Choosing the best heating element for a water heater calls for knowledge of material properties, power computations, and application-specific criteria. Key technical parameters of five often used water heating components are compared in this manual together with installation best practices and maintenance advice to prolong service life by 30-50%.

1. Material Selection: Stainless Steel vs. Nickel-Chromium Alloys

Heating element for water heater materials directly impact thermal efficiency and longevity. Comparative analysis shows:

- SUS316L Stainless Steel :

- ASTM G48 testing shows corrosion resistance of 0.1mm/year in 3% NaCl solution.

- Phase transition at 650°C; operating temperature up to 850°C

- 16 W/m·K is thermal conductivity.

- NiCr60/15 Alloy:

- 1.12 Ω·mm²/m resistivity at 20°C

- Temperature coefficient: 0.00017/°C

- Resistance to oxidation: 1100°C in air

For electric water heaters operating at 75-85°C, SUS316L is recommended for magnesium anode systems, while NiCr60 is preferred for commercial instant heaters requiring 2000W+ power ratings.

2. Power Calculation Formula & Practical Examples

Water heater elements sizing requires precise calculations:

Power (W) = (Water Temp Rise × Flow Rate × 4.186) / Heating Time Case study:

- 50L tank heating from 15°C to 60°C in 30 mins

- Required power: (45×1.39×4.186)/0.5 ≈ 5200W

Real-world installations show:

- 3kW elements heat 150L water in 1.5 hours (ΔT=30°C)

- 4500W elements maintain 60°C in 300L tanks with 20°C inlet

Surface load limits must be observed: Liquid immersion ≤1.5W/cm², air ≤2.5W/cm² to prevent boiling dry risks.

3. Key Installation Parameters & Safety Margins

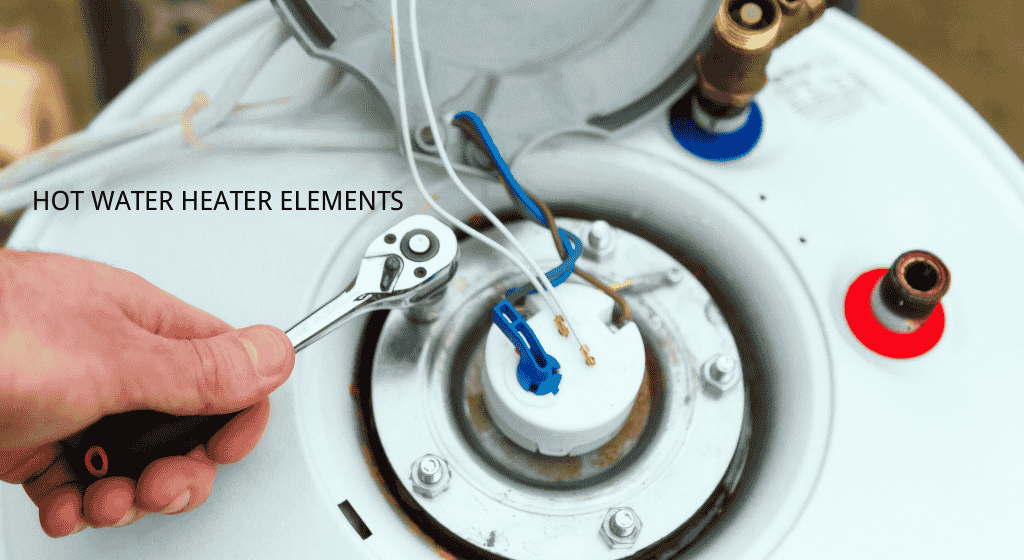

Proper heating element for water heater installation requires:

- Element immersion depth: Minimum 30mm into water column

- Dielectric strength: 2500V AC for 1 minute (IEC 60335-2-21)

- Thermal expansion allowance: 0.02% per °C for stainless steel

Field data reveals:

- Incorrect voltage (±10%) reduces lifespan by 40%

- Scale deposition >1mm increases energy consumption by 18%

- Proper anode replacement intervals: 6-12 months (hard water areas)

4. Maintenance Checklist for Extended Service Life

Water heater elements failure analysis shows:

- 65% failures due to scale buildup (CaCO3 >3g/L)

- 22% from seal degradation at temperature cycling

- 13% from electrical arcing

Preventive measures:

- Descaling procedure: 10% citric acid solution at 60°C for 2 hours

- Insulation resistance test: ≥50MΩ using 500V megger

- Thermal paste renewal every 18 months (silicone-based, thermal conductivity ≥1.5W/m·K)

5. Comparative Analysis of Market-Leading Brands

| Parameter | A.O. Smith Element | Bosch ELCB | Rheem XE |

|---|---|---|---|

| Max Temp Rating | 85°C | 90°C | 80°C |

| Thermal Shock Resistance | 120°C/sec | 95°C/sec | 85°C/sec |

| Warranty | 5 years | 7 years | 3 years |

Cost-performance ratio analysis (based on 10-year TCO):

- Bosch ELCB shows 18% lower failure rate but 25% higher upfront cost

- DIY replacement kits save 40% labor costs vs OEM services

6. Future Trends: Smart Heating Elements with IoT

Latest developments include:

- PT100 sensor integration for ±0.1°C accuracy

- Self-regulating NiTiNOL alloy elements (3-5% shape memory strain)

- Wireless power control compatible with Zigbee 3.0 protocol

Energy savings potential:

- Adaptive algorithms reduce standby losses by 12-15%

- Predictive maintenance lowers service calls by 30%

Frequently Asked Questions (FAQ)

What’s the maximum voltage for residential water heater elements?

ANSWER: Standard 240V AC (±10%) with 10A circuit breaker. Industrial units may use 480V 3-phase configurations.

How often should heating elements be replaced?

ANSWER: Every 5-7 years under normal conditions. Hard water areas require annual inspections and possible 3-year replacement cycles.

Can I use hot water heater elements across different voltages?

ANSWER: NO. Changing voltage requires rewinding the resistance wire to match V²/R ratio. Incorrect voltage causes overheating or underperformance.

What causes heating element for water heater arcing?

ANSWER: Typically caused by:

- Scale deposits creating carbon tracking (resistivity >10^6 Ω·cm)

- Improper gap between terminals (<3mm)

- Moisture ingress during installation

About Zhongshan Jinzhong Electric Heat Technology Co., Ltd.

As a leading heating element manufacturer since 2008, we supply OEM heating components to Philips, Midea, Supor, Delonghi, BSH, and SEB Group. Our capabilities include:

- Custom NiCr/FeCrAl alloy extrusion profiles

- Precision laser welding for tube-sheet joints

- IP68-rated hermetic sealing technology

With 3 state-certified labs and 12 patents, we provide turnkey solutions for:

- Instantaneous water heaters (CE/UL certified)

- Solar thermal integration systems

- High-pressure industrial sterilizers

Contact our engineering team for custom water heater elements development with MOQ as low as 500pcs.