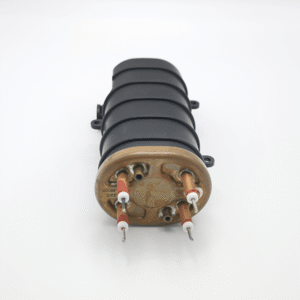

The Die-Cast Heating Element adopts die-cast aluminum alloy substrate and thick film resistor technology, integrates PID temperature control module and NTC temperature sensor, achieves 3 seconds fast heating, energy efficiency ≥96%, working temperature range 50℃-500℃, and supports power (500W-8000W) customization. The surface anodizing treatment improves corrosion resistance, has IPX7 waterproof, anti-dry burning and anti-scaling performance, and has a lifespan of more than 30,000 hours, meeting the stable heating needs of high-frequency industrial and civilian scenarios.

Quantité minimale de commande : 1000

Délai de livraison : 15-25 jours

Emplacement de l'usine : Zhongshan, Guangdong, Chine

Capsule coffee machine steam module, fully automatic coffee machine boiler, electric iron soleplate, instant electric water heater, industrial heat exchanger, new energy battery module constant temperature system, medical sterilization steam generator, laboratory constant temperature water bath device, hotel commercial electric tea stove, mold constant temperature heating component, smart wearable device temperature control unit.

| Paramètre | Gamme de spécifications |

|---|---|

| Plage de puissance | 800W-5000W (covers household to commercial small appliances: electric kettles, coffee machines, electric pots, bottle warmers, soy milk makers, blenders) |

| Tension de fonctionnement | 220 V (monophasé, norme domestique) ; 380 V (triphasé, commercial en option) |

| Valeur de résistance | 3Ω-30Ω (single-unit or multi-unit combination, matched to power and voltage requirements) |

| Température de fonctionnement | Surface : 120℃-300℃ (fonctionnement normal) ; Résistance maximale : 350℃ (protection contre les surcharges de courte durée) |

| Matériau | Heating element: Nickel-chromium alloy (Cr20Ni80, Φ0.6mm-Φ2.5mm, high resistivity + high thermal conductivity); Housing: Die-cast aluminum alloy (A356/6061, corrosion-resistant, thickness 1.2mm-3.0mm) |

| Dimensions | Length: 150mm-600mm; Width: 50mm-150mm; Thickness: 20mm-50mm (customizable to fit circular/square heating slots in target appliances) |

| Durée de vie | 8 000 h à 15 000 h (utilisation normale, pas de combustion à sec, d'accumulation de calcaire ou de corrosion dans des conditions normales) |

Si vous nous fournissez des informations précises sur les paramètres de la demande, nous pourrons vous donner un devis dans les 24 heures au plus tôt.

Il s'agit de listes de questions fréquemment posées par nos clients. À chaque question correspond une brève réponse, couvrant des aspects tels que les produits, la qualité et les services. Si vous avez d'autres questions, veuillez laisser un message pour consultation. Nous vous remercions de votre attention.

Nous sommes une usine source avec une capacité de production indépendante, avec 30 ans d'expérience dans la recherche et le développement et la fabrication d'accessoires de chauffage électrique, une capacité de production annuelle de plus de 5 millions d'ensembles, nous prenons en charge la personnalisation OEM/ODM, et fournissons des services d'inspection vidéo en conditions réelles d'usine.

Nous proposons des tests d'échantillons gratuits et les frais de transport doivent être payés à l'avance (collectés à la livraison). Les modèles conventionnels sont livrés dans un délai de 7 à 10 jours ouvrables, avec les rapports d'essai SGS et les tableaux des paramètres de performance.

Réponse en ligne de 8h30 à 17h30 les jours ouvrables. Pour les besoins urgents, vous pouvez soumettre un ordre de travail via le site web officiel. Nous nous engageons à fournir des réponses techniques dans les 2 heures et des solutions dans les 48 heures.

Nous disposons de deux bases de production à Zhongshan et à Wuhu, avec une production mensuelle de plus de 3 millions d'unités, équipées de lignes d'estampage entièrement automatiques et d'ateliers d'assemblage automatisés. Le délai de livraison des produits standard est de 15 jours, et les commandes personnalisées sont livrées dans les 30 jours. Nous prenons en charge la fourniture de lots.

Certifications ISO9001/14001, CE (UE), ETL (Amérique du Nord), RoHS (protection de l'environnement), les produits antidéflagrants sont doublement certifiés ATEX/IECEx et répondent aux réglementations REACH.

Au service de grandes marques mondiales telles que Philips, Midea, Supor, Delonghi, BSH et le groupe SEB, les produits sont utilisés dans des projets haut de gamme tels que les machines à café, les fers à repasser électriques, les distributeurs d'eau et les systèmes de chauffage solaire, et peuvent fournir une liste de référence de clients similaires.

Obtenez un devis personnalisé en moins de deux jours.