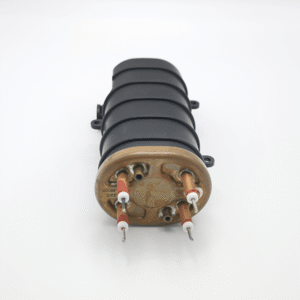

The customized heating plate is based on the composite process of aluminum alloy substrate and nickel-chromium alloy heating element, supports power (500W-3000W), size and temperature curve customization, integrates NTC temperature control module, achieves 3-5 seconds rapid heating, energy efficiency ≥95%, has IPX4 protection and 1000℃ high temperature resistance, adapts to high-frequency dry burning environment, has a lifespan of more than 30,000 hours, and meets the customized needs of multiple scenarios.

Quantité minimale de commande : 1000

Délai de livraison : 15-25 jours

Emplacement de l'usine : Zhongshan, Guangdong, Chine

Electric kettles, coffee machines, industrial ovens, constant temperature control equipment, medical sterilizers, food processing machinery, laboratory heating devices.

Power range: 500W~3000W (customizable, suitable for low power requirements of electrical heating elements and industrial medium temperature scenarios)

Working voltage: 24V~480V AC/DC (wide voltage design, compatible with home appliances and industrial equipment)

Resistance value: 0.05Ω~50Ω (matched by voltage and power, supports customized production of electric heating coils)

Working temperature: -40°C~800°C (aluminum alloy substrate is resistant to 500°C, and ceramic coating is suitable for industrial high temperature scenarios)

Material: aluminum alloy substrate, nickel-chromium alloy heating wire, ceramic insulation layer (customizable composite structure, suitable for electric heating unit requirements)

Dimensions: length 10cm~2m, width 5cm~1m, thickness 0.5mm~10mm (supports special-shaped cutting, suitable for customization of plate-type electric heating elements)

Service life: 30,000~50,000 hours (anti-oxidation coating + nickel-chromium alloy reinforcement, suitable for high-frequency use scenarios)

High-efficiency thermal conductivity: aluminum alloy substrate + ceramic coating, thermal conductivity increased by 40%, suitable for rapid heating requirements of electric heating units.

Precise temperature control: integrated NTC module, ±1°C error range, meets the constant temperature control requirements of aluminum heat exchangers.

Industrial protection: IPX4 waterproof + 800℃ high temperature resistant structure, suitable for electrical heating elements in humid/high temperature environments.

Energy saving and reliability: energy efficiency ≥95%, optimized design of electric heating coils, reducing energy consumption of industrial equipment by more than 30%.

Flexible adaptation: supports special-shaped size and temperature curve adjustment to meet non-standard customization requirements of plate-mounted electric heating elements.

Multiple safety: isolated circuit design, UL/CE certified, adapted to household appliance safety standards.

Fast delivery: standardized production line mass production, 15 days to complete orders, adapted to bulk purchase requirements of electric heating units.

Si vous nous fournissez des informations précises sur les paramètres de la demande, nous pourrons vous donner un devis dans les 24 heures au plus tôt.

Il s'agit de listes de questions fréquemment posées par nos clients. À chaque question correspond une brève réponse, couvrant des aspects tels que les produits, la qualité et les services. Si vous avez d'autres questions, veuillez laisser un message pour consultation. Nous vous remercions de votre attention.

Nous sommes une usine source avec une capacité de production indépendante, avec 30 ans d'expérience dans la recherche et le développement et la fabrication d'accessoires de chauffage électrique, une capacité de production annuelle de plus de 5 millions d'ensembles, nous prenons en charge la personnalisation OEM/ODM, et fournissons des services d'inspection vidéo en conditions réelles d'usine.

Nous proposons des tests d'échantillons gratuits et les frais de transport doivent être payés à l'avance (collectés à la livraison). Les modèles conventionnels sont livrés dans un délai de 7 à 10 jours ouvrables, avec les rapports d'essai SGS et les tableaux des paramètres de performance.

Réponse en ligne de 8h30 à 17h30 les jours ouvrables. Pour les besoins urgents, vous pouvez soumettre un ordre de travail via le site web officiel. Nous nous engageons à fournir des réponses techniques dans les 2 heures et des solutions dans les 48 heures.

Nous disposons de deux bases de production à Zhongshan et à Wuhu, avec une production mensuelle de plus de 3 millions d'unités, équipées de lignes d'estampage entièrement automatiques et d'ateliers d'assemblage automatisés. Le délai de livraison des produits standard est de 15 jours, et les commandes personnalisées sont livrées dans les 30 jours. Nous prenons en charge la fourniture de lots.

Certifications ISO9001/14001, CE (UE), ETL (Amérique du Nord), RoHS (protection de l'environnement), les produits antidéflagrants sont doublement certifiés ATEX/IECEx et répondent aux réglementations REACH.

Au service de grandes marques mondiales telles que Philips, Midea, Supor, Delonghi, BSH et le groupe SEB, les produits sont utilisés dans des projets haut de gamme tels que les machines à café, les fers à repasser électriques, les distributeurs d'eau et les systèmes de chauffage solaire, et peuvent fournir une liste de référence de clients similaires.

Obtenez un devis personnalisé en moins de deux jours.