You can wire the Élément chauffant in your Whirlpool dryer by following a precise process that ensures reliable heat and prevents no heat issues.

- Disconnect all power before starting.

- Identify wires from the Chauffage électrique Jinzhong replacement or other éléments chauffants pour appareils ménagers.

- Attach the correct wires to the terminals, using the Whirlpool electric dryer diagram for guidance.

- Secure connections firmly, referencing Fabricants d'éléments chauffants’ specifications.

Accurate wiring keeps your dryer safe and efficient.

Whirlpool Dryer Heating Element Overview

What the Heating Element Does in a Whirlpool Electric Dryer

You rely on the heating element to generate the heat that dries your clothes efficiently. The heating element in a Whirlpool electric dryer transforms electrical energy into heat, which circulates through the drum and removes moisture from fabrics. Manufacturer documentation highlights that this component is essential for effective drying and for maintaining the overall performance of your appliance. If the element malfunctions, you may notice longer drying times or a complete lack of heat. Understanding how the heating element works helps you troubleshoot and maintain your dryer, ensuring it operates at peak efficiency.

Tip: If your Whirlpool duet electric dryer stops producing heat, the heating element is often the first part you should inspect.

Key Parts and Terminals of the Dryer Heating Element

Identifying Terminals on Whirlpool Dryer Heating Element

When you examine the heating element terminal, you will see several connection points. Each terminal serves a specific purpose, such as delivering power or connecting to safety devices. You must identify these terminals before you begin any wiring or replacement work. The main terminals typically include connections for power (L1 and L2), neutral, and ground. You will also find terminals for the thermostat and thermal fuse, which help regulate temperature and protect the dryer from overheating.

Recognizing Wire Colors and Types in Whirlpool Electric Dryer

You should pay close attention to wire colors and types when working with your Whirlpool dryer. Manufacturers often use red or black wires for power connections, white wires for neutral, and green or bare wires for ground. Thermostat and thermal fuse wires may be blue, yellow, or another color, depending on the model. Always consult your wiring diagram to confirm wire functions before attaching them to the heating element terminal.

| Composant | Role |

|---|---|

| Fil chauffant | Converts electricity into heat, typically made of nichrome, generating temperatures up to 200°F. |

| Airflow Mechanism | Circulates warm air from the heating wire to the drum, ensuring even drying of clothes. |

| Thermostat | Regulates the temperature by controlling the heating wire and airflow to prevent overheating. |

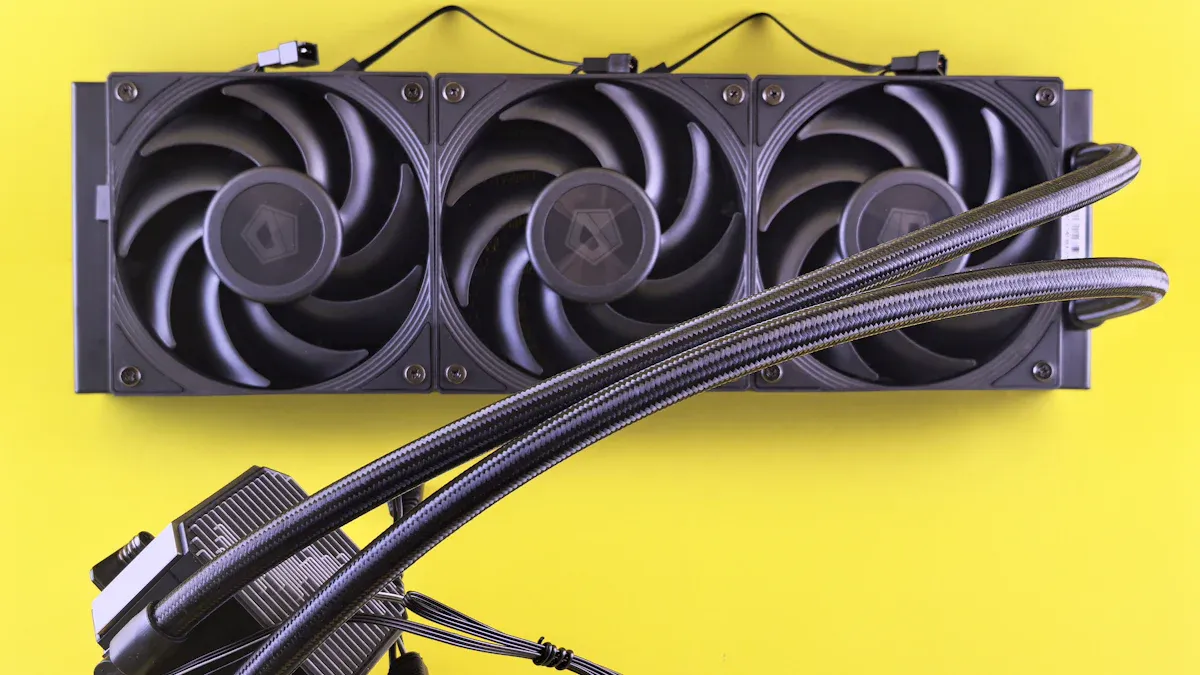

Tools and Materials Needed for Replacing Heating Element

You need the right tools and materials to replace the heating element safely and efficiently. The following table lists the recommended items for servicing your Whirlpool dryer:

| Tool/Material | But |

|---|---|

| Multimètre | Essential for testing the heating element and related parts for continuity. |

| Work Gloves | Protect hands from sharp edges and hot surfaces during repair. |

| Ensemble d'éléments chauffants | Primary component replaced when dryer does not heat properly. |

| Fusible thermique | Cause fréquente de panne de chauffage ; doit être vérifiée avant de remplacer l'élément chauffant. |

| Thermostat | Contrôle la température ; il est recommandé de vérifier et de remplacer en cas de défaut. |

| Bornes de câblage | Peut nécessiter un remplacement s'il est endommagé pendant l'entretien. |

Note: Always disconnect power before you begin any repair or replacement work on your Whirlpool dryer.

Reading the Whirlpool Electric Dryer Wiring Diagram

Diagram Symbols Explained for Whirlpool Dryer

You must understand the symbols in a dryer schematic before you begin any wiring work. The dryer schematic uses standardized icons to represent electrical components and connections. You will see symbols for heating elements, thermostats, fuses, and switches. Each symbol in the dryer schematic helps you identify the part and its function. For example, a zigzag line often represents the heating element, while a rectangle with a diagonal line may indicate a fuse. You should refer to the legend on the dryer schematic to clarify any unfamiliar symbols. This step ensures you interpret the dryer schematic correctly and avoid wiring mistakes.

Tip: Always compare the symbols in your dryer schematic with the legend provided by the manufacturer. This practice helps you avoid confusion and ensures safe repairs.

Locating the Heating Element in Whirlpool Electric Dryer Diagram

You need to locate the heating element in the dryer schematic to replace or repair it. The heating element usually appears near the center or lower section of the dryer schematic. You will notice two main lines connecting to the heating element symbol. These lines represent the power supply and the return path. The dryer schematic may also show connections to safety devices, such as thermostats and thermal fuses. You should trace these lines in the dryer schematic to understand how the heating element interacts with other components. This process helps you identify the correct wires and terminals for your whirlpool dryer.

| Symbol | Signification | Location in Dryer Schematic |

|---|---|---|

| Zigzag Line | Élément chauffant | Center or lower section |

| Rectangle | Fuse or Thermostat | Near heating element |

| Straight Line | Wire Connection | Throughout schematic |

Tracing Wire Paths for Replacing Heating Element

You must trace the wire paths in the dryer schematic to ensure proper installation. Start by identifying the power wires in the dryer schematic. These wires connect to the heating element and supply electricity. Follow the lines in the dryer schematic from the power source to the heating element symbol. Next, locate the safety devices in the dryer schematic, such as the thermostat and thermal fuse. These components often appear in series with the heating element in the dryer schematic. You should check each connection point in the dryer schematic for signs of damage or wear. Use the dryer schematic to verify that each wire attaches to the correct terminal. This step prevents no heat issues and ensures your whirlpool dryer operates safely.

Note: If you encounter unclear wire paths in the dryer schematic, consult the official wiring diagram for your whirlpool dryer model. This resource provides detailed information and helps you avoid errors.

You can use the following checklist when tracing wire paths in the dryer schematic:

- Identify the heating element symbol in the dryer schematic.

- Locate the power wires and trace them to the heating element in the dryer schematic.

- Find the thermostat and thermal fuse symbols in the dryer schematic.

- Check each connection for continuity using the dryer schematic as a guide.

- Confirm that all wires match the official wiring diagram for your whirlpool dryer.

You should always rely on the dryer schematic and wiring diagram to guide your repairs. These documents provide the most accurate information for safe and effective wiring.

Identifying Correct Wires and Terminals in Whirlpool Dryer

When you work on your Whirlpool dryer, you must identify each wire and terminal correctly. This step ensures safe operation and prevents common issues like no heat or electrical shorts. You will find several key wires inside the dryer, each with a specific function.

Main Power Wires in Whirlpool Electric Dryer

The main power wires deliver electricity to the heating element and other components. You must recognize these wires before making any connections.

L1 and L2 Connections for Dryer Heating Element

You will see two main power wires labeled L1 and L2. These wires supply 240 volts to the heating element. L1 usually has a black or red color, while L2 often appears red. You must connect L1 and L2 to the correct terminals on the heating element. If you reverse or misplace these wires, the dryer will not heat properly. Always check the wiring diagram for your model to confirm the correct placement.

Tip: Use a multimeter to verify voltage at L1 and L2 before connecting them to the heating element.

Neutral Wire in Whirlpool Dryer

The neutral wire completes the electrical circuit. You will typically find a white wire serving as the neutral. This wire connects to the terminal marked “N” or “Neutral” on the terminal block. The neutral wire does not carry voltage under normal operation, but it is essential for the safe return path of electricity. Always ensure the neutral wire is secure and free from damage.

Ground Wire Location in Whirlpool Electric Dryer

You must locate and connect the ground wire to prevent electrical shock. The ground wire is usually green or bare copper. You will find a dedicated ground screw or terminal inside the dryer’s cabinet, often near the power cord entry point. Attach the ground wire firmly to this terminal. A proper ground connection protects you and your appliance from electrical faults.

| Couleur du fil | Fonction | Typical Terminal Location |

|---|---|---|

| Black/Red | L1/L2 Power | Heating Element Terminals |

| Blanc | Neutral | Terminal Block (N/Neutral) |

| Green/Bare | Ground | Ground Screw/Terminal |

Thermostat and Thermal Fuse Wires in Dryer

You must also identify the wires for the thermostat and thermal fuse. These wires play a critical role in temperature regulation and safety. The thermostat monitors the temperature of the heating element and prevents overheating. The thermal fuse acts as a safety device. If the dryer overheats, the thermal fuse cuts off power to the heating element, stopping the cycle and preventing fire hazards. If you find an open thermal fuse, you must replace it before the dryer will heat again. Always connect these wires to their designated terminals as shown in your wiring diagram.

Note: Never bypass the thermostat or thermal fuse. These components protect your home and your Whirlpool dryer from dangerous conditions.

Step-by-Step Wiring Instructions for Whirlpool Electric Dryer

Safety First: Power Off and Precautions for Dryer Wiring

You must prioritize safety before you begin any wiring work on your Whirlpool electric dryer. Unplug your dryer to eliminate the risk of electric shock. You should wear protective gloves to shield your hands from sharp edges and hot surfaces. Keep your workspace clean and free of clutter. Always use insulated tools when handling electrical components. If you notice damaged wires or terminals, replace them before proceeding. Never rush the process. Careful preparation helps you avoid accidents and ensures a successful repair.

⚠️ Conseil : Unplug your dryer before starting any repair work. This simple step protects you from electrical hazards.

Disconnecting the Old Heating Element in Whirlpool Dryer

You need to remove the old heating element before installing a new one. Follow these steps to disconnect the faulty element:

- Ensure the dryer is unplugged and put on protective gear.

- Remove screws from the front panel to access the heating element compartment.

- Note the wiring connections and carefully disconnect each wire from the element terminals.

- Remove any screws or clips securing the old heating element, then pull out the faulty part.

You should keep track of each wire and terminal location. Taking a photo before disconnecting wires can help you during reassembly. If you see signs of burning or corrosion, clean the area before installing the new element.

Connecting the New Heating Element in Whirlpool Electric Dryer

You must connect the new heating element correctly to restore heat and prevent no heat issues in your dryer. Pay close attention to each wire and terminal.

Attaching Power Wires to Dryer Heating Element

You will attach the main power wires to the heating element terminals. Use a jumper wire to connect the thermostat to the heating element. Make sure each connection is tight and secure. Loose wires can cause overheating or intermittent heat loss. If you see discoloration or residue on the terminals, clean or lightly sand them. Replace any damaged wire terminals to maintain a safe connection.

- Connect L1 and L2 power wires to the designated terminals on the heating element.

- Use a jumper wire between the thermostat and the heating element as specified in your wiring diagram.

- Inspect each terminal for signs of overheating and clean if necessary.

🔧 Remarque : Secure connections prevent overheating and ensure consistent heat in your Whirlpool dryer.

Securing Ground Wire in Whirlpool Electric Dryer

You must attach the ground wire to the correct terminal inside the dryer cabinet. The ground wire is usually green or bare copper. Fasten it to the ground screw or terminal near the power cord entry. A solid ground connection protects you and your appliance from electrical faults. Do not skip this step. Proper grounding is essential for safe operation.

Connecting Thermostat and Thermal Fuse for Dryer

You need to connect the thermostat and thermal fuse to the heating element. The thermal cutoff acts as a backup to the hi-limit thermostat and is usually located on the heating element. The thermal fuse shuts down the motor if the dryer overheats, while the thermal cutoff allows the dryer to spin. Some Whirlpool models use a thermistor instead of a cycling thermostat. Always follow your wiring diagram to connect these safety devices correctly.

- Attach the thermostat wires to their designated terminals on the heating element.

- Connect the thermal fuse as shown in your wiring diagram.

- If your Whirlpool duet electric dryer uses a thermistor, connect it according to the manufacturer’s instructions.

🛡️ Conseil : Never bypass the thermostat or thermal fuse. These components protect your dryer from overheating and fire hazards.

You should double-check each connection before restoring power. Proper wiring ensures your dryer heats efficiently and prevents no heat problems after replacing heating element.

Double-Checking Connections to Prevent “No Heat” Issues

You must verify every connection before restoring power to your whirlpool dryer. Careful inspection prevents the most common problem after heating element replacement: no heat. Even a single loose or misplaced wire can interrupt the circuit and stop the heating element from working.

Start by reviewing your wiring diagram. Compare each wire on the heating element, thermostat, and thermal fuse to the diagram. Confirm that every wire matches the correct terminal. Use a flashlight to check for hidden or crossed wires. If you see any corrosion or discoloration, clean the terminals with a contact cleaner or replace damaged connectors.

Follow this checklist to ensure all connections are secure:

- Tug gently on each wire to confirm it is firmly attached.

- Inspect the L1 and L2 power wires for tightness and correct placement.

- Check the neutral and ground wires for secure attachment.

- Verify that thermostat and thermal fuse wires connect to their designated terminals.

- Look for any pinched or exposed wires that could cause shorts.

⚡ Conseil : Use a multimeter to test for continuity across the heating element and safety devices. This step confirms that electricity can flow through the circuit without interruption.

You should also examine the wire insulation. Cracked or brittle insulation can lead to shorts or intermittent heating. Replace any wires that show signs of wear. Make sure no wires touch the metal cabinet except for the ground wire.

A quick reference table can help you double-check your work:

| Connection Point | Que vérifier | Action if Problem Found |

|---|---|---|

| Élément chauffant | Tightness, correct terminal | Reattach or replace connector |

| L1/L2 Power Wires | Firm connection, no corrosion | Clean or tighten as needed |

| Neutral Wire | Secure at terminal block | Re-secure or replace terminal |

| Ground Wire | Attached to ground screw/terminal | Fasten securely |

| Thermostat/Thermal Fuse | Correct terminal, no bypassing | Reconnect per diagram |

After you finish, review the entire assembly. Confirm that no tools or debris remain inside the cabinet. Close the access panel securely. Only then should you restore power and test the dryer. If you still experience no heat, repeat the inspection or consult the wiring diagram again.

🛡️ Remarque : Double-checking your connections not only prevents no heat issues but also protects your appliance from electrical hazards.

Common Wiring Mistakes in Whirlpool Dryer and How to Avoid Them

Misidentifying Wires in Whirlpool Electric Dryer

You must identify each wire correctly before making any connections. Many wiring mistakes start with confusing wire colors or misreading terminal labels. Manufacturers use specific colors for power, neutral, and ground wires. If you mix up these wires, you risk damaging the heating element or causing the dryer to stop working. Always check your wiring diagram and match each wire to its correct terminal. Take a clear photo of the wiring before you begin. This simple step helps you reconnect everything accurately. If you feel unsure, label each wire with masking tape and a marker. Careful identification prevents costly errors and keeps your appliance safe.

Conseil : Never guess a wire’s function based on color alone. Always confirm with the wiring diagram for your specific model.

Loose or Improper Connections in Dryer Heating Element

Loose or improper connections create serious risks for your dryer. You might notice unusual noises during operation or detect a burning smell, which often signals overheating. These symptoms point to electrical hazards that can damage your appliance or even start a fire. You should always tighten each terminal securely when installing the heating element. Use a screwdriver to check that every connection feels firm. If you see any corrosion or discoloration, clean the terminals before attaching wires. Replace any damaged connectors immediately.

- Bruits inhabituels pendant le fonctionnement

- Burning smells indicating overheating

- Potential electrical hazards from loose connections

A secure connection ensures the heating element receives the correct voltage and operates efficiently. Double-check your work before restoring power. This habit protects both you and your whirlpool dryer from preventable problems.

Skipping the Ground Wire in Whirlpool Dryer

You must never skip the ground wire when wiring your dryer. The ground wire provides a safe path for stray electricity, protecting you from electric shock. If you leave out this wire, the heating element may heat only partially. In some cases, the heating element could stay on even when the dryer is not running, which creates a major safety hazard.

- Skipping the ground wire can cause the heating element to heat only partially.

- The heating element may remain on even when the dryer is not in use, leading to potential safety hazards.

Always attach the ground wire to the designated terminal or screw inside the cabinet. This step ensures your appliance operates safely and meets electrical codes. Never bypass grounding for convenience. Your safety depends on it.

⚡ Remarque : Proper grounding is not optional. It is a critical part of every safe dryer installation.

Overlooking Safety Devices When Replacing Heating Element

When you replace the heating element in your dryer, you must pay close attention to the safety devices installed within the appliance. Many users focus only on the heating element itself and overlook critical components like the thermal fuse, thermostats, and thermal cutoffs. Ignoring these safety devices can lead to serious risks, including fire hazards and damage to your whirlpool dryer.

You should always inspect the thermal fuse before completing any repair. The thermal fuse serves as a fail-safe mechanism. If the dryer reaches unsafe temperatures, the fuse interrupts the electrical circuit and stops the flow of electricity to the heating element. This action prevents overheating and reduces the risk of fire. You cannot rely solely on the thermostat to regulate temperature. The thermal fuse provides an extra layer of protection that you should never bypass or ignore.

Consider the following reasons why you must check and replace safety devices during heating element repairs:

- The thermal fuse prevents overheating by interrupting the electrical circuit if the dryer reaches unsafe temperatures.

- It acts as a fail-safe mechanism to stop the flow of electricity to the heating element, thereby preventing fire hazards.

- Regular maintenance and checks are essential to ensure the thermal fuse operates effectively, contributing to the overall safety of the dryer.

You should also examine the cycling thermostat and high-limit thermostat. These devices monitor the temperature inside the dryer and help maintain safe operating conditions. If either thermostat fails, the heating element may run continuously, causing the dryer to overheat. You must test these components with a multimeter and replace them if they show signs of malfunction.

When you install a new heating element, always reconnect the thermal fuse and thermostats according to the wiring diagram. Never bypass these devices, even temporarily. Bypassing safety devices may allow the dryer to operate, but it exposes you to significant risks. You should use only manufacturer-approved replacement parts to ensure compatibility and reliability.

You can use a simple checklist to avoid overlooking safety devices:

- Inspect the thermal fuse for continuity before installing the new heating element.

- Test the cycling and high-limit thermostats for proper function.

- Reconnect all safety devices according to the wiring diagram.

- Replace any damaged or worn safety components immediately.

⚠️ Alerte: Never operate your dryer without all safety devices in place. These components protect your home and your appliance from dangerous conditions.

By following these steps, you ensure that your whirlpool dryer operates safely and efficiently. You protect yourself, your family, and your property from preventable hazards.

Troubleshooting Whirlpool Electric Dryer Heating Element Wiring

Dryer No Heat Problems After Replacing Heating Element

If you experience no heat after installing a new element, you need to follow a systematic troubleshooting process. Many users overlook simple issues that prevent the dryer from heating. Start by checking the power supply and safety devices. Use the table below to guide your steps:

| Étape | Action |

|---|---|

| 1 | Check the house circuit breaker for the dryer. Reset if necessary. |

| 2 | Ensure the dryer receives 240 volts by checking the power supply. |

| 3 | Vérifiez que le cordon d'alimentation n'est pas endommagé. |

| 4 | Set the dryer to a timed dry, high-heat cycle to test for heat after resetting breakers. |

| 5 | Unplug the unit and check for burned wires at the terminal block. |

| 6 | Test the heating element for continuity; it should measure around 10 ohms. |

| 7 | Check the operating thermostat and hi-limit thermostat for continuity (should be 0 ohms). |

| 8 | Inspect the thermal fuse; if you find an open thermal fuse, replace it along with the hi-limit thermostat. |

You should also flip the breaker off and on a couple of times to ensure full power. Measure voltage at the plug: L1 to L2 should read 240 volts, while L1 to Neutral and L2 to Neutral should each read 120 volts. If you find no continuity through the circuit, check the heating element for resistance. This approach helps you identify the root cause of no heat in your whirlpool electric dryer.

Tripped Breakers or Blown Fuses in Whirlpool Dryer

Tripped breakers or blown fuses often signal deeper electrical issues. You may encounter these problems after replacing the heating element. Several factors can cause these interruptions:

- Faulty heating element

- Drive motor issues

- Terminal block problems

- Circuit breaker failure

- Court-circuit

- Circuit overloads

- Power surges

- Ground faults

You should inspect each component carefully. A faulty heating element or a short circuit can trip breakers repeatedly. Examine the terminal block for loose or burned connections. If you suspect a circuit overload or power surge, consult a licensed electrician. Addressing these issues quickly prevents further damage to your dryer and home electrical system.

Burning Smell or Sparks from Electric Dryer

A burning smell or visible sparks from your dryer require immediate action. You must stop using the appliance and disconnect the power right away. Safety comes first in these situations. Take the following steps:

- Inspect the power cord and outlet for damage, such as scorch marks or brittleness.

- Check for any unusual signs around the terminal block or wiring.

- If you notice anything abnormal, do not attempt repairs yourself. Contact a professional electrician.

Ignoring these warning signs can lead to fire hazards or severe appliance damage. Always prioritize your safety and the safety of your home when dealing with electrical issues in your whirlpool dryer.

Testing Heating Element with a Multimeter in Whirlpool Dryer

You can quickly determine if your heating element works by using a multimeter. This tool helps you check for electrical continuity, which tells you if the element can conduct electricity and produce heat. You do not need advanced skills to perform this test, but you must follow each step carefully to avoid mistakes.

Start by unplugging your whirlpool dryer. Safety comes first. You should wear gloves and use insulated tools. Remove the back panel or access cover to reach the heating element. Locate the terminals on the element. You will see two or more metal posts where wires connect.

Set your multimeter to the lowest resistance setting, usually marked as Ω (ohms). Touch one probe to each terminal on the element. If your multimeter displays a reading between 8 and 12 ohms, the element has continuity and should work properly. If you see a reading of zero or infinite resistance, the element is faulty and needs replacement.

Here is a simple checklist for testing the heating element:

- Unplug the dryer and put on safety gloves.

- Remove the access panel to locate the heating element.

- Set your multimeter to the lowest resistance setting.

- Touch one probe to each terminal on the element.

- Read the display. A result between 8 and 12 ohms means the element is good.

- If you see zero or infinite resistance, replace the element.

⚡ Conseil : Always test the element before installing a new one. This step saves you time and prevents unnecessary repairs.

You may want to record your results in a table for easy reference:

| Test Step | Expected Result | Action if Failed |

|---|---|---|

| Multimeter reading | 8-12 ohms | L'élément est bon |

| Multimeter reading | 0 or infinite ohms | Replace the element |

If you find the element is faulty, purchase a replacement that matches your whirlpool dryer model. Install the new part and repeat the test to confirm proper function. You should also check the wiring and safety devices before closing the panel.

Testing with a multimeter gives you confidence that your dryer will heat efficiently. You avoid guesswork and ensure your repairs are successful.

Safety Checklist for Wiring Your Whirlpool Electric Dryer

A safety-first approach ensures you complete any repair or replacement on your dryer without risk. Use this checklist to guide your work and protect both yourself and your appliance.

Before You Start Replacing Heating Element

Preparation sets the foundation for a safe and successful repair. Begin by unplugging your dryer from the wall outlet. This step eliminates the risk of electric shock. Gather all necessary tools, such as a multimeter, insulated screwdrivers, and work gloves. Review the wiring diagram for your specific model. You should keep the diagram nearby for quick reference. Inspect the area around your dryer for water, clutter, or flammable materials. Remove any obstacles to create a safe workspace.

⚠️ Alerte: Never attempt to service a dryer while it remains connected to power. Always verify that the appliance is unplugged before you begin.

Check the replacement heating element for visible damage. Confirm that the part matches your model. Organize all screws and small parts in a container to prevent loss during the process.

During Wiring of Whirlpool Dryer Heating Element

You must stay focused and methodical while working with electrical components. Wear gloves to protect your hands from sharp edges and hot surfaces. Use only insulated tools to avoid accidental shocks. Follow the wiring diagram step by step. Attach each wire to its correct terminal. Double-check the color and label of every wire before making a connection.

If you encounter resistance when attaching a wire, stop and inspect the terminal. Forcing a connection can damage both the wire and the terminal. Secure each connection tightly. Loose wires can cause intermittent heat or even create a fire hazard. Keep the workspace organized. Place removed panels and screws in a safe spot.

🛡️ Conseil : Take a photo of the wiring before you disconnect anything. This visual reference helps you reconnect wires accurately.

After Wiring the Electric Dryer Heating Element

Once you finish wiring, perform a thorough inspection. Tug gently on each wire to confirm a secure connection. Check that no wires touch moving parts or the metal cabinet, except for the ground wire. Use a multimeter to test for continuity across the heating element and safety devices. This step verifies that the circuit is complete and ready for operation.

Replace all panels and covers before restoring power. Plug the appliance back in and run a short test cycle. Monitor the dryer for proper heat and listen for unusual sounds. If you detect a burning smell or sparks, disconnect power immediately and review your work.

✅ Remarque : A careful final check prevents most common issues and ensures your whirlpool electric dryer operates safely.

When to Call a Professional for Whirlpool Dryer Wiring

Signs You Need Expert Help with Electric Dryer

You may feel confident handling basic repairs, but some situations require a licensed professional. Recognizing these signs helps you avoid costly mistakes and keeps your home safe. If you notice any of the following, you should contact an expert:

- You see sparks, smoke, or a burning smell after wiring the heating element.

- The circuit breaker trips repeatedly when you run your dryer.

- You find melted wires, scorched terminals, or damaged insulation inside the cabinet.

- The wiring diagram does not match your model, or you cannot identify the correct terminals.

- You feel unsure about any step in the wiring process.

⚠️ Alerte: If you experience electric shocks or tingling when touching the appliance, stop immediately and call a professional. This symptom indicates a serious grounding or wiring issue.

A professional technician has the training and tools to diagnose complex electrical problems. You protect your investment and ensure your whirlpool dryer operates safely when you seek expert help at the right time.

Risks of DIY Electrical Work on Whirlpool Dryer

DIY repairs can save money, but electrical work carries real risks. You must understand these dangers before attempting to wire your dryer. Mistakes can lead to property damage, injury, or even fire. Here are some common risks:

| Risque | Conséquences potentielles |

|---|---|

| Incorrect wiring | No heat, short circuits, fire hazard |

| Loose connections | Overheating, sparks, appliance damage |

| Skipping ground connection | Electric shock, unsafe operation |

| Bypassing safety devices | Loss of protection, fire risk |

You may think a simple fix will solve the problem, but hidden issues can remain. If you wire the heating element incorrectly, the dryer may not heat or could overheat. Skipping the ground wire or bypassing safety devices puts your home and family at risk.

🛡️ Conseil : Always follow the manufacturer’s instructions and local electrical codes. If you feel uncertain, choose safety and call a qualified technician.

You ensure reliable performance and peace of mind when you let a professional handle complex wiring tasks. Your safety should always come first.

- You should follow each wiring step carefully when working on your Whirlpool dryer.

- Always disconnect power before starting repairs on your Whirlpool electric dryer.

- Double-check every connection to prevent no heat problems.

- Use insulated tools and wear gloves for safety.

If you feel unsure at any point, consult the official Whirlpool manual or contact a professional technician. Your safety matters most.

FAQ

How do you know if your heating element is bad?

You can test the heating element with a multimeter. If you see no continuity, the element is faulty. You may also notice your dryer runs but does not heat. Always unplug the appliance before testing.

Can you replace a heating element yourself?

You can replace the heating element if you follow safety steps and use the correct tools. Always disconnect power, follow the wiring diagram, and double-check connections. If you feel unsure, contact a professional.

What causes a whirlpool dryer to stop heating?

A faulty heating element, blown thermal fuse, or tripped breaker can cause heat loss. You should also check the thermostat and wiring connections. Regular maintenance helps prevent these issues.

Is it safe to bypass the thermal fuse?

You should never bypass the thermal fuse. This safety device prevents overheating and fire hazards. Always replace a blown fuse with a manufacturer-approved part.

Why does my dryer keep tripping the breaker?

A short circuit, faulty heating element, or overloaded circuit can trip the breaker. Inspect the wiring and heating element for damage. If the problem continues, consult a licensed electrician.

How often should you check dryer wiring?

You should inspect your dryer wiring during any repair or if you notice performance issues. Regular checks help you spot wear, corrosion, or loose connections early.

What tools do you need to replace a heating element?

You need a multimeter, insulated screwdrivers, work gloves, and a replacement heating element. Keep the wiring diagram nearby for reference. Use only tools rated for electrical work.