Vietnam stands out as a major hub for electric elemento calefactor manufacturing, with leading factories such as Partron Vina, Ariston Thermo Vietnam, Visin Heater, Heidenberg, and Mega Technology & Solution Vietnam. These companies excel through strong product quality, advanced certifications, and proven export experience. International brands like jinzhong also shape the market by introducing innovative technologies and global standards. The industry’s strength is clear, as Vietnam ranks ninth worldwide for exports and fourth for imports, with 6,513 export shipments and 11,059 import shipments annually.

Métrica | Vietnam’s Position | Count |

|---|---|---|

Exporting Countries Rank | 9th | 6,513 shipments |

Importing Countries Rank | 4th | 11,059 shipments |

Number of Heating Element Suppliers | N/A | 442 suppliers |

Principales conclusiones

Vietnam ranks among the top countries globally for electric heating element exports and imports, with over 400 suppliers.

High product quality depends on using advanced materials like nichrome and ceramic, plus strict testing to ensure safety and durability.

Certifications such as ISO9001, ISO14001, and ISO45001 prove a factory’s commitment to quality, safety, and environmental standards.

Strong export experience shows a factory’s ability to meet international demands and adapt to different markets.

Customer feedback helps factories improve products and services, building trust and long-term partnerships.

Innovation drives better heating elements through new materials, smart features, and precise manufacturing techniques.

Leading Vietnamese factories like Partron Vina, Ariston Thermo Vietnam, Visin Heater, Heidenberg, and Mega Technology offer diverse products and customization options.

Buyers should assess their needs, check certifications, request samples, and consider after-sales support when choosing a factory.

Criterios de selección

Product Quality

Factories that produce electric heating elements must meet strict quality standards to ensure safety, efficiency, and durability. High-quality products rely on advanced materials, precise manufacturing, and rigorous testing. The choice of material directly impacts performance and lifespan. For example, manufacturers often select nickel-chromium alloys, iron-chromium-aluminum, or even ceramic and silicon carbide for their unique properties. The following table summarizes common materials and their characteristics:

Material / Element Type | Maximum Operating Temperature (°C) | Key Properties / Applications |

|---|---|---|

Nichrome (Resistance wire) | Up to 1,200 | Stable, uniform heat distribution, medium-high temp |

Elementos cerámicos | Exceeding 1,800 | High-temp lab applications, structural integrity |

carburo de silicio | Up to 2,000 | Industrial furnaces, oxidizing atmospheres |

Disilicida de molibdeno | Up to 1,900 | High-temp furnaces, oxidation resistant |

Tungsten, Graphite | Up to 3,000 (in vacuum) | Ultra-high temp, vacuum furnaces, oxidation sensitive |

Manufacturers also follow strict quality control measures. These include power deviation tests, leakage current tests, and electrical strength tests. For instance, a power deviation test ensures the output remains within +5% or -10% of the rated value. Leakage current tests confirm electrical safety by keeping current below 0.5 mA. Uniform heating wire distribution prevents local overheating and extends product life. Factories also monitor insulation material quality and assign serial numbers for traceability. These steps guarantee that each electric heating element meets industry expectations for reliability and safety.

Certificaciones

Certifications serve as proof that a factory adheres to recognized industry standards. Leading manufacturers obtain both national and international certifications to demonstrate their commitment to quality, safety, and environmental responsibility. Common certifications include ISO9001 for quality management, ISO14001 for environmental management, and ISO45001 for occupational health and safety. Factories may also comply with standards such as JB/T 4088-2012 and GB 4706.1-2005, which set benchmarks for electric heating element performance and safety.

Quality Control Measure | Quantitative Criteria / Standard | Description / Purpose |

|---|---|---|

Industry Standards | JB/T 4088-2012, GB 4706.1-2005 | Ensures product quality and safety. |

Power Deviation Test | +5% / -10% of rated power | Maintains performance consistency. |

Prueba de corriente de fuga | ≤ 0.5 mA | Confirms electrical safety. |

Prueba de resistencia eléctrica | 1000 V for 60 min, 2000-2500 V (enterprise) | Verifies insulation durability. |

Heating Wire Uniformity Test | Visual uniform red-hot color distribution | Prevents local overheating. |

Material Quality Control | MgO powder uniformity, iron impurity removal | Maintains insulation quality and longevity. |

Certifications from organizations like ASTM International and IEC further validate a factory’s ability to meet global requirements. These credentials help buyers identify trustworthy partners and reduce risks in procurement.

Export Experience

Export experience reflects a factory’s ability to meet international standards and adapt to diverse market requirements. Factories with strong export records often use trade data platforms and market analysis tools to track shipments, identify key markets, and optimize their strategies. The International Trade Centre provides resources such as Export Potential Map and Trade Map, which help manufacturers analyze export volumes and market access. Volza and similar platforms offer detailed export shipment data, supplier information, and price bands.

Factories use trade statistics to validate export volumes and market presence.

Market analysis tools help identify new opportunities and strengthen export credentials.

Access to shipment data supports transparency and continuous improvement.

A factory’s export experience demonstrates its reliability, adaptability, and understanding of global market demands. Buyers can use this information to assess a supplier’s ability to deliver electric heating elements that comply with international standards.

Comentarios de los clientes

Customer feedback plays a crucial role in evaluating electric heating element factories. Manufacturers and buyers rely on feedback to assess product performance, reliability, and service quality. Companies collect and analyze feedback using several metrics that provide a comprehensive view of customer satisfaction.

Star ratings offer a direct measure of satisfaction. Customers rate their experience on a scale, usually from one to four stars. Higher ratings indicate better performance and reliability.

Topic prevalence scores show how often specific topics appear in reviews. For example, if many customers mention durability or energy efficiency, these become key focus areas for improvement or promotion.

Mean Rating Profile (MRP) profiles use sentiment analysis to track positive or negative trends over time. This helps factories identify strengths and address recurring issues.

Indicator of Mean Topic Prevalence (IMTP) trends detect sudden changes in feedback. Spikes or drops in certain topics can signal shifts in customer interest or satisfaction.

These metrics help factories identify areas for improvement and maintain high standards. Consistent positive feedback builds trust and strengthens a factory’s reputation. Negative trends prompt quick action to resolve issues and enhance customer experience. By monitoring these indicators, manufacturers ensure their electric heating element products meet or exceed customer expectations.

Innovación

Innovation sets leading electric heating element factories apart from their competitors. Companies invest in research and development to create new materials, improve energy efficiency, and introduce advanced manufacturing techniques. Innovation drives product quality and supports the development of solutions for both household and industrial applications.

Factories often collaborate with research institutions and universities to stay at the forefront of technology. They develop new heating materials, such as advanced alloys or ceramics, that offer better thermal conductivity and longer lifespans. Automation and precision engineering further enhance product consistency and reduce defects.

Manufacturers also focus on integrating smart features, such as intelligent temperature control and safety mechanisms. These advancements make electric heating elements safer, more efficient, and easier to use. Customization options allow factories to meet unique customer requirements, supporting a wide range of applications.

Continuous innovation ensures that factories can adapt to changing market demands and regulatory standards. It also positions them as reliable partners for businesses seeking high-performance heating solutions. By prioritizing innovation, manufacturers contribute to the growth and sustainability of the electric heating element industry.

Electric Heating Element Manufacturers in Vietnam

Partron Vina Company Limited

Descripción general

Partron Vina Company Limited operates as a key player in Vietnam’s electric heating element industry. The company maintains a strong presence in the export market, consistently ranking among the top exporters by shipment volume. Partron Vina leverages advanced manufacturing processes and a skilled workforce to deliver reliable heating solutions for both domestic and international clients.

Key Products

Tubular heating elements

Cartridge heaters

Immersion heaters

Custom-designed electric heating components for industrial and household applications

Strengths

Partron Vina stands out for its high shipment volume and robust export capabilities. The company invests in modern production lines and quality control systems to ensure product consistency. Its ability to customize products for specific client needs enhances its reputation among manufacturers and distributors.

Nota: According to recent shipment data, Partron Vina (TVN) leads the market with 2,640 shipments, indicating the highest market share among Vietnamese electric heating element exporters.

Manufacturer | Shipment Volume | Role in Market Share Proxy |

|---|---|---|

TVN (Partron Vina) | 2,640 | Leading exporter by shipment count |

THERMTROL VSIP COMPANY LIMIT | 1,990 | Second highest shipment volume |

HYOSUNG VIETNAM CO LTD | 1,956 | Third highest shipment volume |

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

Compliance with JB/T 4088-2012 and GB 4706.1-2005 standards

Contact

Address: Lot B_2B_CN, My Phuoc 3 Industrial Park, Ben Cat Town, Binh Duong Province, Vietnam

Phone: +84-274-222-1234

Email: info@partronvina.com

Ariston Thermo Vietnam Company Limited

Descripción general

Ariston Thermo Vietnam Company Limited represents a global leader in water heating technology. The company has established a dominant position in Vietnam’s market for sterile water and storage water heaters. Ariston Thermo Vietnam combines Italian engineering with local expertise to deliver innovative and energy-efficient heating solutions.

Key Products

Electric water heaters (storage and instant)

Solar water heaters

Heat pump water heaters

Industrial heating systems

Strengths

Ariston Thermo Vietnam commands a significant share of the Vietnamese market. The company’s advanced manufacturing facilities and commitment to research and development drive its reputation for quality and reliability. Ariston’s products meet stringent international standards, making them a preferred choice for both residential and commercial projects.

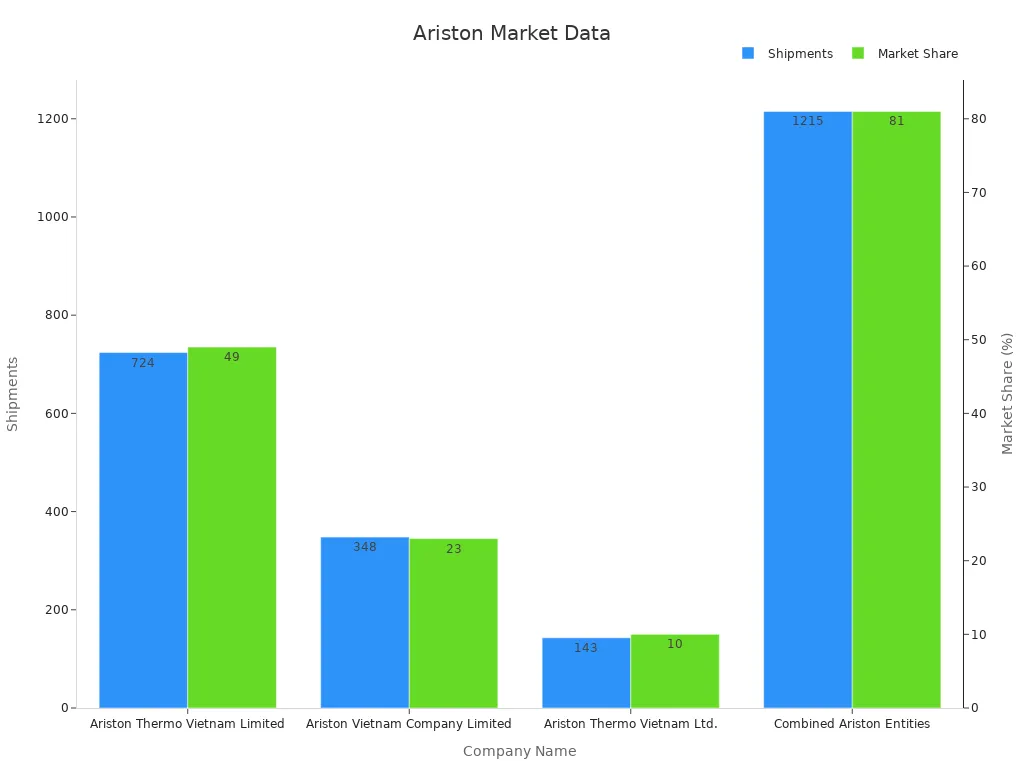

Nombre de la empresa | Market Share (%) | Number of Shipments | Descripción |

|---|---|---|---|

Ariston Thermo Vietnam Limited | 49% | 724 | Leading supplier of sterile water and storage water heaters in Vietnam |

Ariston Vietnam Company Limited | 23% | 348 | Significant contributor to Vietnam’s exports in this category |

Ariston Thermo Vietnam Ltd. | 10% | 143 | Third largest exporter in the category |

Combined Ariston Entities | 1215 | Dominant share of Vietnam’s total exports in sterile water and storage water heaters |

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

ISO45001: Occupational Health and Safety

CE and RoHS compliance

Contact

Address: Lot CN1, Thang Long Industrial Park, Dong Anh District, Hanoi, Vietnam

Phone: +84-24-3951-0300

Email: info.vn@aristonthermo.com

Visin Heater Co., Ltd

Descripción general

Visin Heater Co., Ltd specializes in the design and production of electric heating elements for a wide range of applications. The company has built a reputation for delivering high-quality products tailored to the needs of both industrial and household customers. Visin Heater emphasizes innovation and customer service in its operations.

Key Products

Tubular heating elements

Finned heaters

Band heaters

Customized heating solutions for machinery and appliances

Strengths

Visin Heater focuses on product customization and rapid response to client requirements. The company uses advanced materials and precision manufacturing techniques to ensure durability and efficiency. Its commitment to after-sales support and technical consultation strengthens long-term partnerships with clients.

Consejo: Visin Heater’s flexibility in design and manufacturing makes it a strong choice for businesses seeking tailored electric heating element solutions.

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

Compliance with relevant Vietnamese and international safety standards

Contact

Address: No. 12, Street 6, Tan Tao Industrial Park, Binh Tan District, Ho Chi Minh City, Vietnam

Phone: +84-28-3750-1234

Email: sales@visinheater.com

Heidenberg Electric Heating Element Factory

Descripción general

Heidenberg Electric Heating Element Factory operates as a reputable manufacturer in Vietnam’s heating industry. The company has established a strong presence by focusing on both domestic and international markets. Heidenberg invests in advanced production technology and emphasizes strict quality control throughout its manufacturing process.

Key Products

Tubular heating elements

Finned heating elements

Immersion heaters

Customized electric heating solutions for industrial and household use

Strengths

Heidenberg’s main strengths include its ability to deliver consistent product quality and its flexibility in meeting diverse customer requirements. The factory uses high-grade materials and modern equipment to ensure each electric heating element meets rigorous standards. Heidenberg’s engineering team works closely with clients to develop tailored solutions for specialized applications.

Nota: Heidenberg’s commitment to continuous improvement and customer satisfaction has helped it build long-term partnerships with both local and international clients.

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

Compliance with Vietnamese and international safety standards

Contact

Address: Lot 5, Road No. 2, Tan Tao Industrial Park, Binh Tan District, Ho Chi Minh City, Vietnam

Phone: +84-28-3750-5678

Email: contact@heidenberg.com.vn

Mega Technology & Solution Vietnam Co., Ltd

Descripción general

Mega Technology & Solution Vietnam Co., Ltd stands out as one of Vietnam’s most experienced and innovative manufacturers in the electric heating industry. The company has operated for over 30 years, serving a global customer base and maintaining a reputation for quality and reliability. Mega Technology & Solution Vietnam employs more than 330 skilled technicians and engineers, ensuring a high level of technical expertise in every project.

Key Products

Tubular and cartridge heating elements

PTC (Positive Temperature Coefficient) heaters

Flexible and custom-shaped heating elements

Industrial and household electric heating solutions

Strengths

Mega Technology & Solution Vietnam excels in delivering total solutions, rapid delivery, and robust quality control. The company’s information security practices protect client data and intellectual property. Mega’s broad customer base, which includes over 1,000 clients worldwide, demonstrates its ability to meet diverse market needs. The company’s innovation capabilities set it apart in the industry.

Metric / Aspect | Data / Description |

|---|---|

Years in Business | Over 30 years |

Technicians & Engineers | More than 330 skilled professionals |

Global Customers | Serving over 1,000 customers worldwide |

Core Competencies | Total Solutions, Rapid Delivery, Quality Control & Information Security |

Innovation Trends (2023) | Sustainable Black, Bio Composite, Waste-based Composite, Sustainable Colour |

Capacidades de innovación | CMF Design, Design Prototype, CNC Machining, 3D Printing, Tooling |

Mega Technology & Solution Vietnam actively engages in CMF (Color, Material, Finish) design, rapid prototyping, CNC machining, 3D printing, and tooling. The company’s focus on sustainable materials and eco-friendly innovation aligns with current global trends.

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

ISO45001: Occupational Health and Safety

Compliance with international and Vietnamese safety standards

Contact

Address: No. 18, Street 7, Song Than 1 Industrial Park, Di An City, Binh Duong Province, Vietnam

Phone: +84-274-379-8888

Email: info@megatechsolution.com.vn

jinzhong (China)

Descripción general

jinzhong, based in Zhongshan, Guangdong, China, has established itself as a leading manufacturer of electric heating elements with a focus on clean heating technology. Since its founding in 1991, jinzhong has accumulated over 30 years of experience in the industry. The company supports a full production chain, from product design and mold development to precision manufacturing. jinzhong serves both smart home appliance and industrial markets, providing core components for a wide range of applications.

Heating-Element Product Line

jinzhong offers a comprehensive product line that includes:

Placas calefactoras

Películas calefactoras

Calentadores de fundición a presión

Piezas de calentador eléctrico

The company’s heating elements use high-purity nickel-chromium alloy wires and advanced insulation materials. These products deliver high temperature resistance, corrosion resistance, and excellent thermal efficiency. jinzhong’s solutions fit both household appliances, such as electric kettles and coffee machines, and industrial equipment, including commercial ovens and steam generators.

Product Advantages

jinzhong’s electric heating element products stand out for their efficiency, adaptability, and advanced engineering. The company uses lightweight aluminum and nickel-chromium alloys to ensure optimal heat conduction and durability. Customers benefit from intelligent constant temperature control, rapid heat-up times, and the ability to customize products for specific needs. jinzhong’s extensive experience and international certifications guarantee consistent quality and performance.

Consejo: jinzhong’s one-stop manufacturing chain enables fast delivery, with standard products available in as little as three days.

Certificaciones

ISO9001: Quality Management System

ISO14001: Environmental Management System

ISO45001: Occupational Health and Safety

VDE, UL, and RoHS certifications

Contact

Address: Zhongshan, Guangdong, China

Phone: +86-18142821082

Email: info@jinzho.com

Website: https://jinzho.com

Comparación de elementos calefactores eléctricos

Feature Comparison Table

The following table provides a side-by-side comparison of the leading electric heating element factories in Vietnam and the international benchmark, jinzhong. This overview covers essential aspects such as product range, certifications, export experience, and unique capabilities.

Factory / Brand | Gama de productos | Certificaciones | Export Experience | Customization & Innovation | Notable Strengths |

|---|---|---|---|---|---|

Partron Vina | Tubular, cartridge, immersion heaters | ISO9001, ISO14001, JB/T 4088-2012 | High (2,640 shipments) | Strong customization, QC systems | Leading exporter, reliable quality |

Ariston Thermo Vietnam | Water heaters, solar, heat pumps, industrial | ISO9001, ISO14001, ISO45001, CE, RoHS | Extensive (global brand) | R&D, energy efficiency | Market leader, advanced tech |

Visin Heater | Tubular, finned, band heaters | ISO9001, ISO14001 | Moderado | Flexible design, rapid response | Custom solutions, strong support |

Heidenberg | Tubular, finned, immersion heaters | ISO9001, ISO14001 | Moderado | Engineering support, QC focus | Consistent quality, tailored solutions |

Mega Technology & Solution | Tubular, cartridge, PTC, flexible heaters | ISO9001, ISO14001, ISO45001 | Global (1,000+ clients) | CMF design, rapid prototyping | Innovation, rapid delivery |

jinzhong (China) | Heating tubes, plates, films, die-cast, parts | ISO9001, ISO14001, ISO45001, VDE, UL, RoHS | Extensive (global reach) | Full-chain R&D, intelligent control | Advanced materials, fast delivery, customization |

Consejo: Use this table to quickly identify which factory aligns best with your project requirements, whether you prioritize certifications, product diversity, or innovation.

Key Differentiators

Each factory brings unique strengths to the electric heating element industry:

Partron Vina leads in export volume from Vietnam. The company’s robust quality control and ability to customize products make it a preferred partner for large-scale orders.

Ariston Thermo Vietnam stands out for its dominance in water heating technology. Its global brand reputation and focus on energy-efficient solutions appeal to both residential and commercial clients.

Visin Heater excels in flexibility. The company responds quickly to custom requests and provides strong after-sales support, making it ideal for specialized applications.

Heidenberg emphasizes consistent quality and engineering support. The factory works closely with clients to develop tailored solutions for both industrial and household needs.

Mega Technology & Solution Vietnam demonstrates leadership in innovation. The company’s expertise in CMF design, rapid prototyping, and sustainable materials positions it at the forefront of technological advancement.

jinzhong sets a benchmark for international standards. The company’s full-chain R&D, advanced materials, and intelligent temperature control systems deliver high efficiency and reliability. Its ability to provide rapid delivery and extensive customization makes it a strong choice for both household and industrial electric heating element applications.

Buyers should consider their specific needs, such as order size, required certifications, and the level of customization, when selecting a factory. Factories like jinzhong offer advanced engineering and global certifications, which can be especially valuable for projects requiring high performance and international compliance.

How to Choose a Factory

Evaluación de necesidades

Selecting the right factory starts with a clear understanding of project requirements. Buyers should define the intended application, whether for household appliances, industrial machinery, or specialized equipment. They should estimate the order size and frequency. Large-scale projects may require factories with high production capacity and proven export experience. Smaller or custom orders might benefit from manufacturers that offer flexible production runs.

Buyers should also consider technical specifications. These include voltage, wattage, dimensions, and material preferences. For example, some applications demand high-temperature resistance or corrosion-proof materials. Reviewing these details ensures the chosen factory can deliver products that match operational needs.

Consejo: Create a checklist of essential requirements before contacting suppliers. This approach streamlines communication and helps factories provide accurate quotes.

Opciones de personalización

Customization plays a crucial role in the electric heating element industry. Many projects require unique shapes, sizes, or performance features. Leading factories, such as jinzhong, excel in offering tailored solutions. Their elemento calefactor product line demonstrates the value of customization, with options for heating tubes, plates, films, and die-cast heaters. These products can be adapted for specific voltages, power ratings, and installation environments.

When evaluating factories, buyers should ask about the range of customization services. Important questions include:

Can the factory modify product dimensions or materials?

Does the supplier offer intelligent temperature control or safety features?

What is the process for prototype development and approval?

Factories with strong R&D capabilities and a full-chain manufacturing process, like jinzhong, can deliver rapid prototyping and adapt to evolving project requirements. Customization ensures the electric heating element fits seamlessly into the final product, improving efficiency and reliability.

Soporte posventa

Reliable after-sales support distinguishes top-tier factories from the rest. Buyers should look for manufacturers that provide technical assistance, warranty coverage, and prompt response to service requests. Effective support includes troubleshooting, replacement parts, and guidance on installation or maintenance.

A factory’s commitment to after-sales service reflects its confidence in product quality. Companies like jinzhong back their heating-element products with comprehensive support, ensuring long-term satisfaction for clients. Buyers should review service policies and request references to verify the supplier’s reputation.

Strong after-sales support reduces downtime and protects investments, especially for businesses relying on continuous operation.

Verificación de certificaciones

Certifications play a critical role when selecting a factory for heating components. Buyers should always verify that a manufacturer holds up-to-date certifications from recognized organizations. These certifications demonstrate a commitment to quality, safety, and environmental responsibility. Common certifications include ISO9001 for quality management, ISO14001 for environmental management, and ISO45001 for occupational health and safety. Some factories also hold product-specific certifications such as VDE, UL, or RoHS, which indicate compliance with international standards.

A simple checklist can help buyers evaluate a supplier’s credentials:

Confirm the presence of ISO9001, ISO14001, and ISO45001 certificates.

Request copies of any additional certifications, such as VDE, UL, or RoHS.

Check the validity period and issuing authority for each certificate.

Ask about compliance with local and international product standards.

Factories like jinzhong set a strong example by maintaining more than ten international certifications. Their heating-element products meet strict requirements for quality and safety. This level of certification provides peace of mind for buyers who need reliable and compliant components.

Consejo: Always request documentation directly from the factory. Authentic certificates should include the issuing body’s name, a unique certificate number, and an expiration date.

Certifications not only protect buyers from potential risks but also support long-term business relationships. A certified supplier demonstrates professionalism and a willingness to meet global market demands.

Requesting Samples

Requesting product samples is a practical step in the supplier selection process. Samples allow buyers to evaluate product quality, performance, and compatibility before placing a large order. Most reputable factories offer sample services for their standard and customized products.

Buyers should follow a structured approach when requesting samples:

Identify the specific product type, such as heating tubes, plates, or films.

Provide detailed requirements, including dimensions, voltage, and application.

Ask about lead times for sample production and delivery.

Request technical documentation, such as datasheets or test reports.

Evaluate the sample for build quality, material selection, and performance.

Factories with advanced manufacturing capabilities, like jinzhong, can deliver standard samples quickly—sometimes within three days. Their one-stop production process ensures consistency between samples and mass-produced items. Customization options, such as intelligent temperature control or unique shapes, can also be tested through samples.

Nota: Reviewing samples helps buyers avoid costly mistakes and ensures the selected factory can meet project requirements.

Sample evaluation builds trust between buyers and suppliers. It also provides an opportunity to assess communication, technical support, and responsiveness. A positive sampling experience often leads to successful long-term cooperation.

Vietnam’s leading electric heating element factories demonstrate strong capabilities in quality, innovation, and export experience. Each company offers unique advantages, from advanced certifications to rapid customization. Readers should review the comparison table and selection tips to identify the best fit for their needs. For tailored solutions or further details, they can contact any of the listed manufacturers, including jinzhong. Selecting a reliable electric heating element partner supports long-term business growth and operational success.

PREGUNTAS FRECUENTES

What types of electric heating elements do Vietnamese factories produce?

Vietnamese factories manufacture tubular heaters, cartridge heaters, immersion heaters, PTC heaters, and flexible heating elements. These products serve both household appliances and industrial equipment. Factories often offer custom designs to meet specific application requirements.

How important are certifications when choosing a supplier?

Certifications such as ISO9001, ISO14001, and ISO45001 indicate a factory’s commitment to quality, safety, and environmental standards. Buyers should always verify certifications before placing orders. Certified suppliers reduce risks and ensure compliance with international regulations.

Can factories customize electric heating elements for unique applications?

Most leading factories provide customization services. They adjust dimensions, materials, voltage, and power ratings based on customer needs. Some factories, like jinzhong, also offer intelligent temperature control and rapid prototyping for specialized projects.

How quickly can factories deliver standard or custom heating elements?

Delivery times vary by factory and order size. Many factories ship standard products within a week. Factories with advanced production lines, such as jinzhong, can deliver standard items in as little as three days. Custom orders may require additional time for design and testing.

What after-sales support do top factories provide?

Top factories offer technical assistance, warranty coverage, and replacement parts. They respond quickly to service requests and provide installation guidance. Reliable after-sales support helps customers maintain equipment and resolve issues efficiently.

How can buyers evaluate product quality before placing large orders?

Buyers should request product samples and technical documentation. They can test samples for build quality, performance, and compatibility. Reviewing customer feedback and certifications also helps buyers assess a factory’s reliability.

Do Vietnamese factories export electric heating elements internationally?

Yes, many Vietnamese factories export products worldwide. They comply with international standards and hold relevant certifications. Export experience demonstrates a factory’s ability to meet diverse market requirements and deliver consistent quality.

What is the best way to contact a factory for a quote or consultation?

Buyers can reach out via email, phone, or the official website. Providing detailed requirements ensures accurate quotes. Many factories list contact information on their websites for easy communication.

Tip: Prepare a clear list of specifications before contacting suppliers. This approach speeds up the quotation process and improves communication.