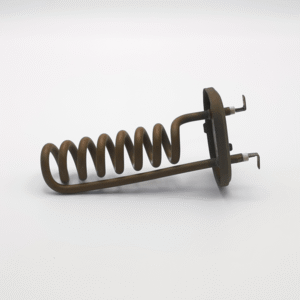

Specially designed for preparing ultrapure water in distilled water machines, it uses high-precision heating technology to evaporate and condense raw water, remove impurities and ions, and produce distilled water with a resistivity of ≥18 MΩ·cm, meeting the high-purity water needs in laboratories, medical treatment, pharmaceuticals and other fields.

MOQ:1000PCS

Délai de livraison:25 jours

Emplacement de l'usine : Zhongshan, Guangdong, Chine

Engineered for distilled water generation systems, high-performance electric heating components are intended to effectively convert water into purifying steam and condense it into high-purity distilled water. These optimized for durability, corrosion resistance, and energy efficiency components are essential for medical, laboratory, and industrial uses demanding ultra-pure water.

Operating at temperatures up to 1200°C, high resistivity and oxidation resistance nickel-chromium (NiCr) or iron-chromium-aluminum (FeCrAl) alloy.

Insulation: magnesium oxide (MgO) powder coating to guarantee thermal stability and prevent current leakage.

Stainless steel 304/316L enclosed with ceramic seals to resist corrosion and contamination .

Power Range: 500W–1500W (adjustable via thermostat) to match varying distillation demands .

Thermal Efficiency: ≥95% energy conversion rate, minimizing heat loss and operational costs .

Steam Generation: Rapid boiling of water (3–5L/hour) with minimal energy consumption .

Overheat Protection: Automatic shutdown at 120°C (adjustable) to prevent dry boiling or component damage .

Anti-Dry Burn: Built-in sensors detect low water levels and cut power to avoid overheating .

IPX4 Waterproof: Protection against splashing and humidity for safe operation in humid environments .

Voltage Compatibility: AC 110V–240V/DC 12V–48V for global use .

Mounting Designs: Vertical or horizontal configurations with flange or threaded interfaces .

Coating Options: Nano-ceramic or PTFE anti-scaling coatings to reduce maintenance frequency .

Produces 0 ppm distilled water for autoclaves, IV solutions, and sensitive experiments .

Eliminates 99.9% of contaminants (e.g., bacteria, heavy metals) via steam distillation .

Critical for battery manufacturing, pharmaceuticals, and electronics cleaning .

Compatible with high-purity water loops requiring continuous distillation.

Compact units for kitchens or clinics, combining energy efficiency with safety features .

Reduced Scaling: Anti-scaling coatings decrease limescale buildup by 60%, lowering maintenance needs .

Uniform Heating: Vertical steam pathways ensure consistent temperature distribution, minimizing hotspots .

Energy Savings: Optimized power consumption reduces operational costs by 20% vs. traditional elements .

Si vous nous fournissez des informations précises sur les paramètres de la demande, nous pourrons vous donner un devis dans les 24 heures au plus tôt.

Il s'agit de listes de questions fréquemment posées par nos clients. À chaque question correspond une brève réponse, couvrant des aspects tels que les produits, la qualité et les services. Si vous avez d'autres questions, veuillez laisser un message pour consultation. Nous vous remercions de votre attention.

Nous sommes une usine source avec une capacité de production indépendante, avec 30 ans d'expérience dans la recherche et le développement et la fabrication d'accessoires de chauffage électrique, une capacité de production annuelle de plus de 5 millions d'ensembles, nous prenons en charge la personnalisation OEM/ODM, et fournissons des services d'inspection vidéo en conditions réelles d'usine.

Nous proposons des tests d'échantillons gratuits et les frais de transport doivent être payés à l'avance (collectés à la livraison). Les modèles conventionnels sont livrés dans un délai de 7 à 10 jours ouvrables, avec les rapports d'essai SGS et les tableaux des paramètres de performance.

Réponse en ligne de 8h30 à 17h30 les jours ouvrables. Pour les besoins urgents, vous pouvez soumettre un ordre de travail via le site web officiel. Nous nous engageons à fournir des réponses techniques dans les 2 heures et des solutions dans les 48 heures.

Nous disposons de deux bases de production à Zhongshan et à Wuhu, avec une production mensuelle de plus de 3 millions d'unités, équipées de lignes d'estampage entièrement automatiques et d'ateliers d'assemblage automatisés. Le délai de livraison des produits standard est de 15 jours, et les commandes personnalisées sont livrées dans les 30 jours. Nous prenons en charge la fourniture de lots.

Certifications ISO9001/14001, CE (UE), ETL (Amérique du Nord), RoHS (protection de l'environnement), les produits antidéflagrants sont doublement certifiés ATEX/IECEx et répondent aux réglementations REACH.

Au service de grandes marques mondiales telles que Philips, Midea, Supor, Delonghi, BSH et le groupe SEB, les produits sont utilisés dans des projets haut de gamme tels que les machines à café, les fers à repasser électriques, les distributeurs d'eau et les systèmes de chauffage solaire, et peuvent fournir une liste de référence de clients similaires.

Obtenez un devis personnalisé en moins de deux jours.