You demand reliable performance and efficiency from every device you use. Ceramic heating elements deliver on this promise, transforming both elementos calefactores de electrodomésticos and industrial systems. Ceramic materials generate more heat per watt, reduce energy consumption, and lower operational costs. The latest market data shows strong growth in ceramic heating components, with rising demand for eco-friendly, energy-saving solutions. Fabricantes de elementos calefactores como Calefacción eléctrica Jinzhong now drive innovation in ceramic technology, ensuring you benefit from enhanced durability, energy efficiency, and user safety. 2025 trends signal even greater breakthroughs in Elemento calefactor design.

Ceramic Heating Element Technology Explained

What Is a Ceramic Heating Element?

You encounter ceramic heating elements in many modern devices. These components use ceramics to convert electrical energy into heat through resistive heating, also known as Joule heating. When you power a ceramic heating element, electrical current passes through the ceramic material. The resistance within the ceramic generates heat, which you can use for precise temperature control in various applications. Ceramic heating elements stand out because they offer quick and safe heating capabilities. You benefit from customizable dimensions, excellent thermal stability, and reduced risk of heat propagation damaging sensitive equipment.

Tip: Ceramic heating elements deliver 100% conversion of electricity to heat, maximizing efficiency in your devices.

Unique Properties of Ceramic Heating Elements

High Thermal Conductivity

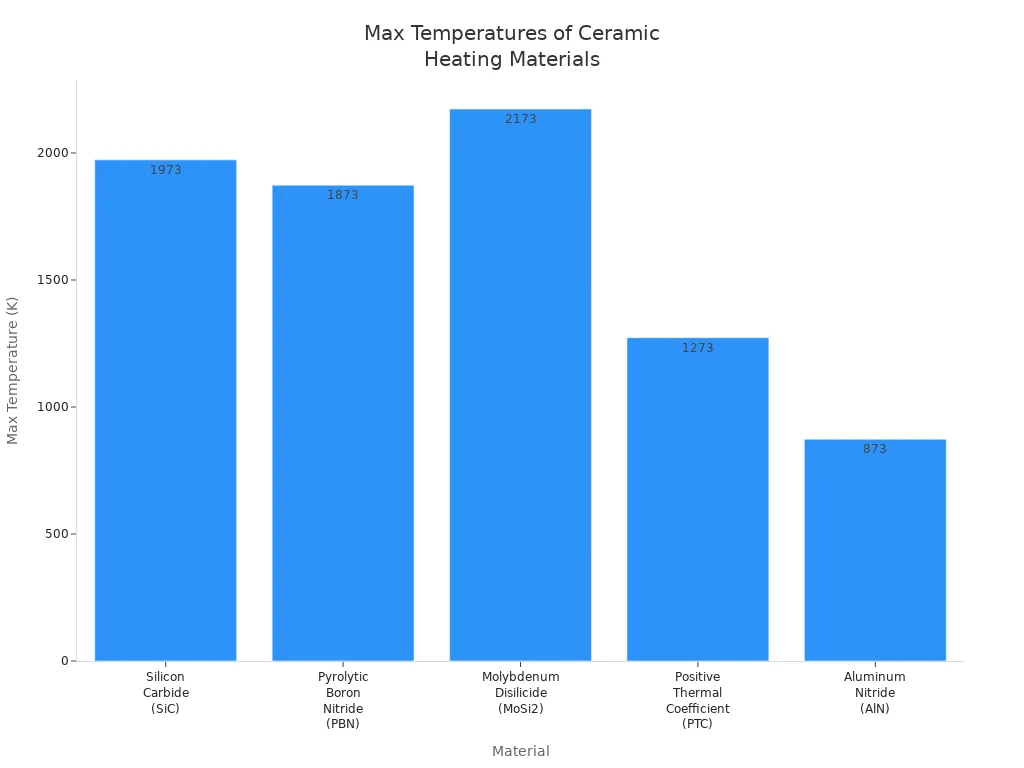

Ceramics such as aluminum nitride and silicon carbide provide high thermal conductivity. You experience rapid and uniform heat distribution, which is essential for applications like heat sinks and furnace linings. Laboratory tests show that ceramic heating elements transfer heat efficiently, minimizing energy loss and improving device performance.

| Material | Propiedades | Maximum Temperature (K) |

|---|---|---|

| Silicon Carbide (SiC) | High melting point, low thermal expansion, chemically inert, resistant to corrosion | 1973 |

| Pyrolytic Boron Nitride (PBN) | Extremely pure, stable in vacuum, ultra-high temperature capability without gas emission | 1873 |

| Molybdenum Disilicide (MoSi2) | High melting point, high oxidation resistance, brittle at room temperature | 2173 |

| Positive Thermal Coefficient (PTC) | Resistance increases with temperature, self-regulating heating capability | 1273 |

| Aluminum Nitride (AlN) | High thermal conductivity, high corrosion resistance, fast heating | 873 |

Electrical Insulation

Ceramic heating elements offer excellent electrical insulation. You gain safety and reliability because ceramics withstand high voltages without breaking down. The dielectric strength of ceramics ensures that your devices remain protected from electrical faults. You can trust ceramic heating elements in environments where electrical safety is critical.

Durability and Longevity

You rely on ceramic heating elements for their durability. Ceramics resist corrosion and thermal fatigue, which means your devices last longer. Ceramic heating elements can operate for 5 to 15 years, far exceeding the lifespan of traditional metal heaters. You save on maintenance and replacement costs, making ceramic heating elements a smart investment.

| Propiedad | Descripción |

|---|---|

| Resistencia al choque térmico | Withstands rapid temperature changes without damage. |

| Coefficient of Thermal Expansion | Minimizes stress from temperature changes. |

| Conductividad térmica | Transfers heat efficiently. |

| Dielectric Strength | Handles high electric fields safely. |

| Dielectric Constant (Permittivity) | Stores electrical energy effectively. |

| Resistivity | Controls electrical current flow. |

Ceramic Heating Elements vs. Traditional Heaters

Ceramic heating elements outperform traditional heaters in several ways. You notice lower energy consumption because ceramic heaters adjust their output based on ambient temperature. Metal heaters operate at a constant level, which wastes energy. Ceramic heating elements last longer—up to 15 years—while metal heaters often fail within 5 years. You benefit from the corrosion resistance and thermal stability of ceramics, which means fewer breakdowns and safer operation.

| Característica | Elementos calefactores cerámicos | Other Heating Technologies |

|---|---|---|

| Principio | Electric resistance heating | Combustion or other heating methods |

| Heat Generation | Generated by high electrical resistance | Varies by method (e.g., combustion) |

| Eficiencia | 100% conversion of electricity to heat | Varies, often less efficient |

| Propiedades del material | High-purity silicon carbide, customizable shapes | Various metals and materials |

| Thermal Output | Determined by electrical load and resistive properties | Depends on fuel type and efficiency |

| Installation | Simplified due to rigidity of materials | Often requires embedding or mounting |

- Ceramic heating elements provide:

- High efficiency with 100% conversion of electricity to heat

- Customizable dimensions for specific applications

- Excellent thermal stability and rigidity

- Reduced risk of heat propagation damaging sensitive equipment

- Quick and safe heating capabilities

You see the advantages of ceramic heating elements in energy savings, reliability, and safety. Advanced ceramics and ptc technology continue to redefine what you expect from modern heaters.

2025 Trends in Ceramic Heating Elements

You see 2025 trends reshaping the ceramic heating element landscape. Manufacturers focus on advanced material science, smart technology integration, and measurable improvements in energy efficiency. These key trends drive continuous innovation and deliver energy-efficient solutions for modern devices.

Advanced Material Developments

Next-Generation Ceramic Composites

You benefit from next-generation ceramic composites that redefine performance. Innovations in engineered ceramics lead to superior thermal conductivity and reduced energy losses. Advanced composites and modified ceramic formulations optimize heating profiles for specific industrial processes. Technical ceramics now compete with polymers and metals in many applications due to their superior properties. You notice these ceramics in high-performance sectors such as aerospace and medical devices. The market expands as regulatory support and demand for energy-efficient solutions increase.

- Engineered ceramics deliver better thermal conductivity.

- Modified ceramic formulations improve heating profiles.

- Technical ceramics compete with polymers and metals.

- Ceramics enter high-performance industries.

- Regulatory support boosts market growth.

Nanotechnology Integration

You experience the impact of nanotechnology in ceramic heating elements. Nanostructured materials like graphene and carbon nanotubes enhance surface area, improving heat transfer and energy efficiency. These materials enable faster and more uniform heating in ceramic heating elements. You rely on improved strength and durability from nanomaterials, which result in longer-lasting components and fewer replacements.

- Nanostructured materials increase surface area.

- Heat transfer and energy efficiency improve.

- Heating becomes faster and more uniform.

- Strength and durability rise, reducing replacements.

Smart Technology Integration in Ceramic PTC Heaters

IoT-Enabled Ceramic Heating Elements

You interact with ceramic heating elements that feature IoT integration. PTC water heating technology now connects with smart control modules. These heaters communicate with environmental sensors and user applications, making them ideal for smart homes. You gain precise control and real-time monitoring, which enhances efficiency and safety.

- IoT modules connect ceramic heating elements to sensors.

- Smart homes benefit from interactive heating systems.

- Real-time monitoring improves efficiency and safety.

AI-Driven Monitoring and Control

You leverage AI-driven monitoring and control in ceramic PTC heaters. Artificial intelligence analyzes data from sensors, adjusting heating profiles for optimal performance. You achieve consistent temperatures and avoid overheating. AI systems predict maintenance needs, reducing downtime and extending the lifespan of ceramic heating elements.

- AI analyzes sensor data for optimal heating.

- Consistent temperatures prevent overheating.

- Predictive maintenance reduces downtime.

Energy Efficiency Innovations

Faster Heat-Up Times

You notice faster heat-up times in ceramic heating elements. Advanced ceramics and PTC technology deliver rapid thermal response, which improves device performance. You save time and energy, especially in applications that require quick temperature changes.

- Rapid thermal response boosts efficiency.

- Devices reach target temperatures faster.

- Time and energy savings increase.

Reduced Power Consumption

You benefit from reduced power consumption in ceramic heating elements. Manufacturers introduce self-regulating temperature features through PTC technology. Integrated sensors provide precise temperature control. Enhanced safety features, including overheat protection, ensure reliable operation. You see significant reductions in energy consumption and improved heating efficiency compared to conventional systems.

| Improvement Type | Measurement |

|---|---|

| Conductividad térmica | Up to 25% better |

| Consumo de energía | Significant reductions |

| Heating Efficiency | More efficient than conventional |

- Self-regulating temperature through PTC technology.

- Integrated sensors enable precise control.

- Overheat protection enhances safety.

You recognize that 2025 trends in ceramic heating elements focus on advanced ceramics, smart technology, and energy-efficient solutions. These key trends deliver efficient, reliable, and sustainable heating for modern devices. You benefit from continuous innovation in ceramic heating element design, which supports energy-efficient heating solutions across industries.

Sustainability and Eco-Conscious Ceramics

You play a vital role in shaping the future of ceramic heating elements by supporting sustainability initiatives. As you explore the latest advancements in ceramics, you see how manufacturers align their processes with sustainability goals. The industry now prioritizes eco-conscious practices, focusing on responsible sourcing and energy-efficient production. These changes help you reduce your environmental impact while benefiting from high-performance ceramic heating elements.

Local Material Sourcing

You notice a shift toward local material sourcing in the ceramics industry. Manufacturers now choose raw materials from nearby regions to minimize transportation emissions. This approach supports local economies and reduces the carbon footprint of ceramic heating elements. You benefit from improved supply chain reliability and faster production cycles.

- You support local mining operations that follow strict environmental standards.

- You see manufacturers select clay, alumina, and other ceramic materials from regional suppliers.

- You help reduce the need for long-distance shipping, which lowers greenhouse gas emissions.

Note: Local sourcing not only strengthens community ties but also ensures that ceramic heating elements meet high-quality standards.

You also find that local material sourcing aligns with broader sustainability initiatives. By choosing regional ceramics, you help manufacturers achieve their sustainability goals and contribute to a cleaner environment.

Solar-Powered Kilns and Waste Reduction

You witness a transformation in ceramic production as companies adopt solar-powered kilns. These kilns use renewable energy to fire ceramics, which significantly lowers the carbon footprint of ceramic heating elements. You support a cleaner manufacturing process that reduces reliance on fossil fuels.

- Solar-powered kilns harness sunlight to reach the high temperatures needed for firing ceramic materials.

- You see a reduction in energy costs and emissions during the production of ceramic heating elements.

- Manufacturers invest in solar infrastructure to meet growing demand for sustainable ceramics.

Waste reduction also plays a key role in sustainability initiatives. You observe companies recycling scrap ceramic materials and reusing them in new products. This practice minimizes landfill waste and conserves valuable resources.

| Sustainability Practice | Impact on Ceramic Heating Elements |

|---|---|

| Solar-powered kilns | Lower emissions, cleaner energy use |

| Waste recycling | Less landfill waste, resource conservation |

| Local sourcing | Reduced transport emissions, faster supply |

You recognize that these efforts make ceramic heating elements more eco-friendly. By supporting manufacturers who invest in solar-powered kilns and waste reduction, you help drive the ceramics industry toward a more sustainable future.

Tip: When you choose ceramic heating elements from companies with strong sustainability initiatives, you contribute to global efforts to reduce environmental impact.

Ceramic heating elements now reflect a commitment to sustainability at every stage. You see how local sourcing, renewable energy, and waste reduction combine to create a new standard for eco-conscious ceramics. These advancements ensure that ceramic heating elements deliver both performance and environmental responsibility.

Market Growth and Expanding Applications for Ceramic Heating Elements

You see market growth accelerating as ceramic heating element solutions become essential across industries. The demand for efficient, reliable, and safe heating drives the adoption of ceramic PTC heater technology. Market trends show that ceramics now power innovation in electric vehicles, consumer electronics, and medical devices. You benefit from the versatility and performance of ceramic heating elements as they redefine what modern devices can achieve.

Electric Vehicles (EVs) and Battery Thermal Management

Ceramic PTC Heater Solutions for EVs

You rely on ceramic PTC heater solutions to maintain optimal battery performance in electric vehicles. The market recognizes the ceramic PTC heater for its simple structure and swift response. You experience quick heating, even in extreme cold, which ensures your EV operates efficiently. The self-regulating nature of the ceramic PTC heater prevents overheating, so you drive with confidence in safety and reliability.

| Característica | Descripción |

|---|---|

| Quick Heating | PTC heaters provide heat almost immediately after being turned on. |

| Low Temperature Performance | Can quickly heat under -40℃. |

| Seguridad | Self-regulating nature prevents overheating, reducing fire hazards. |

| Reliability | Thermostat cuts off power in unusual conditions. |

You see market growth as more manufacturers adopt ceramic PTC heater solutions for battery thermal management. These solutions improve battery conversion efficiency, especially in winter, and support the expanding EV market.

Cabin Heating and Safety

You enjoy comfortable cabin temperatures thanks to ceramic heating element solutions. The ceramic PTC heater delivers heat rapidly, adapting to changing conditions. You avoid fire hazards because the heater never exceeds its design temperature. The thermostat automatically cuts off power if overheating occurs. These solutions ensure safety and efficiency, which drives further market growth in the EV sector.

- Self-regulating to prevent overheating.

- No reliance on open flames or hot surfaces.

- Thermostat automatically cuts off power if overheating occurs.

Consumer Electronics and Smart Devices

Wearables and Home Appliances

You notice ceramics transforming wearables and home appliances. Ceramic heating elements provide compact, efficient solutions for smartwatches, fitness trackers, and kitchen devices. The market trends show rising demand for ceramic-based solutions that offer precise temperature control and long-lasting performance. You benefit from the durability and energy efficiency of these ceramic heating elements.

Laser Printers and Performance Enhancement

You experience sharper prints and lower costs with ceramic heating element solutions in laser printers. Ceramic-based fuser systems use ceramic heating elements to deliver consistent temperatures, which improves toner adhesion and print quality. You save money because these solutions last longer and require fewer replacements.

- Ceramic heating elements improve energy efficiency, leading to lower operational costs.

- They enhance print quality by providing consistent temperatures, resulting in sharper prints and better toner adhesion.

- Their durability and longer lifespan reduce the need for replacements, contributing to overall printer reliability.

Medical Devices and Precision Heating

Diagnostic Equipment

You trust ceramic heating element solutions in diagnostic equipment for their precision and reliability. Ceramics provide stable, uniform heating, which is critical for accurate test results. The market trends highlight growing demand for ceramic-based solutions in medical diagnostics, where efficiency and safety matter most.

Sterilization and Safety

You depend on ceramic heating elements for sterilization in medical devices. These solutions meet strict safety standards. You ensure proper installation and regular maintenance to maintain compliance and functionality.

- Application assessment identifies the specific use of the heater in medical devices, such as patient warming or sterilization, which have distinct temperature requirements.

- Proper positioning and wiring are crucial to ensure safety and compliance with standards, including grounding and insulation.

- Regular inspections and performance tests are necessary to maintain safety and functionality in sensitive environments.

You see market growth as healthcare providers demand efficient, safe, and reliable ceramic heating element solutions. The expanding applications of ceramics in medical devices support ongoing market trends and drive innovation.

Industrial and Commercial Heater Applications

You see ceramics driving innovation in industrial and commercial heating systems. Ceramic heating elements deliver reliable performance in manufacturing automation and food processing. You benefit from consistent heat distribution, high efficiency, and robust design. The market shows strong growth as industries demand advanced solutions for automation and quality control.

Manufacturing Automation

You rely on ceramic heating elements for manufacturing automation. These components withstand high temperatures and harsh environments. You achieve precise thermal processing in curing, drying, and specialized equipment. PTC technology ensures self-regulating heat output, which reduces maintenance and improves safety. You notice that ceramics offer long-term reliability and minimize downtime.

Tip: Ceramic heating elements help you maintain stable production cycles and reduce operational costs.

You see the market expanding as manufacturers demand robust ceramics for automated systems. PTC heaters adapt quickly to changing requirements, supporting growth in industrial automation.

Food Processing and Quality Control

You trust ceramic heating elements in food processing for their safety and efficiency. PTC technology provides rapid heat-up times and consistent temperature control. You ensure product quality with uniform heating, which is essential for baking, drying, and sterilization. Ceramics resist corrosion and contamination, making them ideal for food-grade applications.

| Área de aplicación | Descripción | Métricas de rendimiento |

|---|---|---|

| Electrodomésticos | Used in electric ovens, toasters, and hair dryers for efficient heating. | Consistent heat distribution, high efficiency |

| Industrial Processes | Essential for curing, drying, and thermal processing in specialized equipment. | Robustness, high-temperature tolerance |

| Automotive Industry | Found in seat heaters and engine pre-heating systems for compact efficiency. | Long-term reliability, compact design |

| Medical Devices | Utilized in devices requiring precise temperature control and safety. | Reliable performance, consistent heat output |

You see market growth as food producers demand ceramics for quality control and energy savings. PTC heaters meet strict safety standards and support sustainable practices.

Semiconductor Ceramic Heater Systems

You recognize ceramics as essential in semiconductor manufacturing. Ceramic heater systems provide precise temperature control and reliable performance. The market for semiconductor ceramic heaters shows rapid growth, driven by demand for high-power devices in electric vehicles, renewable energy, and 5G technology.

High-Tech Manufacturing Processes

You benefit from advanced ceramics in high-tech manufacturing. Ceramic heater plates use nanotechnology and telemetry to improve thermal conductivity and heating distribution. PTC technology enables eco-adaptive systems that reduce power consumption and environmental impact. You see manufacturers investing in advanced materials to enhance efficiency and meet market demand.

- Specialized segment within the semiconductor industry.

- Essential for various semiconductor manufacturing processes.

- Provides precise temperature control and reliable performance.

| Tipo de avance | Descripción |

|---|---|

| Advanced Materials | Rising demand for advanced materials to enhance performance and efficiency in heater plates. |

| Innovations in Design | Use of nanotechnology and advanced telemetry for better thermal conductivity and heating distribution. |

| Energy Efficiency and Sustainability | Development of eco-adaptive technology for reduced power consumption and environmental impact. |

You observe market growth with a projected value of $1,507 million in 2025 and a CAGR of 6.2%. The demand for ceramics in semiconductor heater systems continues to rise as industries seek reliable, energy-efficient solutions.

Note: You drive innovation by choosing ceramic heater systems that support high-tech manufacturing and sustainability goals.

Regulatory and Industry Influences on Ceramic Heating Elements

Evolving Safety Standards for Heaters

You operate in a market where safety standards for ceramic heating elements continue to evolve. Regulatory bodies now require more rigorous testing for every heater. You must ensure that ceramic components meet strict guidelines for electrical insulation, thermal stability, and fire resistance. These standards protect users and support market growth by building trust in ceramic technology. As demand for advanced heating solutions rises, you see manufacturers investing in compliance and certification. This commitment drives innovation and ensures that ceramic heaters deliver reliable performance in every application.

Energy Efficiency Regulations in 2025

You face new energy efficiency regulations in 2025 that shape the ceramic heating element market. Governments and industry groups set ambitious targets to reduce energy consumption. You must select ceramic heaters that meet or exceed these requirements. Manufacturers now design products with advanced materials and smart controls to maximize energy efficiency. These improvements help you lower operational costs and support sustainability goals. As demand for eco-friendly solutions grows, you see the market shift toward ceramic heating elements that offer faster heat-up times and reduced power usage. This focus on energy efficiency fuels market growth and encourages further research into high-performance ceramics.

Tip: Choosing ceramic heaters that comply with the latest energy efficiency standards helps you future-proof your devices and reduce long-term expenses.

Global Supply Chain and Tariff Impacts

You navigate a complex global supply chain for ceramic heating elements. Recent tariff changes and supply chain disruptions affect both cost and availability. The following table highlights recent developments:

| Date | Tariff/Duty Description | Affected Products | Impact on Oven Heating Elements |

|---|---|---|---|

| June 23, 2025 | Steel and aluminum import duty doubled to 50% | Appliances with steel content (frames, panels) including ovens, stoves, ranges | Increased cost due to steel content in oven heating elements and appliances |

| August 1, 2025 | Additional 25% country-specific tariff | Appliances imported from Japan and South Korea, including ovens and heating elements | Further price increase for imports from these countries, affecting brands like Samsung and LG |

You experience longer lead times as companies adjust production to new rules. Inventory management becomes more challenging with frequently changing duties. Many manufacturers invest in local tooling and joint ventures to address these issues. You see companies forming partnerships with suppliers in different regions to ensure a steady supply of ceramic heating elements. Nearshoring helps minimize tariff impacts and shipping delays. Digital traceability allows you to monitor the origin of ceramic parts and understand applicable duties.

- Longer lead times result from new production adjustments.

- Inventory management grows more difficult with changing tariffs.

- Companies invest in local tooling and joint ventures to stabilize supply.

You recognize that these global factors influence market growth, pricing, and the ability to meet rising demand. By staying informed and adapting your sourcing strategies, you help drive the continued expansion of the ceramic heating element market.

Impact of Ceramic Heating Elements on Reliability and Cost Savings

Improved Lifespan and Maintenance for Heaters

You gain a significant advantage when you choose a ceramic heating element for your devices. Ceramic heating elements stand out in the market because they last longer and require less maintenance than traditional alternatives. The unique properties of ceramics allow these components to withstand higher temperatures and harsh environments. You benefit from their resistance to oxidation and corrosion, which means fewer breakdowns and less frequent replacements. This durability supports the ongoing growth in demand for efficient heating solutions across industries.

- Ceramic heating elements exhibit superior durability, allowing them to withstand higher temperatures.

- They are less susceptible to oxidation and corrosion, which enhances their lifespan.

- Improved thermal efficiency leads to quicker heating and reduced energy consumption, contributing to lower maintenance needs.

You notice that the market continues to shift toward ceramic heating element technology as industries seek reliable and efficient solutions. The long service life of ceramics reduces downtime and supports the growth of efficient heating systems in both consumer and industrial applications.

Lower Total Cost of Ownership

You experience lower total cost of ownership when you invest in ceramic heating elements. The initial price may seem higher, but you quickly realize the savings over time. Ceramic heating elements require fewer repairs and replacements, which reduces your maintenance expenses. Their high energy efficiency means you spend less on electricity, especially as demand for efficient heating solutions rises in the market. The durability of ceramics ensures that your heater operates at peak performance for years, supporting the growth of sustainable technologies.

You also benefit from the stable supply of ceramic materials, as the market adapts to increased demand and local sourcing. This stability helps you avoid unexpected costs and supports the growth of efficient heating solutions worldwide. As more industries recognize the value of ceramic heating elements, you see the market expand and the demand for advanced ceramics increase.

Enhanced User Safety and Device Performance

You prioritize safety and performance in every application. Ceramic heating elements deliver both, thanks to the advanced properties of ceramics. The following table highlights key features that improve user safety and device reliability:

| Característica | Descripción |

|---|---|

| Lower Operating Temperatures | Ceramic heaters operate at lower surface temperatures, reducing the risk of burns and fires. |

| Protección contra sobrecalentamiento | Built-in mechanisms prevent overheating, automatically shutting off the heater when necessary. |

| Distribución uniforme del calor | Provides uniform heat output, eliminating hot spots that can damage materials or create hazards. |

| Electrical Insulation | Ceramic materials prevent electric shocks and short circuits, enhancing user safety. |

| Stability and Durability | Highly durable and stable, suitable for harsh industrial environments without compromising safety. |

You see how ceramic heating elements support the demand for safer, more efficient devices in the market. The electrical insulation of ceramics protects you from shocks, while even heat distribution prevents damage to sensitive components. As the market grows, you benefit from the enhanced safety and performance that ceramic heating elements provide.

Tip: Choosing ceramic heating elements helps you meet strict safety standards and supports the growth of efficient, reliable devices.

Environmental and Sustainability Benefits of Ceramic Heating Elements

Reduced Carbon Footprint

You play a key role in reducing emissions when you choose a ceramic heating element for your devices. Ceramic heating elements use advanced ceramics that convert electricity into heat with high efficiency. This efficiency means you use less energy, which directly lowers your carbon footprint. The market now sees a shift as more industries demand solutions that support environmental sustainability. Ceramic materials require less frequent replacement, so you help reduce waste and conserve resources.

You notice that ceramic heating element technology supports the growth of renewable energy systems. Many manufacturers now use solar-powered kilns to produce ceramics, which further cuts emissions. The market responds to this demand by investing in cleaner production methods. You benefit from these changes because your devices become more eco-friendly and cost-effective.

Note: Every time you select a ceramic heating element, you contribute to a cleaner environment and support the global push for sustainability.

A ceramic heating element also operates at lower temperatures compared to traditional heaters. This feature reduces the risk of overheating and energy loss. The market values this advantage, as it aligns with stricter regulations and the growing demand for green technologies. You see the growth of ceramic heating elements in sectors like electric vehicles and smart appliances, where energy savings matter most.

Support for Circular Economy Initiatives

You support the circular economy when you invest in ceramic heating elements. The market now encourages manufacturers to recycle and reuse ceramic materials. Many companies collect scrap ceramics from the production process and reintroduce them into new ceramic heating element designs. This practice reduces landfill waste and supports the growth of sustainable manufacturing.

Ceramic heating elements last longer than traditional alternatives. You help extend product lifecycles, which means fewer replacements and less waste. The market rewards this durability by increasing demand for ceramic-based solutions. You also see ceramics used in modular devices, where you can replace only the ceramic heating element instead of the entire unit.

| Circular Economy Practice | Impact on Ceramic Heating Element Market |

|---|---|

| Recycling ceramics | Reduces waste and conserves resources |

| Modular design | Extends product life and lowers costs |

| Local sourcing | Supports regional growth and stability |

You notice that the market now prioritizes ceramics that meet strict environmental standards. Manufacturers respond to this demand by improving recycling processes and sourcing materials locally. You drive the growth of the ceramic heating element market by choosing products that align with circular economy principles.

Tip: When you select a ceramic heating element from a company committed to circular practices, you help shape a more sustainable future for the entire market.

Future Outlook for Ceramic Heating Elements and Heaters

Anticipated Technological Breakthroughs

You stand at the edge of a new era for ceramic heating element technology. The next five years promise major advances in ceramics, driven by research and innovation. You will see new ceramic formulas that use nanomaterials to boost thermal conductivity and mechanical strength. Composite ceramics will offer better thermal shock resistance, making your devices more reliable. Manufacturers now focus on environmentally friendly ceramics to reduce the impact on the planet. You benefit from precision molding, which improves the dimensional accuracy of each ceramic heating element. Automated production lines increase efficiency and quality, while new packaging technology enhances thermal performance. Intelligent control systems give you accurate temperature management, supporting the demand for smarter devices. You can expect a 20%-30% reduction in energy consumption as these breakthroughs reach the market.

| Categoría | Breakthroughs |

|---|---|

| Materiales | New ceramic formulas with nanomaterials for better thermal conductivity and mechanical strength. |

| Composite ceramics for enhanced thermal shock resistance. | |

| Environmentally friendly ceramics to reduce environmental impact. | |

| Tecnología | Precision molding for improved dimensional accuracy. |

| Automated production for better efficiency and quality. | |

| New packaging technology for enhanced thermal efficiency. | |

| Intelligent control for accurate temperature management. | |

| Future Direction | Focus on efficiency, intelligence, and environmental sustainability in ceramic heating technology. |

| Expected reduction in energy consumption by 20%-30% in the next five years. |

You will see advanced heating technologies reshape the ceramic heating element market, making devices smarter and more sustainable.

Emerging Markets and Opportunities

You notice rapid growth in regions that previously had limited access to ceramic heating element solutions. Latin America, the Middle East, and Africa now drive market expansion as investments and infrastructure projects increase. These areas present new opportunities for ceramics, especially as industries modernize and urban populations grow. The Asia Pacific region also shows strong demand, fueled by industrialization and urbanization. You see manufacturers respond by developing ceramic heating elements tailored to local needs, supporting the growth of advanced heating technologies worldwide. The market now values ceramics for their reliability and efficiency, and you benefit from the expanding reach of these solutions.

Challenges and Solutions Ahead

You face several challenges as the ceramic heating element market evolves. Overheating, inefficiency, and safety concerns remain issues with traditional heating elements. You overcome these problems by choosing ceramic heating elements that use PTC technology. This self-regulating and self-limiting feature enhances safety and efficiency. You also see additive manufacturing techniques improve the production of complex ceramic components, solving problems with uniform heating and process optimization. Electric heating technologies, such as Joule heating, offer better efficiency and uniformity in heating applications.

- Overheating and inefficiency in traditional heating elements.

- Safety concerns in older systems.

- PTC technology provides self-regulation and safety.

- Additive manufacturing enables complex ceramic designs.

- Electric heating technologies improve efficiency and uniformity.

You drive the growth of the ceramic heating element market by adopting new solutions and supporting innovation in ceramics. As you look ahead, you will see the demand for advanced heating technologies continue to rise, shaping the future of the industry.

You see the ceramic heating element changing how you approach device performance. The ceramic heating element leads innovation in every industry. You rely on the ceramic heating element for energy efficiency and reliability. The ceramic heating element supports sustainability and cost savings. You notice the ceramic heating element in electric vehicles, medical devices, and smart homes. The ceramic heating element offers precise control and safety. You trust the ceramic heating element for long-term value. The ceramic heating element uses advanced ceramic materials. You benefit from the ceramic heating element’s durability. The ceramic heating element will drive future advancements. The ceramic heating element shapes a new era for ceramic technology. You choose the ceramic heating element for performance and sustainability. The ceramic heating element stands at the center of progress. The ceramic heating element defines the future of ceramic innovation. The ceramic heating element delivers unmatched results. The ceramic heating element sets the standard for modern devices.

PREGUNTAS FRECUENTES

What is a ceramic heating element?

You use a ceramic heating element to convert electrical energy into heat. This component relies on advanced ceramic materials for efficient, safe, and reliable heating in many modern devices.

How does a ceramic heating element improve energy efficiency?

A ceramic heating element maximizes energy conversion. You benefit from rapid heat-up times and minimal energy loss. This efficiency helps you lower electricity costs and supports sustainable device operation.

Where can you find ceramic heating elements in daily life?

You encounter a ceramic heating element in electric vehicles, home appliances, medical devices, and industrial equipment. These elements provide precise temperature control and long-lasting performance in each application.

Why does a ceramic heating element last longer than metal alternatives?

You gain durability because a ceramic heating element resists corrosion, oxidation, and thermal fatigue. This longevity means fewer replacements and less maintenance for your devices.

Are ceramic heating elements safe for sensitive electronics?

You trust a ceramic heating element for its electrical insulation and stable heat output. This safety feature protects sensitive electronics from overheating and electrical faults.

Can you use a ceramic heating element in high-temperature environments?

You rely on a ceramic heating element for high-temperature applications. Its advanced ceramic composition withstands extreme heat, making it suitable for demanding industrial and laboratory settings.

How do you maintain a ceramic heating element?

You keep a ceramic heating element in top condition by following manufacturer guidelines. Regular inspections and proper installation ensure optimal performance and extend the element’s lifespan.

What makes a ceramic heating element eco-friendly?

You support sustainability by choosing a ceramic heating element. Manufacturers use local materials, solar-powered kilns, and recycling practices to reduce environmental impact and promote a circular economy.