Many users discover the remarkable capabilities of a stainless heating element when faced with demanding heating needs. Stainless steel resists corrosion in mineral-rich or slightly corrosive water, ensuring consistent performance with minimal maintenance.

- Water heating systems benefit from stainless steel’s durability and efficiency, especially in variable water quality environments.

- Homeowners and businesses often choose stainless heating elements for their longevity and ability to deliver steady power even under pressure.

Surprisingly, these elements excel where others struggle, making them a reliable choice in both residential and commercial settings.

What Is a Stainless Heating Element?

Definition and Core Function

A stainless heating element serves as a critical component in many heating systems. Industry standards define it by several technical characteristics:

1. High resistivity allows efficient heat generation with minimal material. 2. A high melting point enables operation at elevated temperatures without degradation. 3. Low temperature coefficient maintains stable resistance across temperature changes, ensuring consistent heating. 4. Resistance to oxidation increases durability and reduces maintenance needs. 5. Compact size paired with high power output suits space-limited applications. 6. Fast thermal response provides quick heating and precise temperature control. 7. Versatility includes the ability to be shaped into various forms and easy disassembly. 8. Energy efficiency and cost-effectiveness result from high thermal conversion and long service life. 9. Durability and reliability guarantee consistent performance over extended periods.

A stainless heating element converts electrical energy into heat, using the unique properties of stainless steel to deliver rapid and uniform heating. Engineers select stainless steel for its ability to withstand harsh environments and maintain performance over time. This material supports applications that demand both power and longevity.

Note: Stainless steel’s resistance to corrosion and oxidation makes it ideal for heating elements exposed to water, chemicals, or fluctuating temperatures.

Common Types and Configurations

Manufacturers offer several types and configurations of stainless heating elements to meet diverse residential and industrial needs. The following table highlights primary types:

| Tipo de elemento calefactor | Descripción | Stainless Steel Use | Configuration Details | Aplicaciones típicas |

|---|---|---|---|---|

| Cartridge Heaters | Resistance wire coiled around ceramic core, sheathed in corrosion-resistant material | Stainless steel sheath commonly used | Leads on one end, rectangular or round shapes | Die/mold heating, immersion, surface heating |

| Calentadores tubulares | Similar internals to cartridge but leads on opposite ends; can be bent | Stainless steel sheath common | Can be bent, finned for heat transfer | Versatile, fluid and surface heating |

| Band Heaters | Wrap around cylindrical surfaces, bolted locking tabs | Stainless steel or brass sheath | Clamped around pipes, drums, extruders | Indirect fluid heating, oil/lubricant service |

| Strip Heaters | Flat, rectangular, bolted on surfaces | Stainless steel sheath possible | Flat shape, insulated with mica or ceramics | Surface heating of dies, molds, tanks, ovens |

Additional configurations incluir:

- Flanged heaters use stainless steel sheaths for corrosion resistance in chemical, food, and water applications. They feature ANSI flanges with hairpin or tubular elements and may include thermowells for temperature control.

- Screw plug heaters offer versatile immersion heating with stainless steel options. They suit food, chemical, and HVAC systems and install easily with NPT fittings.

- Circulation (in-line) heaters employ stainless steel flanged immersion elements with pumps to heat liquids in closed circuits. Temperature probes maintain setpoints.

- Over the side heaters use stainless steel tubular elements designed for insertion from tank tops. These heaters serve petroleum and chemical industries and withstand harsh environments.

Engineers select the appropriate type and configuration based on the application’s requirements for power, durability, and environmental resistance. The stainless heating element adapts to a wide range of installation scenarios, supporting both simple and complex heating needs.

The Science Behind Stainless Heating Element Power

Properties of Stainless Steel

High Heat Tolerance

Stainless steel stands out for its ability to withstand extreme temperatures without losing structural integrity. The alloy’s composition, especially the presence of chromium and nickel, allows it to resist oxidation and scaling even at temperatures exceeding 1000°C. Different grades of stainless steel, such as 304/304L and 310/310S, perform reliably in high-heat environments. For example, grade 310/310S contains higher chromium and nickel content, enabling it to resist temperatures up to 1150°C. Titanium-stabilized grades like 321 prevent carbide precipitation, which further improves durability during thermal cycling. These characteristics make stainless steel a preferred choice for heating elements in demanding applications, including industrial furnaces and power generation equipment.

Stainless steel’s high heat tolerance ensures that heating elements maintain their shape, strength, and efficiency even after repeated exposure to intense thermal stress.

Resistencia a la corrosión

Corrosion resistance remains one of the most valuable properties of stainless steel. The alloy forms a thin, stable oxide layer on its surface, primarily due to chromium content. This layer protects the metal from moisture, chemicals, and other corrosive agents. Nickel enhances this resistance, while molybdenum provides additional protection against chloride-induced corrosion. The table below summarizes the roles of key alloying elements:

| Element | Role in Stainless Steel Properties Relevant to Heating Elements |

|---|---|

| Chromium (Cr) | Forms a protective oxide layer providing corrosion resistance and oxidation resistance at high temperatures; enhances hardness and toughness. |

| Nickel (Ni) | Improves ductility, toughness, and weldability; stabilizes austenitic structure making steel non-magnetic and formable. |

| Molybdenum (Mo) | Enhances resistance to chloride-induced corrosion and improves high-temperature strength. |

| Carbon (C) | Increases hardness and tensile strength but must be balanced to maintain corrosion resistance. |

| Nitrogen (N) | Increases strength and corrosion resistance; enhances mechanical properties and weldability. |

| Manganese (Mn) | Improves hardness, toughness, and wear resistance; acts as a deoxidizer. |

| Silicon (Si) | Increases strength and hardness; improves oxidation resistance at elevated temperatures; acts as a deoxidizer. |

These combined properties allow stainless heating elements to operate in harsh environments, such as water heaters and chemical processing equipment, with minimal risk of degradation.

How Stainless Steel Enhances Heating Performance

Uniform Heat Distribution

Stainless steel’s unique thermal conductivity plays a crucial role in the performance of heating elements. Unlike copper or aluminum, stainless steel has lower thermal conductivity, which allows for more controlled and even heat transfer. This property helps prevent hotspots and ensures that heat spreads uniformly across the surface of the element. Engineers can tailor the alloy composition and manufacturing process to optimize this effect for specific applications. As a result, stainless heating elements deliver stable temperatures, which is essential for processes that require precise thermal control, such as food processing and laboratory equipment.

A recent scientific study published in Nano Letters (2025) demonstrated that advanced surface engineering of 304L stainless steel significantly improves boiling heat transfer performance. Researchers used directed energy deposition additive manufacturing to create a metastable microstructure, which enhanced the efficiency and uniformity of heat transfer. This research confirms that stainless steel’s microstructure and surface properties directly impact its superior heating capabilities.

Wattage and Voltage Flexibility

Stainless steel’s mechanical strength and resistance to thermal fatigue allow manufacturers to design heating elements for a wide range of wattages and voltages. The alloy’s stability under electrical load means that elements can operate efficiently at both low and high power settings. This flexibility supports diverse applications, from small household appliances to large-scale industrial systems. The ability to customize wattage and voltage ensures that each stainless heating element meets the specific requirements of its intended use, maximizing both safety and performance.

Tip: Selecting the right grade and configuration of stainless steel allows engineers to fine-tune heating elements for optimal efficiency, durability, and power output.

Stainless Heating Element Advantages Over Other Materials

Stainless vs. Copper Heating Elements

Power Output and Efficiency

Copper heating elements have long served as a standard in many heating applications due to their excellent thermal conductivity. Copper transfers heat quickly, which can lead to rapid temperature changes. However, this high conductivity sometimes results in uneven heating and potential hotspots. In contrast, stainless heating elements provide more controlled and uniform heat distribution. Engineers often select stainless steel for applications that require precise temperature control and consistent performance over time. The lower thermal conductivity of stainless steel allows for gradual, even heating, which benefits processes that demand stability and accuracy.

Stainless heating elements also offer greater flexibility in wattage and voltage configurations. Manufacturers can design these elements to meet specific power requirements, making them suitable for both low- and high-power applications. This adaptability ensures that stainless heating elements deliver reliable efficiency in a wide range of environments.

Durability and Longevity

Durability remains a critical factor when comparing stainless and copper heating elements. Copper, while effective in heat transfer, tends to corrode over time, especially in water heating systems or environments with fluctuating pH levels. Corrosion can reduce the lifespan of copper elements and increase maintenance needs.

Stainless heating elements, on the other hand, resist corrosion and oxidation due to the protective chromium oxide layer on their surface. This resistance extends their operational life and reduces the frequency of replacements. Stainless steel maintains its structural integrity even after repeated heating and cooling cycles, making it a preferred choice for applications that demand long-term reliability.

Note: Stainless heating elements often outlast copper elements in harsh or variable environments, providing a better return on investment for both residential and industrial users.

Stainless vs. Aluminum Heating Elements

Corrosion and Maintenance

When comparing stainless steel and aluminum heating elements, corrosion resistance stands out as a decisive factor. Stainless steel consistently outperforms aluminum in chemically aggressive or moist environments. The following points highlight key differences:

- Stainless steel forms a robust chromium oxide layer that protects against corrosion, even in harsh or chloride-rich settings.

- Aluminum develops an oxide layer as well, but this barrier is less effective against pitting, crevice, and galvanic corrosion, especially in the presence of chlorides or alkaline substances.

- Stainless steel maintains its heat resistance and structural strength under demanding conditions, while aluminum can degrade quickly when exposed to aggressive agents like hydrochloric or sulfuric acids.

- Chlorides and sulfides corrode aluminum rapidly, limiting its use in many industrial and water-based applications.

- Stainless steel’s superior corrosion resistance makes it highly versatile and durable, even in environments where aluminum would fail.

Maintenance requirements also differ significantly. Over a five-year period, aluminum heating elements often require more frequent inspection, cleaning, or replacement due to their susceptibility to corrosion. Stainless steel elements, by contrast, need less maintenance and offer better longevity. The anodic index of stainless steel aligns more closely with brass, reducing the risk of galvanic corrosion in mixed-metal systems. Aluminum elements, especially when paired with brass or exposed to water, face a higher risk of rapid deterioration.

Tip: For applications involving water, chemicals, or fluctuating temperatures, stainless steel heating elements provide a more reliable and low-maintenance solution than aluminum.

Cost-Effectiveness Over Time

Initial costs for aluminum heating elements may appear lower, but long-term expenses often tell a different story. Aluminum’s vulnerability to various types of corrosion—such as pitting, crevice, and galvanic corrosion—can lead to early failure and frequent replacements. The need for ongoing maintenance increases operational costs and downtime.

Stainless heating elements, while sometimes more expensive upfront, deliver greater value over their lifespan. Their resistance to corrosion and structural degradation reduces the need for repairs and replacements. This durability translates into lower total cost of ownership, especially in demanding or corrosive environments. Users benefit from fewer interruptions, less maintenance, and a longer service life.

Choosing a stainless heating element ensures dependable performance and cost savings over time, making it the preferred option for both residential and industrial heating needs.

Real-World Applications of Stainless Heating Elements

Electrodomésticos

Water Heaters

Water heaters rely on stainless heating elements for reliable and efficient performance. These elements deliver rapid heat-up times and maintain high thermal efficiency, often exceeding 97%. Many modern water heaters use advanced features such as anti-scale coatings and smart temperature controls. These features help reduce energy consumption by up to 60% in some hybrid models. The use of nickel-chromium alloys increases durability, supporting a long service life and reducing maintenance needs. Overheat protection and smart sensors enhance user safety, while custom designs allow precise heating tailored to specific water heater requirements.

Electric Ovens

Electric ovens benefit from stainless heating elements through fast and even heat distribution. This technology ensures uniform cooking results and reduces energy waste. The high power density, typically between 60-100W/cm², enables quick temperature rise. For example, heating 250ml of water can take as little as 20 seconds, compared to 60 seconds with traditional elements. The compact and flexible design of these elements allows installation in various oven models, including those with unique shapes or limited space. Users experience energy savings of 10-25% and enjoy a longer appliance lifespan, often exceeding 10,000 hours of operation.

Home appliances that commonly use stainless heating elements include:

- Kettles

- Hot pots

- Coffee machines

- Hornos

- Stoves

- Dishwashers

- Food warmers

These appliances benefit from features such as high mechanical strength, resistance to vibration, and strong insulation. The elements also provide environmentally friendly operation, producing no harmful substances during use.

Industrial and Commercial Uses

Manufacturing Equipment

Manufacturing facilities depend on stainless heating elements for process heating, liquid immersion, and packaging equipment. These elements provide rapid and uniform heat transfer, which is essential for maintaining process efficiency. Stainless steel’s corrosion and oxidation resistance make it suitable for harsh environments, such as chemical processing and water treatment plants. The following table highlights the energy and operational benefits in manufacturing:

| Aspecto | Detalle de las pruebas |

|---|---|

| Ahorro de energía | Up to 30% reduction in energy waste compared to conventional heating methods |

| Heat Transfer Efficiency | Up to 95% heat transfer efficiency, enabling faster heat-up and less energy use |

| Durabilidad y mantenimiento | Elements last 40% longer, reducing maintenance and downtime |

| Operational Cost Reduction | Annual savings up to $15,000 through improved heating cycles |

| Automation and Control | Advanced systems reduce operator intervention by up to 50% |

| Thermal Management | Precise temperature control improves product quality |

| Power Management Features | Programmable cycles and standby modes cut power use by up to 50% |

| Maintenance Impact | Protective sheaths reduce maintenance frequency by up to 40% |

These advantages support a lower total cost of ownership and improved productivity in industrial settings.

Food Service and Brewing

Food service operations and breweries use stainless heating elements for consistent and safe heating. In commercial kitchens, these elements heat water, cook food, and maintain serving temperatures. Breweries rely on them for precise temperature control during brewing and fermentation. The corrosion resistance of stainless steel ensures hygiene and prevents contamination, which is critical in food and beverage production. The elements’ durability and uniform heat distribution help maintain product quality and reduce energy consumption.

Stainless heating elements play a vital role in both home and industrial environments, offering efficiency, safety, and long-term reliability.

Common Misconceptions About Stainless Heating Elements

Underestimating Power and Performance

Many people assume stainless steel cannot deliver strong heating performance because it has lower thermal conductivity than copper or aluminum. This belief often leads to the misconception that stainless steel elements heat up slowly or unevenly. However, engineers design these elements to maximize efficiency in real-world applications. Stainless steel’s higher melting point, around 1400°C, allows it to operate at temperatures that would soften or damage other metals. This property enables stainless steel to excel in demanding environments, such as industrial furnaces and commercial ovens.

- Stainless steel tolerates higher temperatures without losing strength.

- It resists corrosion in aggressive environments, including acidic or marine settings.

- The material’s durability offsets its lower raw heat transfer rate.

Many industries choose stainless steel for heating elements because it maintains performance where other metals fail.

Myths About Stainless Steel and Heat

A common myth claims stainless steel cannot transfer heat effectively. Scientific data shows that stainless steel, especially the austenitic 304 grade, has a moderate thermal conductivity of about 16 W/m·K. While this value is lower than copper or aluminum, it does not mean stainless steel performs poorly in heating applications. The alloy’s composition, including chromium and nickel, creates scattering points that slow down heat-conducting electrons. Temperature also affects conductivity. For example, austenitic steels increase conductivity by 10-15% above 500°C, while ferritic grades remain stable at high temperatures.

Practical examples demonstrate stainless steel’s heat tolerance and reliability:

- Medical instruments withstand repeated autoclaving cycles.

- Automotive exhaust systems maintain structural integrity under extreme heat.

- Industrial heat exchangers use stainless steel for controlled heat conduction.

Surface finish and alloying elements further influence heat transfer. Innovations, such as alloying with copper or using nanotechnology, continue to improve thermal performance. These facts dispel the myth that stainless steel is unsuitable for heating.

Setting the Record Straight

Misconceptions about stainless steel often arise from comparing raw thermal conductivity values without considering the full context. Stainless steel’s unique combination of high temperature tolerance, corrosion resistance, and mechanical strength makes it ideal for many heating applications. The material’s ability to maintain structural integrity and resist degradation under stress ensures long-term reliability.

| Propiedad | Acero inoxidable | Cobre | Aluminio |

|---|---|---|---|

| Conductividad térmica | Moderado | Alta | Alta |

| Punto de fusión | Muy alto | Moderado | Bajo |

| Resistencia a la corrosión | Excelente | Moderado | Poor |

| Durability in Harsh Use | Excelente | Bien | Justo |

When selecting a heating element, engineers look beyond conductivity alone. They consider the entire performance profile, including safety, durability, and efficiency.

Maximizing the Power of Your Stainless Heating Element

Installation Tips for Best Results

Proper installation ensures optimal performance and longevity. Technicians should follow these best practices:

- Ground all equipment to protect personnel and facilities in case of electrical faults.

- Match the heater’s rated voltage exactly to the supply voltage. This prevents wattage deviations that can shorten the element’s lifespan.

- Use advanced control systems, such as PID controllers with solid state relays or SCR power controllers. These systems minimize excessive cycling, reducing thermal stress and extending service life.

- Select sheath materials and watt densities that suit the heating medium and operating temperature. Stainless steel sheaths work well at higher temperatures and with various fluids or gases.

- Mount immersion heaters horizontally near the tank bottom. This placement maximizes convective flow and ensures the heated length remains fully immersed, preventing sludge buildup.

- Clean heater elements regularly to prevent scale, coking, or sludge accumulation. Clean surfaces maintain efficient heat transfer and prevent overheating.

- Implement tight temperature control using separate process and high-limit sensors. PID controllers provide stable and responsive regulation.

Tip: Careful installation and control system selection can significantly improve efficiency and extend the life of heating elements.

Maintenance and Care

Routine maintenance preserves performance and prevents premature failure. The following steps support reliable operation:

- Clean elements regularly with a soft cloth or sponge and mild detergent to remove debris, residue, or grease.

- Inspect elements for physical damage, such as burn marks, breaks, or corrosion. Address any issues promptly.

- Check all electrical connections for security and absence of corrosion.

- Test elements with a multimeter to verify proper continuity and resistance.

- Follow manufacturer instructions for cleaning agents and maintenance routines.

Monthly checks for discoloration or corrosion help prevent insulation breakdown. Non-abrasive cloths and pH-neutral detergents protect surfaces. Professional inspections every six months ensure wiring and element integrity. Avoid harsh chemicals, such as bleach or vinegar, which can damage stainless steel.

Regular maintenance, including cleaning and inspection, prevents blockages and allows early detection of faults. These practices maintain heat transfer efficiency and extend the lifespan of heating elements.

Choosing the Right Stainless Heating Element

Selecting the correct heating element requires careful consideration of several criteria:

- Voltage: Confirm the available supply voltage.

- Application: Identify what material or fluid will be heated.

- Design Envelope: Assess size, length, diameter, and lead length constraints.

- Wattage: Determine based on size, material, temperature, and required heating time.

- Terminations: Choose connection types and environmental protection features.

- Sheath Material: Match corrosion resistance needs and select the appropriate stainless steel grade.

- Special Features: Consider custom flanges, connectors, or shapes.

- Quantities: Estimate the number of elements needed, which affects pricing and lead time.

Other important factors include corrosion resistance, mechanical properties, and compliance with industry standards. For example, austenitic grades like 304 and 316 offer high corrosion resistance and perform well at elevated temperatures, making them suitable for harsh or chemical environments. Ferritic and martensitic grades serve best in mild or indoor settings. Duplex grades provide superior strength and corrosion resistance for aggressive environments but may be harder to machine.

Note: Consulting with a metallurgist or manufacturer can help match the alloy and design to the specific application, ensuring safety, durability, and regulatory compliance.

Stainless heating elements deliver impressive power, efficiency, and durability in both home and industrial settings. Users report benefits such as resistencia a la corrosión, rapid heating, and long service life.

- High thermal efficiency

- Easy cleaning and maintenance

- Reliable performance under demanding conditions

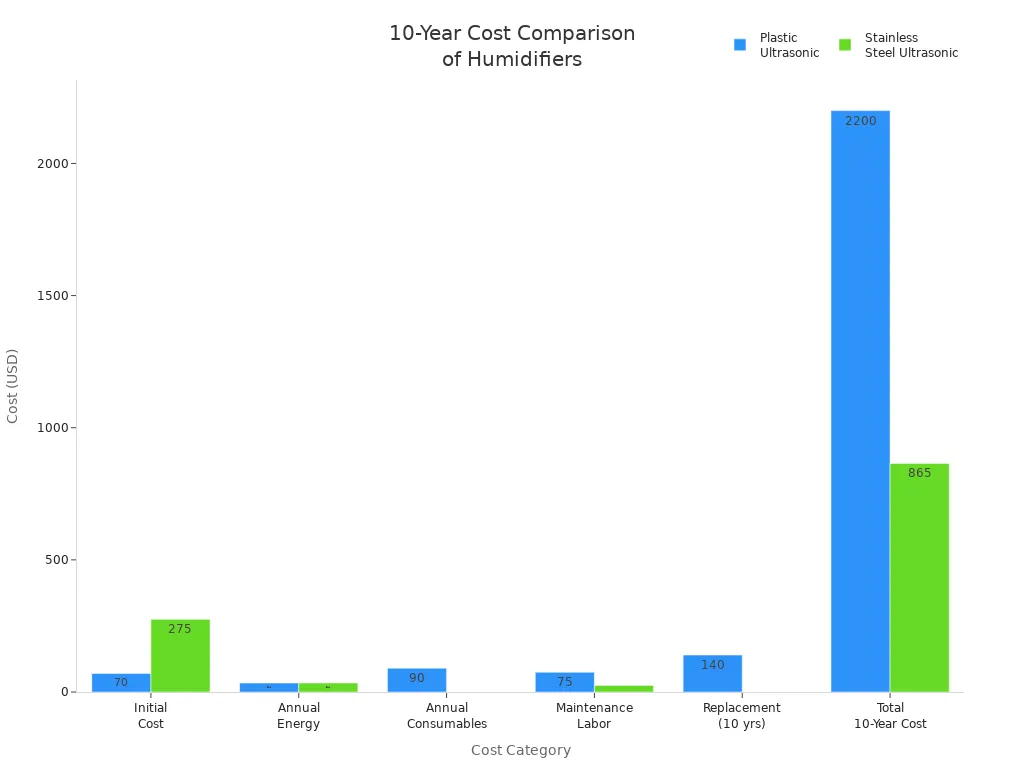

| Categoría de costo | Plastic Ultrasonic | Stainless Steel Ultrasonic |

|---|---|---|

| Coste inicial | Low ($70) | Higher ($275) |

| Annual Energy Cost | $34 | $34 |

| Annual Consumables | $90 (filters) | $0 |

| Maintenance Labor | $75 | $25 |

| Replacement (10 yrs) | $140 (2 replacements) | $0 |

| Total 10-Year Cost | $2,200 | $865 |

Manufacturers continue to favor stainless heating element designs for their sustainability and cost-effectiveness. This trend supports their role as a top choice for reliable, long-lasting, and powerful heating solutions.

PREGUNTAS FRECUENTES

What makes stainless heating elements more durable than other types?

Stainless heating elements resist corrosion and oxidation. The chromium in stainless steel forms a protective layer. This layer prevents rust and damage, even in harsh environments. Manufacturers choose stainless steel for applications that require long service life and reliability.

Can stainless heating elements be used in hard water conditions?

Yes. Stainless heating elements perform well in hard water. The material resists scale buildup and corrosion. This property reduces maintenance needs and extends the element’s lifespan in water heaters and similar appliances.

Are stainless heating elements energy efficient?

Stainless heating elements convert electrical energy into heat with high efficiency. Their design allows for rapid and uniform heating. This efficiency helps reduce energy consumption in both residential and industrial applications.

How do I clean and maintain a stainless heating element?

Use a soft cloth and mild detergent to clean the element. Avoid abrasive materials and harsh chemicals. Regular inspection for residue or corrosion helps maintain performance. Follow manufacturer guidelines for best results.

What applications benefit most from stainless heating elements?

Industries such as food service, manufacturing, and water heating benefit from stainless heating elements. Home appliances like ovens, kettles, and dishwashers also use them. Their durability and efficiency make them suitable for demanding environments.

Do stainless heating elements work with all voltage levels?

Manufacturers design stainless heating elements for a wide range of voltages. Always match the element’s rated voltage to the supply voltage. This practice ensures safe operation and optimal performance.

Can stainless heating elements be custom-shaped for specific uses?

Yes. Engineers can shape stainless heating elements into various forms, such as coils, bands, or strips. This flexibility allows them to fit unique equipment and specialized applications.

What grade of stainless steel is best for heating elements?

Grades 304 and 316 are common choices. Grade 316 offers higher corrosion resistance, especially in chemical or marine environments. The application determines the best grade. Consult with a manufacturer or metallurgist for specific recommendations.