Heater heating element

Electric heater heating element

The heating element of the electric heater is the core functional component of the electric heating equipment. It is essentially an “energy converter” that converts electrical energy into thermal energy. Its main body is usually made of resistive materials. Common types include metal wires such as nickel-chromium alloy wire (such as Cr20Ni80), iron-chromium-aluminum alloy (such as 0Cr25Al5), or thick film heating coatings (such as ceramic semiconductors), PTC ceramic sheets and other new materials. The structure is mostly filamentous, sheet-like, tubular or integrated on a substrate (such as an aluminum substrate). The Joule heat is generated by the current flowing through the resistive material, and the heat is directly or indirectly transferred to the target medium (water, air, liquid, etc.).

Its core advantages are high conversion efficiency (electrical energy to thermal energy is more than 90%), fast response (heating as soon as power is turned on, no delay) and strong adaptability (through material and structural design, it can adapt to different temperature requirements, such as low-temperature drying below 100°C and high-temperature furnaces above 1000°C).

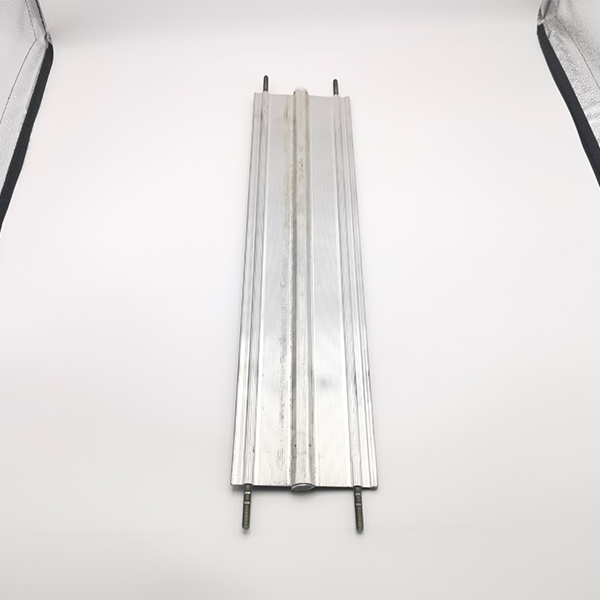

The electric heater heating element adopts high-purity nickel-chromium alloy heating wire and ceramic insulation skeleton,

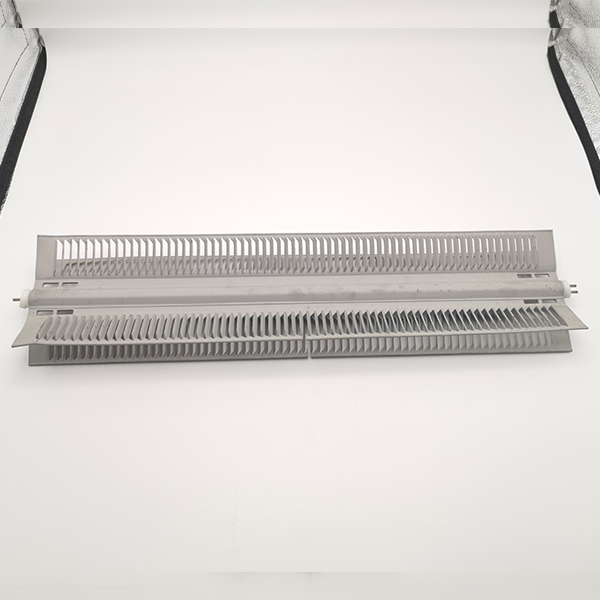

The finned heating element is designed for high-efficiency radiators, automotive heating systems and industrial hot air equipment.

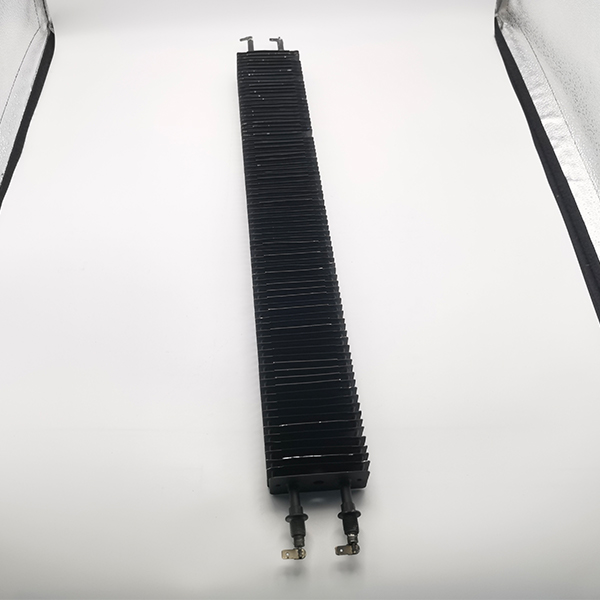

Fin-type heating elements designed for home heaters, commercial industrial HVAC systems and cold chain equipment

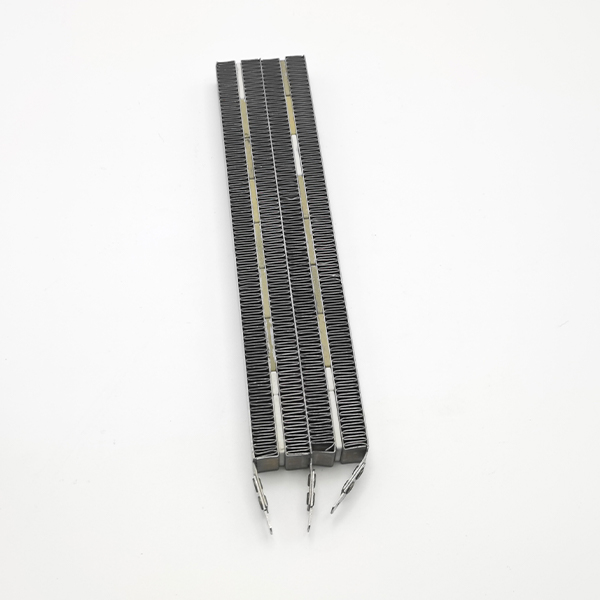

Semiconductor ceramic heating elements designed for home appliances, industrial equipment and new energy vehicles, using rare earth doped barium titanate

Electric fireplace heating element

The electric fireplace heating element is the core component of the electric fireplace to achieve the dual functions of “heat-visual”. It must not only efficiently generate heat to simulate the heating effect of a traditional fireplace, but also cooperate with optical design (such as flame lamps and reflective structures) to create a realistic flame visual experience. Its design must take into account thermal efficiency, safety, and aesthetics. Compared with ordinary electric heater elements, it emphasizes the integration with the “simulation scene”.

Electric fireplace heating elements are mostly made into sheets, honeycombs or tubes, with an insulating layer (such as aluminum oxide) on the surface, and are often integrated into aluminum heat sinks or embedded in simulated firewood textures. PTC is responsible for stable heating, and LED lights simulate flame jumping through dynamic light and shadow (with a microprocessor to control the flashing frequency), achieving a “heat-visual” separation but synergistic effect.

Home appliances: industrial heaters, air conditioning auxiliary heating modules, electric heaters, constant temperature water heaters.

Specially designed for home appliances, industrial equipment and new energy vehicles, the semiconductor ceramic heating element adopts rare earth doped barium titanate

The tubular heating element is designed for industrial hot air systems, agricultural greenhouse heating and household heaters. It adopts stainless steel 316L + ceramic fiber insulation structure

commercial display equipment and smart homes adopts nano-ceramic infrared radiation coating + aviation-grade aluminum alloy heat dissipation structure

Air conditioner heating element

The heating element of an air conditioner is the core component of its heating function. It is mainly used to supplement or replace heat pump heating to ensure that heat can be efficiently delivered to the room in low temperature environments (such as winter). Unlike the cooling mode (heat transfer through refrigerant circulation), the essence of the heating element is to directly convert electrical energy into thermal energy (electrical heat conversion) or to assist in improving the heating efficiency of the heat pump.

Air conditioning heating elements are key components for “emergency heating” and “comfort protection”, among which PTC ceramics have become the mainstream due to their safety and reliability. In the future, air conditioning heating elements will pay more attention to high efficiency and energy saving (such as intelligent power regulation) and user experience (such as low noise and uniform heating), and adapt to different climate and scene requirements.

The heating element is specially designed for split air conditioners, central air conditioners and industrial heat pump systems.

Consumer Appliances: Central air conditioning auxiliary heating, residential heat pump systems, smart home ventilation units.

The finned tube heating element is designed for industrial duct systems, agricultural greenhouse heating and commercial heaters.

A high-performance heating element designed for industrial heat treatment furnaces, semiconductor annealing equipment

取得 カスタム見積もり

正確な需要パラメータ情報をご提供いただければ、最短で24時間以内にお見積もりをお出しできます。

We are a source factory with independent production capacity, with 40 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

無料サンプルテストに対応しており、運賃は前払い(配達時に徴収)です。従来のモデルは、SGS試験報告書および性能パラメータ表とともに7~10営業日でお届けします。

営業日8:30~17:30までオンライン対応。お急ぎの場合は、公式ウェブサイトから作業依頼を送信してください。2時間以内に技術的な回答を提供し、48時間以内にソリューションを提供することをお約束します。

中山と蕪湖に2つの生産拠点があり、月産300万個以上で、全自動プレスラインと自動組立工場を備えています。標準製品の納期は15日で、カスタマイズ注文は30日以内に納品されます。バッチ供給にも対応しています。

ISO9001/14001、CE(EU)、ETL(北米)、RoHS(環境保護)の認証を取得し、防爆製品はATEX/IECExの二重認証を受けており、REACH規制にも適合しています。

Philips、Midea、Supor、Delonghi、BSH、SEB Groupなどの世界的な一流ブランドにサービスを提供し、製品はコーヒーメーカー、電気アイロン、ウォーターディスペンサー、太陽熱暖房システムなどのハイエンドプロジェクトで使用されています。