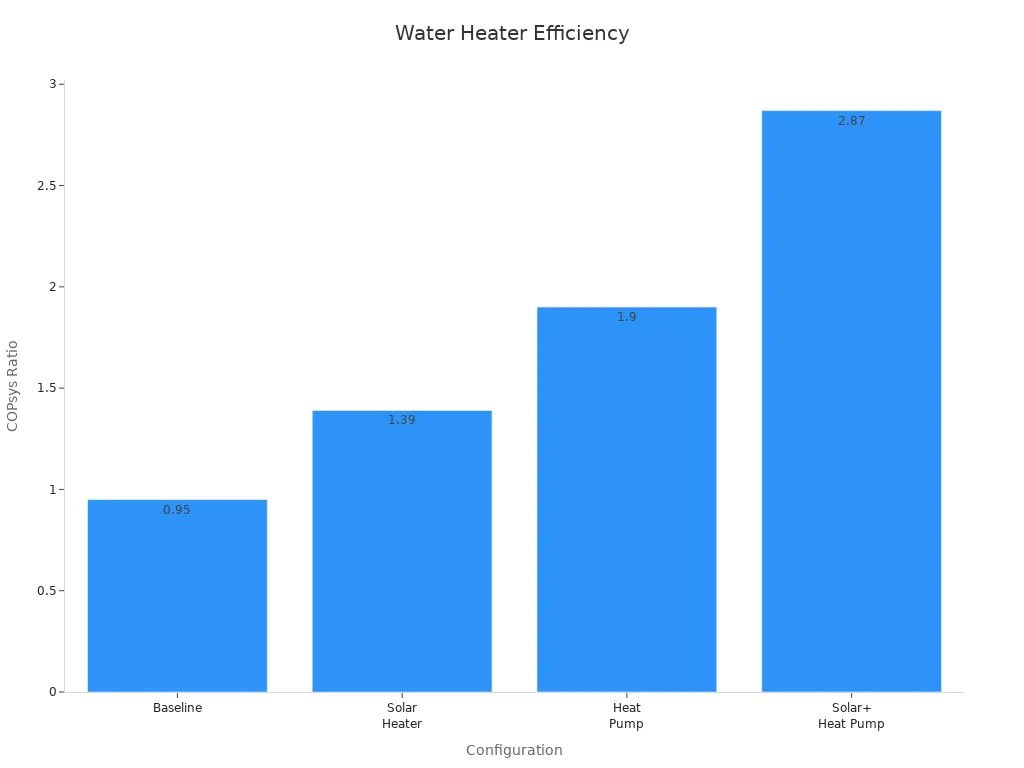

You rely on the water heater element inside your water heater to deliver a constant supply of hot water for daily needs. This heating element, often made of robust heating tubes, converts electrical energy directly into heat, maintaining your hot water supply at temperatures between 55°C and 57°C. The efficiency of each water heating element impacts how much energy your system uses. For example, the baseline electric water heater configuration achieves a Coefficient of Performance (COPsys) of 0.95, as shown below.

On average, you use around 246 liters of hot water every day, highlighting the critical role of the water heater element in keeping your water consistently hot.

Water Heater Element Basics

What Is a Water Heater Element?

You find the water heater element at the core of every electric water heater. This component looks like a metallic rod, often straight or spiral-shaped, and sits inside the tank. Manufacturers design these elements to convert electrical energy into heat, raising the temperature of the water stored in your tank. Most water heater elements use a resistance wire, usually made from nichrome, encased in a metal sheath to prevent corrosion. The element’s length, typically around 12 inches for residential models, and its wattage rating determine how quickly it can heat water. You can identify the correct replacement by checking the voltage and wattage ratings marked on the element itself. These specifications ensure compatibility and safe operation within your water heater.

How Water Heater Elements Work in an Electric Water Heater

When you turn on your electric water heater, electrical current flows through the water heater element. The resistance wire inside the element heats up as electricity passes through it. This process converts electrical energy directly into thermal energy, which then transfers to the surrounding water. The thermostat monitors the water temperature and activates the element when the temperature drops below your set point. Once the water reaches the desired temperature, the thermostat cuts off power to the element, preventing overheating. Safety switches add another layer of protection by shutting off the element if the water temperature exceeds safe limits.

Empirical data supports this process. For example, the Engineering ToolBox demonstrates that the electrical energy supplied to a water heater element translates directly into a measurable increase in water temperature. The relationship follows the equation: electrical energy (U × I × t × μ) equals the thermal energy change (c × m × ΔT). In practice, a 12 V, 10 A heater running for five minutes can raise the temperature of 0.4 kg of water by about 21.4°C, assuming perfect efficiency. This direct conversion ensures you get hot water quickly and reliably.

Why Water Heater Elements Are Essential

You depend on the water heater element to deliver hot water for showers, cleaning, and cooking. Without a functioning element, your electric water heater cannot heat water, leaving you with only cold water from the tap. The element’s efficiency and durability directly affect your energy bills and the reliability of your hot water supply. Most residential water heater elements operate at 240 volts, with wattage ratings between 1000 and 6000 watts, tailored to the size and recovery rate of your water heater. Using the correct element ensures safe operation and optimal performance.

Water heater elements also come in different designs and materials, such as metal alloys or ceramics. Ceramic elements offer better efficiency and resist corrosion, especially in areas with hard water. The dual-element design, with both upper and lower elements, allows your electric water heater to heat water in stages, improving efficiency and recovery time. You can see the impact of different water heater types in the table below:

| Water Heater Type | Average Cost Range | Average Lifespan (Years) | Energy Efficiency Level |

|---|---|---|---|

| Tank | $500 – $700 | 10 – 15 | Lower |

| Tankless | $800 – $1,200 | 15 – 20 | Higher |

| Gas | Medium | High | Medium |

| Electric | Low | Low | Low |

| Solar | High | High | High |

| Heat Pump | Moderate to High | Moderate to High | High |

Tip: Always match the wattage and voltage of your replacement hot water heater element to your water heater’s specifications. This step ensures safety and extends the life of your system.

You rely on water heater elements to maintain a steady supply of hot water. Their design, material, and correct installation play a crucial role in the comfort and efficiency of your home.

Types of Water Heater Elements

When you choose a water heater, you need to understand the different types of heating elements available. Each type affects how efficiently your water heater delivers hot water and how long the system lasts. Let’s explore the main types of heating elements you will encounter.

Screw-In Heating Element

You will find screw-in heating elements in most modern electric water heaters. Manufacturers design these elements with a threaded base, so you can easily screw them into the side of the tank. This design allows for quick replacement and maintenance. If you ever need to replace a heating element, you can use a standard wrench or a special socket tool. Screw-in heating elements offer a secure fit and reduce the risk of leaks. You often see these elements in residential water heaters because they provide reliable performance and straightforward installation.

Tip: Always turn off the power to your water heater before replacing a screw-in heating element to avoid electrical hazards.

Flange Heating Element

Some older or commercial water heaters use flange heating elements. These elements attach to the tank with a flat, square, or round flange and several bolts. You need to remove the bolts and the flange to replace the element. Flange heating elements provide a strong seal and work well in larger tanks. However, you may find them less common in new residential models. If your water heater uses a flange heating element, check the gasket and bolts for wear during routine maintenance.

| Type | Installation Method | Common Use Cases |

|---|---|---|

| Screw-In | Threaded | Residential, easy repair |

| Flange | Bolted Flange | Commercial, older units |

Low-Watt Density vs. High-Watt Density Water Heater Elements

You need to consider watt density when selecting heating elements for your water heater. Low-watt density heating elements spread the heat over a larger surface area. This design reduces the risk of mineral buildup and extends the life of the element, especially in areas with hard water. You will notice that low-watt density elements operate at a lower temperature, which helps prevent scorching and keeps your hot water cleaner.

High-watt density heating elements concentrate more heat in a smaller area. These elements heat water quickly and cost less upfront. However, they may wear out faster if your water contains a lot of minerals. If you want your water heater to last longer and deliver consistent hot water, you should consider low-watt density elements.

Note: Always match the wattage and voltage of your heating elements to your water heater’s specifications for safe and efficient operation.

By understanding these types of heating elements, you can make informed decisions about maintenance, replacement, and upgrades for your water heater. The right choice ensures you always have access to hot water when you need it.

Upper and Lower Elements in Electric Water Heaters

When you look inside a typical electric water heater, you will find two main heating elements: one at the top (upper element) and one at the bottom (lower element). Each element plays a specific role in how your water heater delivers hot water efficiently and reliably.

The upper heating element sits near the top of the tank. Its main job is to heat the upper portion of the water first. When you turn on your water heater after a period of inactivity, the upper thermostat senses the temperature. If the water is cold, the upper element activates. Once the upper part of the tank reaches the set temperature, the thermostat switches off the upper element and sends power to the lower heating element.

The lower heating element takes over after the upper section is hot. It heats the rest of the water in the tank, ensuring you have a full supply of hot water. This process, called non-simultaneous operation, means only one element runs at a time. Most residential water heaters use this setup because it balances energy use and safety.

You can see the benefits and differences between these configurations in the following list:

- Most water heaters use non-simultaneous operation, where the upper element heats first, then the lower element finishes the job.

- A double throw thermostat controls which element receives power, preventing both from running at the same time.

- Recovery times for non-simultaneous systems range from about 25 minutes to an hour, depending on tank size and wattage.

- Some advanced water heaters use simultaneous operation, allowing both heating elements to run together. This setup cuts recovery time by more than half but requires heavier wiring and a larger breaker.

- In simultaneous systems, the lower element does most of the work, which can help you take advantage of reduced electricity rates if your utility offers separate circuits.

Note: If you notice your water heater running out of hot water quickly, one of the heating elements may have failed. Testing both elements ensures your system works at peak efficiency.

The design of upper and lower heating elements helps your water heater deliver consistent hot water while managing energy use. You benefit from faster recovery times and reliable performance, especially during periods of high demand. When you understand how these elements work together, you can make better decisions about maintenance and upgrades for your water heater.

Structure and Materials of a Water Heater Element

Understanding the structure and materials of water heater components helps you make informed decisions about maintenance and replacement. Each part of the heating element plays a specific role in delivering reliable hot water and ensuring the longevity of your water heater.

Main Components of a Heating Element

A typical heating element consists of several key water heater components. These parts work together to convert electrical energy into heat and transfer it efficiently to the water in your tank.

Metal Sheath

You will find the metal sheath as the outermost layer of the heating element. Manufacturers use this protective tube to shield the internal coil from direct contact with water. The sheath resists corrosion and withstands high temperatures, which is essential for long-term performance. Selecting the right sheath material, such as stainless steel or Incoloy, helps prevent chemical attacks from minerals in your water supply.

Heating Coil

Inside the sheath, the heating coil acts as the core of the heating element. This coil, usually made from a nickel-chromium alloy, generates heat when electricity passes through it. The coil’s resistivity determines how efficiently it produces heat. A stable temperature coefficient of resistance ensures that the coil maintains consistent performance, even as temperatures fluctuate during operation.

Insulation and Seals

Insulation surrounds the heating coil, keeping it electrically isolated from the metal sheath. This insulation, often made from magnesium oxide, conducts heat while preventing electrical shorts. Seals at each end of the element keep water out and protect the internal components from moisture. Hermetic sealing becomes especially important in demanding environments, where exposure to water or chemicals could damage the element.

Tip: Regularly inspect the seals and insulation on your water heater components to prevent leaks and electrical hazards.

Common Materials Used in Water Heater Elements

The choice of materials for your water heater components directly affects durability, efficiency, and resistance to corrosion. Here are the most common options:

Copper

Copper elements offer excellent heat transfer and cost-effectiveness. You often see copper in standard residential water heater models. However, copper can corrode quickly in hard or aggressive water, so these elements usually have a protective coating.

Stainless Steel

Stainless steel provides superior corrosion resistance and mechanical strength. If you live in an area with hard water or high mineral content, stainless steel elements help extend the life of your water heater. These elements also resist oxidation at high temperatures, maintaining performance over time.

Incoloy

Incoloy, a nickel-iron-chromium alloy, stands out for its exceptional resistance to oxidation and chemical attack. You will find Incoloy elements in high-end or commercial water heaters, where demanding conditions require maximum durability. Incoloy maintains its integrity at higher temperatures and offers a longer service life than copper or standard stainless steel.

You can compare the properties that impact the durability and performance of these materials in the table below:

| Property / Factor | Description | Impact on Durability and Performance |

|---|---|---|

| Resistivity | Electrical resistance of the material, critical for efficient heat production and energy use. | Ensures consistent heating and energy efficiency. |

| Oxidation Resistance | Ability to resist oxidation at high temperatures, often via protective oxide layers in alloys or ceramics. | Prevents degradation and extends element lifespan. |

| Temperature Coefficient of Resistance (TCR) | Change in resistivity with temperature; lower TCR preferred for stable heating output. | Maintains predictable heating performance under temperature changes. |

| Mechanical Properties | Includes creep resistance, tensile strength, and ductility at elevated temperatures. | Ensures structural integrity and long-term reliability. |

| Melting Point | Maximum operating temperature limited by melting point and oxidation resistance. | Determines safe operating temperature range and prevents failure. |

| Watt Density | Heat output per unit area; must be matched to application to avoid premature failure. | Optimizes heat delivery and prolongs element life. |

| Power Supply Compatibility | Voltage and amperage ratings must align with available power to avoid electrical issues. | Prevents electrical overload and element damage. |

| Fluid Flow | Flow rate and type of fluid affect heat transfer and element temperature. | Influences element temperature control and prevents overheating. |

| Corrosion Resistance | Sheath materials (e.g., stainless steel, Incoloy) protect against chemical attack from fluids or environment. | Maintains sheath integrity and protects internal components. |

To maximize the life of your water heater, you should:

- Flush the tank regularly to remove sediment and prevent corrosion.

- Choose sheath materials that resist chemical attack.

- Match watt density to your application to avoid overheating.

- Place temperature sensors accurately to monitor element temperature.

- Use hermetic sealing in harsh environments to protect internal parts.

Selecting the right structure and materials for your water heater components ensures safe, efficient, and long-lasting hot water in your home.

How a Heating Element Heats Water

Electrical Resistance and Heat Generation

You rely on the principle of electrical resistance to generate heat in your water heater. When you switch on your electric water heater, electrical current flows through the heating element. The element contains a resistance wire, often made from a nickel-chromium alloy, that resists the flow of electricity. This resistance causes the wire to heat up, and the heat transfers directly to the surrounding water.

You can measure the effectiveness of your heating element by checking its resistance. A properly functioning element typically shows a resistance between 5 and 25 ohms. For a 1400W element, you usually see a reading close to 10 ohms. If the resistance drops below 5 ohms, you might have a short circuit. If it rises above 25 ohms or you get no reading, the element likely needs replacement.

| Resistance Range | Interpretation |

|---|---|

| 5 to 25 ohms | Heating element likely working properly |

| Close to 10 ohms | Typical for a 1400W heating element |

| Below 5 ohms | Possible short circuit |

| Above 25 ohms or no reading | Element is burned out and needs replacement |

You see a direct relationship between the electricity supplied and the heat produced. Experimental data confirms this link. The water heater’s heating rate, electricity rate, and total heating energy all show that as you increase electrical input, you get more heat output. This process ensures your water heater can deliver hot water efficiently and consistently.

Immersion in Water and Heat Transfer

Once the heating element gets hot, it must transfer that heat to the water. You achieve this by immersing the element directly in the tank. The surrounding water absorbs the heat, raising its temperature. The efficiency of this heat transfer depends on several factors, including water temperature, flow rate, and how close the water moves past the element.

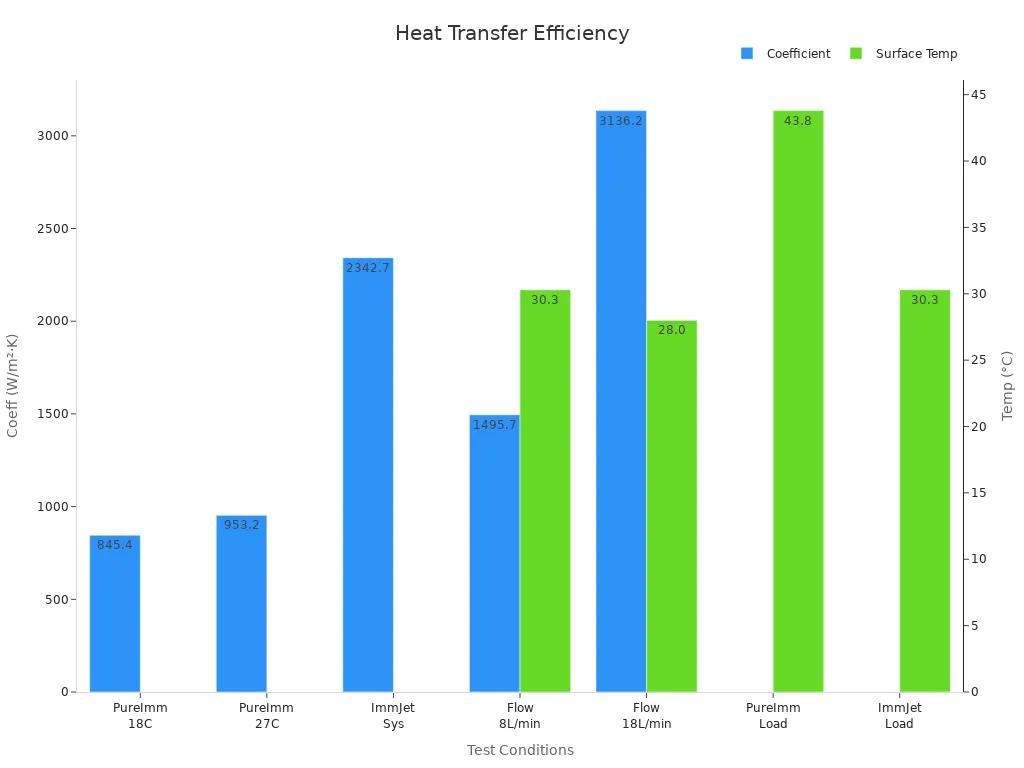

Laboratory studies show that the surface heat transfer coefficient increases as the inlet water temperature rises. For example, at 18°C, the coefficient is about 845.4 W/(m²·K), but it jumps to 953.2 W/(m²·K) at 27°C. If you use an immersion jet system, you can boost this value to over 2300 W/(m²·K), making the process much more efficient. Increasing the water flow rate also improves heat transfer. At 8 liters per minute, the coefficient is around 1495.7 W/(m²·K), but at 18 liters per minute, it climbs to 3136.2 W/(m²·K). These changes lower the surface temperature of the heating element, which helps prevent overheating and extends its life.

You can see that the way water flows around the element makes a big difference. Closer jet distances and higher flow rates disrupt the thermal boundary layer, allowing more efficient heat transfer. This means your water heater can heat water faster and maintain a steady supply of hot water, even during periods of high demand.

The Role of the Thermostat in a Water Heater

The thermostat acts as the control center for your water heater. It monitors the water temperature and ensures the heating element only operates when needed. When the water temperature drops below your set point, the thermostat sends power to the element. Once the water reaches the desired temperature, the thermostat cuts off the power, preventing overheating and saving energy.

Standardized test methods from around the world help you assess the efficiency of this process. These tests measure how well your water heater generates and transfers heat under controlled conditions. Performance benchmarks, such as combustion efficiency and thermal efficiency, allow you to compare different models and technologies. For example, improvements in baffle design and turbulence can raise thermal efficiency from 35% to over 67%. Computational Fluid Dynamics (CFD) and dimensionless numbers like the Nusselt number help engineers optimize heat transfer and design better systems.

Tip: Regularly check your thermostat and heating element to ensure your electric water heater operates at peak efficiency. This simple step can help you avoid unexpected cold showers and extend the life of your water heater.

By understanding how electrical resistance, immersion, and thermostat control work together, you can appreciate the engineering behind every hot shower and clean dish. Your water heater uses these principles to deliver reliable hot water whenever you need it.

Common Issues with Water Heater Elements

Symptoms of a Failing Water Heater Element

No Hot Water

You may notice that your water heater suddenly stops delivering hot water. This is often the first sign of a heating element failure. When the element burns out, it cannot transfer heat to the water. As a result, you only get cold water from your taps. If you experience this issue, check the circuit breaker and thermostat first. If both work properly, the heating element likely needs replacement. This is a common cause of element replacement in many households.

Inconsistent Water Temperature

Sometimes, you find that your water temperature fluctuates between hot and lukewarm. This symptom points to a partially working element or one covered in mineral deposits. When minerals coat the element, it cannot heat water efficiently. You may notice insufficient hot water during showers or when running multiple appliances. Inconsistent temperatures often indicate that the element struggles to keep up with demand.

Strange Noises from the Water Heater

Unusual sounds, such as popping or hissing, can signal trouble inside your water heater. These noises usually come from mineral buildup on the heating element. As water heats, trapped air bubbles escape through the sediment, creating these sounds. If you hear persistent noises, inspect the tank for sediment and scale. Addressing these issues early helps prevent complete failure of the heating element.

Causes of Heating Element Problems

Mineral Buildup

Mineral buildup ranks as a leading cause of heating element failure. Hard water introduces minerals that settle at the bottom of the tank and coat the element. This layer insulates the element, forcing it to work harder and eventually burn out. You can reduce this risk by flushing the tank annually and considering a water softener for your home.

Corrosion of the Element

Corrosion weakens both the heating element and the tank. Over time, the anode rod inside your water heater degrades, allowing rust to form. High mineral content accelerates this process. Inspect the anode rod every year and replace it if it shows heavy corrosion or is less than half its original size. This simple step extends the life of your water heater and prevents premature failure.

Electrical Faults in the Water Heater

Electrical faults can also lead to heating element failure. Loose wiring, faulty thermostats, or damaged connections disrupt the flow of electricity. When this happens, the element cannot heat water properly. Regular inspections help you catch these problems before they cause insufficient hot water or complete system breakdown.

Tip: Schedule professional inspections every two years to assess your water heater’s condition and prevent unexpected failures.

| Cause | Quantified Details | Effect on Heating Element Failure | Preventive Measures |

|---|---|---|---|

| Mineral Buildup | Hard water leads to sediment accumulation | Insulates and damages heating elements, reducing efficiency and causing failure | Regular flushing to remove sediment; water softening |

| Corrosion | Anode rod degrades typically every 3-5 years | Rust and corrosion weaken heating elements and tank, leading to malfunction | Inspect and replace anode rod; install sacrificial anode rod |

| High Mineral Content | Accelerates anode rod degradation | Faster corrosion and sediment buildup | Water softening; regular inspection |

You can prevent many common issues by following a few simple steps:

- Drain and flush the tank every year to remove sediment and scale.

- Set the water heater temperature to around 120°F to avoid damage.

- Test and replace the pressure relief valve if needed.

- Conduct regular visual inspections for rust or corrosion.

By staying proactive, you ensure your water heater delivers reliable hot water and avoids costly failures.

Maintenance and Troubleshooting for Water Heater Elements

Routine Maintenance for Electric Water Heaters

Flushing the Water Heater Tank

You can extend the life of your water heater by flushing the tank regularly. Sediment and mineral buildup at the bottom of the tank reduce heating efficiency and can cause the element to overheat. To keep your hot water flowing efficiently, drain about one-quarter of the tank every few months. In areas with hard water, you should flush the entire tank at least once a year. This routine helps prevent scale from forming on the heating element, which can lead to costly water heater repairs.

Tip: Schedule annual professional inspections to detect leaks, corrosion, or faulty components early.

Inspecting for Corrosion and Wear

You should inspect your water heater for signs of corrosion and wear during regular maintenance. Check the anode rod annually. If you see significant corrosion or the core wire is exposed, replace the rod before rust spreads to the tank. Examine the tank and connections for leaks. Test the pressure relief valve several times a year to ensure it opens and closes properly. These steps help you avoid unexpected breakdowns and keep your hot water supply reliable.

- Flush the tank about once per year to remove sediment buildup.

- Check the anode rod annually and replace as needed.

- Inspect for leaks regularly during maintenance.

- Test the pressure relief valve annually to ensure proper function.

Troubleshooting a Faulty Heating Element

Testing the Water Heater Element with a Multimeter

If you notice a lack of hot water or inconsistent temperatures, you may have a faulty heating element. You can test the element using a multimeter. First, turn off power to the water heater at the circuit breaker. Remove the metal covers and insulation to expose the element terminals. Set your multimeter to the lowest ohms setting. Place the probes on the two screws of the heating element. A properly functioning element should show a resistance reading between 10 and 30 ohms. If you see a reading of 0 or 1 ohm, the element is likely broken or burned out. Repeat this process for each element if your water heater has more than one.

Checking the Water Heater Thermostat

Sometimes, the thermostat causes heating issues rather than the element itself. After confirming the element’s resistance, check the thermostat for proper operation. Remove the cover and insulation, then use a non-contact voltage tester to ensure the power is off. Inspect the thermostat for visible damage or loose connections. If the thermostat fails to switch the element on when the water cools, you may need to replace it. Regular thermostat checks help you maintain consistent hot water and prevent unnecessary water heater repairs.

Note: Consistent water heater maintenance reduces the risk of sudden failures and extends the lifespan of your equipment.

Replacing a Water Heater Element: DIY or Professional Help

When to Replace a Heating Element

Irreparable Damage to the Element

You should consider element replacement when you see visible signs of damage. If the heating element in your water heater shows cracks, heavy corrosion, or burns, it cannot function safely. Testing with a multimeter may reveal no continuity, confirming the need to replace a water heater element. Continuing to use a damaged element can lead to further water heater repairs and even safety hazards.

Persistent Issues After Troubleshooting

If you have already flushed the tank, checked the thermostat, and tested the element, but your water heater still fails to deliver consistent hot water, you likely need a replacement element. Persistent problems such as fluctuating temperatures or repeated tripping of the circuit breaker often point to a failing component. In these cases, element replacement restores reliable performance.

DIY Water Heater Element Replacement Guide

Tools and Safety Precautions for Replacement

Before you begin, gather the following tools:

- Screwdriver

- Element wrench or socket

- Multimeter

- Garden hose (for draining the tank)

- Towel or bucket

Always turn off the power at the circuit breaker. Confirm with a voltage tester that no electricity flows to the water heater. Allow the tank to cool before starting. Wear gloves and safety glasses to protect yourself from hot water and electrical parts.

Tip: Never attempt element replacement if you feel unsure about electrical work. Safety comes first.

Step-by-Step Replacement Process

- Turn off the power supply and water inlet valve.

- Attach a hose to the drain valve and empty the tank below the element level.

- Remove the access panel and insulation to expose the element.

- Use a multimeter to confirm the element needs replacement.

- Loosen and remove the old element with the wrench.

- Clean the opening and insert the replacement element, tightening it securely.

- Refill the tank and check for leaks.

- Restore power and test the water heater.

By following these steps, you can complete element replacement safely and efficiently. Installing the new element correctly ensures your water heater operates at peak performance.

| Aspect | DIY Replacement | Professional Replacement |

|---|---|---|

| Upfront Cost | $10 to $60 (parts only) | $200 to $300 (service and parts) |

| Risks | Improper installation, potential damage, voided warranties, safety hazards | Precision, safety, peace of mind, prevents costly future repairs |

| Long-term Cost Implications | Potentially higher due to mistakes or damage | Generally lower due to professional quality and warranty |

| Skill Required | Mechanical skill and electrical knowledge needed | Professional expertise and experience |

| Outcome | Cost-effective upfront but risky | Higher initial cost but safer and more reliable |

When to Call a Professional for Water Heater Repair

Complex Electrical Issues in the Water Heater

If you encounter wiring problems, repeated tripping of breakers, or signs of electrical burning, call a licensed technician. Professionals have the expertise to diagnose and repair complex issues that go beyond simple element replacement. Attempting these repairs yourself can increase the risk of injury or further damage.

Warranty and Insurance Considerations

Many water heater warranties require professional service for repairs. DIY work may void your coverage. Insurance policies may also exclude damage caused by improper installation. Hiring a professional for replacement element installation protects your investment and ensures compliance with warranty terms.

| Replacement Method | Cost Range | Notes and Warnings |

|---|---|---|

| DIY | $10 to $60 (parts only) | Requires mechanical and electrical skills; risk of electrical hazards; not recommended for those unfamiliar with wiring |

| Professional | $200 to $300 (service and parts) | Ensures safe, proper installation; reduces risk of damage and safety hazards |

Note: Weigh the upfront savings of DIY against the long-term benefits of professional water heater repairs. Safe, reliable hot water often depends on expert installation of your replacement element.

Maximizing the Life of Your Water Heater Element

Preventive Maintenance Tips for Water Heater Elements

Reducing Mineral Buildup in the Water Heater

You can extend the life of your heating elements by reducing mineral buildup inside your water heater. Hard water introduces minerals that settle on the element surface, causing scale and reducing efficiency. To combat this, flush your tank quarterly to remove sediment. This simple step keeps the element clean and helps maintain consistent hot water output. Inspect the anode rod every three months and replace it annually or when you see significant corrosion. The anode rod attracts minerals, protecting both the tank and the element from damage. Regular cleaning and inspection of heating elements, performed monthly or semi-annually, further prevent scale accumulation.

Tip: Use predictive maintenance tools, such as sensors or real-time data monitoring, to detect inefficiencies early. These tools help you address problems before they lead to costly repairs.

Regular Inspections of the Heating Element

Routine inspections play a crucial role in maximizing the lifespan of water heater elements. Check the pressure relief valve every month to ensure it works properly. Examine the heating element for signs of corrosion, scale, or uneven heating. If you notice any issues, address them promptly to avoid further damage. Ensure proper ventilation around your water heater to prevent gas buildup and maintain safety. For gas models, monitor the flame color during semi-annual checks to detect burner problems. These preventive actions keep your water heater running efficiently and reduce the risk of unexpected failures.

- Inspect and clean heating elements regularly.

- Test the pressure relief valve monthly.

- Flush the tank every three months.

- Replace the anode rod as needed.

Choosing the Right Replacement Water Heater Element

Matching Wattage and Voltage for Your Water Heater

Selecting the correct replacement element requires careful attention to wattage and voltage. Always match the element’s voltage to your water heater’s electrical system, typically 120V or 240V. Using the wrong voltage can cause safety hazards or poor performance. Wattage determines how quickly your water heater heats water and how much energy it uses. Higher wattage heats water faster but increases energy consumption. Consider your tank size and household hot water demand when choosing wattage. Watt density, or power output per surface area, also affects element longevity. Low watt density elements heat more evenly and last longer, making them ideal for most residential applications.

Note: Look for energy efficiency ratings like the Uniform Energy Factor (UEF) and the Energy Star label. These ratings help you choose water heater elements that minimize operating costs and environmental impact.

Selecting Durable Materials for Longevity

Material selection directly impacts the durability of heating elements. Choose elements made from materials like stainless steel or Incoloy for superior resistance to corrosion and high temperatures. Studies show that material composition, operating temperature, and watt density all influence element lifespan. High temperatures and watt densities accelerate wear, while regular cleaning and inspection prevent hotspots and uneven heating. Environmental factors, such as exposure to oxygen or harsh water conditions, also affect durability. Manufacturers typically offer warranties against defects, but your maintenance practices and usage patterns play a significant role in how long your element lasts.

| Material | Durability | Corrosion Resistance | Best Use Case |

|---|---|---|---|

| Copper | Moderate | Low | Soft water areas |

| Stainless Steel | High | High | Hard water environments |

| Incoloy | Very High | Very High | High-demand systems |

By following these guidelines, you ensure your water heater delivers reliable hot water and your heating elements achieve maximum service life.

You depend on the water heater element to deliver a constant supply of hot water for your daily needs. Regular maintenance, such as flushing sediment and inspecting for corrosion, helps you avoid breakdowns and keeps your hot water supply reliable. By following manufacturer guidelines and addressing issues early, you reduce costly repairs and extend your system’s lifespan. Proactive care not only maintains efficiency but also supports sustainability by minimizing waste from frequent replacements.

FAQ

How often should you replace a water heater element?

You should inspect your water heater element every 2 to 3 years. Replace it if you notice corrosion, reduced heating efficiency, or visible damage. Regular maintenance helps you extend the lifespan of your water heater.

Can you replace a water heater element yourself?

You can replace a water heater element if you have basic electrical skills and the right tools. Always turn off the power and follow safety guidelines. If you feel unsure, contact a licensed professional.

What causes a water heater element to fail?

Common causes include mineral buildup, corrosion, and electrical faults. Hard water accelerates scale formation, which insulates the element and reduces efficiency. Regular flushing and inspections help you prevent premature failure.

How do you know if your water heater element is bad?

You may notice no hot water, inconsistent temperatures, or strange noises. Use a multimeter to test the element’s resistance. A reading outside the normal range indicates a faulty element.

Does water quality affect the lifespan of your heating element?

Yes, hard water with high mineral content shortens the lifespan of your heating element. Minerals form scale on the element, causing overheating and early failure. Consider installing a water softener for better performance.

What is the difference between low-watt and high-watt density elements?

Low-watt density elements spread heat over a larger area, reducing scale buildup and lasting longer in hard water. High-watt density elements heat water faster but may fail sooner in mineral-rich environments.

Tip: Always match the wattage and voltage of your replacement element to your water heater’s specifications for safe operation.