Industrial heating tubes are modular thermal energy equipment for high-temperature industrial scenarios. They use high-temperature resistant alloys/ceramics and other materials to support continuous operation at 300℃-1200℃.

MOQ:1000PCS

Plazo de entrega:25días

Ubicación de la fábrica: Zhongshan, Guangdong, China

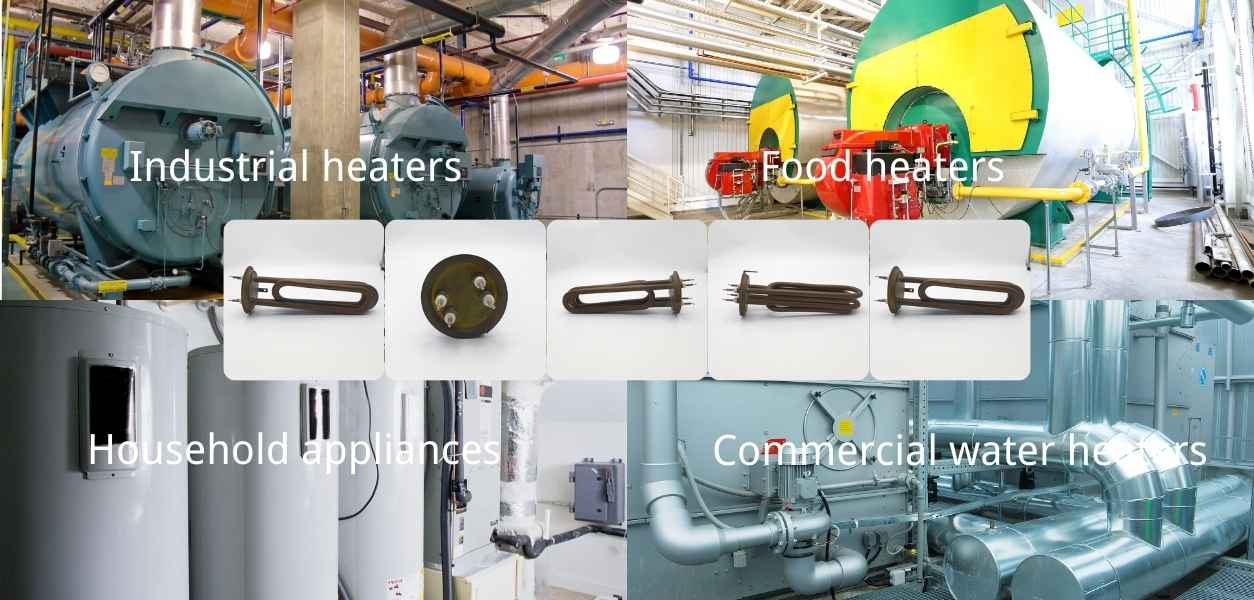

Industrial boilers (steam/hot water), electric furnace heating elements, chemical fluid heaters, plastic molding mold constant temperature systems, glass kiln hot air modules, medical sterilization equipment core heating components, laboratory high-temperature reactors, new energy battery module thermal management systems, food processing high-temperature sterilization pipelines, oil pipeline heating systems, metallurgical equipment preheating components.

Power range: 1kW~30kW (customizable, suitable for high-frequency requirements of industrial boilers/new energy battery thermal management)

Working voltage: 24V~600V AC/DC (wide voltage design, compatible with industrial-grade equipment)

Resistance value: 0.1Ω~50Ω (matched by voltage and power, supports customization of high-temperature alloy/ceramic structure)

Working temperature: 300°C~1200°C (nickel-chromium alloy is resistant to 1000°C, and ceramic substrate is suitable for ultra-high temperature scenarios)

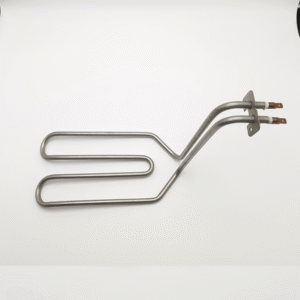

Material: stainless steel 310S, nickel-chromium alloy (NiCr), alumina ceramic (customizable composite structure)

Dimensions: length 200mm~5m, outer diameter 8mm~30mm (supports non-standard processing such as bending and welding)

Service life: 50,000~100,000 hours (anti-oxidation coating + high-pressure sealing process, suitable for continuous high-temperature operation)

High-efficiency thermal conductivity: nickel-chromium alloy + spiral structure, thermal efficiency ≥92%, suitable for industrial boiler steam generation scenarios.

Ultra-high temperature stability: 1200℃ continuous operation, ceramic substrate is resistant to thermal shock, suitable for extreme working conditions of glass kilns/metallurgical equipment.

Corrosion-resistant design: 310S stainless steel + ceramic coating, anti-sulfidation corrosion, and extend the life of chemical fluid heating elements.

Flexible adaptation: Supports special-shaped bending and temperature gradient control to meet the requirements of constant temperature of plastic molds/thermal management of new energy batteries.

Energy-saving and reliable: Energy efficiency ≥94%, seamless pipes reduce the risk of scaling and reduce the maintenance cost of food processing sterilization systems.

Multiple protection: IPX6 waterproof + overpressure protection, suitable for the humid environment of ship pipeline heating systems.

Modular solution: Supports rapid disassembly and assembly structure, suitable for non-standard customization of laboratory high-temperature reactors.

Fast delivery: Standardized production line mass production, 25 days to complete orders, suitable for bulk procurement of industrial equipment.

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 30 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de conjuntos, apoyamos la personalización OEM/ODM, y ofrecemos servicios de inspección por vídeo real en fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.

Obtenga un presupuesto personalizado en menos de dos días.