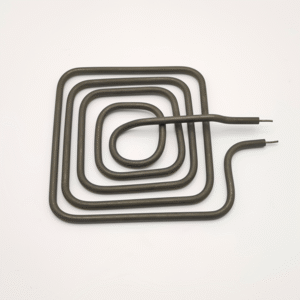

The instant pot heating element uses food-grade 304/316L stainless steel substrate and thick film resistor technology, integrated PID temperature control module and anti-dry burning protection system, achieving 3 seconds of fast heating, energy efficiency ≥96%, working temperature range 80℃-350℃, supporting high pressure (100kPa-150kPa) and multi-stage power adjustment (500W-3500W). The surface nano-ceramic coating enhances corrosion resistance, adapts to high-frequency high-pressure stewing scenes, has IPX7 waterproof and anti-scaling performance, life span exceeds 30,000 hours, complies with EU CE certification, and meets the high stability requirements of home and commercial use.

Quantité minimale de commande : 1000

Délai de livraison : 15-25 jours

Emplacement de l'usine : Zhongshan, Guangdong, Chine

Electric pressure cooker (including firewood rice mode), wall breaker heating module, commercial electric stew pot (hotel/restaurant), laboratory high-pressure sterilization auxiliary heating, industrial high-temperature sterilization equipment, smart electric pressure cooker (IoT temperature control), slow cooker, embedded electric pressure cooker, health pot (high-pressure stewing model)

1. Puissance nominale: 800-2500W (customizable: 800-1500W for 3-5L small instant pots; 1500-2500W for 5-8L large models).

2. Tension de fonctionnement: 110V/220-240V AC (global voltage compatibility for international appliance markets).

3. Dimensions de l'appareil: Length: 150-400mm; Width: 80-200mm; Thickness: 0.5-1.5mm (304/316 stainless steel, food-grade compliant for direct food contact).

4. Charge de surface: 6-12W/cm² (optimized for rapid, uniform heating: 6-8W/cm² for small pots; 8-12W/cm² for high-capacity models).

5. Temp. de surface max. Temp. de surface: ≤350°C (normal operation ≤300°C; dry-burn cutoff activated at >300°C to prevent overheating).

6. Dimensional Tolerance: ±0.15-0.25mm (precision machining for secure fit with instant pot base grooves/clips).

Customization: Shape (spiral/coiled/flat plate), lead wire (silicone/PTFE/tinned terminals), or anti-corrosion coatings (e.g., PTFE layer for acidic food environments).

Si vous nous fournissez des informations précises sur les paramètres de la demande, nous pourrons vous donner un devis dans les 24 heures au plus tôt.

Il s'agit de listes de questions fréquemment posées par nos clients. À chaque question correspond une brève réponse, couvrant des aspects tels que les produits, la qualité et les services. Si vous avez d'autres questions, veuillez laisser un message pour consultation. Nous vous remercions de votre attention.

Nous sommes une usine source avec une capacité de production indépendante, avec 30 ans d'expérience dans la recherche et le développement et la fabrication d'accessoires de chauffage électrique, une capacité de production annuelle de plus de 5 millions d'ensembles, nous prenons en charge la personnalisation OEM/ODM, et fournissons des services d'inspection vidéo en conditions réelles d'usine.

Nous proposons des tests d'échantillons gratuits et les frais de transport doivent être payés à l'avance (collectés à la livraison). Les modèles conventionnels sont livrés dans un délai de 7 à 10 jours ouvrables, avec les rapports d'essai SGS et les tableaux des paramètres de performance.

Réponse en ligne de 8h30 à 17h30 les jours ouvrables. Pour les besoins urgents, vous pouvez soumettre un ordre de travail via le site web officiel. Nous nous engageons à fournir des réponses techniques dans les 2 heures et des solutions dans les 48 heures.

Nous disposons de deux bases de production à Zhongshan et à Wuhu, avec une production mensuelle de plus de 3 millions d'unités, équipées de lignes d'estampage entièrement automatiques et d'ateliers d'assemblage automatisés. Le délai de livraison des produits standard est de 15 jours, et les commandes personnalisées sont livrées dans les 30 jours. Nous prenons en charge la fourniture de lots.

Certifications ISO9001/14001, CE (UE), ETL (Amérique du Nord), RoHS (protection de l'environnement), les produits antidéflagrants sont doublement certifiés ATEX/IECEx et répondent aux réglementations REACH.

Au service de grandes marques mondiales telles que Philips, Midea, Supor, Delonghi, BSH et le groupe SEB, les produits sont utilisés dans des projets haut de gamme tels que les machines à café, les fers à repasser électriques, les distributeurs d'eau et les systèmes de chauffage solaire, et peuvent fournir une liste de référence de clients similaires.

Obtenez un devis personnalisé en moins de deux jours.