Heater heating element

Elemento calefactor del calentador eléctrico

The heating element of the electric heater is the core functional component of the electric heating equipment. It is essentially an “energy converter” that converts electrical energy into thermal energy. Its main body is usually made of resistive materials. Common types include metal wires such as nickel-chromium alloy wire (such as Cr20Ni80), iron-chromium-aluminum alloy (such as 0Cr25Al5), or thick film heating coatings (such as ceramic semiconductors), PTC ceramic sheets and other new materials. The structure is mostly filamentous, sheet-like, tubular or integrated on a substrate (such as an aluminum substrate). The Joule heat is generated by the current flowing through the resistive material, and the heat is directly or indirectly transferred to the target medium (water, air, liquid, etc.).

Its core advantages are high conversion efficiency (electrical energy to thermal energy is more than 90%), fast response (heating as soon as power is turned on, no delay) and strong adaptability (through material and structural design, it can adapt to different temperature requirements, such as low-temperature drying below 100°C and high-temperature furnaces above 1000°C).

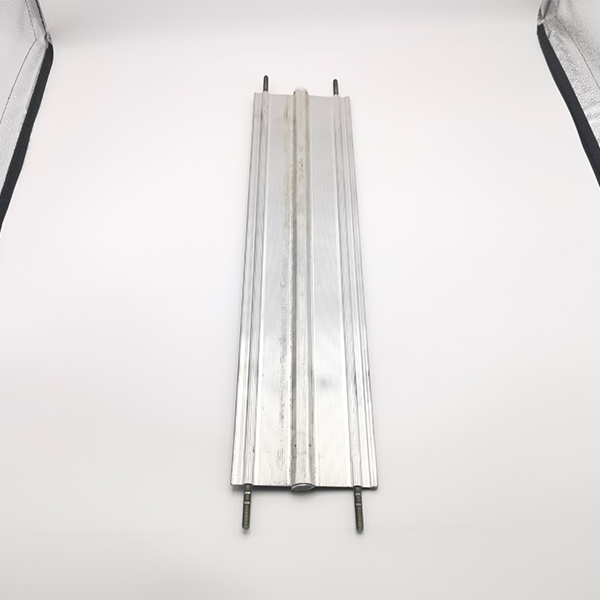

The electric heater heating element adopts high-purity nickel-chromium alloy heating wire and ceramic insulation skeleton,

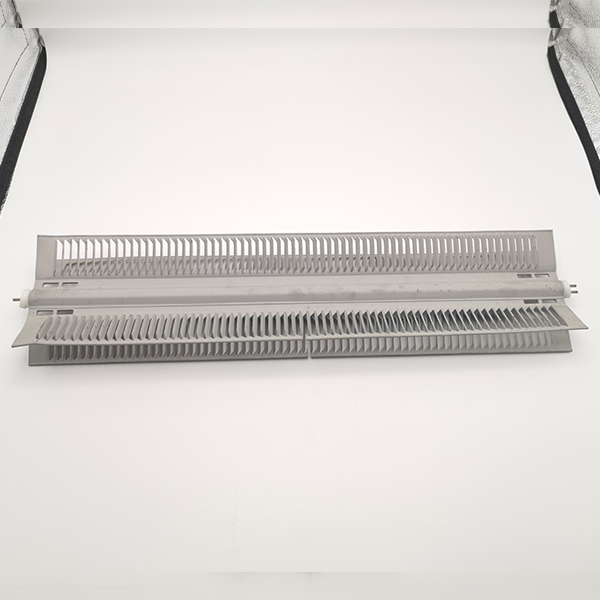

The finned heating element is designed for high-efficiency radiators, automotive heating systems and industrial hot air equipment.

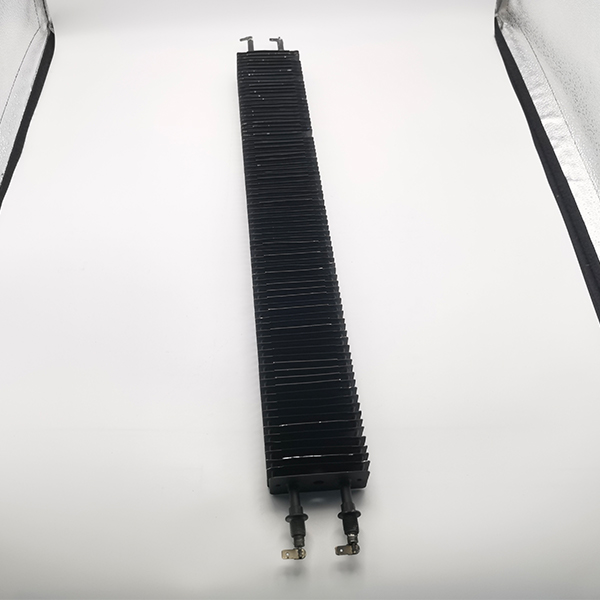

Fin-type heating elements designed for home heaters, commercial industrial HVAC systems and cold chain equipment

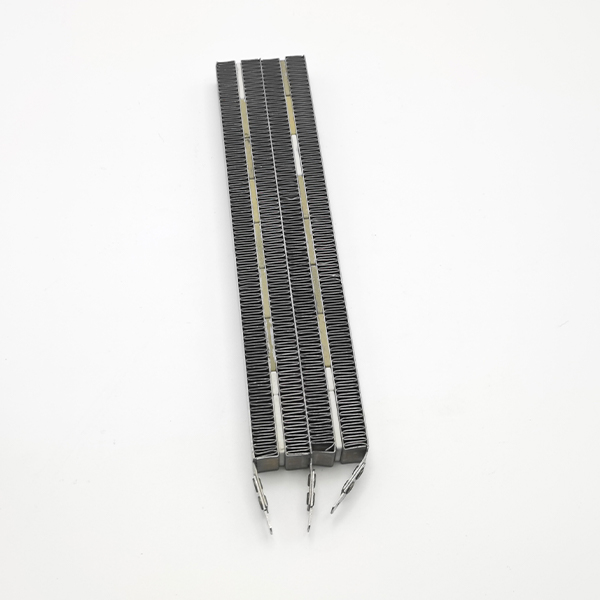

Semiconductor ceramic heating elements designed for home appliances, industrial equipment and new energy vehicles, using rare earth doped barium titanate

Electric fireplace heating element

The electric fireplace heating element is the core component of the electric fireplace to achieve the dual functions of “heat-visual”. It must not only efficiently generate heat to simulate the heating effect of a traditional fireplace, but also cooperate with optical design (such as flame lamps and reflective structures) to create a realistic flame visual experience. Its design must take into account thermal efficiency, safety, and aesthetics. Compared with ordinary electric heater elements, it emphasizes the integration with the “simulation scene”.

Electric fireplace heating elements are mostly made into sheets, honeycombs or tubes, with an insulating layer (such as aluminum oxide) on the surface, and are often integrated into aluminum heat sinks or embedded in simulated firewood textures. PTC is responsible for stable heating, and LED lights simulate flame jumping through dynamic light and shadow (with a microprocessor to control the flashing frequency), achieving a “heat-visual” separation but synergistic effect.

Home appliances: industrial heaters, air conditioning auxiliary heating modules, electric heaters, constant temperature water heaters.

Specially designed for home appliances, industrial equipment and new energy vehicles, the semiconductor ceramic heating element adopts rare earth doped barium titanate

The tubular heating element is designed for industrial hot air systems, agricultural greenhouse heating and household heaters. It adopts stainless steel 316L + ceramic fiber insulation structure

commercial display equipment and smart homes adopts nano-ceramic infrared radiation coating + aviation-grade aluminum alloy heat dissipation structure

Air conditioner heating element

The heating element of an air conditioner is the core component of its heating function. It is mainly used to supplement or replace heat pump heating to ensure that heat can be efficiently delivered to the room in low temperature environments (such as winter). Unlike the cooling mode (heat transfer through refrigerant circulation), the essence of the heating element is to directly convert electrical energy into thermal energy (electrical heat conversion) or to assist in improving the heating efficiency of the heat pump.

Air conditioning heating elements are key components for “emergency heating” and “comfort protection”, among which PTC ceramics have become the mainstream due to their safety and reliability. In the future, air conditioning heating elements will pay more attention to high efficiency and energy saving (such as intelligent power regulation) and user experience (such as low noise and uniform heating), and adapt to different climate and scene requirements.

The heating element is specially designed for split air conditioners, central air conditioners and industrial heat pump systems.

Aparatos de consumo: Calefacción auxiliar de aire acondicionado central, sistemas de bomba de calor residenciales, unidades de ventilación domésticas inteligentes.

The finned tube heating element is designed for industrial duct systems, agricultural greenhouse heating and commercial heaters.

A high-performance heating element designed for industrial heat treatment furnaces, semiconductor annealing equipment

Visite un presupuesto a medida

Si puede facilitarnos información precisa sobre los parámetros de la demanda, podremos darle un presupuesto en 24 horas como muy pronto.

Estas son listas de preguntas frecuentes de nuestros clientes. A cada pregunta corresponde una breve respuesta, que abarca aspectos como productos, calidad y servicios. Si tiene otras preguntas, deje un mensaje para consultarlas. Muchas gracias.

Somos una fábrica de origen con capacidad de producción independiente, con 40 años de experiencia en I+D y fabricación de accesorios de calefacción eléctrica, una capacidad de producción anual de más de 5 millones de juegos, admitimos la personalización OEM/ODM y brindamos servicios de inspección de video en vivo de fábrica.

Realizamos pruebas de muestras gratuitas, y los portes deben pagarse por adelantado (se recogen en el momento de la entrega). Los modelos convencionales se entregan en 7-10 días laborables, con informes de pruebas de SGS y tablas de parámetros de rendimiento.

Respuesta en línea de 8:30 a 17:30 en días laborables. Para necesidades urgentes, puede enviar una orden de trabajo a través del sitio web oficial. Nos comprometemos a proporcionar respuestas técnicas en 2 horas y a ofrecer soluciones en 48 horas.

Tenemos dos bases de producción en Zhongshan y Wuhu, con una producción mensual de más de 3 millones de unidades, equipadas con líneas de estampación totalmente automáticas y talleres de montaje automatizados. El plazo de entrega estándar de los productos es de 15 días, y los pedidos personalizados se entregan en 30 días. Apoyamos el suministro por lotes.

Posee las certificaciones ISO9001/14001, CE (UE), ETL (Norteamérica), RoHS (protección del medio ambiente), los productos antideflagrantes tienen doble certificación ATEX/IECEx y cumplen la normativa REACH.

Prestamos servicio a marcas líderes mundiales como Philips,Midea,Supor,Delonghi,BSH y el Grupo SEB, y nuestros productos se utilizan en proyectos de gama alta como cafeteras, planchas eléctricas, dispensadores de agua y sistemas de calefacción solar, y podemos proporcionar una lista de referencia de clientes similares.