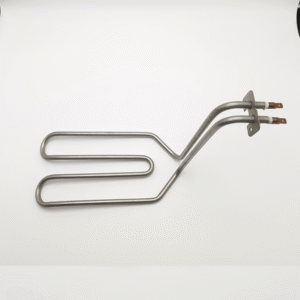

The electric boiler heating system is designed for efficient thermal energy management. It uses a stainless steel substrate and thick film resistor technology, integrates a PID temperature control module and an NTC temperature sensor, achieves 3-second heating, energy efficiency ≥ 96%, an operating temperature range of 80℃–350℃, and supports high pressure (100kPa–300kPa) and multi-stage power adjustment (500W–5000W). The system is equipped with waterproof, anti-dry burning and anti-scaling protection, and the surface anodizing treatment enhances corrosion resistance. The life span exceeds 30,000 hours, is suitable for industrial-grade continuous operation scenarios, complies with the EU CE certification, and meets high stability and energy-saving requirements.

Cantidad mínima de pedido: 1000

Plazo de entrega: 15-25 días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Commercial electric boilers, instant electric water heaters, steam generators (hotels/hospitals)

Electric boiler heating systems are integrated thermal solutions designed to generate controlled steam for diverse steam-based appliances across residential, commercial, and light industrial settings. They are widely used in steam irons (for rapid garment pressing), espresso machines (to produce brewing steam), electric steamers (for cooking/steaming food), humidifiers (to maintain optimal indoor humidity), industrial steam generators (for process heating in small-scale manufacturing), and commercial instant steam systems (for high-frequency demand environments like laundries or catering services). These systems ensure efficient, stable steam output to meet end-use requirements.

Aligned with industry standards and our manufacturing capabilities, key parameters for electric boiler heating systems are as follows (customizable to client specifications):

| Parámetro | Alcance típico | Opciones de personalización |

|---|---|---|

| Potencia nominal | 500W–30,000W | Adjustable (e.g., 300W for mini steamers; 40,000W for industrial units) |

| Tensión de funcionamiento | 110V/220V (monofásico) | Trifásico (380 V) para sistemas comerciales pesados |

| Máx. Temperatura de trabajo | ≤350℃ (continuous); ≤450℃ (peak) | Hasta 550℃ (con revestimiento de aleación de Inconel) |

| Material | Acero inoxidable 316L (estándar) | Acero inoxidable 321/310S (alta corrosión/alta temperatura) |

| Tolerancia dimensional | ±0.5mm (standard) | ±0.2mm (precision-machined for tight fits) |

| Resistencia a la presión | 10 bar (continuous); 15 bar (peak) | Hasta 35 bar (carcasa de aleación de cobre espesada) |

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.