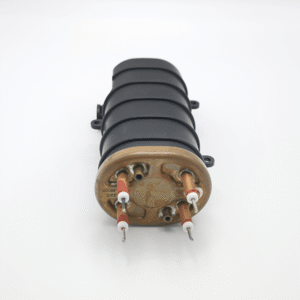

The special heating plate for electric oven adopts the composite process of stainless steel substrate and nickel-chromium alloy heating tube, integrated with PID temperature control module, supports power (800W-3000W) and size customization, achieves 3-5 seconds of fast heating, energy efficiency ≥96%, working temperature range 80℃-300℃, has high temperature oxidation resistance and oil corrosion resistance, adapts to continuous high temperature operation scenes, life span exceeds 50,000 hours, and meets diversified oven heating needs.

Cantidad mínima de pedido: 1000

Plazo de entrega: 15-25 días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Household electric ovens, commercial electric ovens, embedded ovens, industrial tunnel ovens, baking equipment, laboratory high temperature ovens, food processing plant sterilization equipment.

Power range: 800W~3000W (customizable, suitable for high frequency requirements of household ovens/industrial tunnel ovens)

?Working voltage: 12V~480V AC/DC (wide voltage design, compatible with home appliances and industrial equipment)

Resistance value: 0.5Ω~50Ω (matched by voltage and power, supports customized production of electric heating coils)

Working temperature: 80°C~300°C (stainless steel substrate can withstand 300°C, suitable for high-temperature baking scenarios)

Material: sustrato de acero inoxidable, tubo calefactor de aleación de níquel-cromo, módulo de control de temperatura PID (estructura compuesta personalizable)

Dimensions: length 50cm~2m, width 20cm~1m, thickness 1mm~5mm (supports special-shaped cutting, suitable for customized heating plates)

Service life: 50,000~80,000 hours (anti-oxidation coating + high-temperature anti-corrosion process, suitable for continuous high-temperature operation)

Extremely fast thermal conductivity: stainless steel substrate + nickel-chromium alloy tube, 3-5 seconds fast heating, suitable for high-frequency heating requirements of electric ovens.

Precise temperature control: integrated PID algorithm, ±1°C error, meets the constant temperature control requirements of laboratory high-temperature ovens.

High temperature corrosion protection: Oxidation coating + oil corrosion protection process, suitable for the oily and high temperature environment of industrial tunnel ovens.

Energy saving and high efficiency: Energy efficiency ≥ 96%, the thermal conductivity of the electric heating unit is increased by 30%, and the energy consumption of commercial equipment is reduced.

Industrial grade durability: 50,000 hours of life, anti-oxidation coating extends the stability of the heating plate in baking scenarios.

Flexible adaptation: Supports special-shaped size and temperature curve adjustment to meet the non-standard requirements of microwave heating plates/food processing.

Safe and reliable: Isolated circuit design, CE certified, adapted to household appliances leakage protection standards.

Fast delivery: Standardized production line mass production, 15 days to complete the order, adapted to the batch purchase needs of oven equipment.

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.