air temperature inside the drum and signals the heating element to turn on or off to maintain the heat level you selected.

Function and Average Cost

If the cycling thermostat fails, it can either get stuck open, preventing the element from ever turning on, or stuck closed, causing the dryer to overheat. The cost to replace this component varies significantly depending on your dryer’s make and model. For instance, a common Whirlpool cycling thermostat may have a special price of $56.69, down from a regular price of $62.99. Prices for a brand like Maytag show an even wider range based on the specific part number:

- Maytag Dryer Cycling Thermostat (WP3387134): $29.76

- Maytag Dryer Cycling Thermostat (WP694674): $52.66

- Maytag Dryer Cycling Thermostat (WP503979): $74.72

- Maytag Dryer Cycling Thermostat (WP8318268): $102.46

Other Potential Wear-and-Tear Parts

While you have your dryer disassembled for the heating element repair, you have a valuable opportunity. You can inspect other mechanical parts that are prone to wear and tear. Addressing these components now can save you from another breakdown and repair bill in the near future.

Dryer Belt and Idler Pulley

The dryer belt is a long rubber belt that wraps around the drum, enabling it to spin. The idler pulley is a small wheel on a spring-loaded arm that keeps the belt tight.

プロのアドバイス You should inspect the belt for any signs of cracking, fraying, or glazing. A worn belt can slip or break, leaving you with a dryer that runs but does not tumble. A squeaking noise often points to a failing idler pulley.

Drum Rollers and Bearings

Drum rollers are small wheels, typically located at the rear of the drum, that support its weight as it turns. Some models use a bearing instead of or in addition to rollers. When these parts wear out, you will usually hear it. A loud, rhythmic thumping or a high-pitched squeal during operation are classic signs of failing rollers. Ignoring this noise is a mistake, as worn rollers put extra strain on the drive motor, risking a much more expensive repair down the line.

Step-by-Step Guide to DIY Dryer Heating Element Replacement

If you have confirmed the heating element is faulty, you can save a significant amount of money by tackling the replacement yourself. This guide provides the foundational knowledge you need to decide if this project is right for you and what to expect along the way.

Is This a Good DIY Project for You?

Before you start taking your dryer apart, you should honestly evaluate your comfort level with appliance repair. This self-assessment will help you avoid a frustrating and potentially costly experience.

Assessing Your Skill Level

Replacing a dryer heating element is a relatively straightforward task that you can accomplish with good DIY skills. You do not need to be a master technician. You should feel comfortable using basic hand tools, following a video or written tutorial, and keeping track of screws and small parts. Patience and a methodical approach are your most valuable assets for this job.

Time Commitment (1-3 Hours)

You should set aside one to three hours for this repair. An experienced DIYer working on a common dryer model might finish in about an hour. If you are new to appliance repair, or if your dryer is stacked or in a tight space, you should plan for the process to take closer to three hours. Rushing the job often leads to mistakes.

Essential Tools and Materials

You will need a few common tools to complete this repair. Gathering everything before you start will make the process much smoother.

- Nut Driver or Socket Set 🛠️: You will use this to remove the hex-head screws that hold the dryer’s panels and internal components in place. A 1/4-inch or 5/16-inch driver is most common.

- Screwdrivers (Phillips and Flathead): You need these for various screws and for gently prying open plastic tabs or connectors.

- Putty Knife or Spatula: A thin, flexible putty knife is often needed to release the spring clips that secure the top panel to the dryer’s frame.

- マルチメーター: You need this essential diagnostic tool to test the old element for continuity and confirm it is the source of the problem.

- Work Gloves and Safety Glasses: You should always protect your hands from sharp metal edges inside the appliance and shield your eyes from dust and debris.

- New Parts: You will need the correct replacement dryer heating element and any related components, like a new thermal fuse or thermostat.

Safety Precautions Before You Begin

You must prioritize safety above all else. An electric dryer uses high voltage, and skipping these steps can lead to serious injury.

⚠️ CRITICAL SAFETY WARNING Failure to follow these precautions can result in severe electric shock or other hazards. Do not proceed until you have completed both steps.

乾燥機のプラグを完全に抜く

This is the single most important step. You must physically unplug the dryer’s power cord from the 240-volt wall outlet. Do not simply turn the dryer off using its control knob. You must completely disconnect it from its power source to ensure there is no electricity flowing to the appliance.

Shut Off the Gas Supply (for gas dryers)

This guide is intended for electric dryers. As stated previously, you should always hire a professional for any gas appliance repair due to the risks of gas leaks and carbon monoxide. If a professional is working on your gas dryer, they will shut off the gas supply line at the valve located behind the unit before beginning any work.

A General Step-by-Step Process

This guide outlines the general steps for an electric dryer repair. You should remember that every dryer model is different. You must consult a repair manual or an online video specific to your model for precise instructions.

Accessing the Dryer’s Interior

Your first task is to open the dryer cabinet. The method depends on your dryer’s design. Most models require one of two approaches:

- Front-loading access: You will use a putty knife to release clips under the top panel. Then you can lift the top and remove the front panel.

- Rear-panel access: You will simply unscrew and remove a large metal panel on the back of the dryer. This is often the most direct route.

プロのアドバイス Keep all your screws organized in a magnetic tray or a small container. This simple step prevents you from losing them and makes reassembly much easier.

Locating the Heating Element Housing

You will find the heating element inside a long, cylindrical metal canister. This housing is typically located at the bottom rear of the dryer cabinet. The element itself is a coil of wire strung across ceramic insulators inside this canister. You can identify it by the two wires connected to its terminals.

Disconnecting and Removing the Old Element

You must carefully disconnect the old component. First, take a clear photo of the wire connections with your phone. This picture will be your reference for installing the new part. Next, gently pull the wire connectors off the element’s terminals. You may need pliers for a snug connection. Finally, remove the screws that secure the heating element housing or the element itself to the dryer frame. You can then slide the old element out.

新しい要素のインストール

You will now install the new dryer heating element. Carefully slide the new component into the housing, making sure it sits correctly on the insulators.

- Secure the new element or its housing with the mounting screws you removed earlier.

- Refer to the photo you took. Reconnect the wires to the correct terminals on the new element.

- Ensure the connections are firm and secure. A loose wire can cause overheating.

Reassembling the Dryer

You are now ready to put your dryer back together. You will work in the reverse order of how you took it apart. Reattach all panels and secure them with their original screws. Make sure no wires are pinched between panels. Once the dryer is fully reassembled, you can plug it back in and test your work.

DIY vs. Hiring a Pro: A Cost-Benefit Analysis

You have a choice between a DIY repair and hiring a professional. While doing it yourself seems cheaper upfront, you must weigh the potential savings against the risks and hidden expenses. This analysis will help you determine the most sensible path for your situation.

The True Cost of a DIY Repair

The DIY route involves more than just the price of the part. You must consider all factors to understand the true cost of your project.

Part and Tool Expenses

Your primary expense will be the new heating element, which costs between $20 and $80. You may also need to purchase tools like a multimeter or a specific nut driver if you do not already own them. These initial expenses are tangible and easy to calculate.

The Value of Your Time

Your time is a valuable asset. A DIY repair can take one to three hours, or even longer if you encounter problems. You should consider what that time is worth to you. A professional repair frees up those hours for other priorities.

The Risk of Misdiagnosis

You might incorrectly diagnose the problem. If you buy a new heating element but the real issue was a faulty thermostat, you have wasted money on an unnecessary part. A professional diagnosis prevents this kind of costly error.

When You Should Always Hire a Professional

In certain situations, the risks of a DIY repair far outweigh any potential savings. You should always defer to a qualified technician in these cases.

For All Gas Dryer Repairs

You must never attempt to repair a gas dryer yourself. Working with gas lines is extremely dangerous and requires specialized training.

- Improper handling can lead to gas leaks, fires, explosions, and deadly carbon monoxide poisoning.

- The U.S. Department of Transportation reports an average of 155 gas explosion incidents each year, often linked to faulty equipment.

- Carbon monoxide is an odorless, tasteless gas produced by malfunctioning gas appliances that can build up silently in your home.

Safety Warning: Due to the life-threatening risks, only a licensed professional should ever work on a gas appliance.

If You Own a Complex, High-End Model

Modern smart dryers with steam functions and advanced sensors have intricate systems. You risk damaging expensive electronic components if you are unfamiliar with their specific design. A professional has the correct training for these complex models.

If You Are Unsure About the Diagnosis

If you are not 100% certain the heating element is the problem, you should hire a pro. Paying a diagnostic fee is often cheaper than buying multiple parts through trial and error.

To Get a Warranty on Parts and Labor

Reputable repair companies guarantee their work. You get peace of mind knowing that if the repair fails within the warranty period, the technician will fix it at no additional charge.

The Risks of an Improper DIY Repair

A mistake during a DIY repair can have serious consequences that go far beyond the initial problem.

Causing More Expensive Damage

You could accidentally short-circuit the control board or break a plastic mounting tab. A simple mistake can easily turn a $40 part replacement into a $400 repair bill.

Creating a Serious Fire Hazard

If you fail to secure a wire connection properly, it can arc and create intense heat. This poses a significant fire hazard inside your appliance. An improper installation negates the safety features built into the dryer.

Voiding Your Appliance’s Warranty

If your dryer is still under a manufacturer’s or extended warranty, performing an unauthorized repair will almost certainly void it. This leaves you responsible for the full cost of any future failures.

Repair or Replace? Making the Smart Financial Decision

You have diagnosed the problem and know the repair cost. Now you face a critical decision: should you fix your old dryer or invest in a new one? Making the right financial choice requires you to look beyond the immediate repair bill and consider the long-term value of your appliance.

Using the 50% Rule

A simple guideline can help you make a logical decision. The 50% rule is a widely used principle in appliance repair.

How to Calculate Your Break-Even Point

You should apply this simple formula. If the cost of the repair is more than 50% of the price of a new, comparable dryer, replacement is usually the better financial option. This rule helps you avoid over-investing in an aging machine.

Comparing Repair Cost to a New Dryer Price

You need to know the price of a new appliance to use the rule effectively. For a new, mid-range electric dryer, most models are priced between $800 and $1,200. If your professional repair quote is $450, you are approaching that 50% threshold. This makes the decision to repair a much closer call.

The Age and Condition of Your Dryer

The age of your dryer is one of the most significant factors in this decision. An appliance’s lifespan directly impacts its reliability and the wisdom of further investment.

Under 5 Years Old: Repair is Likely Best

Your dryer is still relatively new. A heating element failure is likely an isolated issue. A repair is a smart and cost-effective choice that should give you many more years of service.

5-10 Years Old: A Judgment Call

Your dryer is in its middle age. You should consider its overall condition. Has it been reliable, or have you faced multiple repairs? If it has been trouble-free, a repair is reasonable. If it is showing signs of wear, replacement might be a wiser long-term move.

Over 10 Years Old: Replacement is Often Wiser

Your dryer is past its expected lifespan. Even after you fix the heating element, other major components like the motor or drum bearings could fail next. Investing in a new machine is often the more practical and economical solution.

Factoring in Energy Efficiency

Modern dryers offer significant advantages in energy consumption. You should look at the long-term savings a new model can provide.

Long-Term Savings with a New ENERGY STAR Model

New technology can lower your utility bills. Households can save between $90 and $120 annually on utility bills by switching to an ENERGY STAR certified heat pump dryer. These models use advanced technology to consume far less energy.

Comparing Old vs. New Operating Costs

Your old dryer may function, but it likely operates inefficiently compared to today’s standards. The money you save on electricity with a new, efficient model can help offset its purchase price over time, making it a sound financial investment.

Extending the Life of Your New Heating Element

You have invested time and money into installing a new heating element. You can protect that investment and prevent another premature failure with simple, consistent maintenance. These habits reduce strain on your dryer’s heating system, ensuring it operates efficiently for years to come. Proper care is the key to maximizing the lifespan of your new part and the appliance itself.

The #1 Rule: Clean Your Lint Trap

This is the single most important maintenance task you can perform for your dryer. You must make it a non-negotiable habit.

After Every Single Load

You need to remove the lint from the screen after every single drying cycle. A clean lint trap allows for maximum airflow. When the screen is clogged, hot air gets trapped inside the drum. This forces the heating element to work harder and stay on longer, leading to overheating and a significantly shorter lifespan.

プロのアドバイス You should also wash the lint screen with soap and water every few months. Dryer sheets can leave an invisible film on the mesh that restricts airflow even when the screen looks clean.

Regularly Clean Your Dryer Vent Duct

The lint trap catches most, but not all, of the lint. The rest builds up in your dryer’s vent duct over time, creating a hidden and dangerous problem.

Annually for Optimal Airflow

You should perform a thorough cleaning of your entire dryer vent line at least once a year. This includes the duct running from the back of the dryer to the outside of your home. A clogged vent is the primary cause of dryer fires and the number one reason heating elements and thermal fuses fail. Restricted airflow causes extreme heat buildup, putting immense stress on all heating components.

- Improved Safety: You drastically reduce the risk of a house fire. 🔥

- Better Performance: Your clothes will dry faster.

- Longer Part Life: You prevent the overheating that destroys heating elements.

Avoid Overloading the Dryer

You might be tempted to stuff as many clothes as possible into the dryer to save time. This common mistake is counterproductive and damaging to your appliance.

How It Strains the System

Your dryer needs space for hot air to circulate freely around the clothes. When you overload the drum, you create a dense, wet mass that blocks this airflow. The heating element must run continuously to try and penetrate the clump of laundry. This constant operation generates excessive heat and puts a heavy load on the element, motor, and belt. You force the components to work much harder than they were designed to, which inevitably leads to premature failure.

Use Automatic Dry Cycles

You can significantly influence your new heating element’s lifespan by choosing the right setting on your dryer’s control panel. Your dryer likely offers two primary modes: Timed Dry and Automatic Dry. You should make the automatic cycle your default choice. This simple habit is one of the most effective ways to protect your appliance from unnecessary wear and tear. Using the correct setting ensures your dryer operates efficiently, saving the heating element from needless stress and extending its operational life.

Preventing Unnecessary Overheating

The fundamental difference between timed and automatic cycles lies in how they determine when to stop. Understanding this distinction reveals why one setting is far superior for the health of your dryer’s components. A timed dry cycle operates on a simple clock. You set it for a specific duration, like 60 minutes, and it runs the heater for that entire period. The machine has no awareness of the clothes’ condition. It will continue to blast hot air long after your laundry is dry. This process generates excessive heat for no reason, forcing the heating element to endure prolonged, high-temperature operation.

Automatic cycles, on the other hand, work much more intelligently.

- They use built-in moisture sensors to monitor the humidity level of the air inside the drum.

- These sensors detect when the moisture from your clothes has evaporated.

- Once the clothes reach the selected dryness level (e.g., More Dry, Normal Dry), the system automatically shuts off the heating element.

This intelligent operation is the key to preventing unnecessary overheating. The dryer only produces heat when it is actually needed to dry your clothes. It avoids the pointless and damaging process of baking already-dry laundry, which is the primary flaw of the timed dry setting.

💡 By choosing an automatic cycle, you directly reduce the total runtime of your heating element. This simple action has several powerful benefits:

- It extends component life: Less use means less wear, directly contributing to a longer lifespan for your new heating element and thermostats.

- It saves you money: The dryer uses less electricity, which lowers your utility bills.

- It protects your clothes: You avoid “cooking” your fabrics, which can cause shrinkage, fading, and damage to delicate fibers.

Making the switch to automatic cycles is a free and easy way to safeguard your repair investment and keep your dryer running efficiently for years.

You have a clear financial choice when your dryer stops heating. A professional repair will cost you between $150 and $350. You can do the job yourself for the part cost of $20 to $80. Your final price depends on your dryer’s type, brand, and local labor rates.

💡 Your Smart Decision Guide:

- Apply the 50% Rule: You should compare the repair cost to 50% of a new dryer’s price.

- Consider Age: A repair is a sound investment for dryers under five years old. You should consider replacing a unit that is over a decade old.

よくあるご質問

How long should a new heating element last?

You can expect a new heating element to last between 3 and 10 years. Its lifespan depends heavily on your usage habits and maintenance. You can extend its life by cleaning the lint trap after every load and regularly cleaning the dryer vent duct.

Why does my new heating element have a burning smell?

A slight burning or oily smell is normal during the first one or two uses. New elements have a factory coating that burns off. If the smell is strong or persists after a few cycles, you should unplug the dryer and inspect for installation issues.

Is it safe for me to replace the heating element myself?

You can safely replace an electric dryer’s heating element if you follow proper precautions.

⚠️ Crucial Safety Step: You must unplug the dryer from its 240V outlet before starting any work. You should always hire a professional for any gas dryer repair.

Why isn’t my dryer heating after I replaced the element?

You may have another failed part. You should test the thermal fuse and high-limit thermostat for continuity with a multimeter. These safety components often fail at the same time as the element, especially if a clogged vent caused the initial problem.

How do I find the correct part number for my dryer?

You can find your dryer’s model number on a sticker, usually located inside the door, on the side, or on the back panel. You can then use this model number on an appliance parts website or the manufacturer’s site to find the exact heating element you need.

Should I replace the thermostats when I replace the element?

Yes, replacing the thermal fuse and high-limit thermostat is a smart practice. These parts are inexpensive and often fail due to the same overheating that destroyed the element. You can buy them together in a convenient and cost-effective kit.