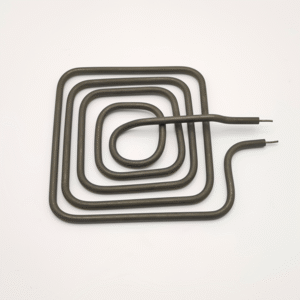

The heating element for steamer adopts a composite structure of stainless steel substrate and nickel-chromium alloy heating tube, integrated with PID intelligent temperature control system, supports 3-5 seconds rapid heating, energy efficiency ≥96%, working temperature range 80℃-300℃, with IPX5 waterproof and steam corrosion resistance, suitable for high-frequency continuous operation scenarios, and life span of more than 30,000 hours.

Mindestbestellmenge: 1000

Lieferfrist: 15-25 Tage

Standort der Fabrik: Zhongshan, Guangdong, China

Electric steamer, commercial steamer, built-in steam oven, industrial tunnel steamer, food processing plant sterilization equipment, medical disinfection steamer.

Power range: 800W~2500W (customizable, suitable for medium frequency requirements of electric steamer/industrial tunnel steamer)

Working voltage: 12V~480V AC/DC (wide voltage design, compatible with home appliances and industrial equipment)

Resistance value: 0.2Ω~10Ω (matched by voltage and power, supports customization of electric heating coils)

Working temperature: 80°C~300°C (stainless steel substrate is resistant to high temperature oxidation and suitable for steam environment)

Material: Edelstahlsubstrat, Heizrohr aus Nickel-Chrom-Legierung, PID-Temperaturregelmodul (anpassbare Verbundstruktur)

Dimensions: length 10cm~1.5m, width 5cm~30cm, thickness 2mm~8mm (supports special-shaped cutting, suitable for hot plate customization)

Service life: 30,000~50,000 hours (anti-oxidation coating + steam anti-corrosion process, suitable for high-frequency continuous operation)

Extremely fast heat conduction: stainless steel substrate + nickel-chromium alloy tube, 3-5 seconds fast heating, suitable for high-frequency steam requirements of commercial electric steamers.

Precise temperature control: integrated PID algorithm, ±1°C error, meeting the constant temperature control requirements of sterilization equipment in food processing plants.

Waterproof and anti-corrosion: IPX5 waterproof grade + steam anti-corrosion coating, suitable for the humid and high-pressure environment of medical disinfection steamers.

Energy-saving and efficient: Energy efficiency ≥ 96%, the thermal conductivity of the hot plate is increased by 35%, reducing the energy consumption cost of commercial equipment.

Industrial-grade durability: 30,000 hours of life, anti-oxidation coating extends the stability of the hot plate in the tunnel steamer.

Flexible adaptation: Supports special-shaped size and temperature curve adjustment to meet the non-standard customization needs of small household appliances/industrial steam cabinets.

Safe and reliable: Isolated circuit design, CE certified, adapted to household appliances leakage prevention standards.

Fast delivery: Standardized production line mass production, 15 days to complete the order, adapted to the bulk purchase needs of commercial equipment.

Wenn Sie uns genaue Angaben zu den Bedarfsparametern machen können, können wir Ihnen frühestens innerhalb von 24 Stunden ein Angebot unterbreiten.

Dies sind Listen mit häufig gestellten Fragen unserer Kunden. Zu jeder Frage finden Sie eine kurze Antwort, die Aspekte wie Produkte, Qualität und Dienstleistungen abdeckt. Wenn Sie weitere Fragen haben, hinterlassen Sie uns bitte eine Nachricht zur Rücksprache. Wir danken Ihnen.

Wir sind eine Quellenfabrik mit unabhängiger Produktionskapazität, mit 30 Jahren Erfahrung in der Forschung und Entwicklung und Herstellung von elektrischem Heizungszubehör, einer jährlichen Produktionskapazität von über 5 Millionen Sätzen, unterstützen OEM/ODM-Kundenanpassungen und bieten Videoinspektionsdienste in der Fabrik.

Wir unterstützen kostenlose Mustertests, und die Fracht muss im Voraus bezahlt werden (wird bei Lieferung abgeholt). Herkömmliche Modelle werden in 7-10 Arbeitstagen geliefert, mit SGS-Prüfberichten und Tabellen mit Leistungsparametern.

Online-Antwort von 8:30 bis 17:30 Uhr an Werktagen. In dringenden Fällen können Sie einen Arbeitsauftrag über die offizielle Website einreichen. Wir versprechen, technische Antworten innerhalb von 2 Stunden zu geben und Lösungen innerhalb von 48 Stunden bereitzustellen.

Wir verfügen über zwei Produktionsstätten in Zhongshan und Wuhu mit einem monatlichen Ausstoß von mehr als 3 Millionen Stück, die mit vollautomatischen Stanzlinien und automatisierten Montagewerkstätten ausgestattet sind. Die Standardlieferzeit beträgt 15 Tage, und kundenspezifische Bestellungen werden innerhalb von 30 Tagen geliefert. Wir unterstützen Chargenlieferungen.

Wir verfügen über die Zertifizierungen ISO9001/14001, CE (EU), ETL (Nordamerika), RoHS (Umweltschutz), explosionssichere Produkte sind doppelt ATEX/IECEx-zertifiziert und erfüllen die REACH-Vorschriften.

Wir beliefern weltweit führende Marken wie Philips, Midea, Supor, Delonghi, BSH und die SEB-Gruppe, deren Produkte in High-End-Projekten wie Kaffeemaschinen, Bügeleisen, Wasserspendern und Solaranlagen eingesetzt werden, und können eine Referenzliste ähnlicher Kunden vorlegen.

Erhalten Sie in weniger als zwei Tagen ein individuelles Angebot.