The electric boiler heater is designed for high-efficiency thermal systems. It uses a stainless steel substrate and thick film resistor technology, integrates a PID temperature control module and an NTC temperature sensor, achieves 3-second heating, energy efficiency ≥96%, and an operating temperature range of 80℃–350℃. It supports wide power customization (500W–5000W) and high-voltage compatibility (100kPa–300kPa). The surface anodizing treatment enhances corrosion resistance. It has IPX7 waterproof, anti-dry burning and anti-scaling performance. The life span exceeds 30,000 hours, and it is suitable for industrial and commercial high-frequency continuous heating scenarios. It complies with the EU CE certification and meets high stability requirements.

Cantidad mínima de pedido: 1000

Plazo de entrega: 15-25 días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Commercial electric boilers, instant electric water heaters, steam generators (hotels/hospitals), coffee machine boilers (capsule/fully automatic models)

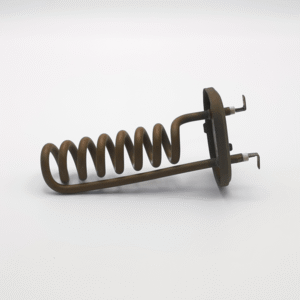

the electric boiler heaters are specialized heating elements engineered for efficient thermal energy conversion in steam-generating appliances across residential, commercial, and light industrial use cases. They are primarily integrated into steam irons (for rapid garment pressing), espresso machines (to produce brewing steam), electric steamers (for cooking/steaming food), humidifiers (to maintain optimal indoor humidity), industrial steam generators (for process heating in small-scale manufacturing), and commercial instant steam systems (for high-frequency demand environments like laundries or catering services). Their robust design ensures consistent steam output in diverse operational contexts.

Aligned with industry standards and our manufacturing capabilities, key parameters for Model 7002 are as follows (customizable to client specifications):

| Parámetro | Typical Range | Customization Options |

|---|---|---|

| Potencia nominal | 800W–25,000W | Adjustable (e.g., 500W for mini steamers; 30,000W for industrial units) |

| Tensión de funcionamiento | 110V/220V (single-phase) | 3-phase (380V) for heavy-duty commercial systems |

| Max. Working Temperature | ≤380℃ (continuous); ≤480℃ (peak) | Up to 550℃ (with Inconel alloy cladding) |

| Material | 316L stainless steel (standard) | 321/310S stainless steel (high-corrosion/ high-temp) |

| Dimension Tolerance | ±0.6mm (standard) | ±0.3mm (precision-machined for tight fits) |

| Resistencia a la presión | 12 bar (continuous); 18 bar (peak) | Up to 35 bar (thickened copper-alloy casing) |

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.