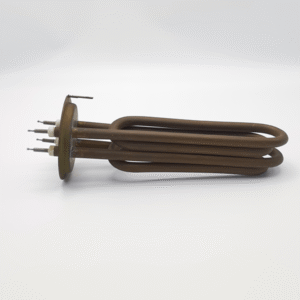

The special heater for electric cookers adopts food-grade stainless steel substrate and thick film resistor technology, integrates PID temperature control module and anti-dry burning protection system, achieves 3 seconds of fast heating, energy efficiency ≥ 96%, working temperature range 80℃-350℃, and supports power (800W-3500W) customization. The surface nano-ceramic coating enhances corrosion resistance, adapts to high-frequency stewing scenes, has IPX7 waterproof and anti-scaling performance, and has a lifespan of more than 30,000 hours, meeting the high stability requirements of home and commercial use.

Cantidad mínima de pedido: 1000

Plazo de entrega: 15-25 días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Electric pressure cookers, health pots, electric stew pots, wall-breaking machine heating modules, commercial electric soup pots (hotels/restaurants), laboratory constant temperature water pots, industrial high-temperature sterilization equipment, embedded electric cookers, smart electric kettles (high-power models), rice cookers

1. Power Rating: 500-3000W (customizable per appliance: 500-1500W for bottle warmers; 1500-3000W for electric pots).

2. Operating Voltage: 110V/220-240V AC (dual-voltage options for global market compatibility).

3. Dimensions: Length: 100-400mm; Width: 50-200mm; Thickness: 0.4-1.5mm (304/316 stainless steel, food-grade compliant).

4. Surface Load: 4-12W/cm² (adjusted for heat uniformity: 4-8W/cm² for bottle warmers; 6-12W/cm² for electric pots).

5. Max. Surface Temp.: ≤350°C (normal operation ≤300°C; dry-burn cutoff activated at >300°C).

6. Tolerance: ±0.2mm (precision fitting for compact appliance cavities).

Customization: Shape (spiral/coiled/flat plate), lead wire (silicone/PTFE/tinned terminals), or anti-corrosion coatings (e.g., PTFE layer).

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.