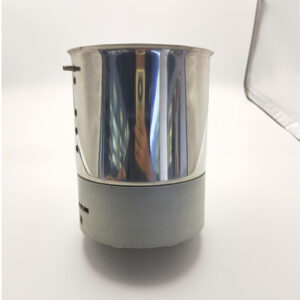

Heating elements for electric pressure cookers are being researched and developed in our factory. Among the fundamental components in our products appropriate for all types of residential and business high-pressure cooking devices are heating chassis and temperature control modules. Made of food-grade stainless steel of excellent quality, it resists corrosion and high pressure and complies with worldwide electrical safety standards. At high temperatures, the original layered heat-conducting system produces fast pressure rise and consistent heat distribution. It has smart PID temperature control technology to precisely adjust the power thereby avoiding any overheating danger. Built-in anti-dry burning, overvoltage power-off, among other forms, it has several safety protection systems to guarantee operational stability. The modular design is easily installed, low maintenance cost, and compatible with popular brand electric pressure cookers.

MOQ:1000PCS

Lead time:15-25days

Standort der Fabrik: Zhongshan, Guangdong, China

Our electric heating components are specialized for electric pressure cookers, serving as core heating elements in their bases or integral heating plates. They enable rapid, uniform heat transfer to generate high-pressure steam (via boiling water under pressure), facilitating fast cooking of foods like stews, rice, or meats while maintaining safety and energy efficiency in high-pressure, high-temperature environments (up to 120–130°C at 15–20 psi).

| Parameter | Specification Range | Anpassungsoptionen |

|---|---|---|

| Power Rating | 800W–3000W (standard); up to 4000W for high-capacity pressure cookers | Adjustable to match cooker wattage limits |

| Operating Voltage | 110V/220V AC (standard); 220V/240V AC for heavy-duty models | Custom voltage for global market compatibility |

| Dimension Range | Length: 100mm–300mm; Diameter: 80mm–150mm; Thickness: 2.0mm–5mm; Shape: flat plate, coil, or finned | Custom shapes/sizes to fit cooker base contours |

| Material | Food-grade 304 stainless steel (standard); 316 stainless steel for acidic/high-corrosion cooking | Material grade/finish (polished for easy cleaning) customization |

| Temperature Range | Ambient (20°C) to max 150°C (continuous operation, auto-shutoff at pressure limit) | High-temp variants (up to 200°C) for industrial-style cookers |

| Control Compatibility | Compatible with pressure sensors (±5 psi) or external thermocouples (±3°C) | Custom interfaces (e.g., PID, pressure-switch linked) |

We offer tailored solutions, including dimensions, power, material grade, and interface design, to align with specific pressure cooker structures (e.g., multi-functional cookers with steam baskets, compact travel models) while maintaining safety, efficiency, and brand compatibility.

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.