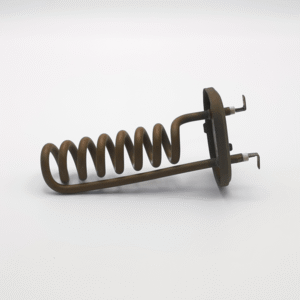

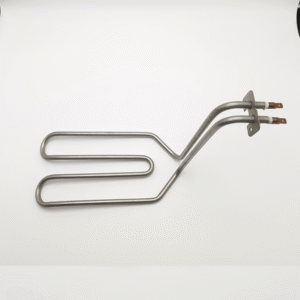

Tubular Air Heating Element——High thermal conductivity tubular air heating solution

The tubular heating element is designed for industrial hot air systems, agricultural greenhouse heating and household heaters. It adopts stainless steel 316L + ceramic fiber insulation structure, suitable for 500W-20kW power range, temperature resistance up to 400℃ (short time), hot air efficiency ≥92%.

MOQ:1000PCS

Plazo de entrega:25días

Ubicación de la fábrica: Zhongshan, Guangdong, China

Household appliances: heaters, air conditioning auxiliary heating modules, electric heaters, instant water heaters.

Industrial equipment: automotive air conditioning heater cores, agricultural greenhouse constant temperature systems

Rango de potencia:

Household: 500W–3000W (electric heater, air purifier, bathroom heater)

Industrial: 3000W–20kW (industrial oven, HVAC system, pipe heating)

Tensión de trabajo: 110V/220V CA monofásica o 380V CA trifásica (compatible con la red eléctrica mundial, error ≤±5%).

Valor de resistencia: 2Ω-50Ω (ajustado con precisión por tensión y potencia, error ≤±3%).

Temperatura de trabajo:

Modelo convencional: funcionamiento continuo y estable de 150°C-300°C (diseño de temperatura autolimitante, antisobrecalentamiento).

Modelo de alta temperatura: tolerancia a corto plazo de 400°C (se requiere una estructura de disipación térmica personalizada y un revestimiento cerámico de alta temperatura).

Material:

Base material: stainless steel 304/316L (corrosion-resistant and anti-oxidation) or aluminum alloy (lightweight, thermal conductivity ≥200W/m·K).

Heating wire: nickel-chromium alloy (NiCr) or iron-chromium-aluminum (FeCrAl), resistant to high temperature oxidation.

Surface treatment: anodized layer (corrosion resistant) or ceramic coating (resistant to high temperature up to 600°C).

Dimensiones:

Diameter: Φ10mm–Φ50mm, length 100mm–2000mm (supports customized length and fin density).

Distancia entre aletas: 5mm-30mm (resistencia al viento ajustable y eficiencia de disipación de calor).

Vida útil: 20,000–80,000 hours (based on operating temperature and heat dissipation conditions, anti-oxidation coating extends life).

Servicio personalizable: support power, voltage, fin shape adjustment, optional explosion-proof certification, IP protection level (such as IP68), integrated temperature control probe, etc.

Efficient heat dissipation and thermal efficiency:

The spiral fin structure optimizes the airflow path through CFD, the heat convection efficiency is increased by 50%, and the heat exchange rate under forced air cooling is ≥95%.

The thermal conductivity of stainless steel/aluminum alloy substrate is 5 times that of steel, and the volume is reduced by 60% at the same power, which is suitable for compact equipment.

Self-limiting temperature safety feature:

Adopt PTC ceramic chip (optional) or nickel-chromium alloy heating wire, automatically reduce power when the temperature exceeds the set value, no external thermostat is required, and overheating and combustion are prevented.

Quick response and energy saving:

Diseño ligero (densidad 2,7g/cm³) + características de baja capacidad calorífica, calentando a 200°C en 30 segundos, el consumo de energía se reduce en 30% en comparación con los calentadores tradicionales.

Corrosion resistance and long life:

316L stainless steel is resistant to acid and alkali corrosion (pH 1–14), and the anodized layer or ceramic coating is resistant to salt spray test ≥500 hours, and the life is extended by 2–3 times.

Multi-scenario adaptability:

Supports IP68 waterproof and dustproof (suitable for bathrooms, outdoor equipment), explosion-proof certification (Ex d IIB T4, suitable for petrochemical environments).

Compatibilidad inteligente:

Integrated NTC temperature sensor and PWM power regulation module, supports IoT remote temperature control (APP/PLC), and is suitable for smart building systems.

Global compliance:

Complies with CE, UL, CCC, RoHS certifications, and supports AEC-Q200 automotive-grade standards (vibration resistance, wide temperature range -40°C~+85°C).

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.