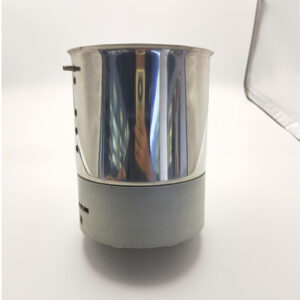

Our factory specializes in the production of special accessories for electric heating mixers, including heating chassis, temperature control modules and mixing components, suitable for wall breaking machines, handheld mixers and other equipment. Made of food-grade 304 stainless steel and high-temperature resistant coating, it is corrosion-resistant and non-sticky, supports fast heat conduction and precise temperature control (30℃-100℃ multi-speed adjustment), ensuring that the ingredients are evenly heated and finely mixed. Integrated PID intelligent temperature control chip, with dual safety protection of anti-dry burning and overload power off, to ensure stable operation.

MOQ:1000PCS

Délai de livraison:15-25 jours

Emplacement de l'usine : Zhongshan, Guangdong, Chine

Our electric heating accessories for blenders serve as integral components in blenders, soy milk makers, and food processors that require integrated heating functions. They enable efficient, uniform heat transfer during tasks such as boiling water (for hot soups), cooking grains (for porridge), or warming blended mixtures (e.g., baby food, nut milks). By maintaining precise temperatures (e.g., 80–100°C for sterilization, 40–60°C for delicate blends), these accessories ensure consistent cooking results, prevent overheating, and enhance the versatility of multi-functional blending appliances.

| Paramètres | Gamme de spécifications | Options de personnalisation |

|---|---|---|

| Puissance nominale | 50W–2000W (standard); up to 3000W for high-capacity industrial blenders | Adjustable to match blender motor/wattage limits |

| Tension de fonctionnement | 110V/220V AC (standard); 12V/24V DC available for battery-powered or portable models | Tension personnalisée pour une compatibilité avec le marché mondial |

| Gamme de dimensions | Length: 80mm–250mm; Diameter: 30mm–100mm; Thickness: 1.2mm–4mm; Shapes: annular, spiral, or custom contour | Compact designs to fit blender jar/chamber |

| Matériau | Food-grade 304 stainless steel (standard); 316 stainless steel for acidic ingredients (e.g., fruit purees, yogurt) | Material grade/finish (polished for easy cleaning) customization |

| Plage de température | Ambient (20°C) to max 150°C (continuous operation, auto-shutoff at upper limit) | High-temp variants (up to 200°C) for heavy-duty cooking |

| Compatibilité des contrôles | Compatible with external thermistors (±3°C) or blender-integrated sensors (±2°C) | Custom interfaces (e.g., PID, thermocouple-linked) |

We offer tailored solutions, including dimensions, power, material grade, and interface design, to align with specific blender structures (e.g., compact travel blenders, high-speed blending jars) while maintaining safety, efficiency, and brand compatibility.

Si vous nous fournissez des informations précises sur les paramètres de la demande, nous pourrons vous donner un devis dans les 24 heures au plus tôt.

Il s'agit de listes de questions fréquemment posées par nos clients. À chaque question correspond une brève réponse, couvrant des aspects tels que les produits, la qualité et les services. Si vous avez d'autres questions, veuillez laisser un message pour consultation. Nous vous remercions de votre attention.

Nous sommes une usine source avec une capacité de production indépendante, avec 30 ans d'expérience dans la recherche et le développement et la fabrication d'accessoires de chauffage électrique, une capacité de production annuelle de plus de 5 millions d'ensembles, nous prenons en charge la personnalisation OEM/ODM, et fournissons des services d'inspection vidéo en conditions réelles d'usine.

Nous proposons des tests d'échantillons gratuits et les frais de transport doivent être payés à l'avance (collectés à la livraison). Les modèles conventionnels sont livrés dans un délai de 7 à 10 jours ouvrables, avec les rapports d'essai SGS et les tableaux des paramètres de performance.

Réponse en ligne de 8h30 à 17h30 les jours ouvrables. Pour les besoins urgents, vous pouvez soumettre un ordre de travail via le site web officiel. Nous nous engageons à fournir des réponses techniques dans les 2 heures et des solutions dans les 48 heures.

Nous disposons de deux bases de production à Zhongshan et à Wuhu, avec une production mensuelle de plus de 3 millions d'unités, équipées de lignes d'estampage entièrement automatiques et d'ateliers d'assemblage automatisés. Le délai de livraison des produits standard est de 15 jours, et les commandes personnalisées sont livrées dans les 30 jours. Nous prenons en charge la fourniture de lots.

Certifications ISO9001/14001, CE (UE), ETL (Amérique du Nord), RoHS (protection de l'environnement), les produits antidéflagrants sont doublement certifiés ATEX/IECEx et répondent aux réglementations REACH.

Au service de grandes marques mondiales telles que Philips, Midea, Supor, Delonghi, BSH et le groupe SEB, les produits sont utilisés dans des projets haut de gamme tels que les machines à café, les fers à repasser électriques, les distributeurs d'eau et les systèmes de chauffage solaire, et peuvent fournir une liste de référence de clients similaires.

Obtenez un devis personnalisé en moins de deux jours.