The core of the heating system of Delonghi coffee machines (such as EC680/EC860/EC9155 models) is a stainless steel boiler or a copper heat exchanger, which is suitable for a power range of 300W-1500W, a temperature control accuracy of ±1°C, and a thermal efficiency of ≥90%. The core of the heating element of Delonghi coffee machines lies in precise temperature control + efficient heat conduction. In view of the characteristics of its models, it is recommended to give priority to the combination of copper heat exchanger + titanium alloy electrode, and match it with an intelligent self-cleaning function to cope with hard water environments. Regular maintenance can ensure that the life of the equipment is extended to more than 8 years while maintaining the stability of coffee production.

MOQ:1000PCS

Plazo de entrega:25días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Electrodomésticos: hervidores eléctricos, dispensadores de agua instantánea, freidoras de aire, ollas saludables, bases calentadoras para cafeteras.

Boiler-Based Systems (e.g., DeLonghi EC885)

Power: 1.8kW–3kW (residential) / 3kW–15kW (commercial).

Voltage: 110V/220V single-phase AC or 380V three-phase AC.

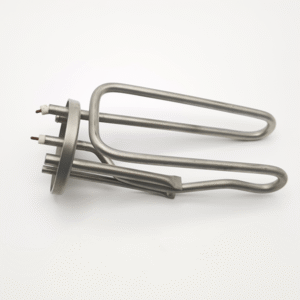

Material:

Boiler: Food-grade stainless steel 316L (corrosion-resistant, high thermal stability).

Heating Element: Nickel-chromium (NiCr) alloy (high-temperature oxidation resistance).

Control de temperatura:

PID algorithm with ±1°C accuracy.

Termostatos duales (circuitos de preparación y vapor separados).

Recovery Time: 30–45 seconds (after pulling a shot).

Thermoblock Systems (e.g., DeLonghi Dedica EC685)

Power: 1.2kW–1.8kW (compact residential machines).

Material: Aluminum thermoblock (lightweight, rapid heat transfer).

Features:

Integrated pressurestat for real-time brewing adjustments.

Pre-infusion control via flow meters.

Heat Exchanger (HX) Systems (e.g., DeLonghi La Specialista)

Power: 1.5kW–4kW (residential) / 4kW–12kW (commercial).

Material: Stainless steel 316L HX coil (dual-purpose steam + water heating).

Efficiency: Energy-saving design (no dual boilers), 20% lower energy consumption.

Precision Temperature Control

PID Algorithms: Maintain 92°C–96°C (±0.5°C) for optimal espresso extraction.

Separate Brewing/Steam Circuits: Prevent temperature fluctuations during milk steaming.

Rapid Heat Recovery

High-Flow Boilers: Recover to brewing temperature in <30 seconds (commercial machines like EC885).

Thermoblock Systems: Achieve brewing readiness in 15 seconds (compact models like EC685).

Durability & Safety

Calderas de acero inoxidable: resisten la formación de incrustaciones y la corrosión (ideales para zonas de agua dura).

Protección contra sobrecalentamiento: Apagado automático a >120 °C (certificado CE/UL).

Sensores de nivel de agua: evitan la ebullición en seco (resistencia al agua IPX7).

Versatility

Steam Wand: Generates microfoam for latte art (adjustable steam pressure: 0.5–1.5 bar).

Pre-Infusion: Gradual water pressure build-up (5–10 bar) for even extraction.

Smart Features (Higher-End Models)

PID Tuning: Customizable Kp/Ki/Kd values for specific coffee blends.

Auto-Clean Cycle: Descaling reminders and automated flushing.

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.